High-hardenability big-diameter 65MnCr grinding ball and preparation method thereof

A high-hardenability, large-diameter technology, applied in the field of high-hardenability large-diameter 65MnCr grinding balls and their preparation, can solve the problems of inability to meet large-diameter grinding balls, unable to achieve accurate control, and difficult to control and prepare. , to achieve the effect of simple and feasible control of processing technology and heat treatment process, uniform hardness distribution, and excellent wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0039] According to the chemical composition given in Table 1, the cast billet was rolled into a billet of Ф130 mm by vacuum melting in an electromagnetic induction furnace for subsequent processes.

[0040] Table 1 chemical composition (mass percentage)

[0041]

[0042] The hot rolling process is to heat the billet to 1100°C for 1 hour, and then hot-roll it into a Ф130mm ball on a two-roll hot rolling mill. Due to the small amount of deformation, the requirements for the rolling mill are relatively low, which reduces production costs. After rolling, the ball is ground The temperature is 950°C.

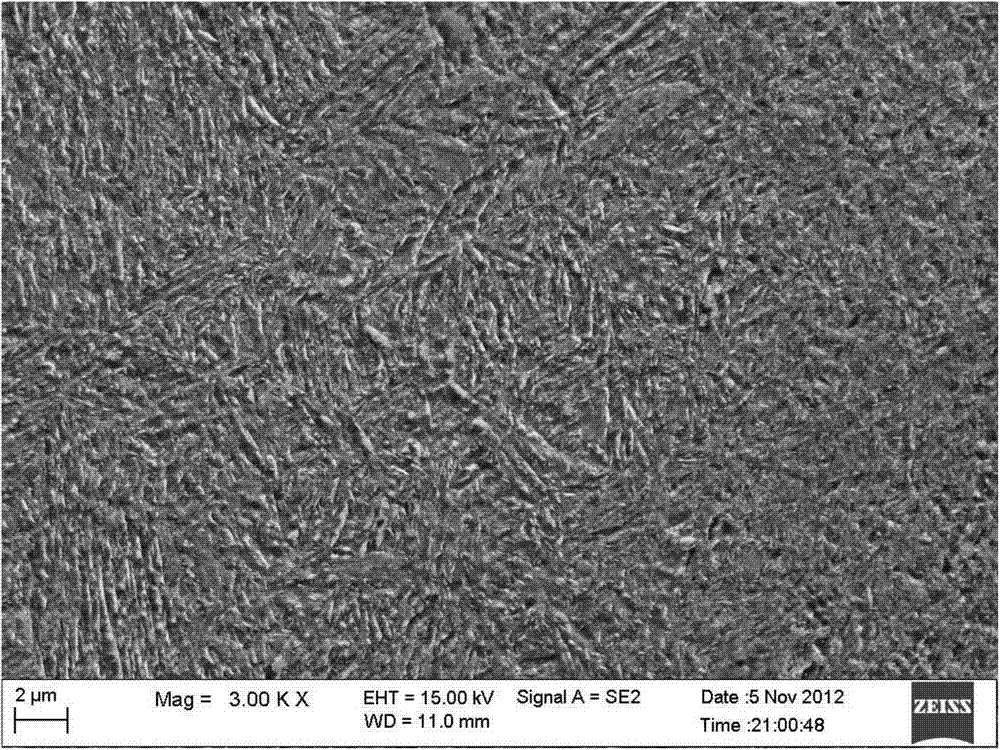

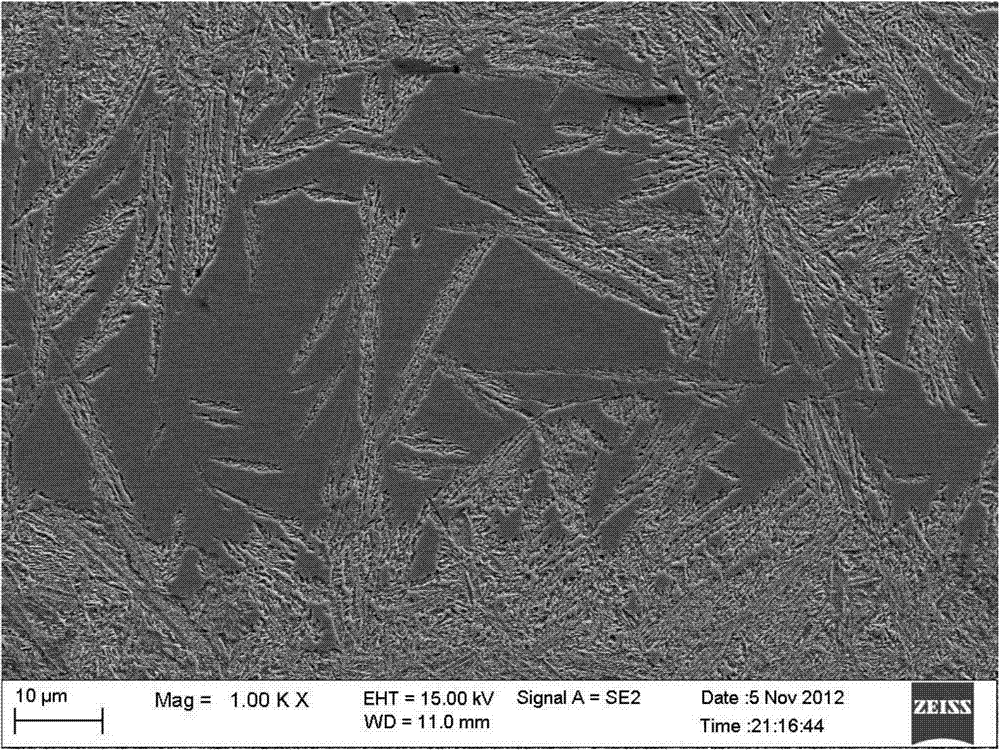

[0043] After the final rolling, the balls are quenched in water for 2.5 minutes, and the temperature of turning red after exiting the water is 130°C, and then they are kept in a 320°C holding furnace for 6 hours, and then cooled out of the furnace. The present invention only adopts a grinding ball with a diameter of Ф130mm as an experiment, and the composition design and process ...

Embodiment 4

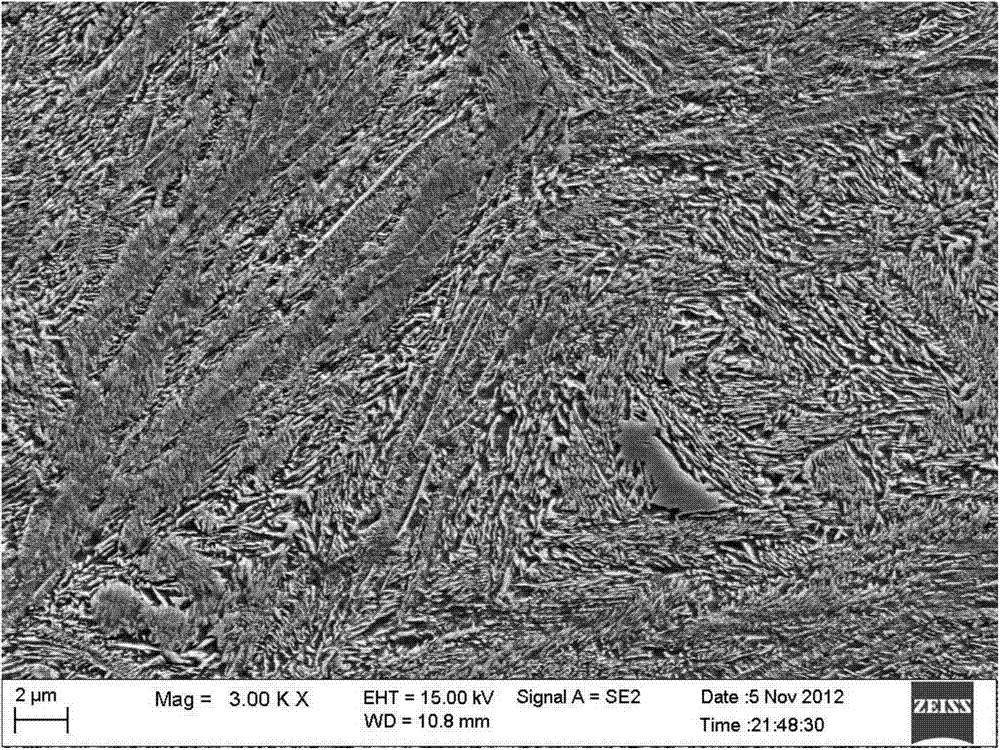

[0045] Using the composition design and process steps of Example 1, the only difference is that the balls are quenched in water for 2.5 minutes after the final rolling, and the temperature of reddening after water discharge is 150°C, and then kept in a 400°C holding furnace for 6 hours, and then cooled in the furnace.

[0046] In the present invention, the hardness distribution of the grinding balls of the ingredients of Example 1 tempered at 320°C (Example 1) and 400°C (Example 4) for 6h is shown in Table 2, and the impact toughness performance is shown in Table 3. 1# represents the grinding balls in The performance after tempering at 320°C, 2# represents the performance of the ball after tempering at 400°C. It can be seen that the hardness distribution of the large-diameter grinding ball of the present invention is uniform, and the strength and toughness are well matched.

[0047] Table 2 Hardness distribution of tempered grinding balls at 2320°C and 400°C

[0048]

[00...

Embodiment 5

[0052] Select and prepare the raw material of the embodiment 2 of the large-diameter 65MnCr grinding ball with high hardenability to smelt, cast and hot-roll into a large-diameter round steel billet for subsequent use according to the above-mentioned composition;

[0053] 2) The steel billet is heated at 1050°C, and after soaking for 1 hour, it is rolled on a two-roll rolling mill. According to different rolls, it can be rolled into grinding balls of different diameters. After rolling, the water temperature is 900°C and quenched in water. After 3 minutes, the redness temperature of the balls is 120°C, and then they are kept in a furnace at 350°C for 6 hours, and then taken out for stack cooling to obtain large-diameter 65MnCr balls with high hardenability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com