Laser-cladding repairing method of mold with snakeskin grains

A technology of laser cladding and repair method, applied in the direction of metal material coating process, coating and other directions, can solve the problems such as the inability to guarantee the smooth transition of the snake skin pattern on the surface of the mold, the insufficient bonding strength of the repair surface, and the easy occurrence of undercuts. Good economic benefits, small deformation, uniform hardness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

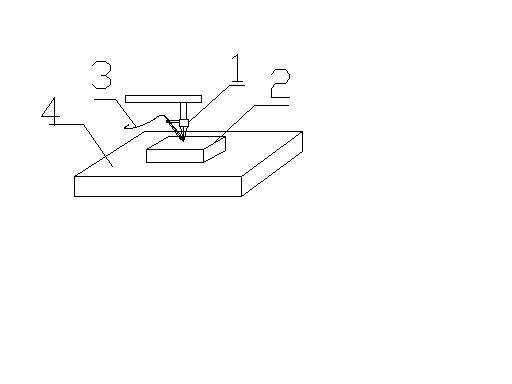

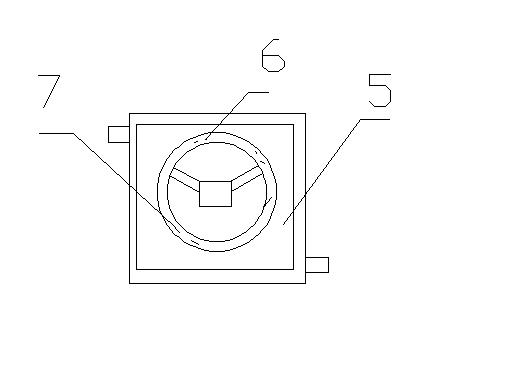

[0018] Embodiment 1: as figure 1 , figure 2 As shown, the steering wheel mold 5 to be repaired in this example is point wear, and the laser uses CO 2 Laser, the specific repair steps are as follows:

[0019] 1. Fix the steering wheel mold 5 on the workbench 4, polish off the oxide layer on the surface of the worn point 6 with electric friction, and trim it into a regular round hole shape, and clean the surface with acetone;

[0020] 2. Input the wire 3 for cladding to the top of the small hole in advance, determine the length of the wire 3, adjust the position of the laser focusing head 1, adjust the size of the spot and the center of the spot is located at the center of the hole;

[0021] 3. Set the process parameters: laser power P=4KW, spot diameter D=3mm, laser action time T=1s.

[0022] 4. Open the laser shutter for cladding. After the cladding area is cooled, spray the colorant to check whether there is any defect, grind it to the reserved size, and generate snakeski...

Embodiment 2

[0023] Embodiment 2: as figure 1 , 2 As shown, the steering wheel mold 5 to be repaired in this example is line wear, and the laser uses a fiber laser. The specific repair steps are as follows:

[0024] 1. Fix the steering wheel mold 5 on the workbench 4, polish off the oxide layer on the surface of the worn part 7 with an electric motor, and trim it into a regular straight line shape, and clean the surface with acetone;

[0025] 2. Measure the length of the scanning line, set the start and end points of the scan, compile the machine tool program, and carry out cladding by synchronous wire feeding;

[0026] 3. Set the process parameters: laser power P=3KW, spot diameter D=2mm, scanning speed 100mm / min, wire feeding 3 speed 100mm / min;

[0027] 4. Adjust the position of the laser focusing head 1, open the program for cladding, and for a relatively large repair area, it can be cladding with multiple laps, and the lap rate is about 40%;

[0028] 5. After the cladding area is co...

Embodiment 3

[0029] Embodiment 3: as figure 1 , 2 As shown, the mold 2 to be repaired in this example has both a little wear and thread wear. The laser uses a YAG laser. The specific repair steps are as follows:

[0030] 1. Fix the mold 2 on the workbench, polish the oxide layer on the surface of the worn part of the mold 2, and trim it into a regular geometric shape, and clean the area to be clad with acetone;

[0031] 2. Write the machine tool program according to the cladding position, set the process parameters: laser power is 2-4kw, scanning speed is 80-200mm / min, spot diameter is 1-3mm, start the laser and cladding material is used for cladding;

[0032] 3. After cooling, check whether there are any crack defects by coloring, and smooth the cladding layer after passing the test;

[0033] 4. Regenerate the serpentine skin on the surface of the ground cladding layer.

[0034] The laser described in the present invention is semiconductor laser, fiber laser, YAG laser or CO 2 laser. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com