Antiwear laser strengthened pick and its processing method

A laser strengthening and anti-wear technology, applied in the field of picks, can solve the problems of matrix wear at the end of picks, short service life, peeling of alloy heads, etc., and achieve the effect of uniform thickness, uniform hardness distribution and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

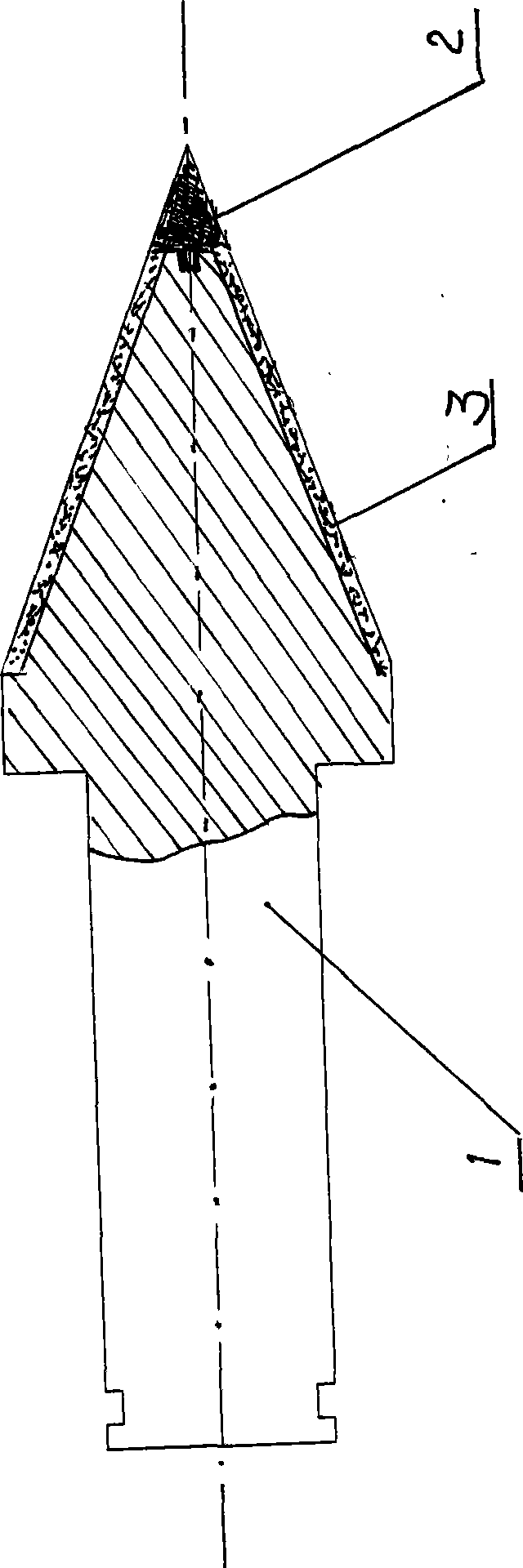

[0015] From figure 1 It can be seen that the wear-resistant laser strengthened pick includes a pick body 1 and a hard alloy head 2, and a laser strengthening layer 3 is processed on the conical surface of the pick body.

[0016] Processing method 1: Laser scan the conical surface of the pick body 1 on the laser strengthening equipment (produced by Shenyang Continental Group), the output power of the laser gun is 5kw, the scanning speed is 5mm / min, and the powder feeding rate is 18g / min. Metal powder containing wear-resistant materials is clad onto the conical surface of the pick body 1 to form a laser strengthening layer 3 with a cladding thickness of 3 mm.

[0017] Processing method 2: surface alloying: uniformly coat nano-scale cermet particles on the conical surface of the pick body 1, and use high energy density laser energy beams to remelt the cermet particles and the pick body 1 , so that the cermet particles and the matrix are bonded at a metallurgical level to form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com