Cast iron horizontal continuous casting double-water jacket type crystallizer

A crystallizer and double water jacket technology, which is applied in the field of cast iron horizontal continuous casting production equipment, can solve the problems that the production capacity is difficult to reach 20 tons, the cooling effect is not satisfactory, and the length of the crystallizer is short, so as to avoid leakage accidents , safe use and small machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

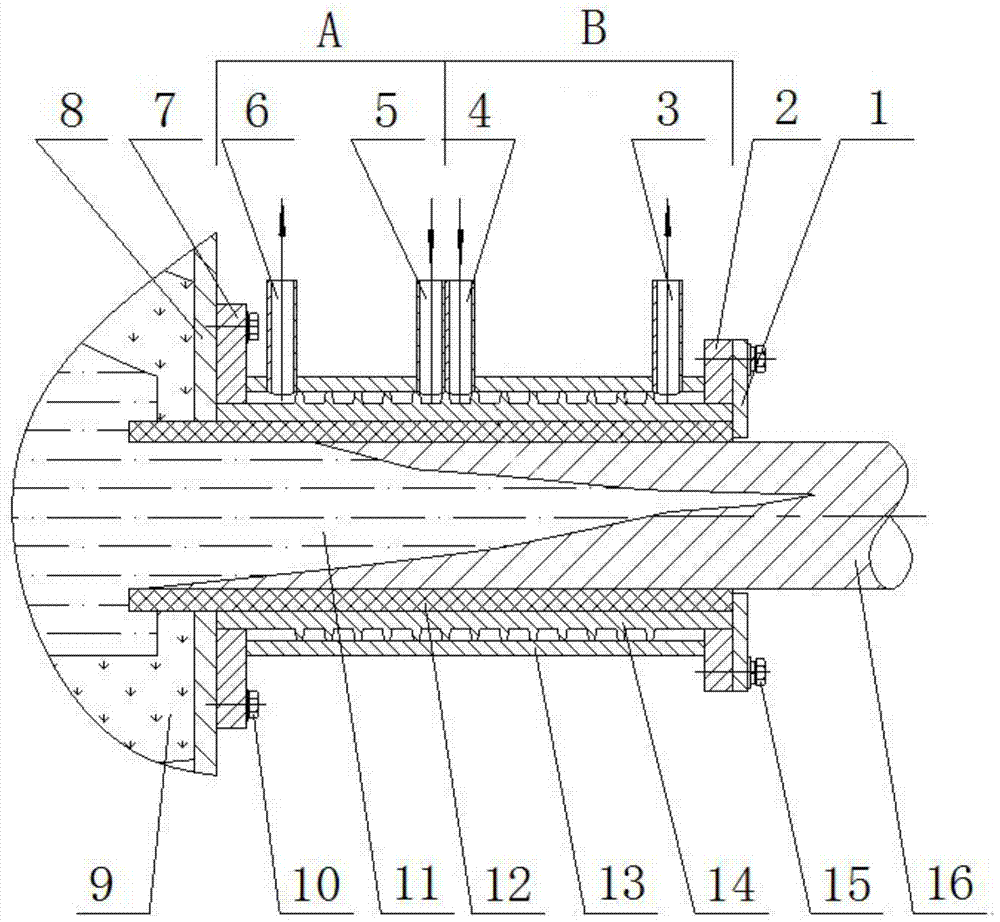

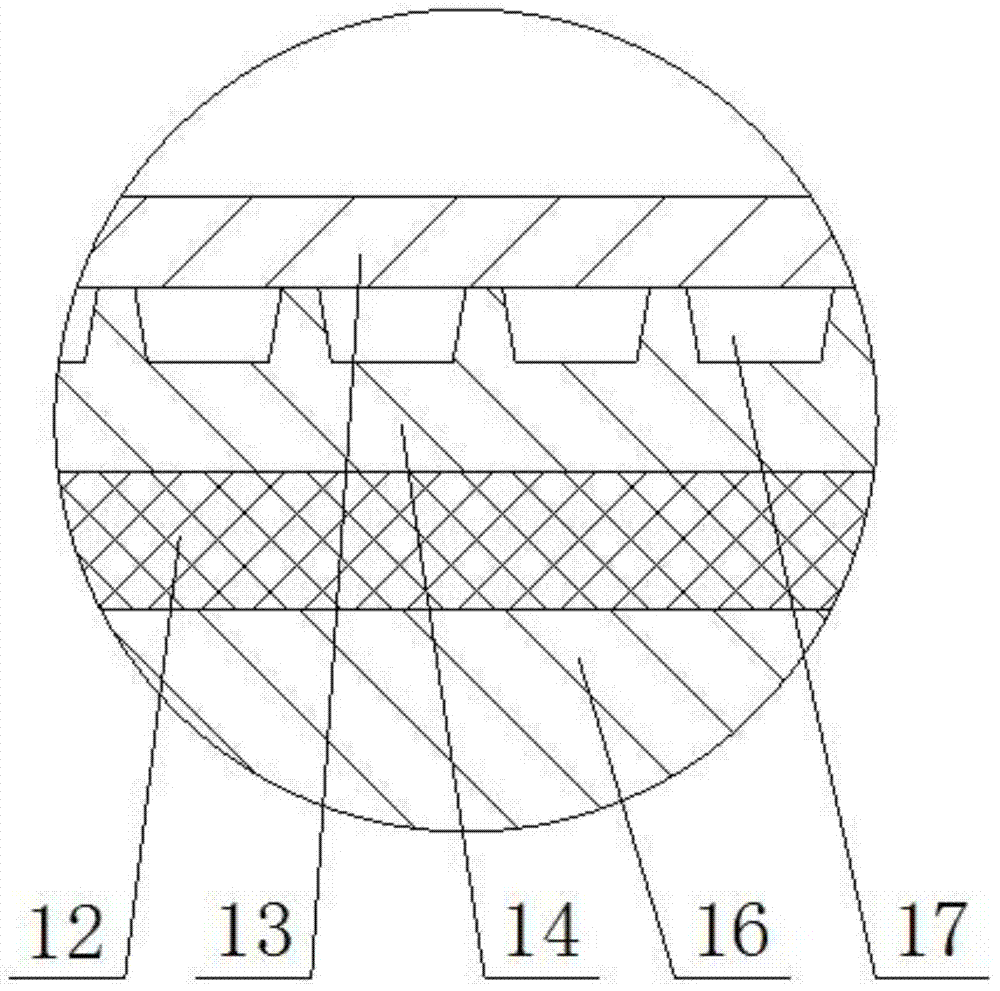

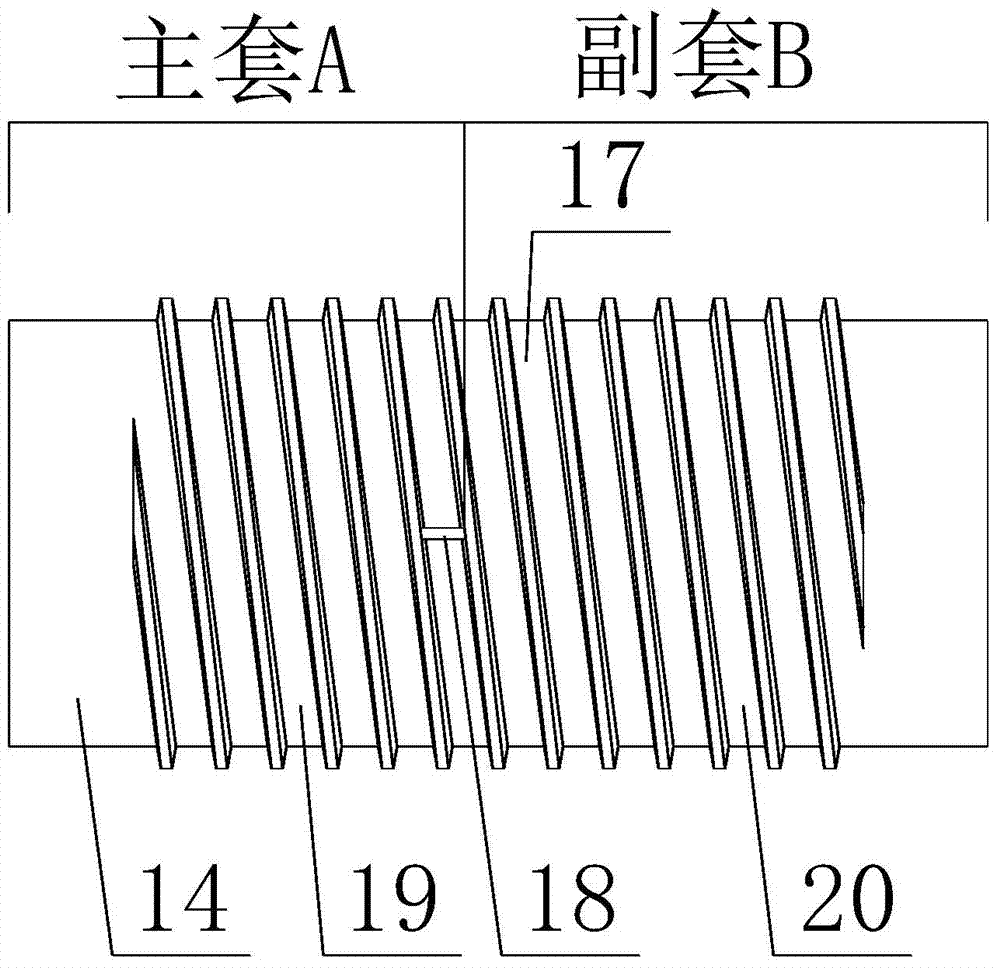

[0019] The present invention is a cast iron horizontal continuous casting double water jacket type crystallizer, see attached figure 1 , including double-water-jacketed mold steel sleeves and high-purity graphite sleeves 12 embedded in double-water-jacketed mold steel sleeves, such as figure 2 As shown, the double water jacket type crystallizer steel sleeve includes a mold steel sleeve inner sleeve 14, a crystallizer steel sleeve outer sleeve 13 arranged outside the mold steel sleeve inner sleeve 14, and a mold steel sleeve inner sleeve 14 and a crystallization mold sleeve. The crystallizer graphite baffle flange 2 and the crystallizer and the holding furnace connecting flange 7 at both ends of the device steel sleeve jacket 13, such as image 3 As shown, the inner sleeve 14 of the crystallizer steel sleeve is provided with a trapezoidal cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com