Patents

Literature

33results about How to "Change cooling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

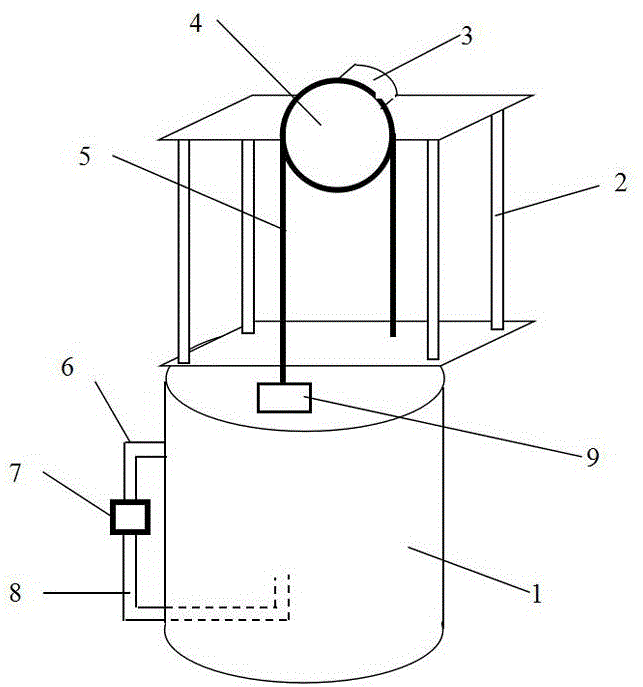

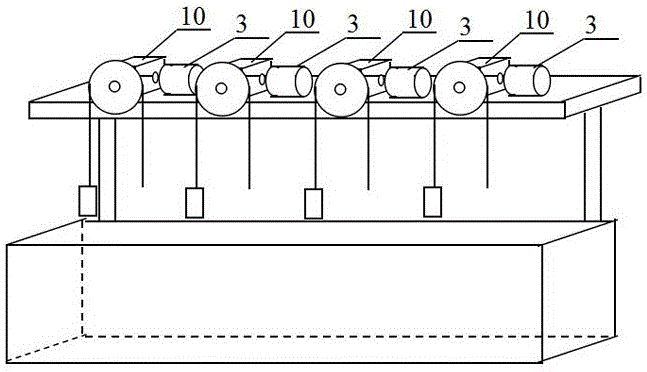

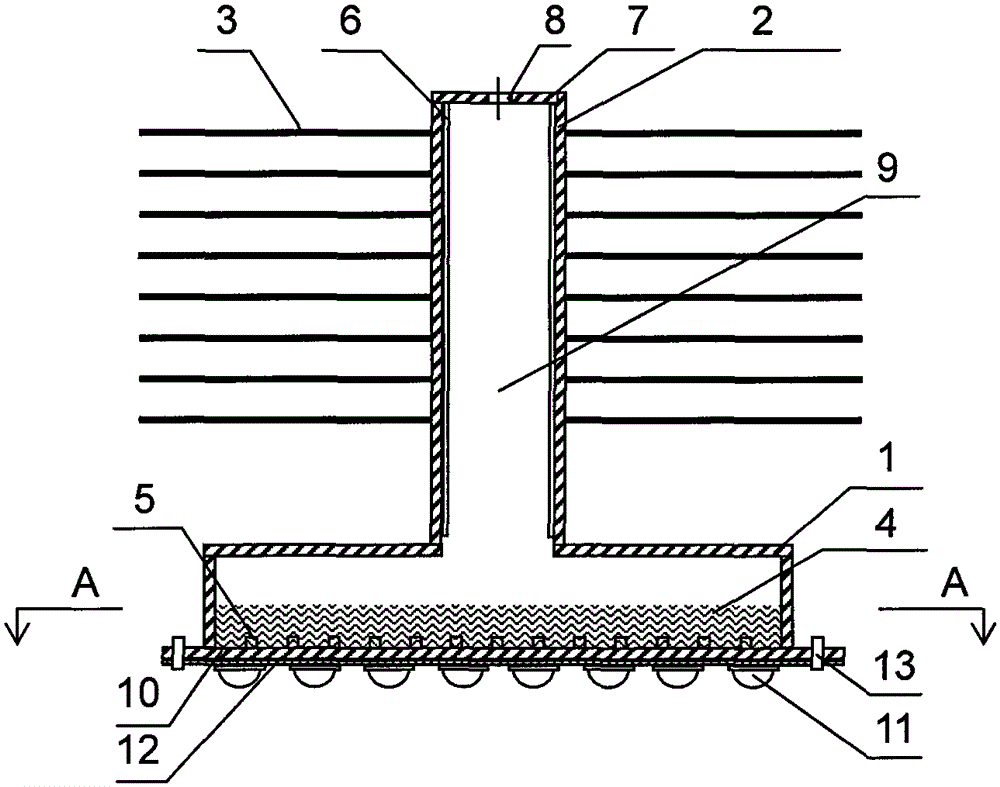

Improved gravity assisted heat pipe radiator used for high-power LED

InactiveCN103196116AEasy to processLow pricePoint-like light sourceLighting heating/cooling arrangementsRefluxHeat conducting

The invention discloses an improved gravity assisted heat pipe radiator used for a high-power LED, which comprises an improved gravity assisted heat pipe and radiating fins, and is characterized in that the improved gravity assisted heat pipe consists of a flat-plate-shaped evaporation section and a cylindrical condensation section, wherein the evaporation section is directly connected with an LED circuit baseplate; the condensation section is connected with the radiating fins; a heat conduction column is arranged on the inner wall of the lower end of the evaporation section; a reflux tank channel is axially arranged on the inner wall of the condensation section; the interior of the heat pipe is vaccumized and is filled with a heat-conducting medium; and the inner wall of the heat pipe is sandblasted for heat transfer enhancement. The improved gravity assisted heat pipe radiator used for the high-power LED transmits the heat to the radiating fins rapidly by the circulating convection with the participation of gravity, and has the benefits of flexibility, convenience, simplification, low cost, high start speed, capability of accelerating the radiating rate with the temperature rising of the high-power LED, and the like.

Owner:CHINA JILIANG UNIV

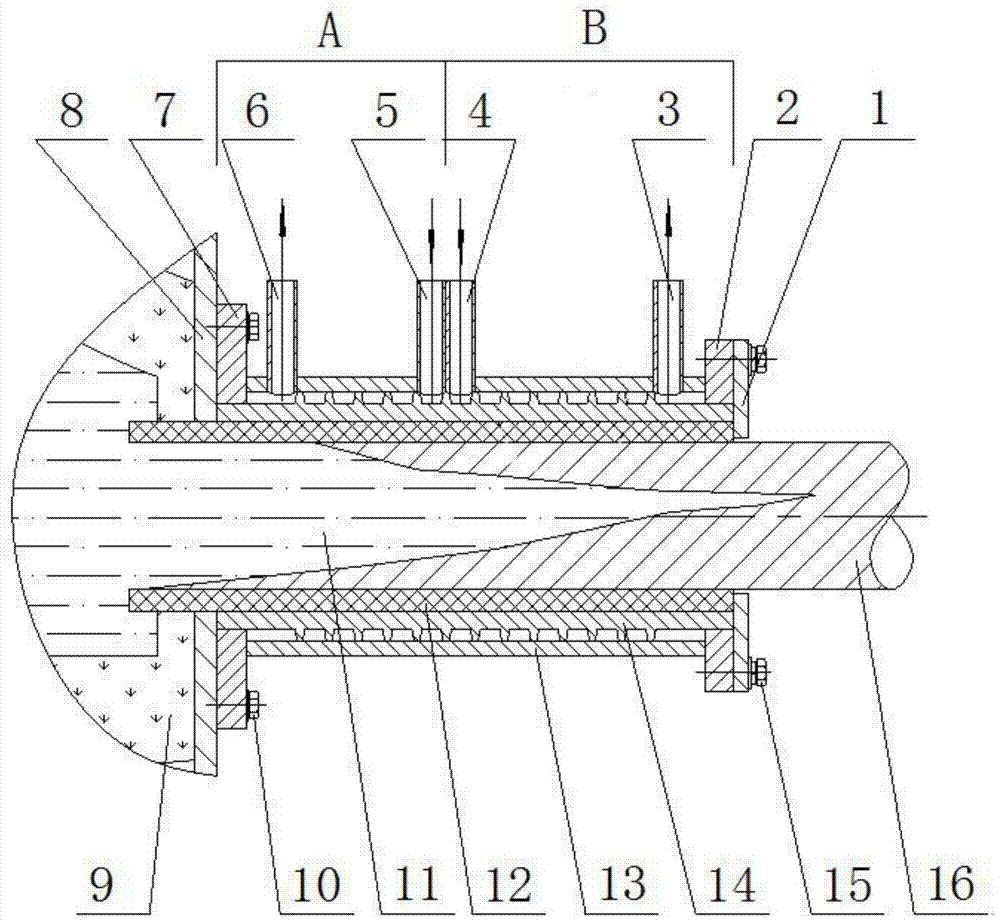

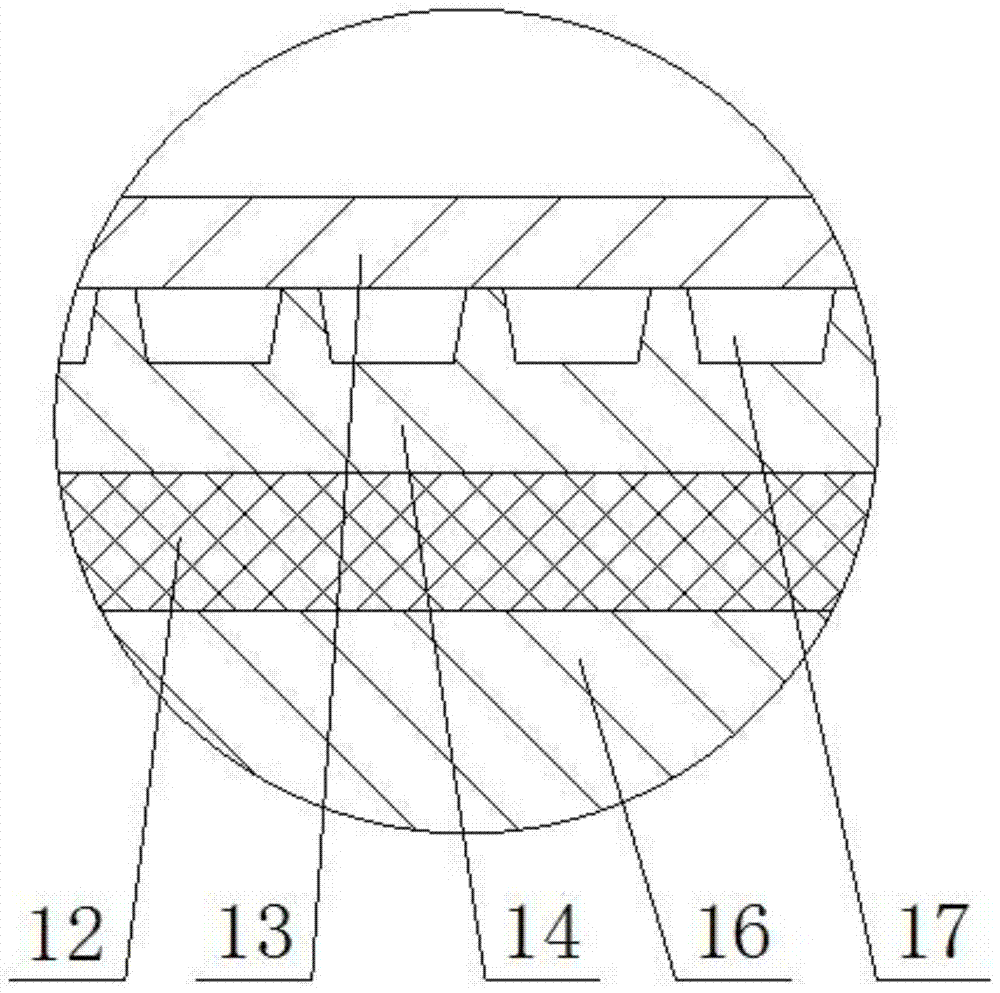

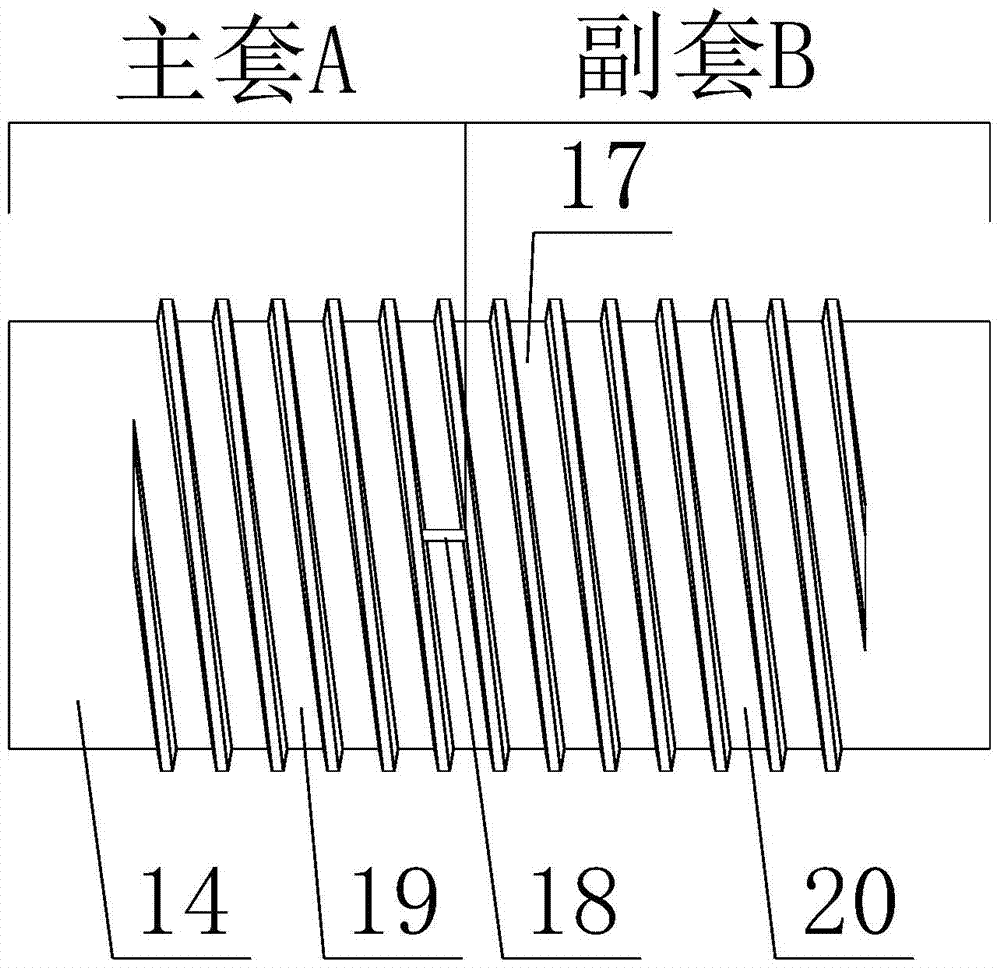

Cast iron horizontal continuous casting double-water jacket type crystallizer

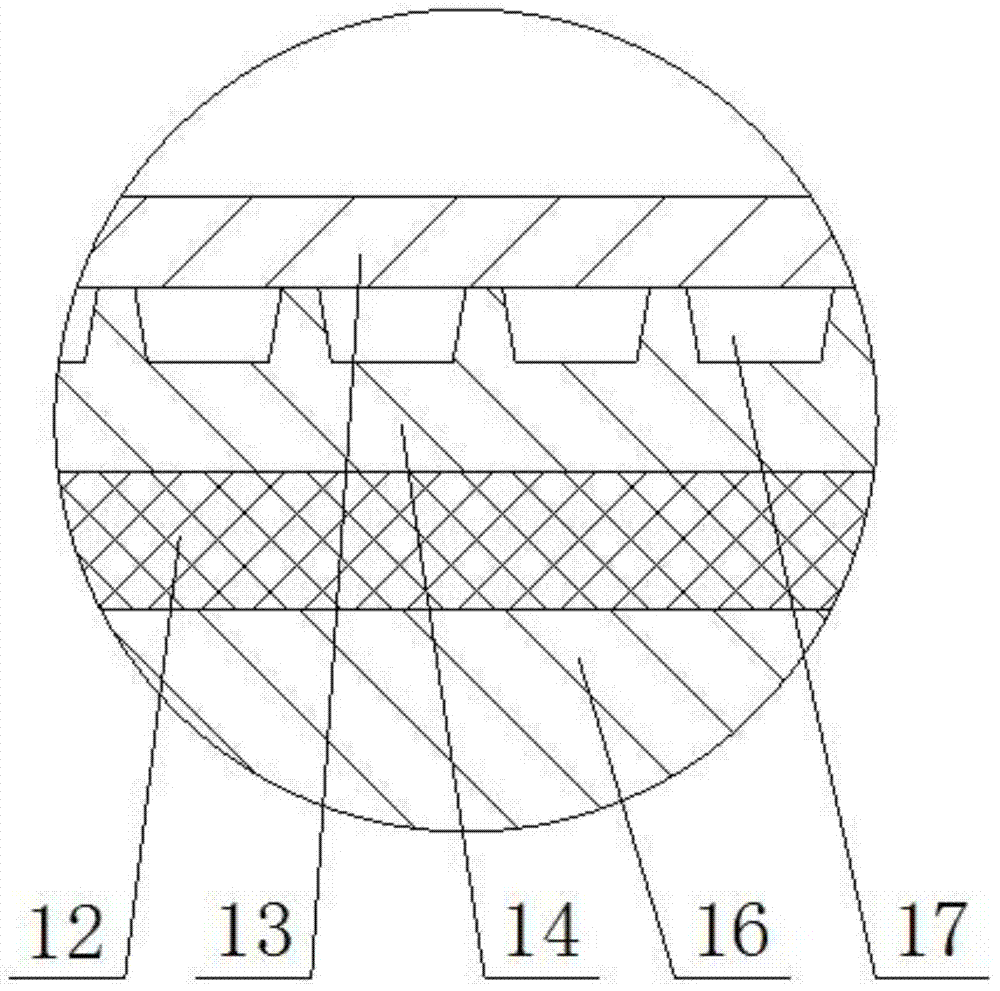

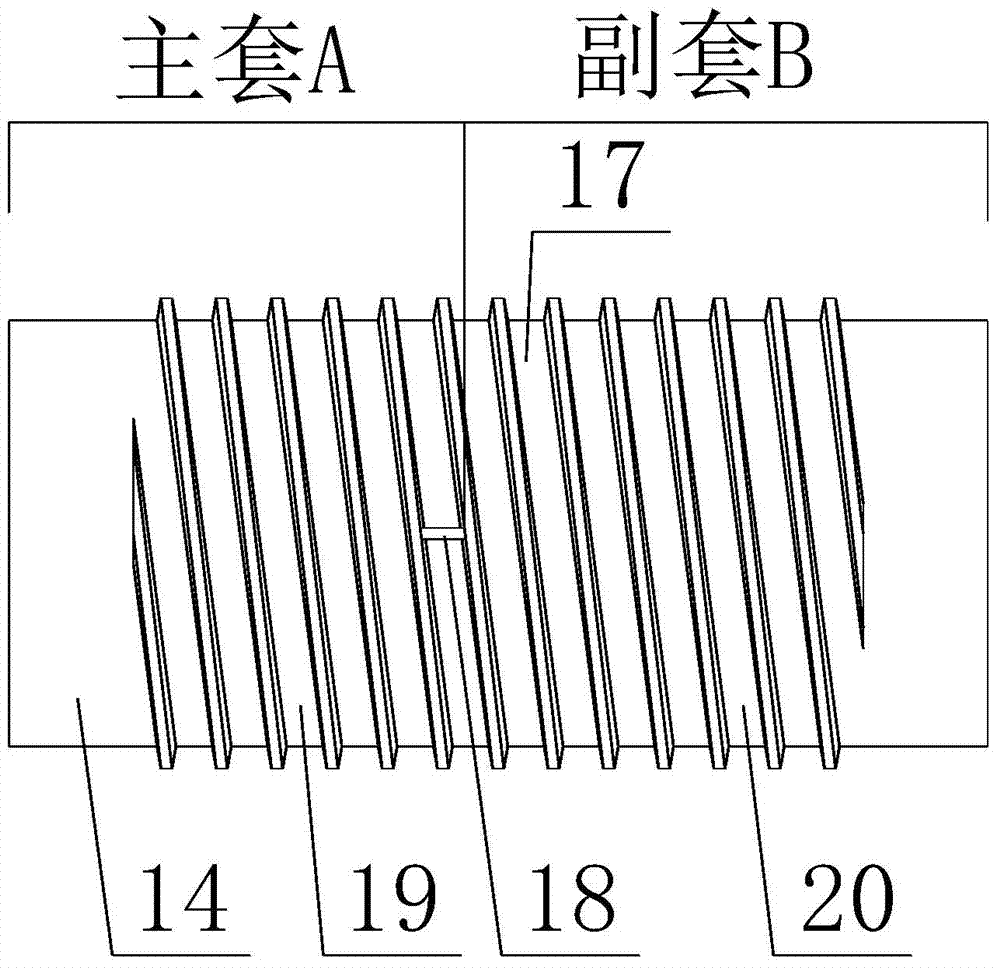

The invention relates to a cast iron horizontal continuous casting double-water jacket type crystallizer, which comprises a double-water jacket type crystallizer steel sleeve and a high-purity graphite sleeve, wherein the high-purity graphite sleeve is embedded in the double-water jacket type crystallizer steel sleeve, the double-water jacket type crystallizer steel sleeve comprises a crystallizer steel sleeve inner sleeve and a crystallizer steel sleeve outer sleeve, the crystallizer steel sleeve outer sleeve is arranged at the exterior of the crystallizer steel sleeve outer sleeve, the crystallizer steel sleeve inner sleeve is provided with a spiral water passage with a trapezoidal cross section, a separating plate is arranged in the spiral water passage with the trapezoidal cross section, and is used for separating the spiral water passage with the trapezoidal cross section into a spiral water passage with a trapezoidal cross section I and a spiral water passage with a trapezoidal cross section II, the crystallizer steel sleeve outer sleeve is respectively welded with a water inlet pipe of a main sleeve A, a water outlet pipe of the main sleeve A, a water inlet pipe of an auxiliary sleeve A and a water outlet pipe of the auxiliary sleeve B, the water inlet pipe of the main sleeve A and the water outlet pipe of the main sleeve A are respectively communicated with the spiral water passage with the trapezoidal cross section I to form the main sleeve A, and the water inlet pipe of the auxiliary sleeve B and the water outlet pipe of the auxiliary sleeve B are respectively communicated with the spiral water passage with the trapezoidal cross section II to form the auxiliary sleeve B. The cast iron horizontal continuous casting double-water jacket type crystallizer has the advantages that the process advantages of horizontal continuous casting using separate control of the two water jackets are fully realized, the leakage of furnaces is avoided, the drawing speed is improved, and the cost is reduced.

Owner:陕西均安精工科技有限公司

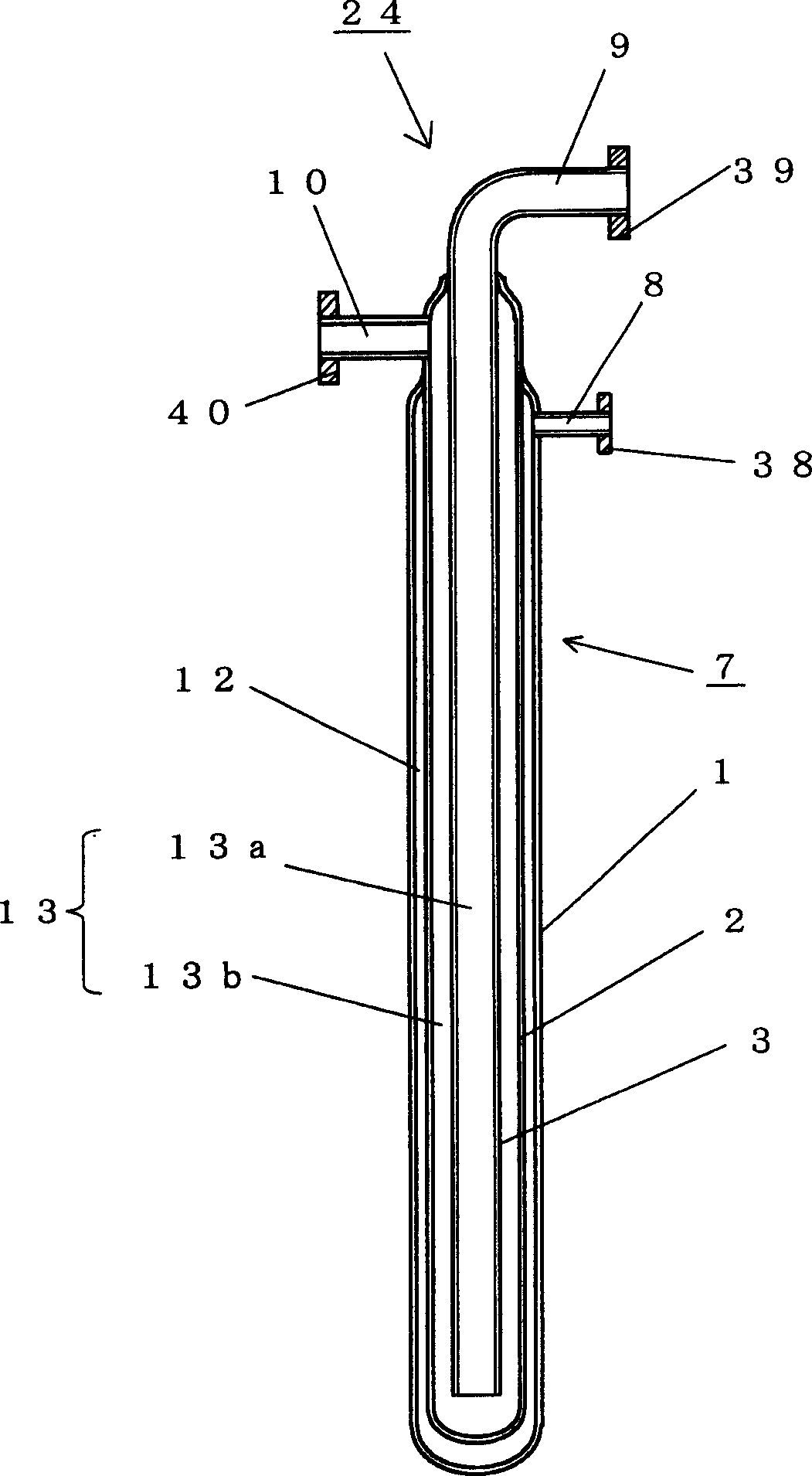

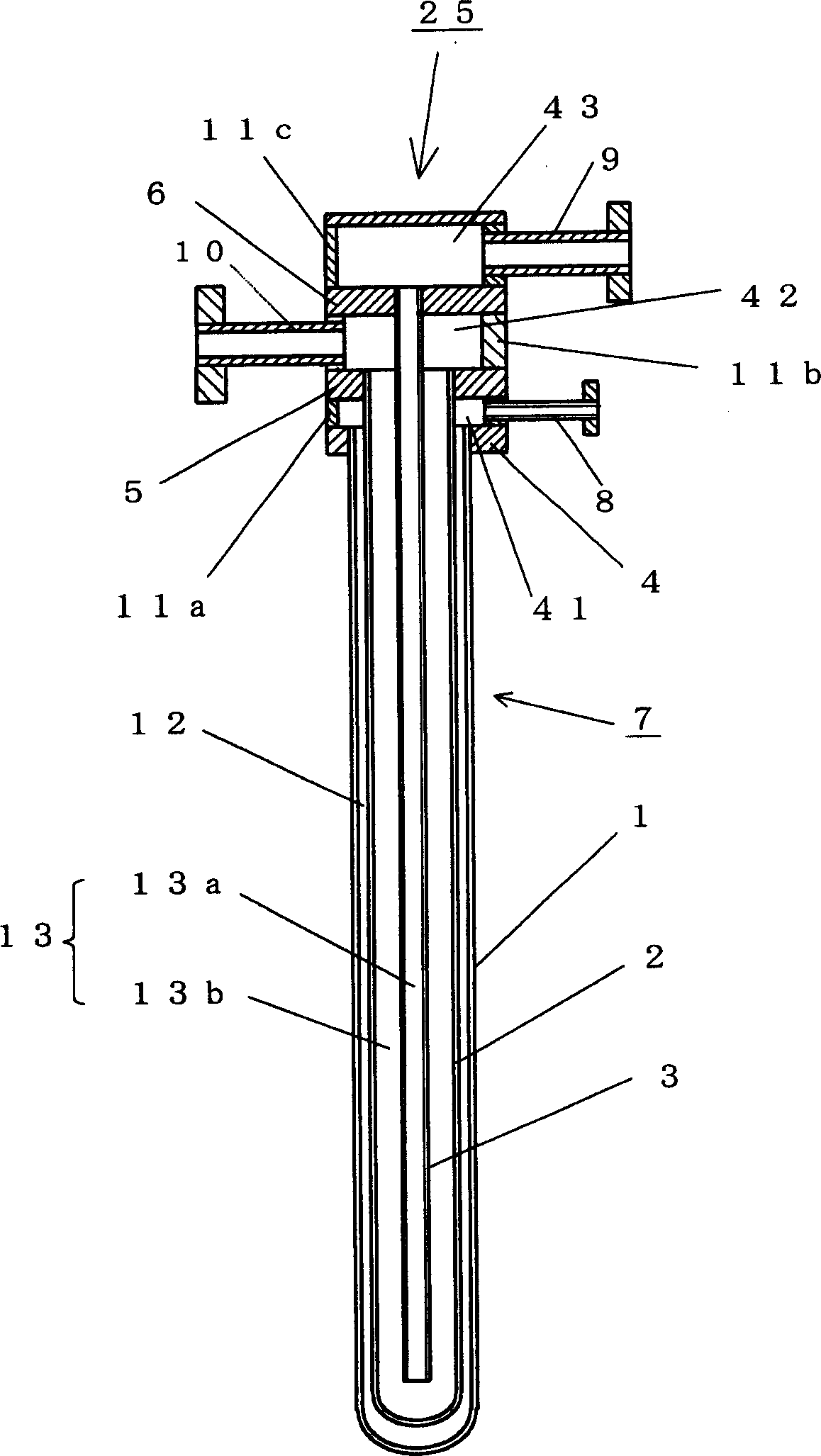

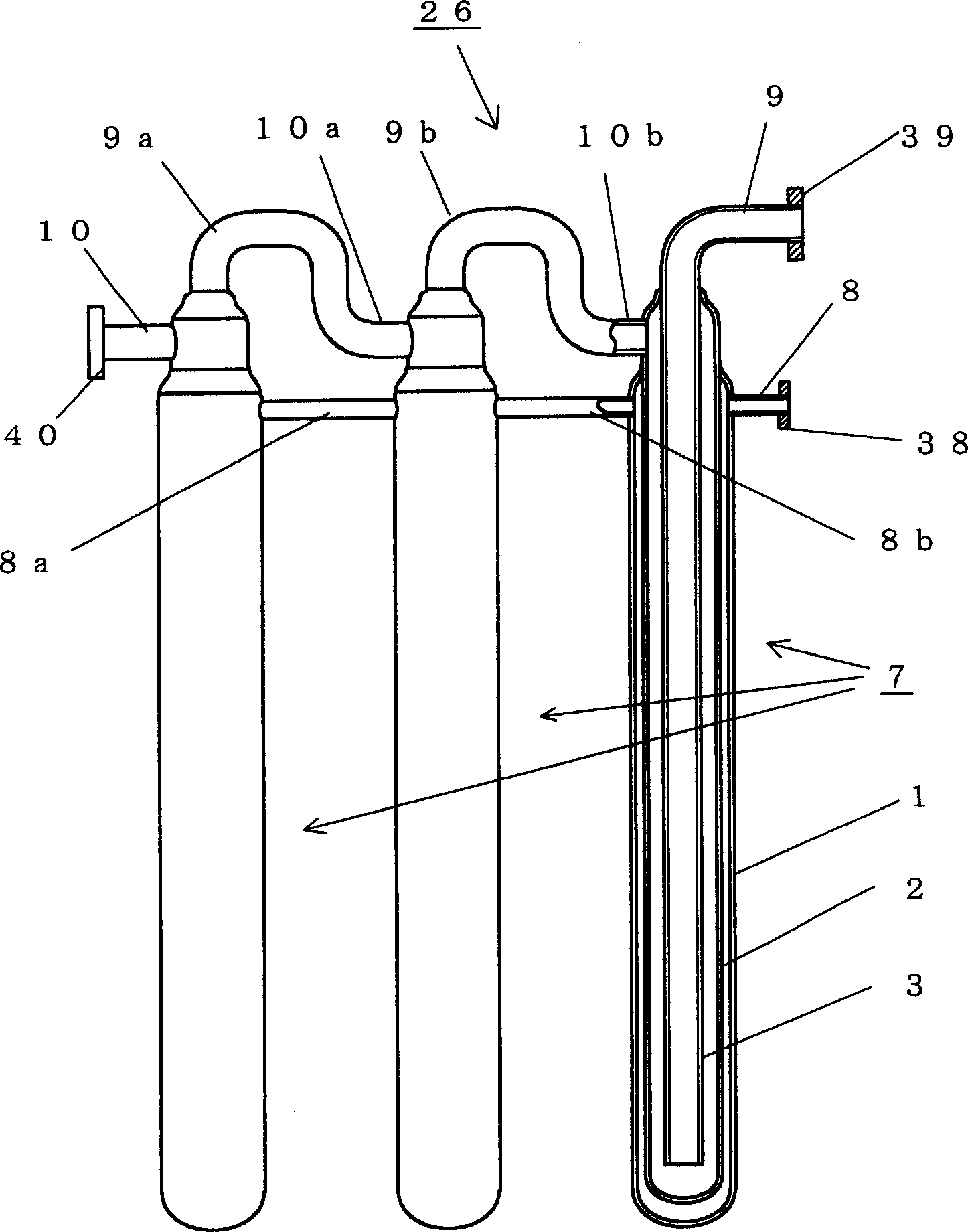

Cooling device and thin strap continuous casting apparatus and cooling method for casting thin strap

InactiveCN1576768AAchieve Cooling ControlIncrease heat transfer areaStationary tubular conduit assembliesRare earthAlloy

Provided is a cooling device variable of a cooling power and capable of decreasing the cooling power in a high temperature zone particularly without decreasing the cooling power in the low temperature zone affecting a cooling time, and to provide an apparatus for strip-casting a rare earth metal magnet alloy, which is provided with the cooling device and a method therefor. In this cooling device, the cooling power is changed and controlled by using a triple-tube system cooling tube unit constituted of an outer tube, a middle tube and an inner tube, and allowing a cooling medium to flow through a passage constituted of the inner tube and the middle tube and exhausting gas under vacuum or introducing helium for promoting the cooling through the annular gap part between the outer tube and the middle tube.

Owner:广濑洋一

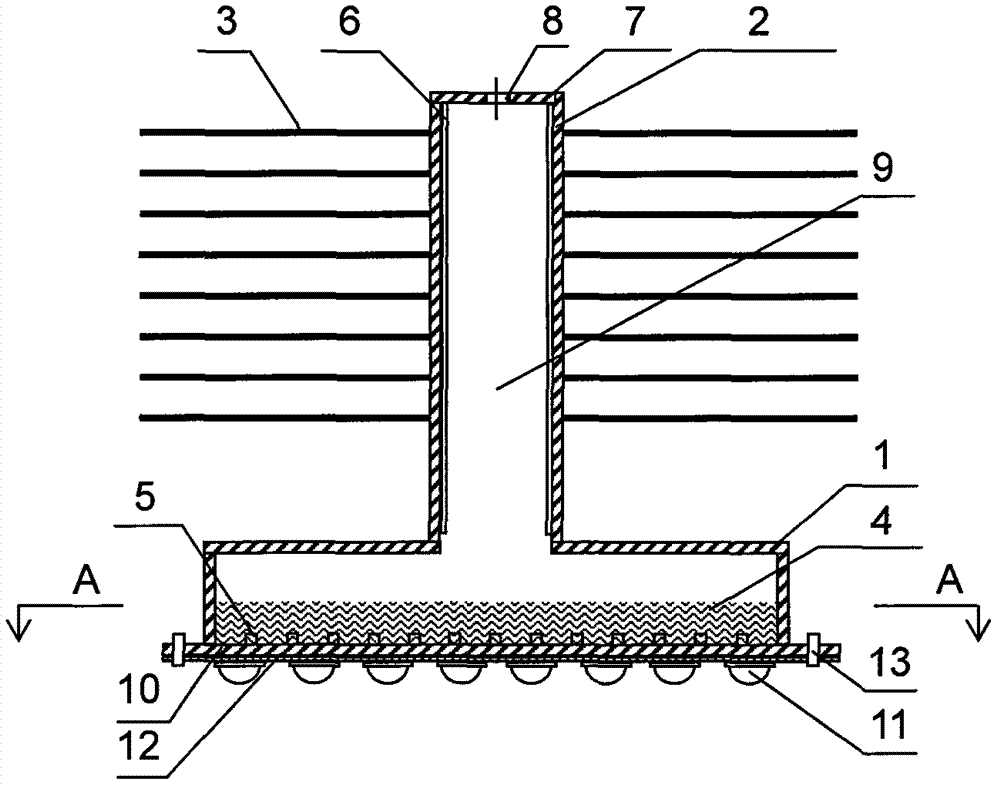

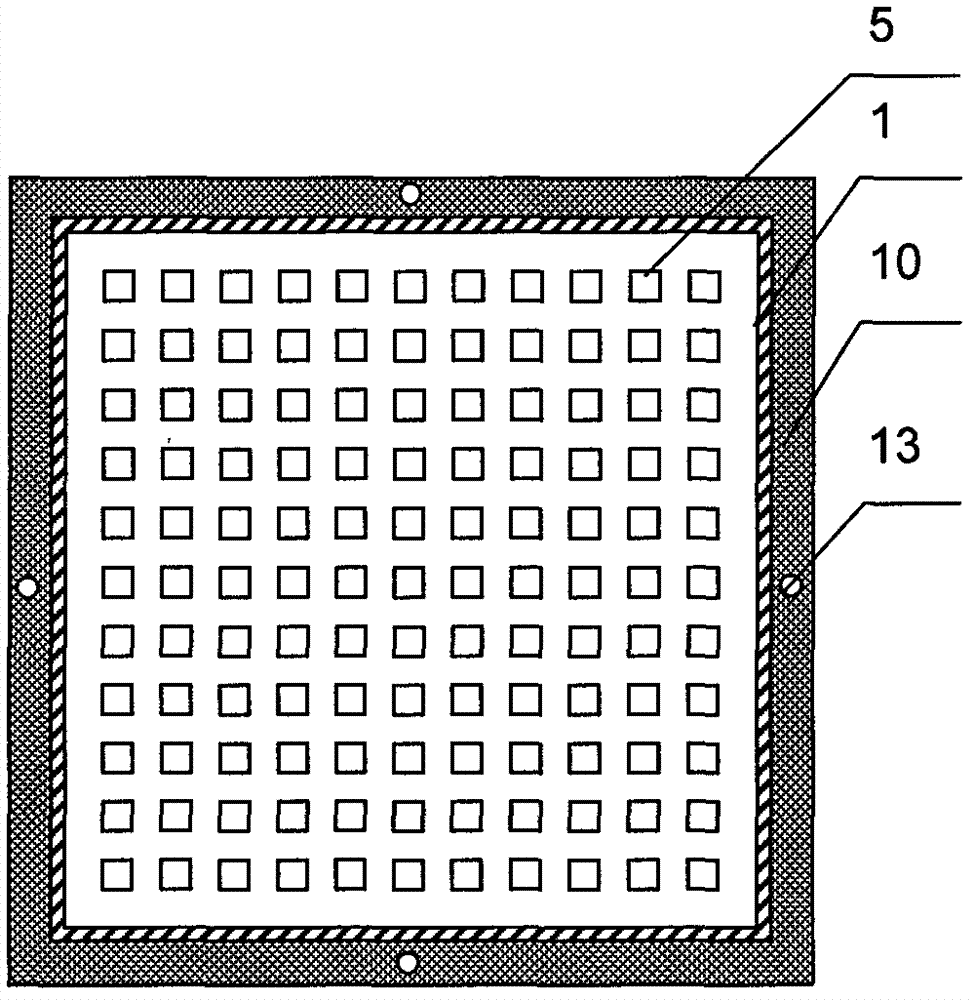

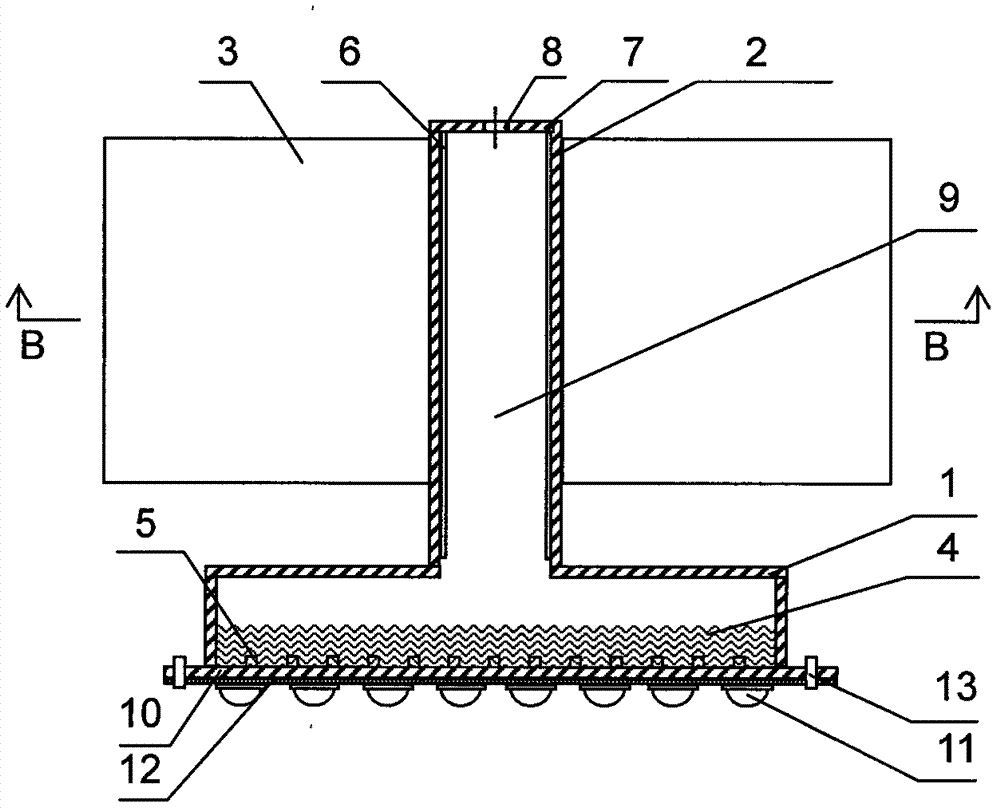

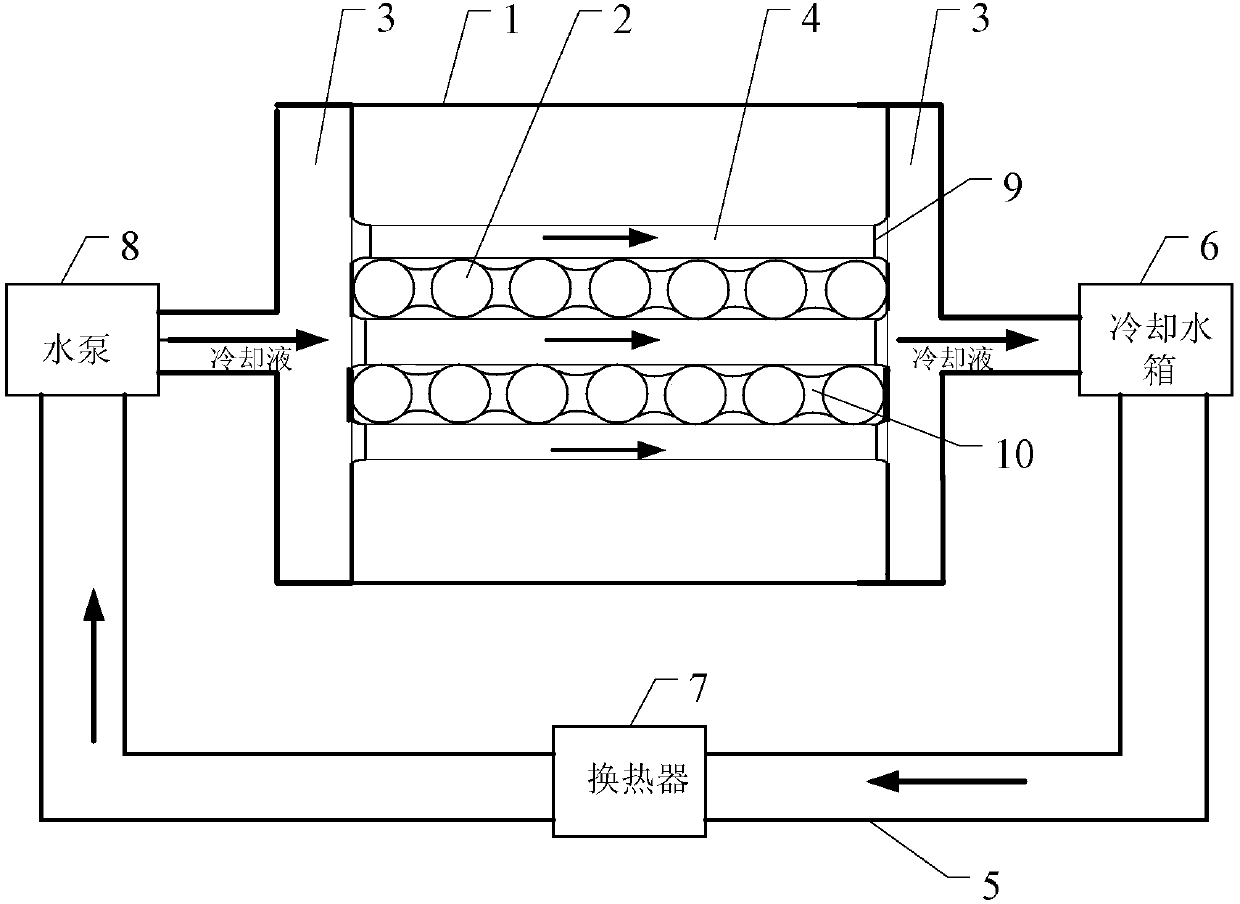

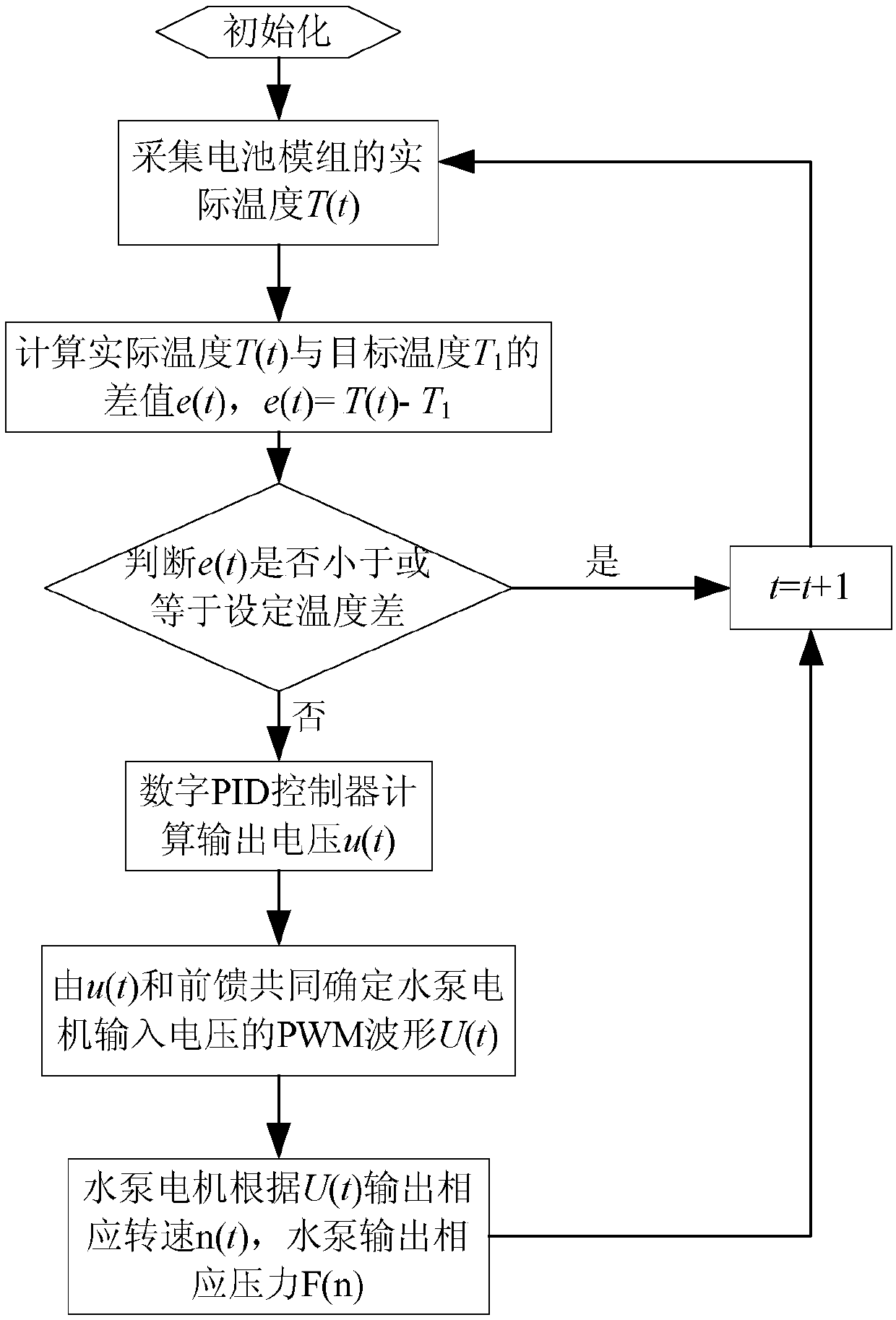

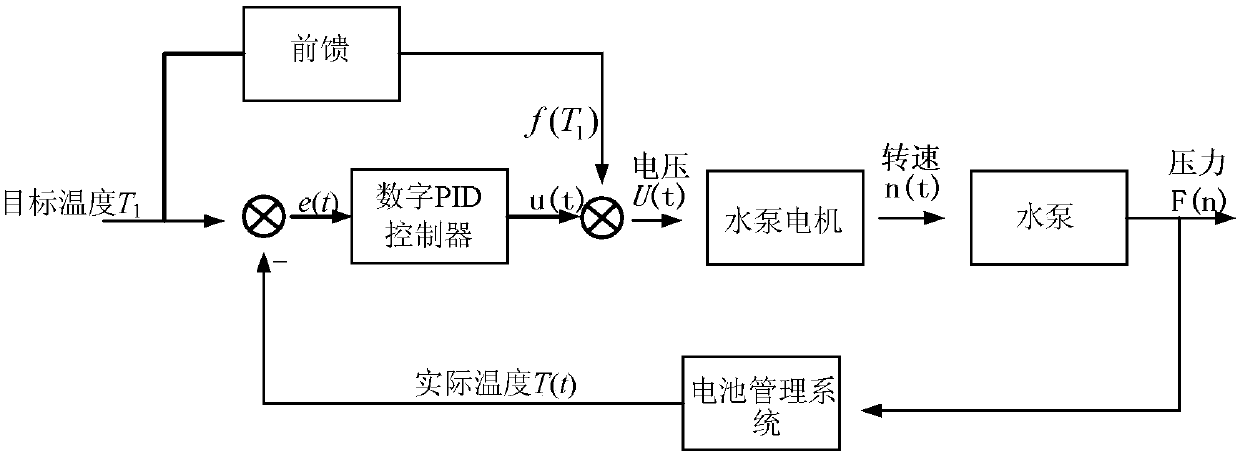

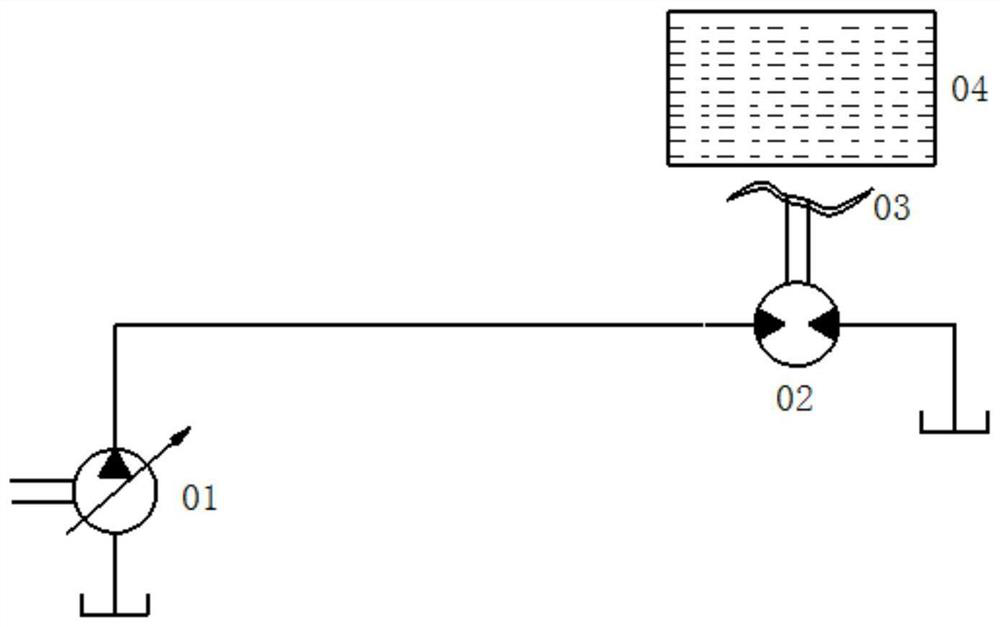

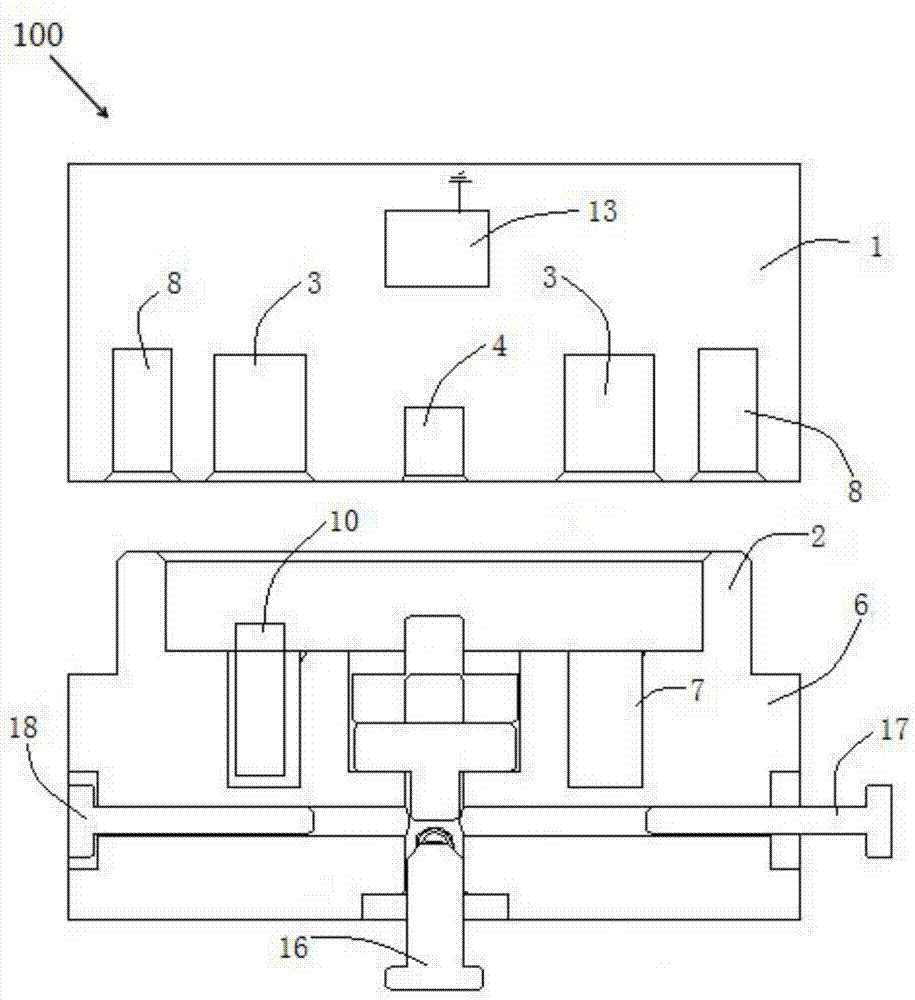

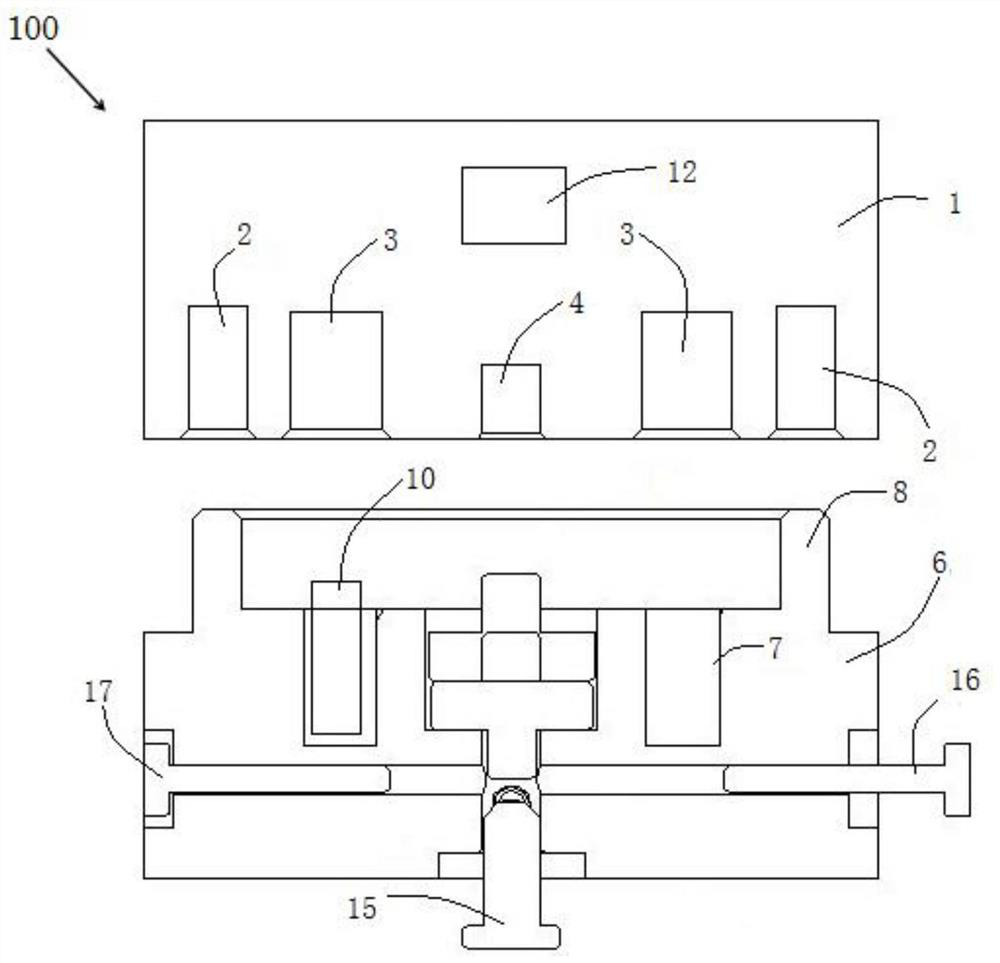

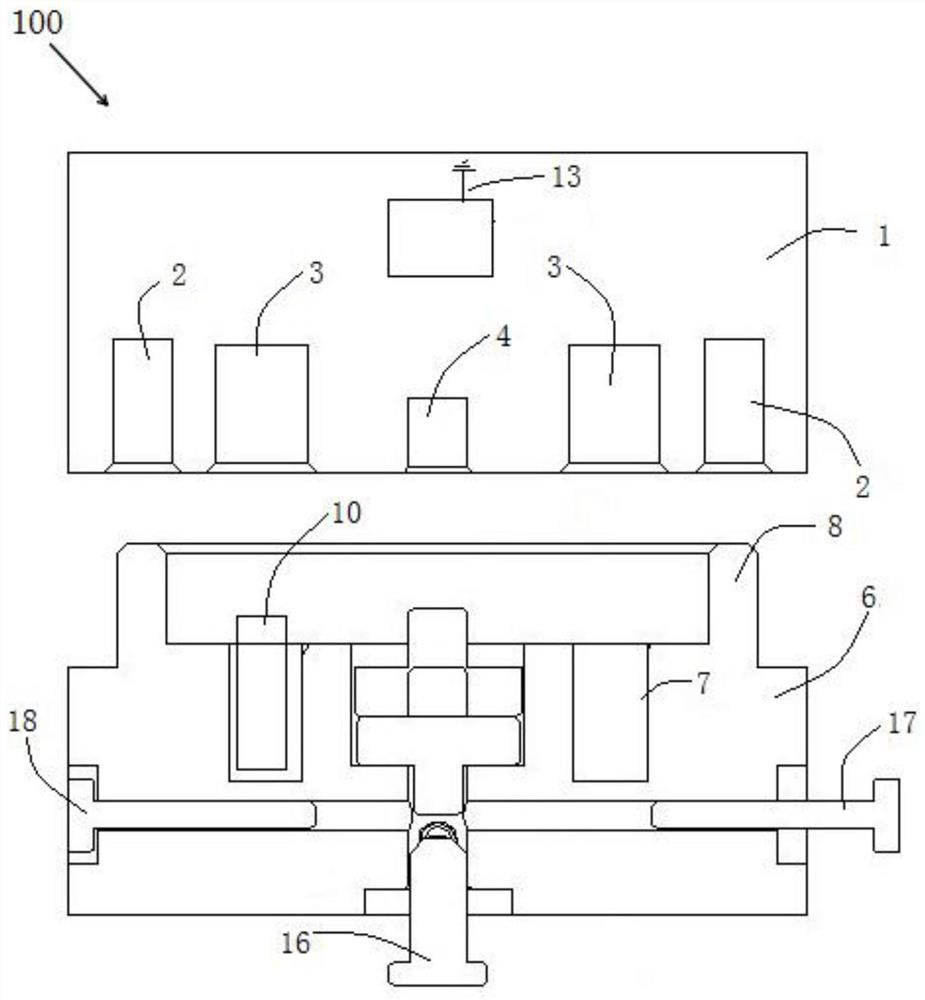

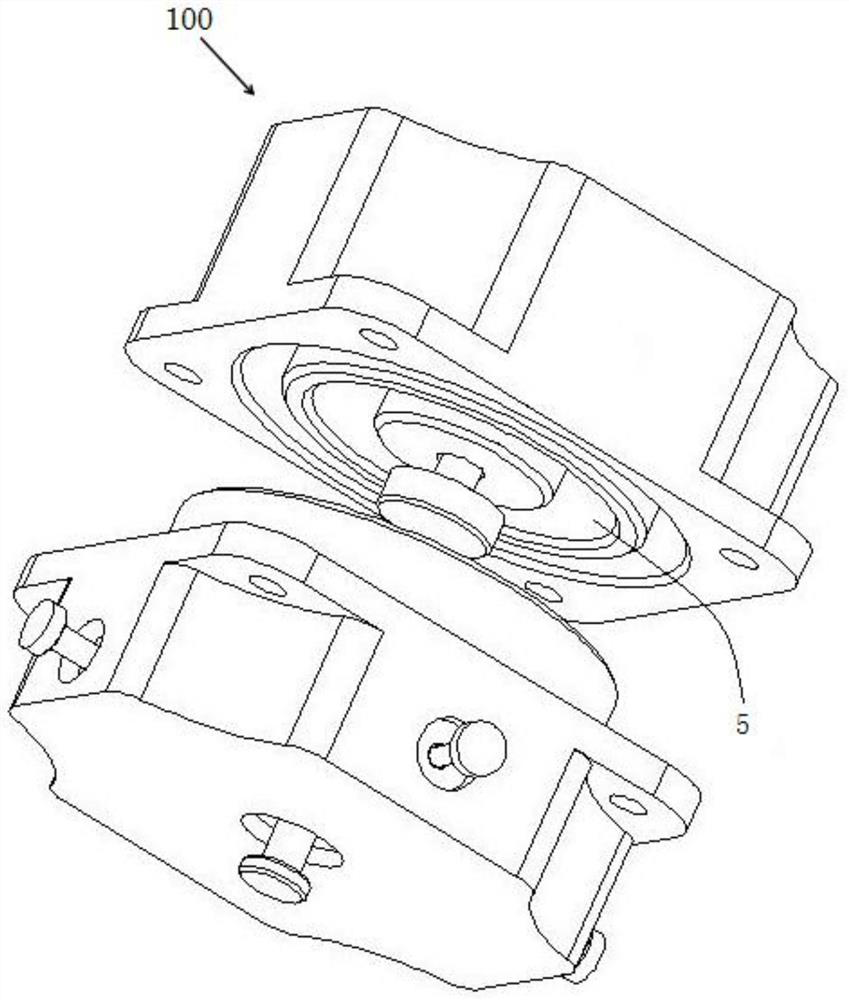

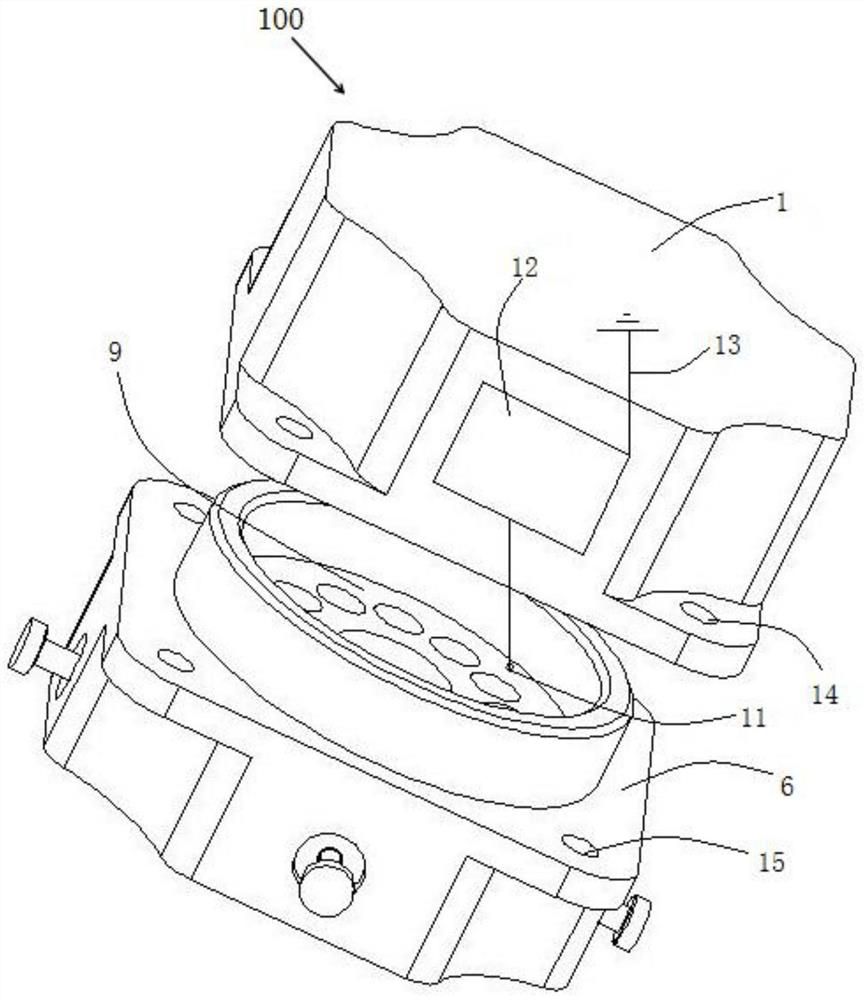

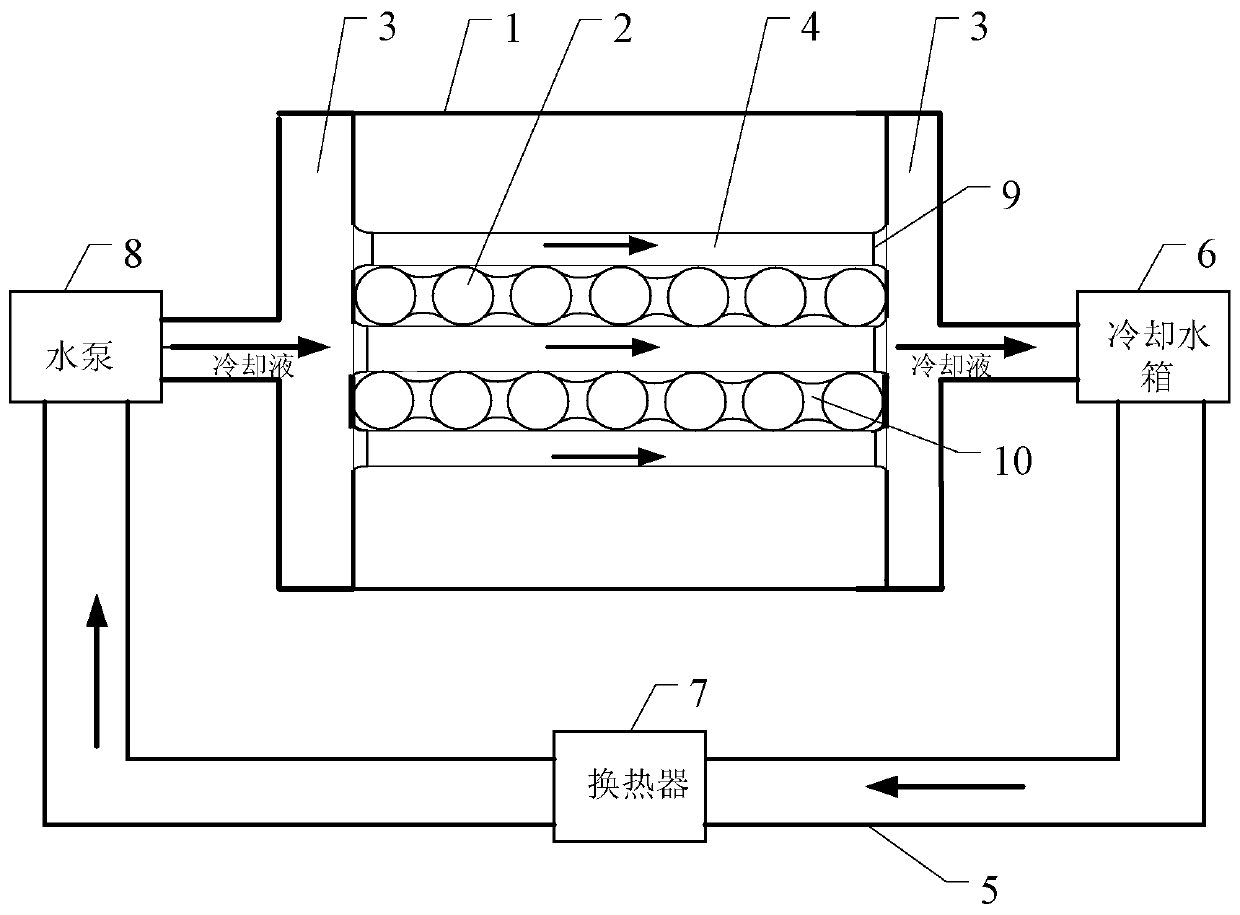

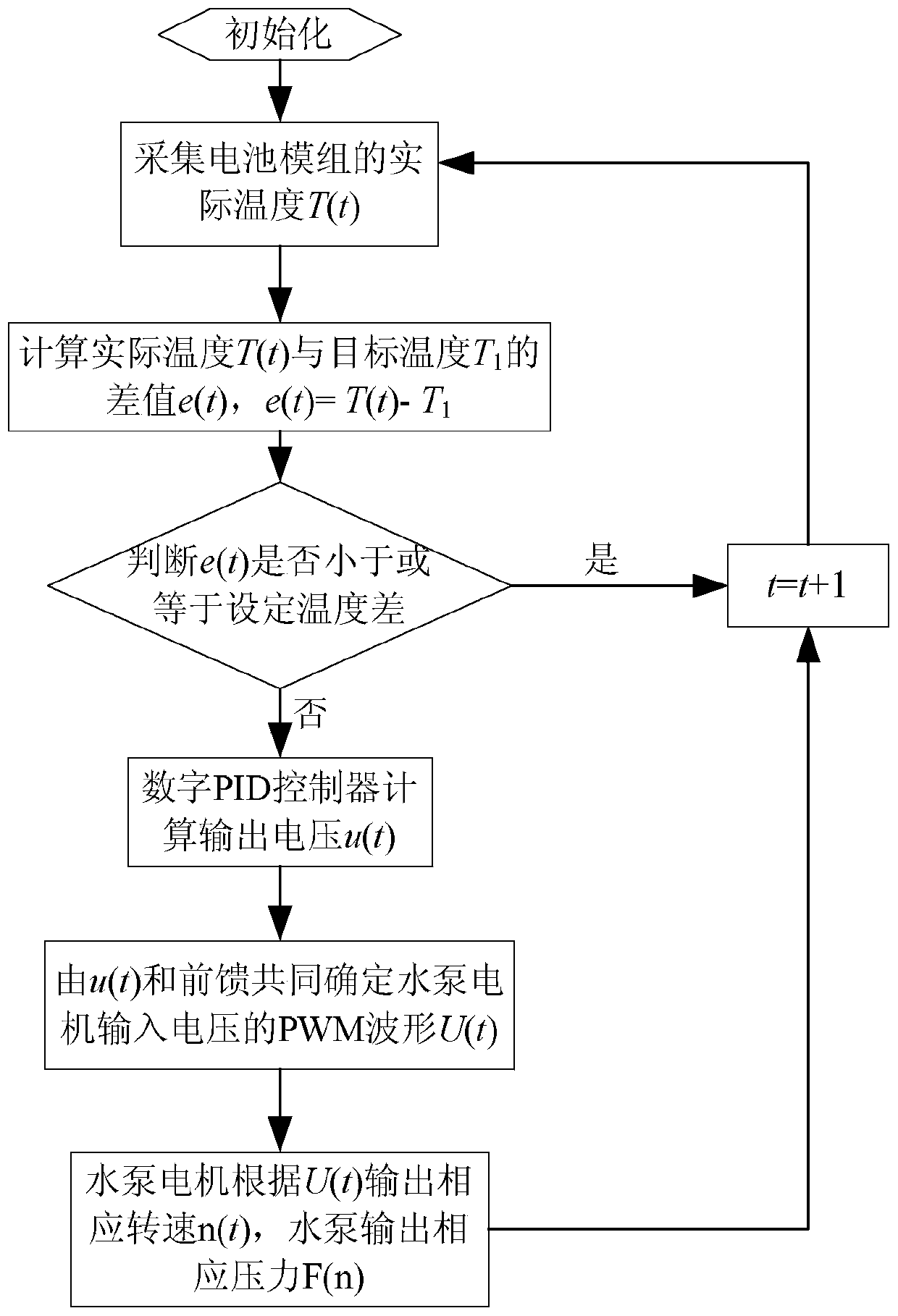

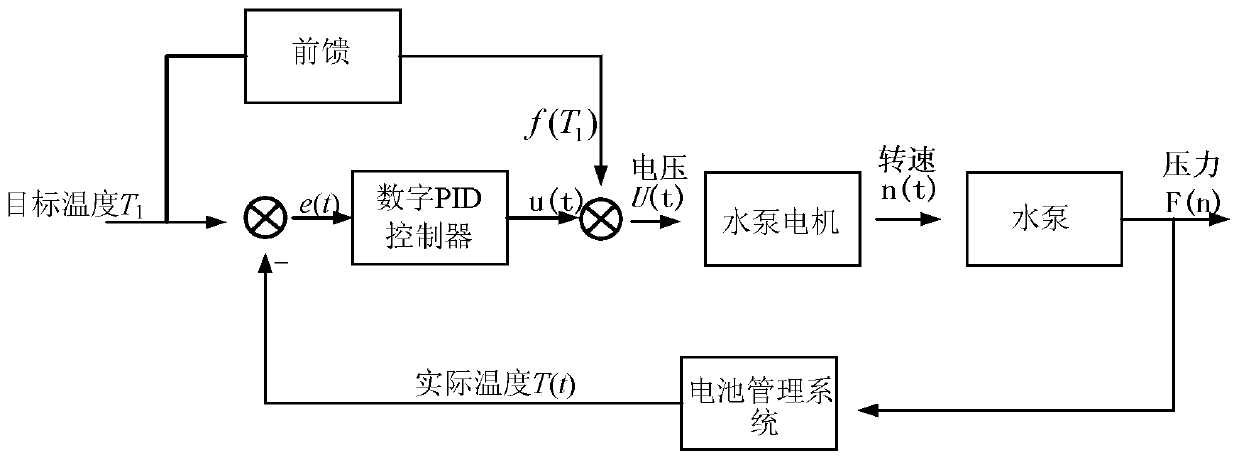

Power battery box cooling structure and control method thereof

ActiveCN108110370AChange cooling rateSave electricityCell temperature controlCell component detailsElectrical batteryWater storage tank

The invention provides a power battery box cooling structure and a control method thereof, and belongs to a battery box cooling technology. According to the structure and the control method thereof, the possible problems that the existing rigid pipeline is deformed in structure, and the cooling efficiency is low after the existing rigid pipeline operates for a long time, are solved. In the structure, a flexible water jacket is arranged between adjacent battery modules; two small water storage tanks are communicated with each other by an external water channel outside a box body of a battery box, so as to form a circulation waterway; a cooling water tank, a heat exchanger and a water pump are sequentially arranged on the external water channel in the direction of water flow. According to the method, the actual temperature T(t) of the battery modules is collected, the difference e(t) between the actual temperature T(t) and the target temperature T1 is calculated, the output voltage u(t)is calculated by a digital PID (proportion integration differentiation) controller, the PWM (pulse-width modulation) waveform U(t) of the input voltage of a water pump motor is determined, the corresponding rotation speed n(t) is output by the water pump motor according to the U(t), and the corresponding pressure F(n) is output by the water pump. The structure is suitable for cooling batteries.

Owner:HARBIN UNIV OF SCI & TECH

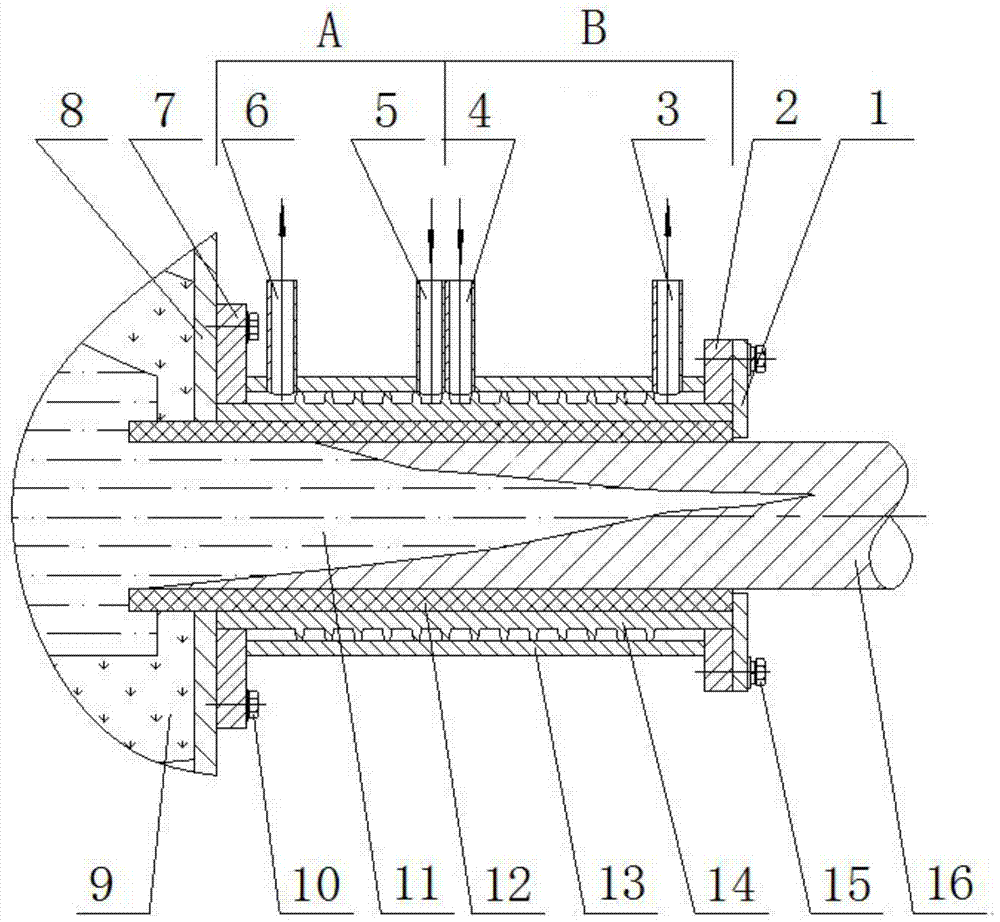

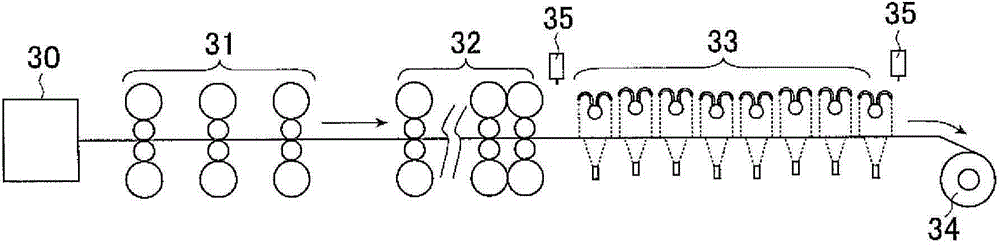

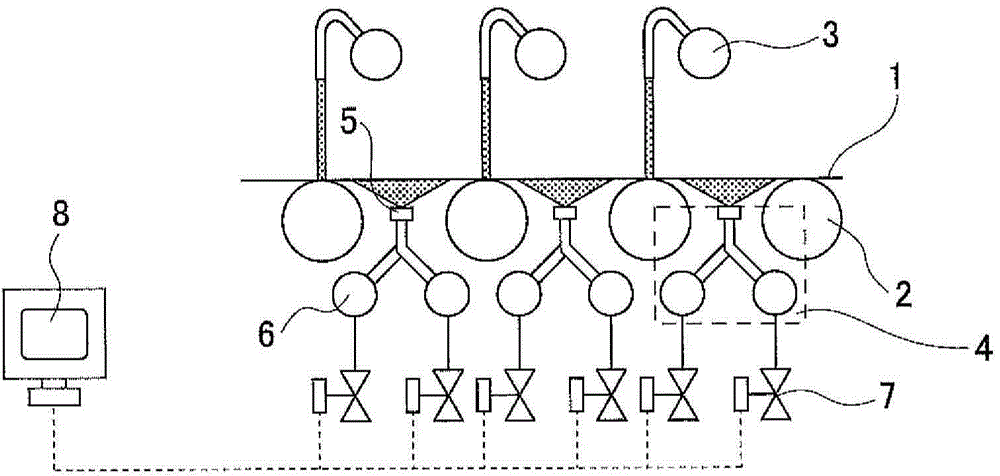

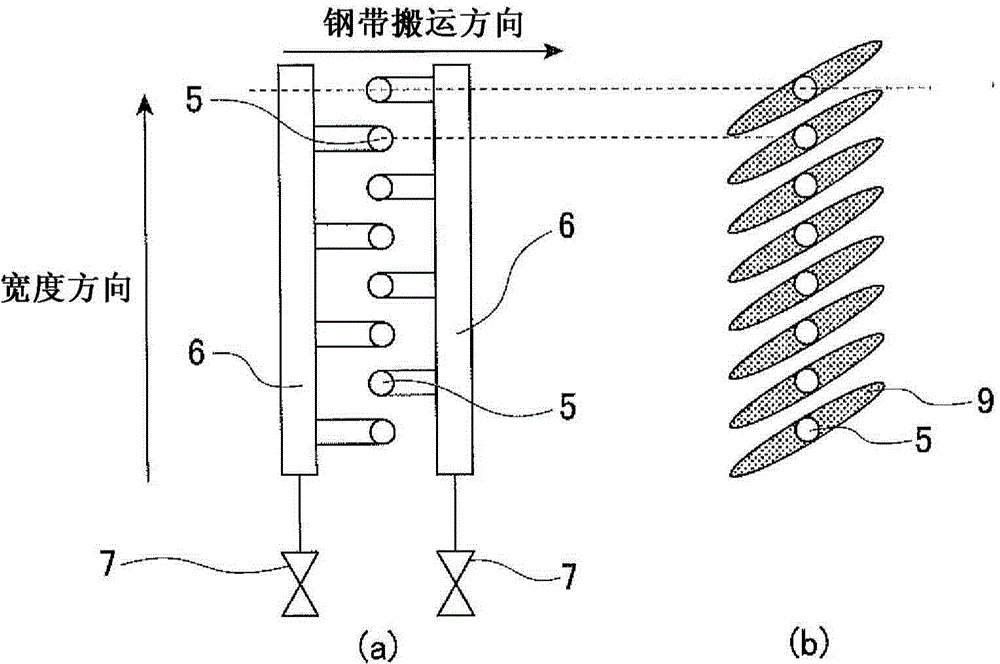

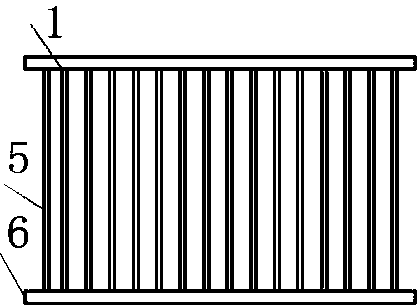

Cooling method and cooling device for hot-rolled steel strip

ActiveCN104884182AChange cooling rateAids in Manufacturing ClassificationWork cooling devicesMetal rolling arrangementsSurface coolingSpray nozzle

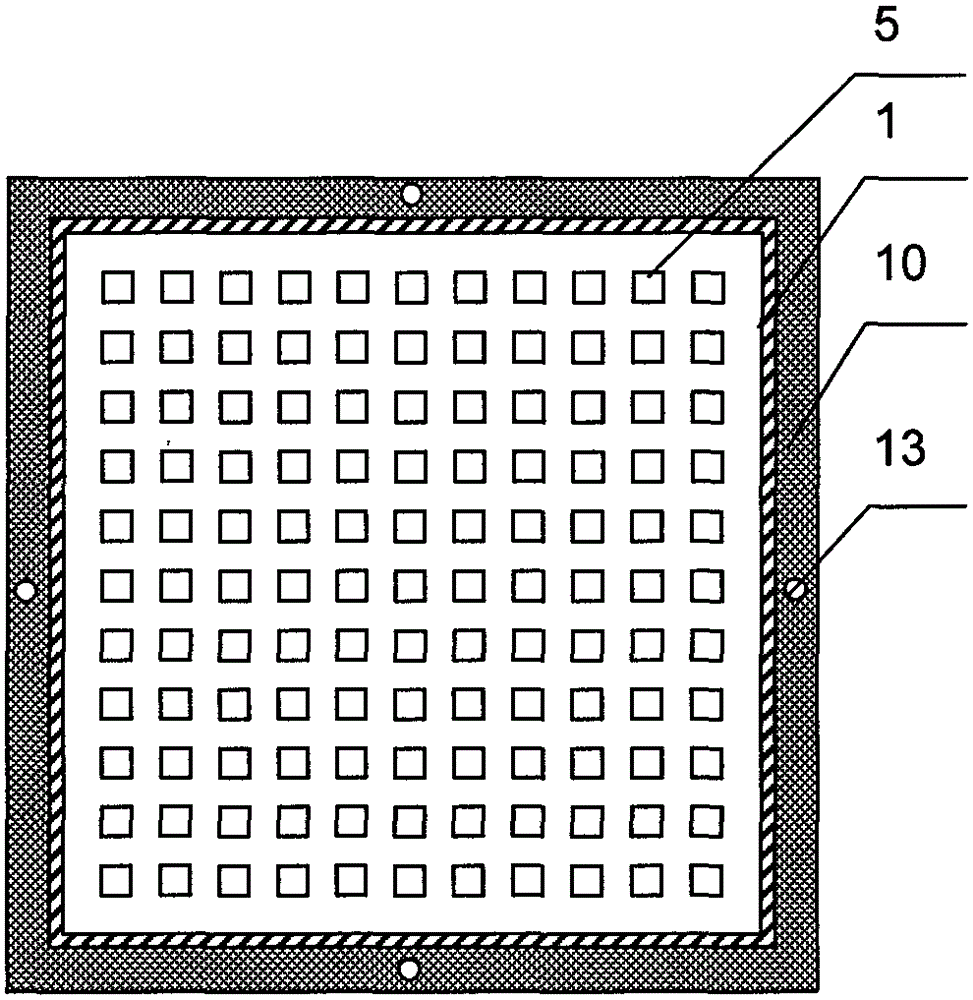

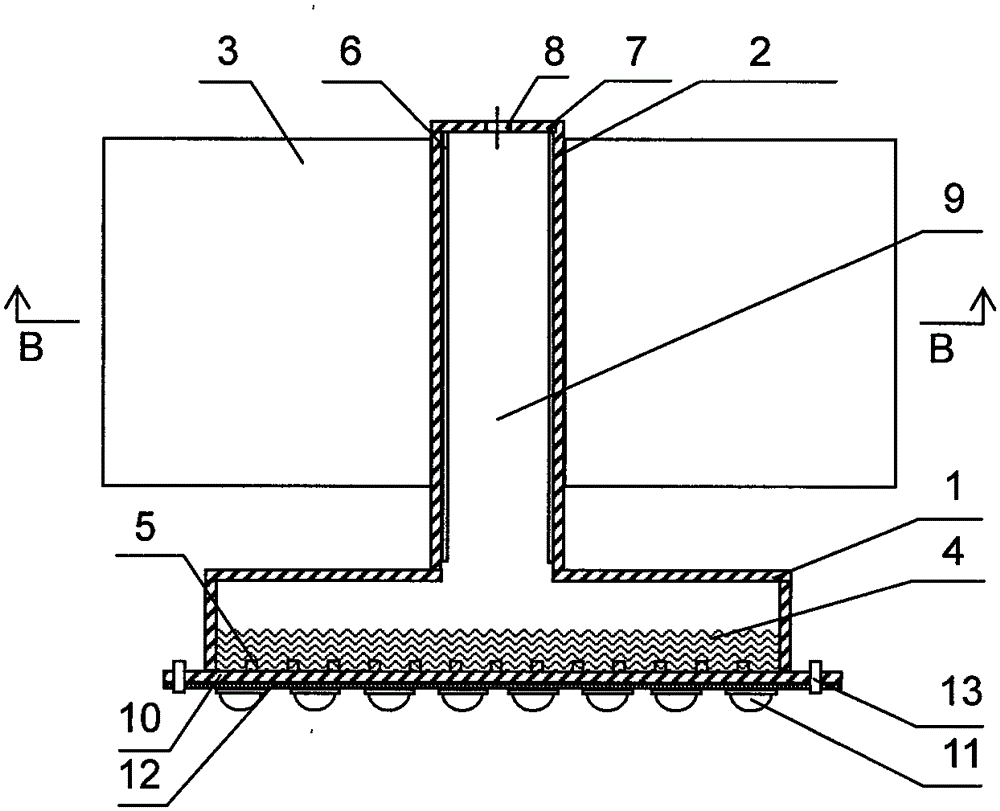

Provided are a cooling method and a cooling device for adjusting the volume of cooling water in two levels for each set of width direction headers when cooling a hot-rolled steel strip and for changing the steel strip cooling velocity in multiple levels using a simple method, the method and device being particularly effective for cooling the lower surface of a steel strip in a narrow space. Spray nozzles (5) are disposed in a row at a specified pitch in the width direction of the steel strip. In order that cooling water can be supplied from different piping systems for spray nozzles (5) that are adjacent in the width direction, the cooling headers (6) are configured so that: two systems are disposed per one set; a jetting valve (7) is installed on each; and individual cooling water jetting / stopping is possible.

Owner:JFE STEEL CORP

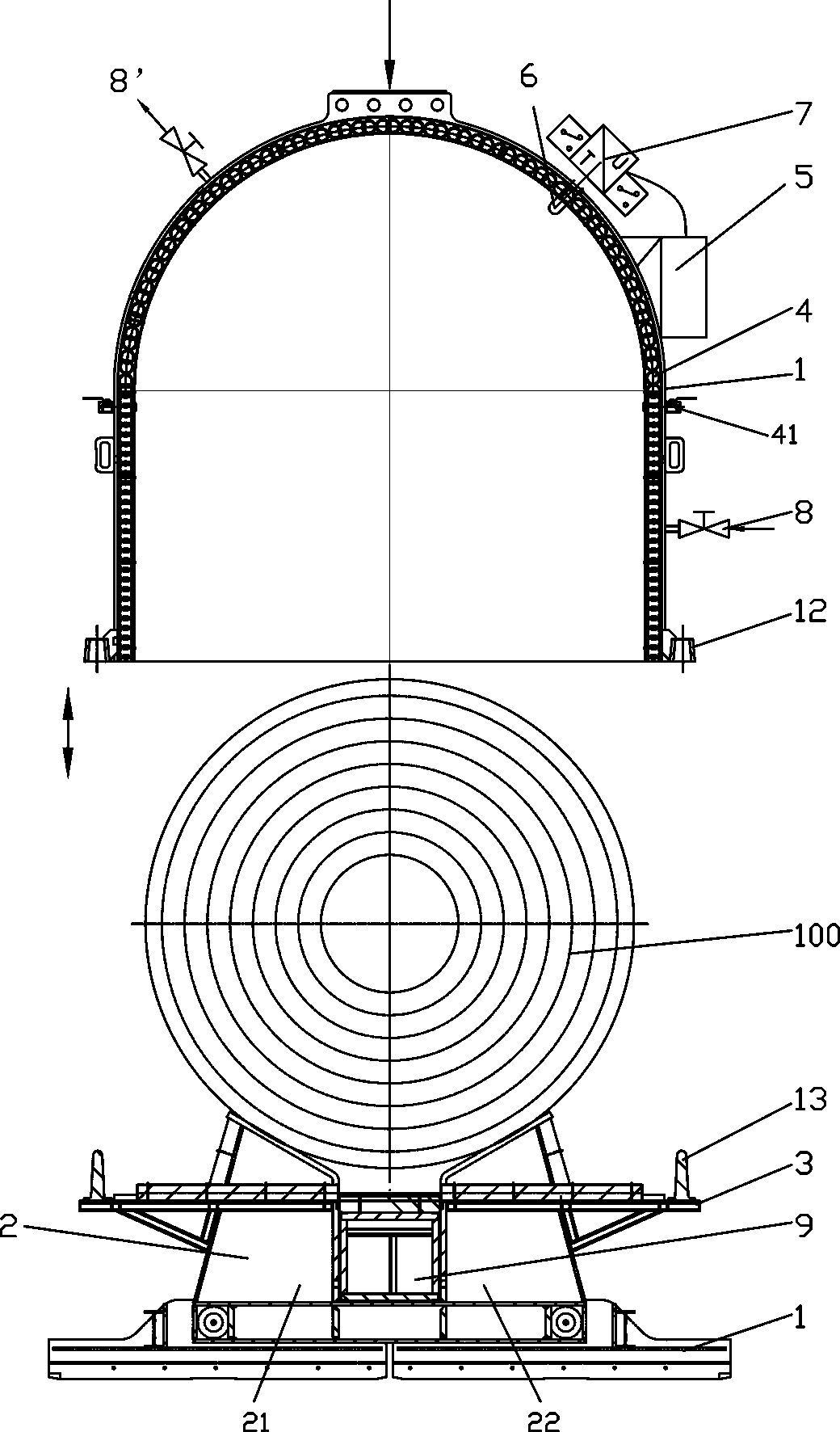

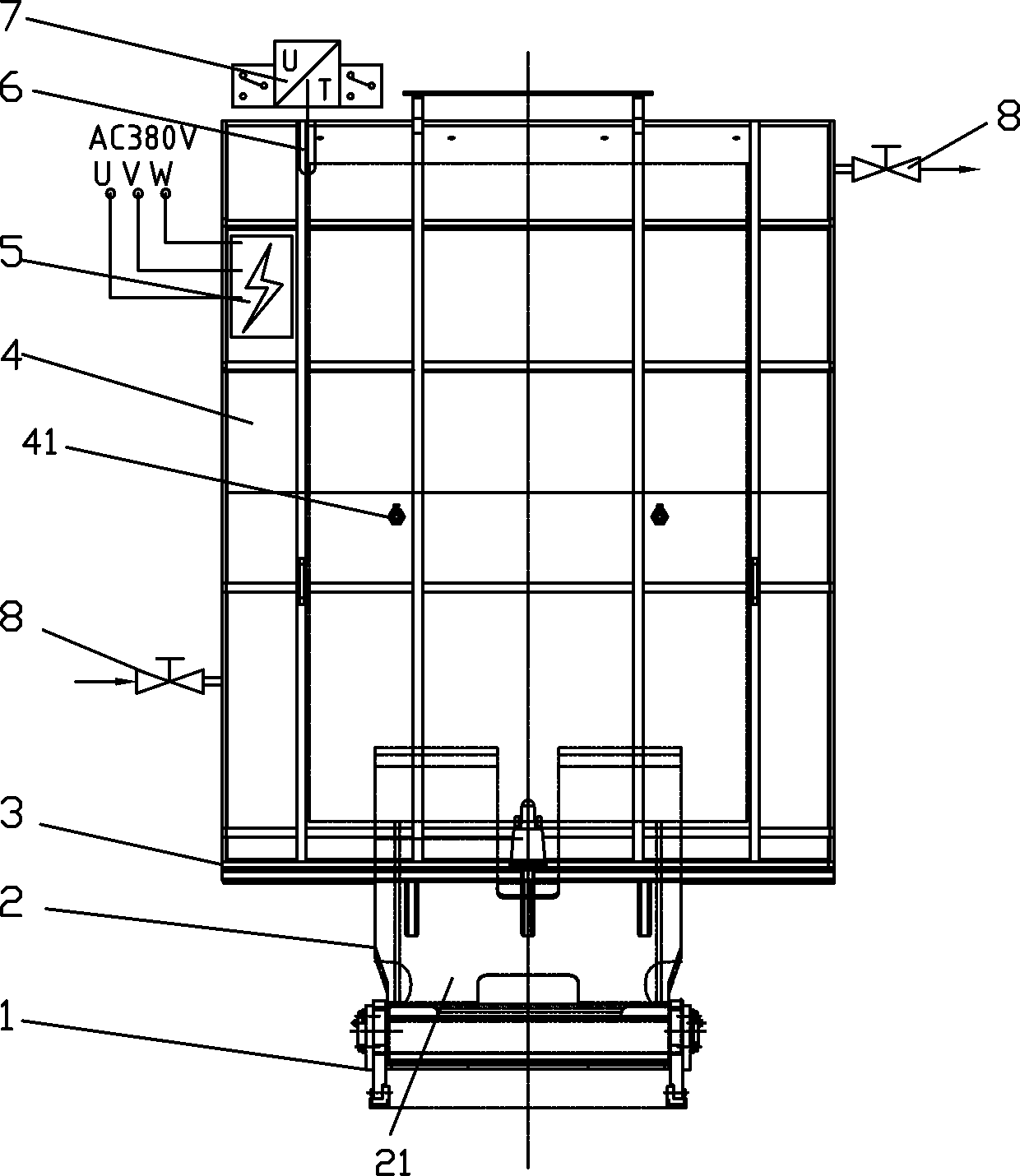

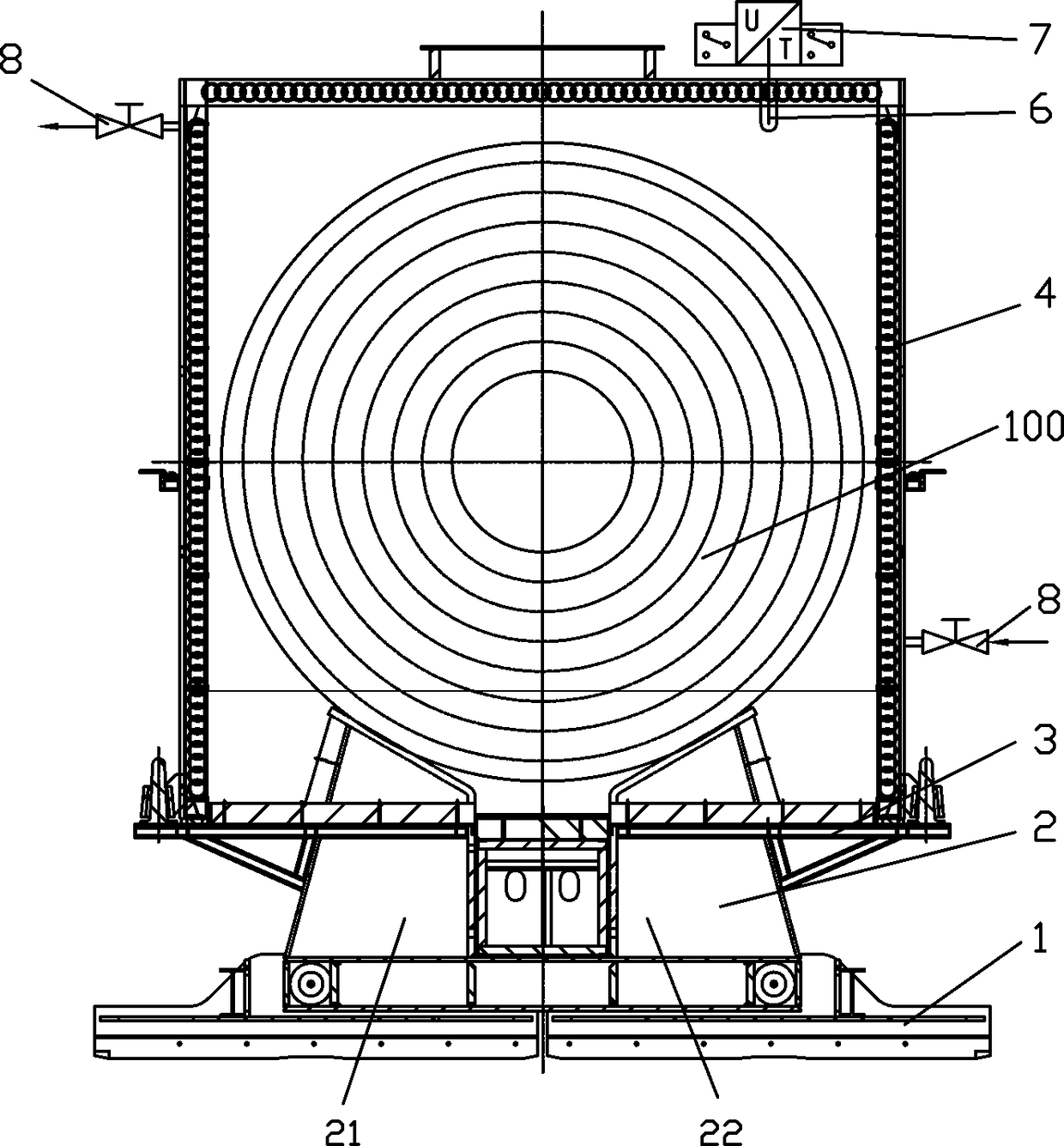

Movable hot rolling thermal insulation heat treatment device

PendingCN108441621AReduce churnGuaranteed air tightnessFurnace typesHeat treatment process controlThermal insulationEngineering

The invention discloses a movable hot rolling thermal insulation heat treatment device. The movable hot rolling thermal insulation heat treatment device comprises a base plate, a steel coil fixed basearranged in the center on the base plate, a tray being an annular structure and horizontally sleeving the middle part of the steel coil fixed base, a thermal insulation cover opened at the lower endand covering the tray and with a larger inner cavity volume than a steel coil, an electric heating device arranged on the inner side wall of the thermal insulation cover, a temperature sensor arrangedin the thermal insulation cover, and an information acquiring control module electrically connected with the electric heating device and the temperature sensor. The movable hot rolling thermal insulation heat treatment device can use self heat of the steel coil for uniform-heating and slow-cooling heat treatment process on the steel coil to achieve the purposes of high efficiency, energy conservation and improvement of the yield.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +2

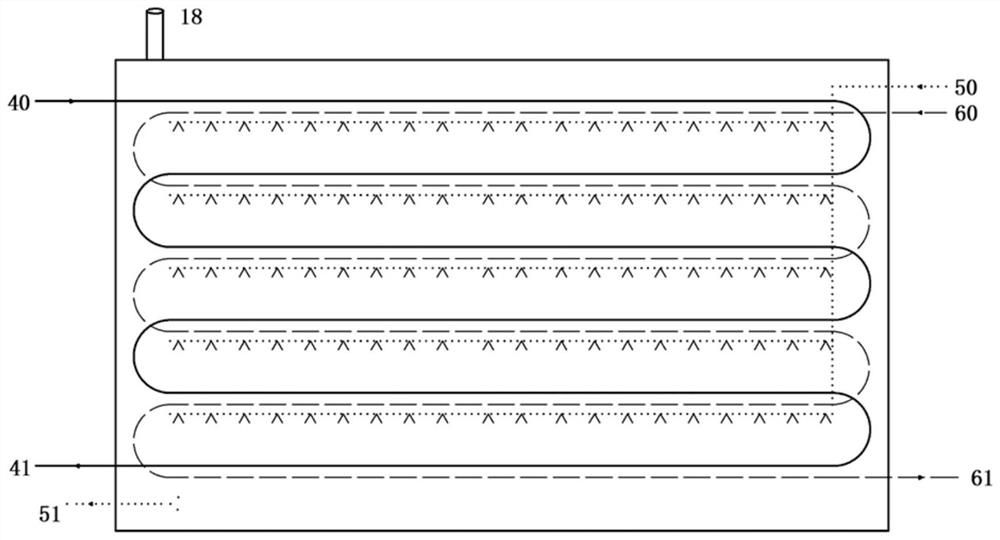

Mixed refrigeration system and quick freezing method thereof

PendingCN112815596AChange cooling rateEasy to storeMechanical apparatusDomestic refrigeratorsQuick FreezeCrystallization temperature

Provided are a mixed refrigeration system and a quick freezing method thereof. The mixed refrigeration system mainly comprises a freezing chamber (16), a contact type cascade heat exchanger (21), a contact type quick freezing system and a carbon dioxide quick freezing circulating system, wherein a tray is arranged in the freezing chamber (16), a contact type cascade heat exchanger (21) is arranged below the tray, the contact type cascade heat exchanger (21) is formed by overlapping an evaporator of a contact type quick-freezing system and a condenser of a carbon dioxide quick-freezing circulating system and serves as a tray support, and the tray is placed on the support. According to the invention, objects to be frozen in different temperature zones are frozen, so that the cooling rate of the objects to be frozen in the cooling zone and the crystallization temperature zone is changed, and the quality of the objects to be frozen is better preserved. The contact type quick-freezing system and the carbon dioxide spraying type quick-freezing system are overlapped, the condensation pressure of carbon dioxide is reduced, and the requirement for high pressure resistance of condensation equipment is lowered.

Owner:PEKING UNIV

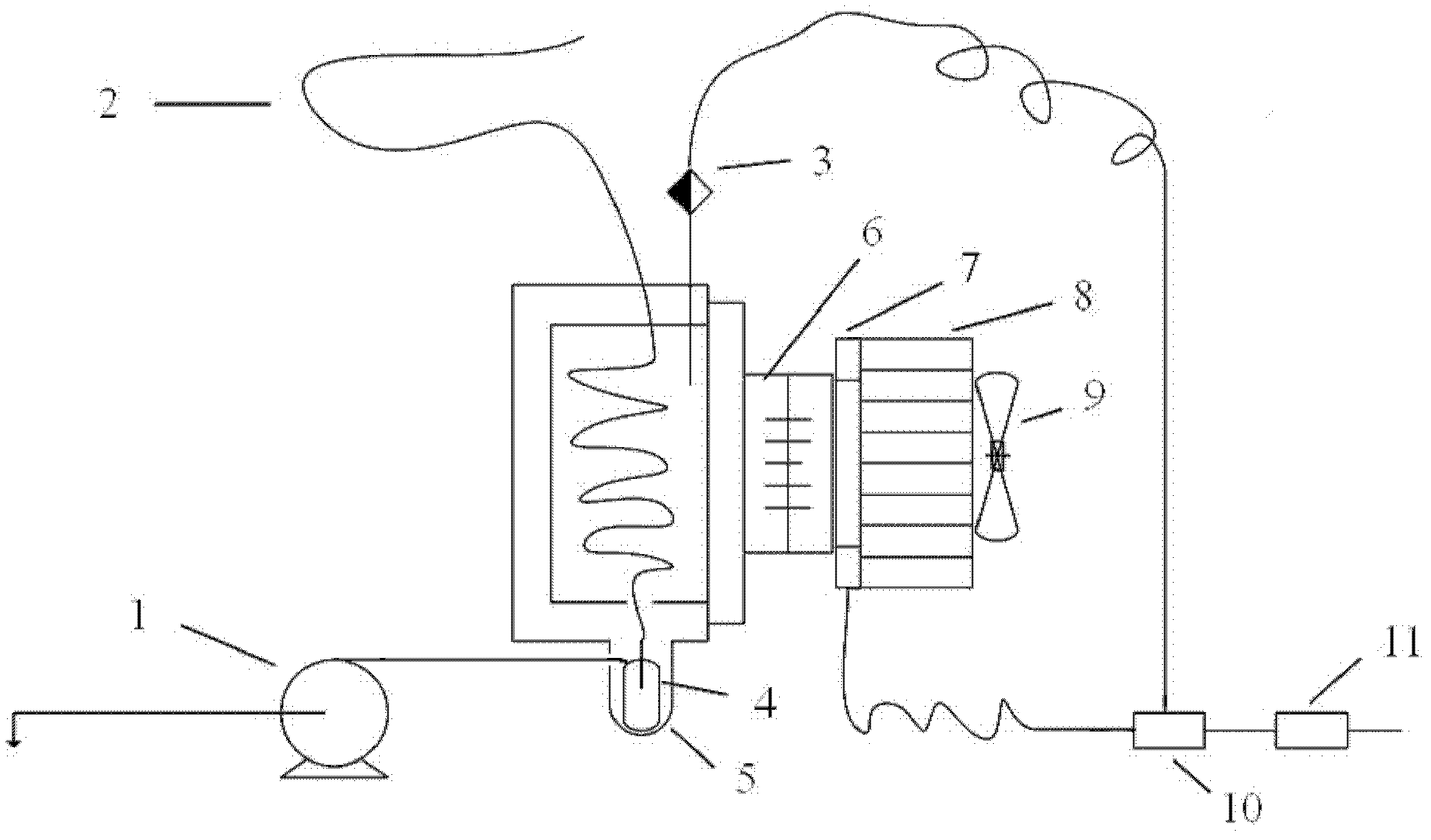

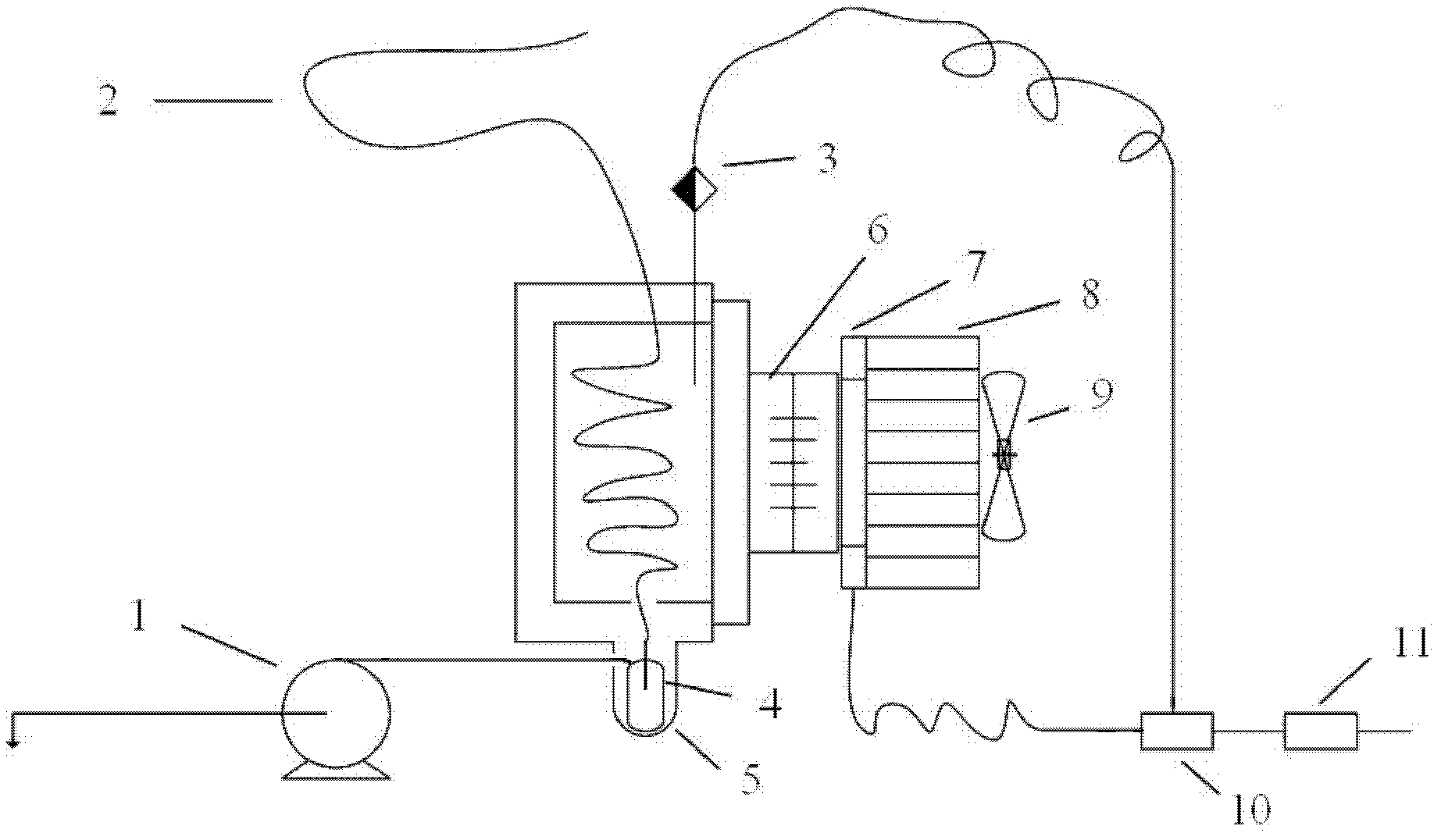

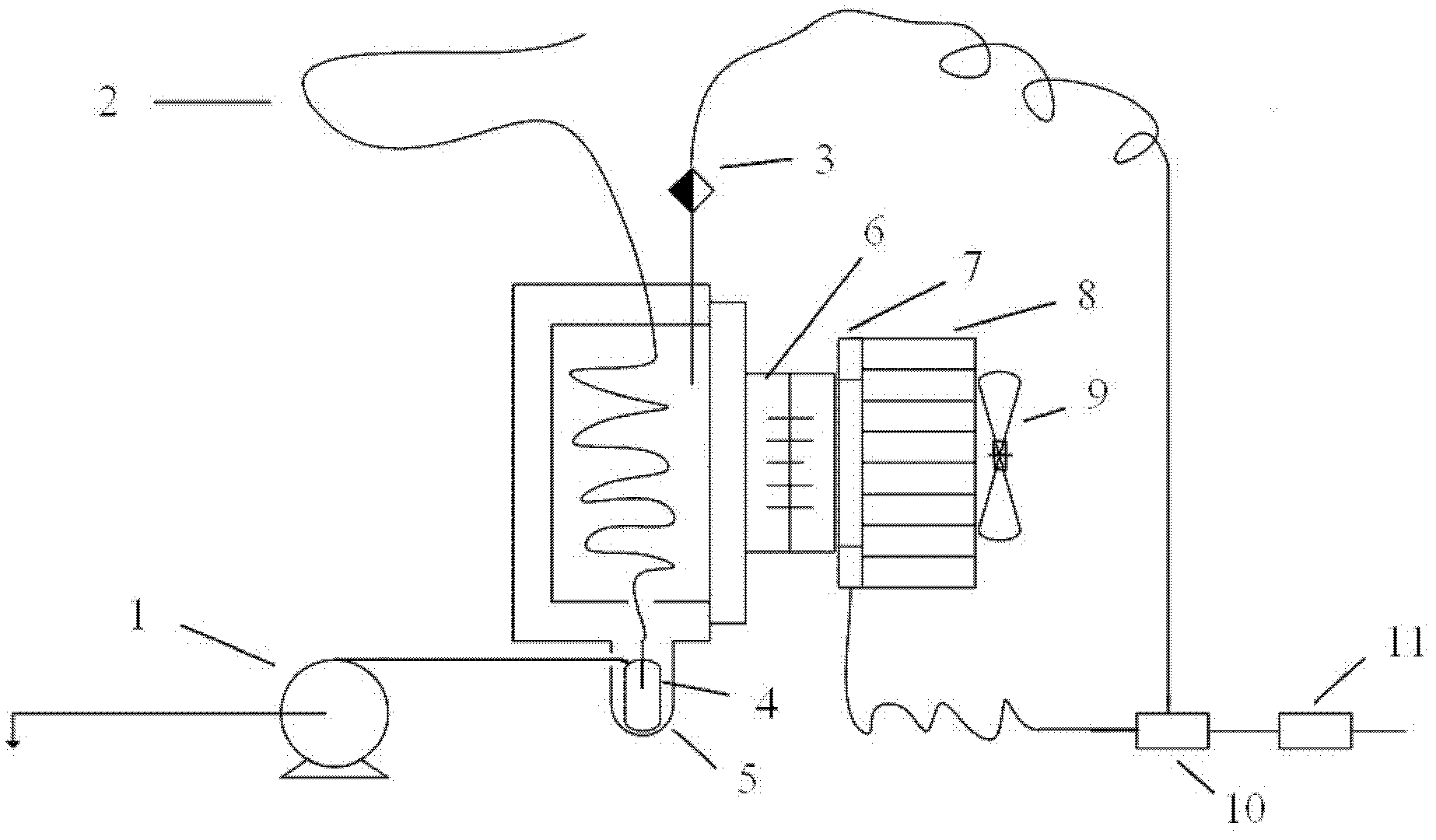

Semiconductor refrigeration sampling device for ceiling test

InactiveCN102435471AAvoid harmChange cooling rateComponent separationWithdrawing sample devicesEngineeringBottle

The invention relates to a semiconductor refrigeration sampling device for a ceiling test. The sampling device comprises a sucking pump, a sampling pipeline, a temperature probe, a ceiling bottle, a radiating plate, a semiconductor cooler, a radiating component and a fan, wherein the sucking upm, the sampling pipeline and the ceiling bottle form a sampling channel; the radiating plate, the semiconductor cooler, the radiating component and the fan form a refrigeration channel; and the semiconductor cooler provides a cold source. Compared with the prior art, the sampling device has the advantages that: the size is mall, the weight is light, a mechanical transmission part is not arranged, the refrigeration rate can be convenient to adjust by adjusting working current, the service life is long, the controllability is high, the environmental properties are high, the economy is good and the like.

Owner:SHANGHAI RES INST OF CHEM IND

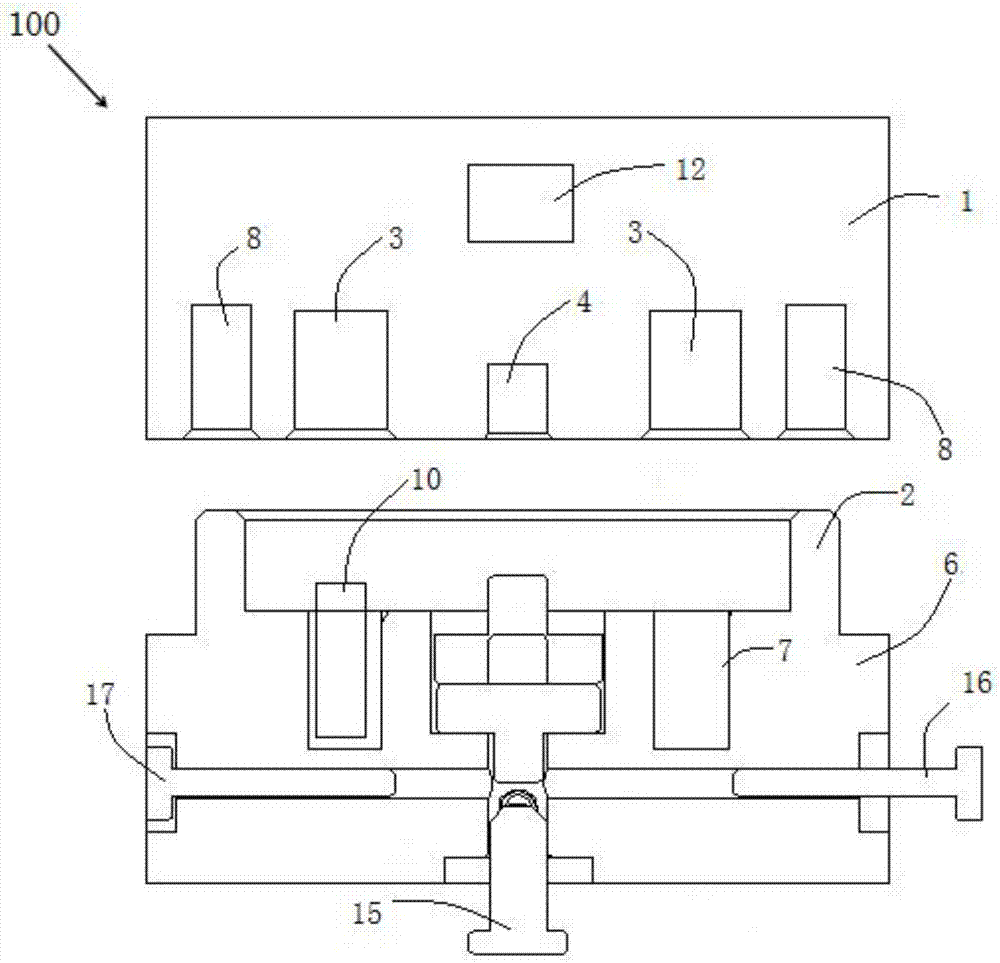

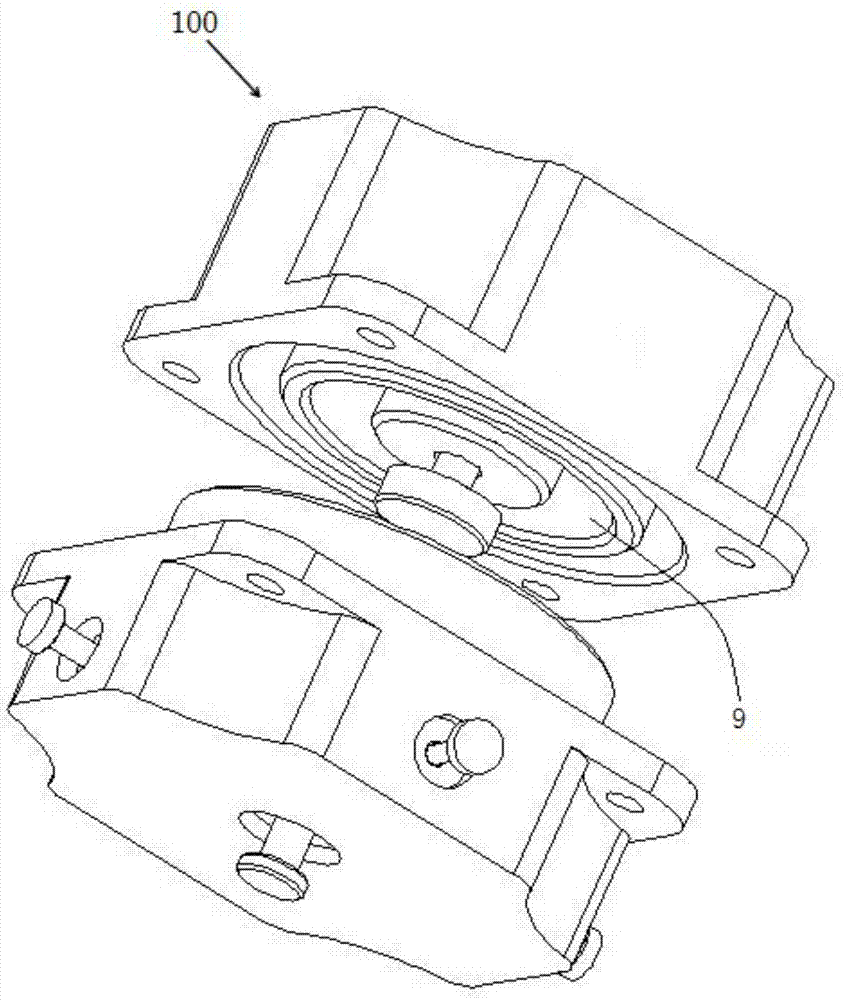

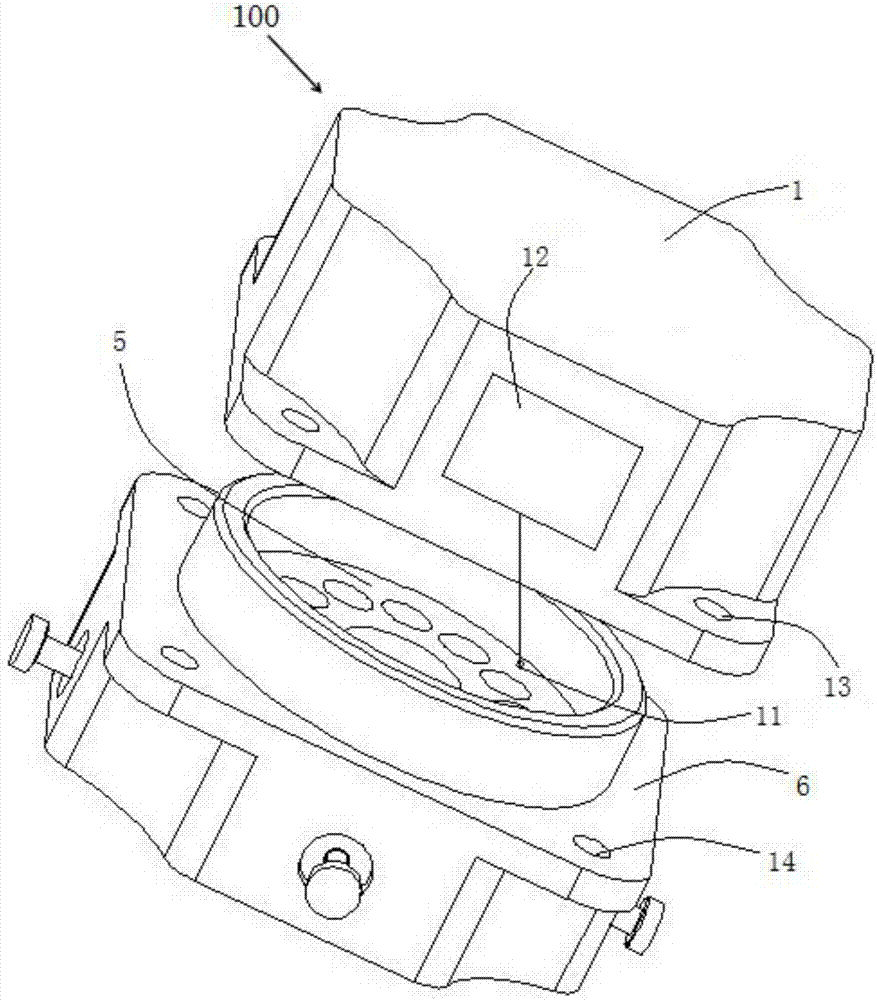

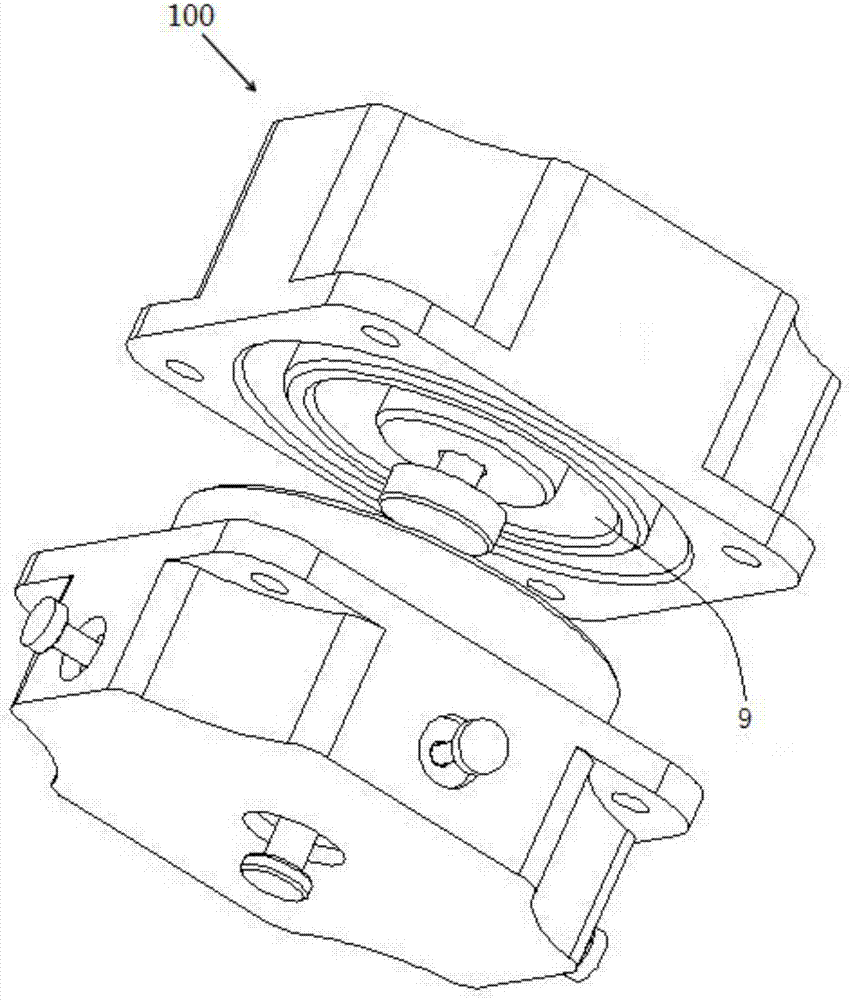

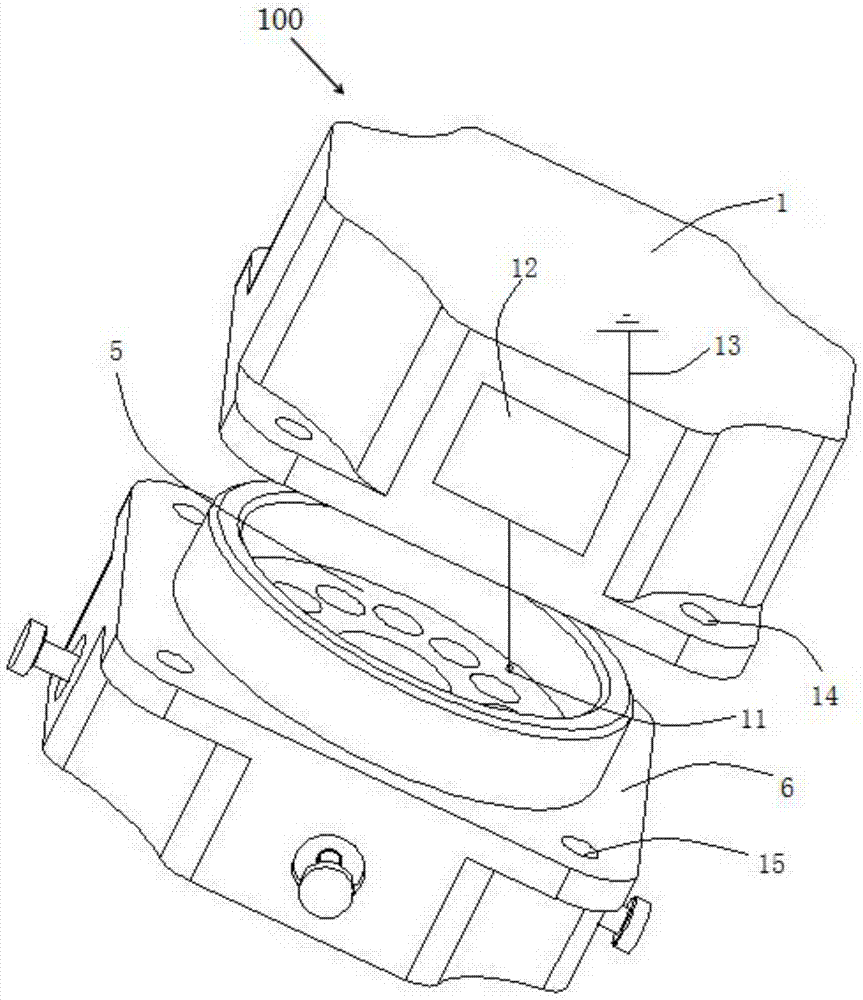

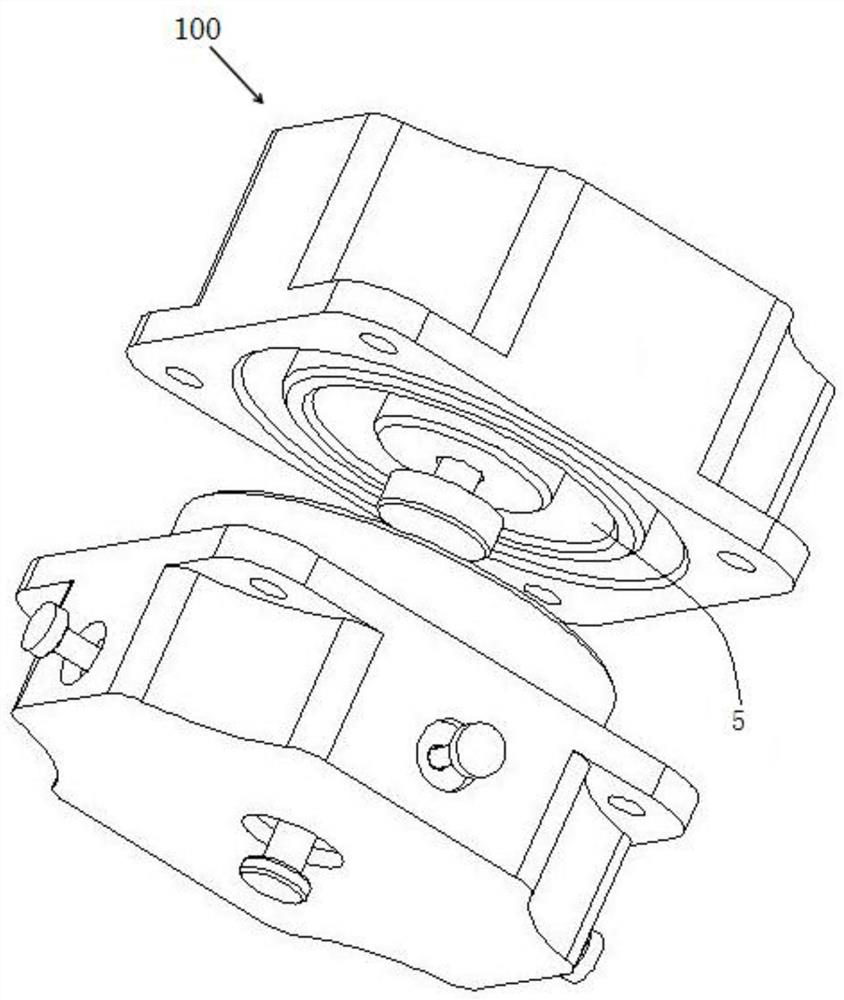

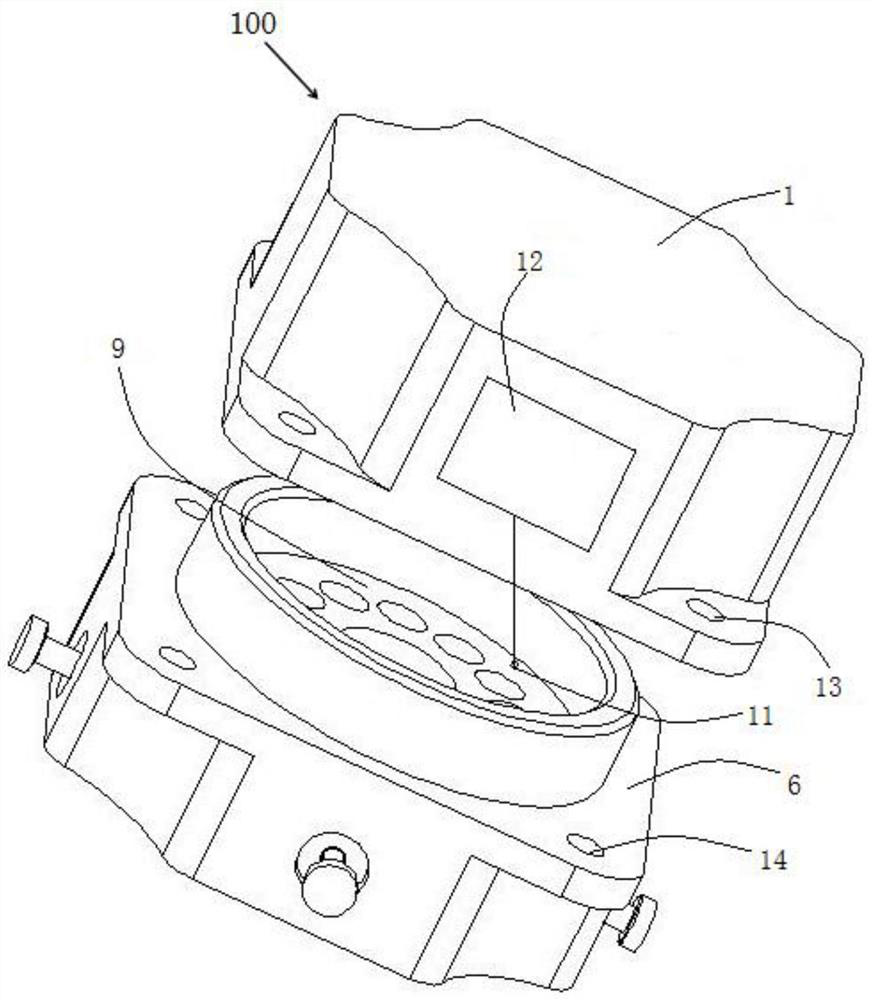

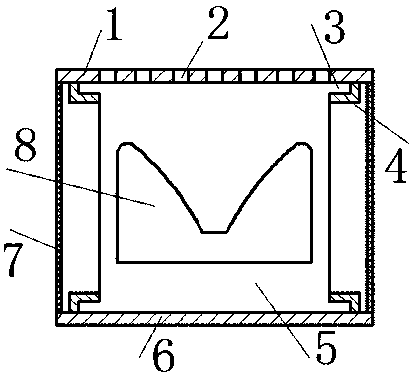

Medical speed-regulating cooling device

ActiveCN107136052AIncreased vitrificationIncrease chances of survivalDomestic cooling apparatusLighting and heating apparatusEngineeringPhase change

The invention discloses a medical speed-regulating cooling device. The medical speed-regulating cooling device comprises an upper shell, a lower shell, a temperature adjusting device, a temperature-moisture probe, a temperature-moisture display panel and a made-to-order energy-storing material, wherein a first shell sealing cavity, a first refrigerating pipe cavity, a first made-to-order energy storing material cavity and a second made-to-order energy storing cavity are formed inside the upper shell; the lower shell is connected with the upper shell through a metal rod; a plurality of second refrigerating pipe cavities, second shell sealing cavities and third made-to-order energy storing materials are arranged inside the lower shell; the second refrigerating pipe cavities are used for holding refrigerating pipes; phase-change materials are also placed in the second refrigerating pipe cavities; the temperature adjusting device comprises four made-to-order energy storing rods; the moisture-temperature probe is arranged on an outer side of one of the second refrigerating pipe cavities, and is used for collecting temperature information through a temperature probe and collecting moisture information through a moisture probe; the temperature-moisture display panel is arranged on a front surface of the upper shell, and is used for displaying the moisture information and the temperature information; the made-to-order energy storing material comprises a first made-to-order energy storing material, a second made-to-order energy storing material and a third made-to-order energy storing material, and is used for changing the cooling rate.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

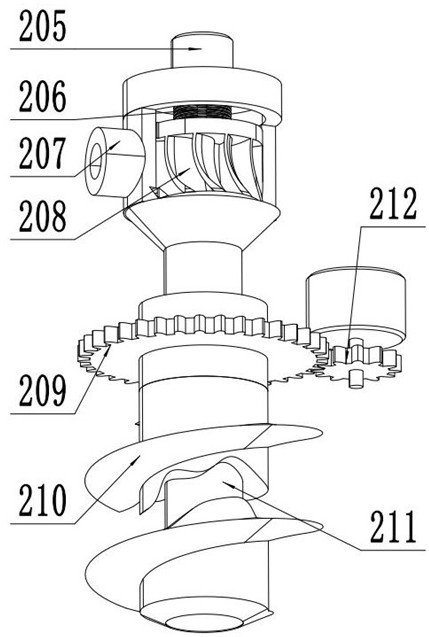

Quenching robot

InactiveCN106702108AReduce labor intensityImprove quenching qualityFurnace typesHeat treatment furnacesLiquid mediumUltimate tensile strength

The invention relates to a quenching robot. The quenching robot comprises a quenching tank and a lifting mechanism. The upper end of the quenching tank is opened, and the quenching tank is further provided with an inlet pipe and an outlet pipe. The outlet pipe is located below the inlet pipe. A pipeline pressurizing pump for pressurizing quenching media is arranged between the outlet pipe and the inlet pipe. The lifting mechanism comprises a motor, a chain wheel and a chain. One end of the chain is a quenched workpiece connecting end, and the other end of the chain is a free end. According to the quenching robot, the motor is used for driving a quenched workpiece to move up and down, so that the quenched workpiece is subjected to alternated cooling in air and liquid media, manual quenching operation is replaced, the labor intensity of quenching workers is relieved, the quenching quality can be stabilized as well, and the ideal quenching effect is achieved. Through control over the rotation direction, the rotation speed, the staying time and the like of the motor, the staying time, namely the cooling time, of the quenched workpiece in the air and the quenching media is controlled, and accordingly the purpose of changing the cooling speed is achieved.

Owner:HENAN UNIV OF SCI & TECH

Two-coating and one-baking novel energy-saving powder coating capable of replacing baking varnish

The invention provides a two-coating and one-baking novel energy-saving powder coating capable of replacing baking varnish. A processing method of the powder coating comprises the following steps: 1,preparing an outer layer coating: adding 35-55% of film-forming resin, ultrafine powdery graphite, a curing agent, 10-30% of a filler and 1-5% of assistants into a container, performing sufficient mixing, carrying out melting high-pressure extrusion after the mixing is finished, tabletting the extruded raw materials until the pressed tablets are uniform in size, crushing the tablets by using a crusher, and grinding the obtained powder after the crushing is finished; and 2, preparing an inner layer coating: adding 35-55% of the film-forming resin, the ultrafine powdery graphite, the curing agent, the pigment, nano-copper powder, 10-30% of the filler and 1-5% of the assistants into the container, performing sufficient mixing, carrying out melt high-pressure extrusion after the mixing is finished, tabletting the extruded raw materials until the pressed tablets are uniform in size, crushing the tablets by using the crusher, and grinding the powder after the crushing is finished. The two-coating and one-baking novel energy-saving powder coating has the advantages of increase of the construction speed, and reduction of environmental pollution.

Owner:科威嘉粉末涂料(天津)股份有限公司

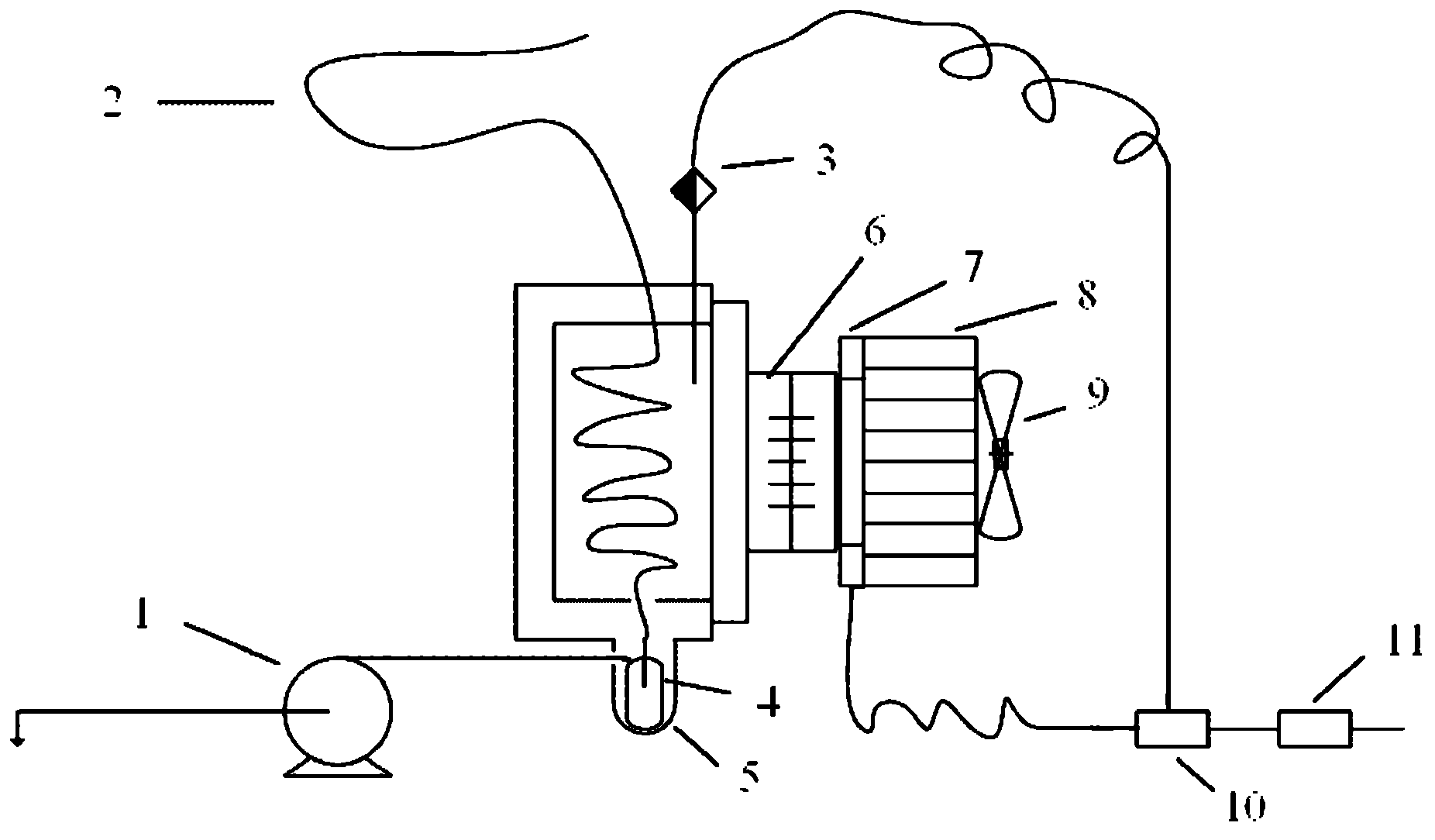

Sampling device for semiconductor refrigeration type headspace test

InactiveCN102494925AAvoid interferenceReduce pollutionComponent separationWithdrawing sample devicesTemperature controlEngineering

The invention relates to a sampling device for a semiconductor refrigeration type headspace test. The sampling device comprises an air pump, a sampling pipeline, a temperature probe, a headspace bottle, a headspace bottle arrangement component, a heat dissipation plate, a semiconductor cooling stack, a heat dissipation component, a fan, a temperature control switch and a direct-current power supply, wherein the air pump is connected with the headspace bottle; one end of the sampling pipeline is emptied, and the other end of the sampling pipeline is inserted into the headspace bottle; one end of the temperature probe is used for detecting the temperature of the sampling pipeline, and the other end of the temperature probe is connected with the temperature control switch; the headspace bottle is arranged in the headspace bottle arrangement component; the heat dissipation plate is positioned on one side of the sampling pipeline; the semiconductor cooling stack is arranged between the heat dissipation plate and the heat dissipation component, and is connected with the temperature control switch; the fan is arranged on one side of the heat dissipation component; and the temperature control switch is connected with the direct-current power supply. Compared with the prior art, the sampling device has the advantages of safety, reliability, wide applicability range, high efficiency and the like.

Owner:SHANGHAI RES INST OF CHEM IND

Novel preparation method for noble composite metallic bond composite wire materials

The invention discloses a preparation method for noble / noble composite wire materials, and noble / cheap composite wire materials, wherein the preparation method is simple to operate, and the composite wire materials are controllable in thickness of a composite layer, clean in limiting surface, good in limiting surface bonding and easy to process subsequently. The preparation process includes that an outer layer of metal is machined to a round pipe by ingot casting, extruding and drawing, and wall thickness is designed according to demand of product design. The noble metal round pipe is placed in a water-cooling mold, core material metal is placed in a vacuum induction melting furnace to be melted, core material molten metal is poured into the water-cooling mode to be fast set, the water-cooling mold is adjusted, and cooling speed of the core material molten metal is changed so as to produce a composite bar of clad materials and a core material binding layer (a transition layer). The composite bar is machined through rotary swaging, and is carried out with heat treatment and wire drawing in the middle process to meet product size requirements of customers. The composite wire materials are wrapped evenly by outer layer metal, and the wrapping layer and the core materials are good in cooperated transformation. The wrapping materials and the core materials are closely combined. The wrapping materials can be used for advanced packing of an integrated circuit and the like, and part of wrapping materials or all wrapping materials can replace the noble metallic bond composite wire materials.

Owner:KUNMING INST OF PRECIOUS METALS

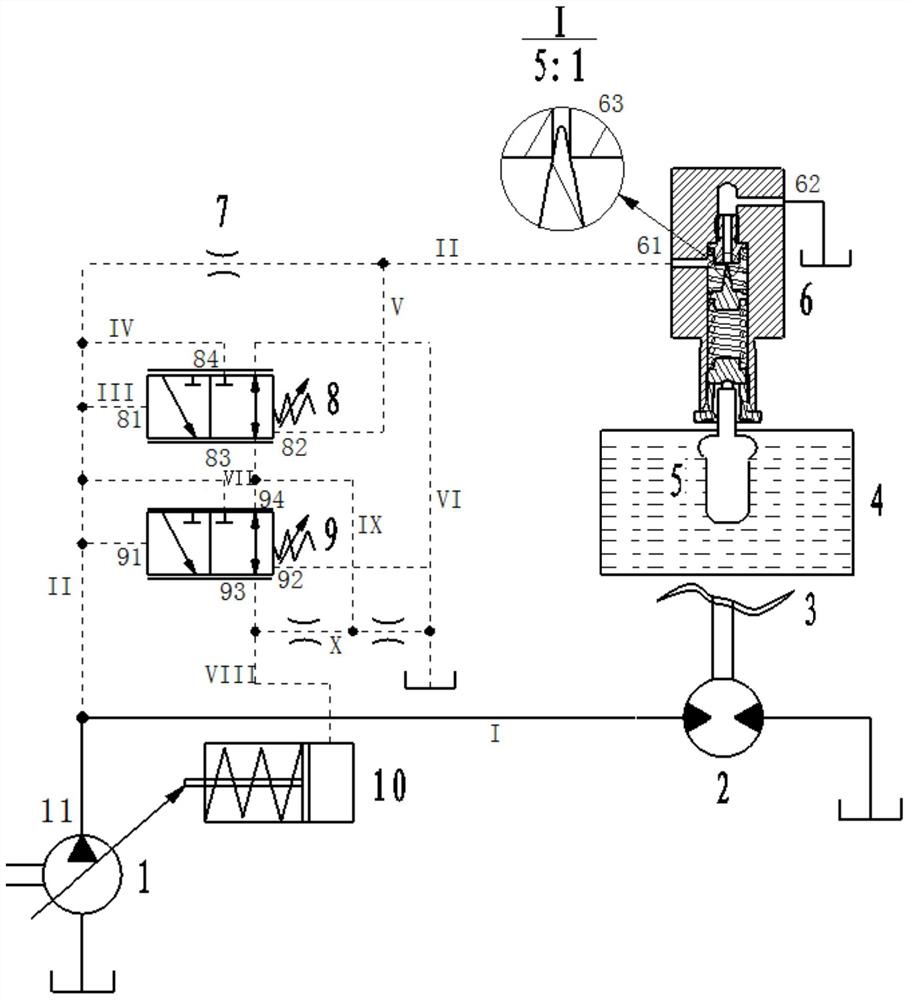

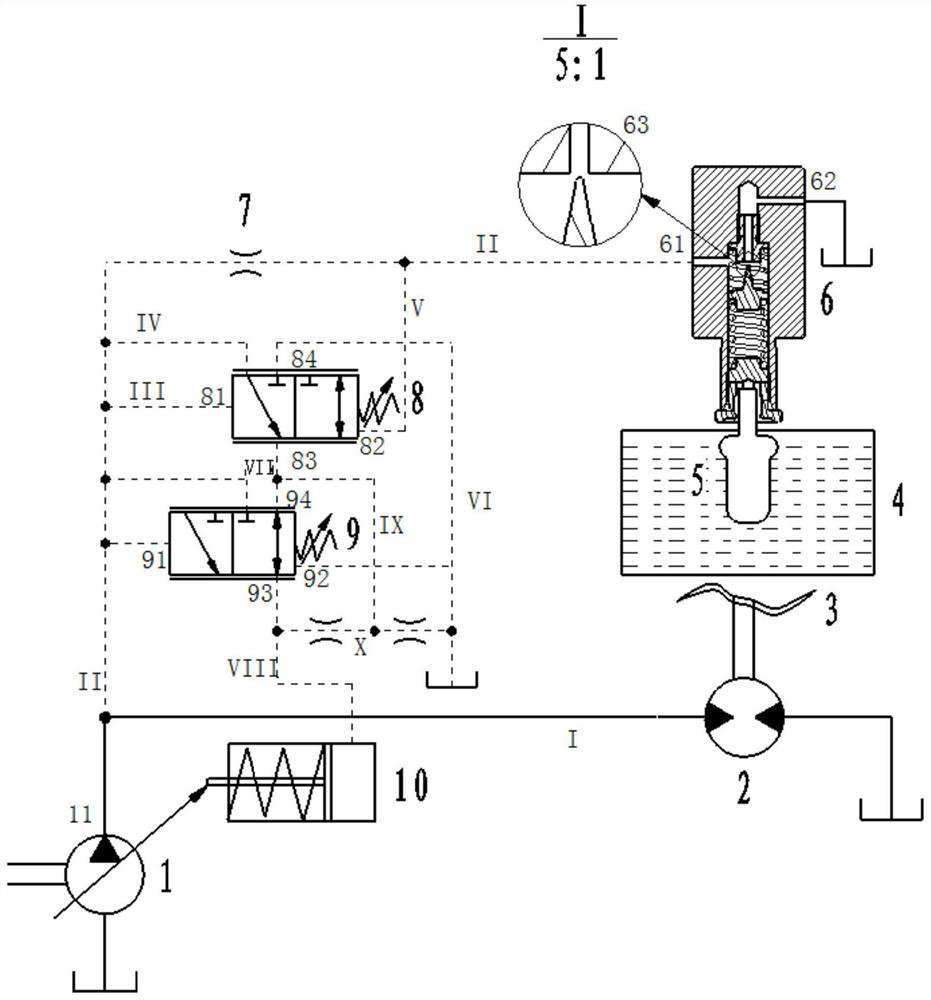

Hydraulic system and method for accurately controlling oil temperature

PendingCN114370445AOil temperature control with high precisionAdaptableServomotor componentsServomotorsAutomatic controlEngineering

The invention relates to a hydraulic system and method for accurately controlling oil temperature. The problems that an existing temperature control system is poor in temperature control precision, large in power loss and the like are solved. The system comprises a plunger pump, a plunger motor, an air supply device, a temperature bulb, a temperature control valve, a throttler, a first proportional valve and a hydraulic cylinder. The temperature bulb senses the oil temperature in the oil tank in real time and controls the opening degree of a cone valve in the temperature control valve, so that the flow passing through the throttler is changed, the pressure difference between the left side and the right side of the first proportional valve is changed, the working position of the first proportional valve and the opening degree of a variable valve port are changed, and the flow entering a hydraulic cylinder control cavity is changed; therefore, the angle of the swash plate of the plunger pump is changed, and the output flow of the plunger pump is further changed; the output flow of the plunger pump is changed, so that the rotating speeds of the plunger motor and the air supply device are changed, and the cooling speed of oil in the oil tank is changed. The whole control process is full-automatic control, the oil temperature can be adjusted in real time, and it is always guaranteed that the oil temperature in the oil tank is within the required temperature range.

Owner:XIAN AERO ENGINE CONTROLS

High pressure gas quenching cooling method of aerosol forced circulation

InactiveCN1240854COvercome the shortcomings of uneven quenching and coolingImprove cooling effectQuenching agentsQuenching devicesEngineeringHigh pressure

The present invention belongs to the field of heat treatment of metal material. Gas and water fog is led into a container with forced stirring blower and heat exchanger for heat exchange with the hot workpiece, and the heat the gas and water fog absorb from the workpiece is taken away by the forced stirring blower and the heat exchanger to reach the aim of quickly cooling the quenched workpiece. The combination of gas and water fog can raise the heat exchange coefficient between the medium and the workpiece obviously and cooling capacity and the cooling capacity may be adjusted in certain range.

Owner:SHANGHAI JIAOTONG UNIV

A Cast Iron Horizontal Continuous Casting Double Water Jacket Mold

The invention relates to a cast iron horizontal continuous casting double-water jacket type crystallizer, which comprises a double-water jacket type crystallizer steel sleeve and a high-purity graphite sleeve, wherein the high-purity graphite sleeve is embedded in the double-water jacket type crystallizer steel sleeve, the double-water jacket type crystallizer steel sleeve comprises a crystallizer steel sleeve inner sleeve and a crystallizer steel sleeve outer sleeve, the crystallizer steel sleeve outer sleeve is arranged at the exterior of the crystallizer steel sleeve outer sleeve, the crystallizer steel sleeve inner sleeve is provided with a spiral water passage with a trapezoidal cross section, a separating plate is arranged in the spiral water passage with the trapezoidal cross section, and is used for separating the spiral water passage with the trapezoidal cross section into a spiral water passage with a trapezoidal cross section I and a spiral water passage with a trapezoidal cross section II, the crystallizer steel sleeve outer sleeve is respectively welded with a water inlet pipe of a main sleeve A, a water outlet pipe of the main sleeve A, a water inlet pipe of an auxiliary sleeve A and a water outlet pipe of the auxiliary sleeve B, the water inlet pipe of the main sleeve A and the water outlet pipe of the main sleeve A are respectively communicated with the spiral water passage with the trapezoidal cross section I to form the main sleeve A, and the water inlet pipe of the auxiliary sleeve B and the water outlet pipe of the auxiliary sleeve B are respectively communicated with the spiral water passage with the trapezoidal cross section II to form the auxiliary sleeve B. The cast iron horizontal continuous casting double-water jacket type crystallizer has the advantages that the process advantages of horizontal continuous casting using separate control of the two water jackets are fully realized, the leakage of furnaces is avoided, the drawing speed is improved, and the cost is reduced.

Owner:陕西均安精工科技有限公司

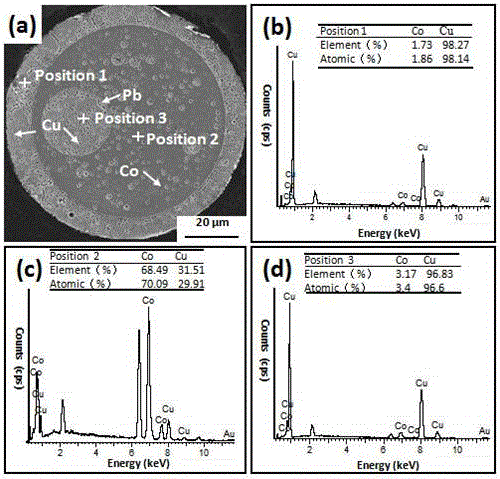

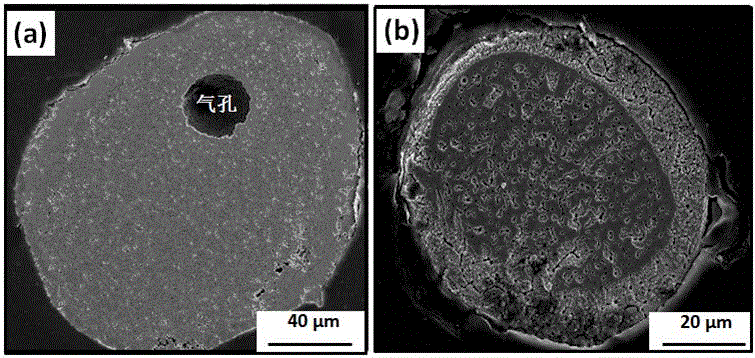

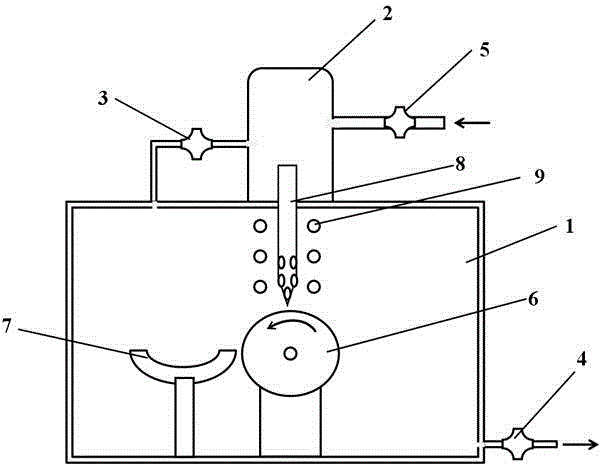

Multi-layer shell-core structure CoxCuyPbz alloy particle and preparation method thereof

The invention belongs to the field of immiscible alloy particles, and particularly discloses a multi-layer shell-core structure CoxCuyPbz alloy particle and a preparation method thereof. According to the method, a solidification forming device is utilized, and the hollow CoxCuyPbz alloy particle is prepared through the reasonably-designed alloy composition proportion, the pressure of two vacuum chambers and the roller surface linear speed of a Cu roller. The prepared shell-core alloy particle is high in sphericity and smooth in surface; no breaking or hole appear in a shell-core layer; only a solidification reaction happens inside; a precipitated phase is simple; the operation process is simple; and cost is low.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

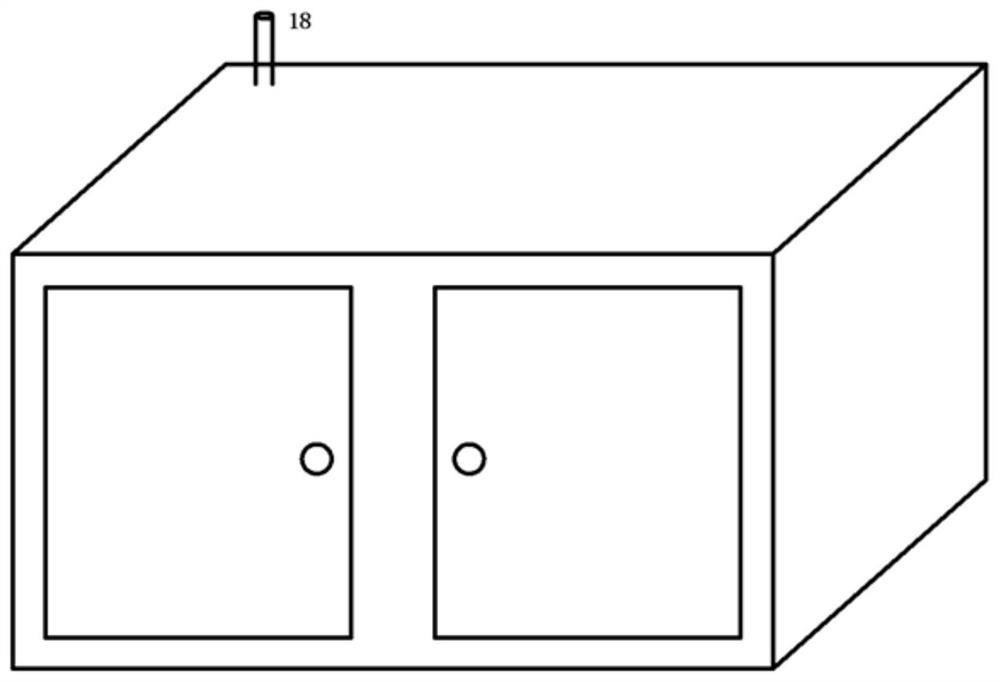

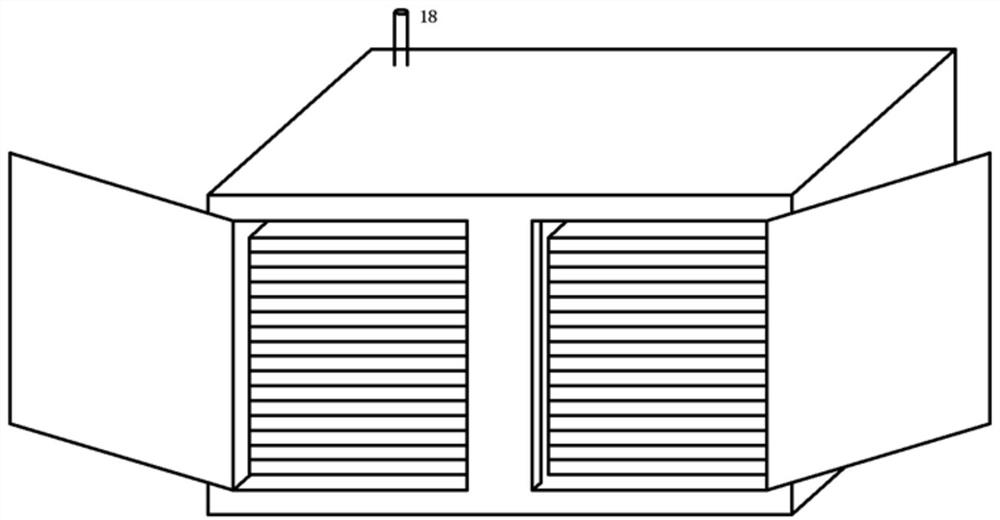

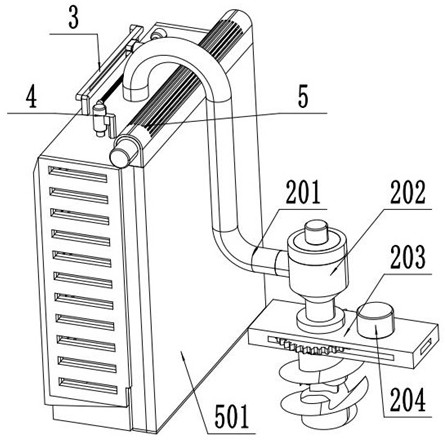

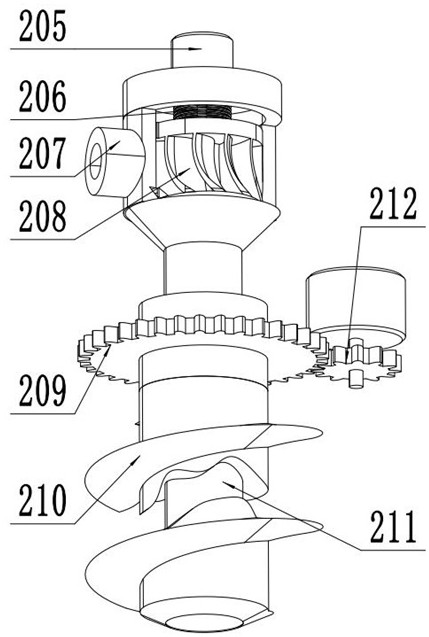

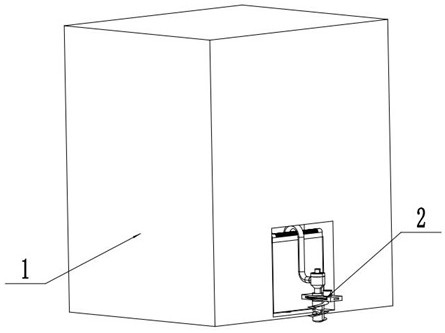

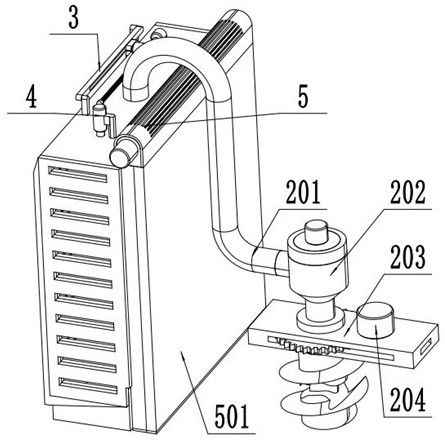

A kind of refrigeration equipment suitable for electrical cabinets under high temperature conditions

ActiveCN113518548BChange sizeControl contact areaConstructionsPump installationsWind runCooling effect

The invention discloses a refrigeration device suitable for electrical cabinets under high-temperature conditions, which relates to the technical field of refrigeration, and includes a water supply mechanism, a diffuser mechanism, a cooling mechanism, and an air supply mechanism installed in the electrical cabinet, and the diffuser mechanism makes the airflow flow, The cooling mechanism includes a number of water guide plates arranged in the refrigeration box, two adjacent water guide plates are arranged alternately and every two water guide plates are rotatably connected by cooling connecting rods, and one end of the lowermost water guide plate is set There are counterweights to guide the flow of water, and the air supply mechanism realizes multi-angle air supply. The invention uses underground cold water, controls the contact area between air flow and cold water flow, and adjusts the wind direction and speed to cool down the electrical cabinet. It is energy-saving and environmentally friendly, and has a good cooling effect. , high cooling efficiency.

Owner:徐州金宸制冷设备有限公司

Electric appliance cabinet refrigeration equipment suitable for high-temperature condition

ActiveCN113518548AChange sizeControl contact areaConstructionsPump installationsAir velocityWater flow

The invention discloses electric appliance cabinet refrigeration equipment suitable for a high temperature condition, and relates to the technical field of refrigeration. The electric appliance cabinet refrigeration equipment comprises a water supply mechanism, an air dispersion mechanism and a cooling mechanism which are installed in an electric appliance cabinet, the air supply mechanism and the air dispersion mechanism enable air flow to flow, and the cooling mechanism comprises a plurality of water guide plates arranged in a refrigeration box; two adjacent water guide plates are arranged in a staggered mode, every two water guide plates are rotationally connected through a cooling connecting rod, a balancing weight is arranged at one end of the lowermost water guide plate, water flow is guided to flow, and the air supply mechanism achieves multi-angle air supply. According to the invention, underground cold water is used in a cycled way, the contact area between the air flow and the cold water flow is controlled, and the wind direction and speed are adjusted to cool the electric appliance cabinet; and thus, the energy is saved, the environment is protected, the refrigeration effect is good, and the refrigeration efficiency is high.

Owner:徐州金宸制冷设备有限公司

Medical speed regulation and temperature reduction device with communication function

ActiveCN107318827AIncreased vitrificationIncrease chances of survivalDead animal preservationFrozen storageEngineering

The invention discloses a novel medical speed regulation and temperature reduction device with a communication function. The medical speed regulation and temperature reduction device comprises an upper casing, a lower casing, a temperature regulating device, temperature and humidity probes, a temperature and humidity display panel, a WIFI (Wireless Fidelity) generator and a purpose made energy storage material, wherein a first casing sealing cavity, a first frozen storage pipe cavity, a first purpose made energy storage material cavity and a second purpose made energy storage material cavity are arranged inside the upper casing; the lower casing is connected with the upper casing through a metal rod; a plurality of second frozen storage pipe cavities, a second casing sealing cavity and a third purpose made energy storage material cavity are arranged inside the lower casing; the second frozen storage pipe cavities are used for storing frozen storage pipes; phase change materials are also stored in the second frozen storage pipe cavities; the temperature regulating device comprises four purpose made energy storage rods; the temperature and humidity probes are arranged at the outer side of one of the second frozen storage cavities; the temperature information is collected through the temperature probe; the humidity information is collected through a humidity probe; the temperature and humidity display panel is arranged on the front surface of the upper casing and is used for displaying the humidity information and the temperature information; the WIFI generator is used for sending temperature information; the purpose made energy storage material comprises a first purpose made energy storage material, a second purpose made energy storage material and a third purpose made energy storage material and is used for changing the temperature reduction speed.

Owner:上海理工资产经营有限公司

A medical speed regulating cooling device

ActiveCN107136052BIncreased vitrificationIncrease chances of survivalDomestic cooling apparatusLighting and heating apparatusEngineeringMechanical engineering

The invention discloses a medical speed-regulating cooling device. The medical speed-regulating cooling device comprises an upper shell, a lower shell, a temperature adjusting device, a temperature-moisture probe, a temperature-moisture display panel and a made-to-order energy-storing material, wherein a first shell sealing cavity, a first refrigerating pipe cavity, a first made-to-order energy storing material cavity and a second made-to-order energy storing cavity are formed inside the upper shell; the lower shell is connected with the upper shell through a metal rod; a plurality of second refrigerating pipe cavities, second shell sealing cavities and third made-to-order energy storing materials are arranged inside the lower shell; the second refrigerating pipe cavities are used for holding refrigerating pipes; phase-change materials are also placed in the second refrigerating pipe cavities; the temperature adjusting device comprises four made-to-order energy storing rods; the moisture-temperature probe is arranged on an outer side of one of the second refrigerating pipe cavities, and is used for collecting temperature information through a temperature probe and collecting moisture information through a moisture probe; the temperature-moisture display panel is arranged on a front surface of the upper shell, and is used for displaying the moisture information and the temperature information; the made-to-order energy storing material comprises a first made-to-order energy storing material, a second made-to-order energy storing material and a third made-to-order energy storing material, and is used for changing the cooling rate.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Improved Gravity Heat Pipe Heat Sink for High Power LEDs

InactiveCN103196116BEasy to processLow pricePoint-like light sourceLighting heating/cooling arrangementsRefluxHeat conducting

Owner:CHINA JILIANG UNIV

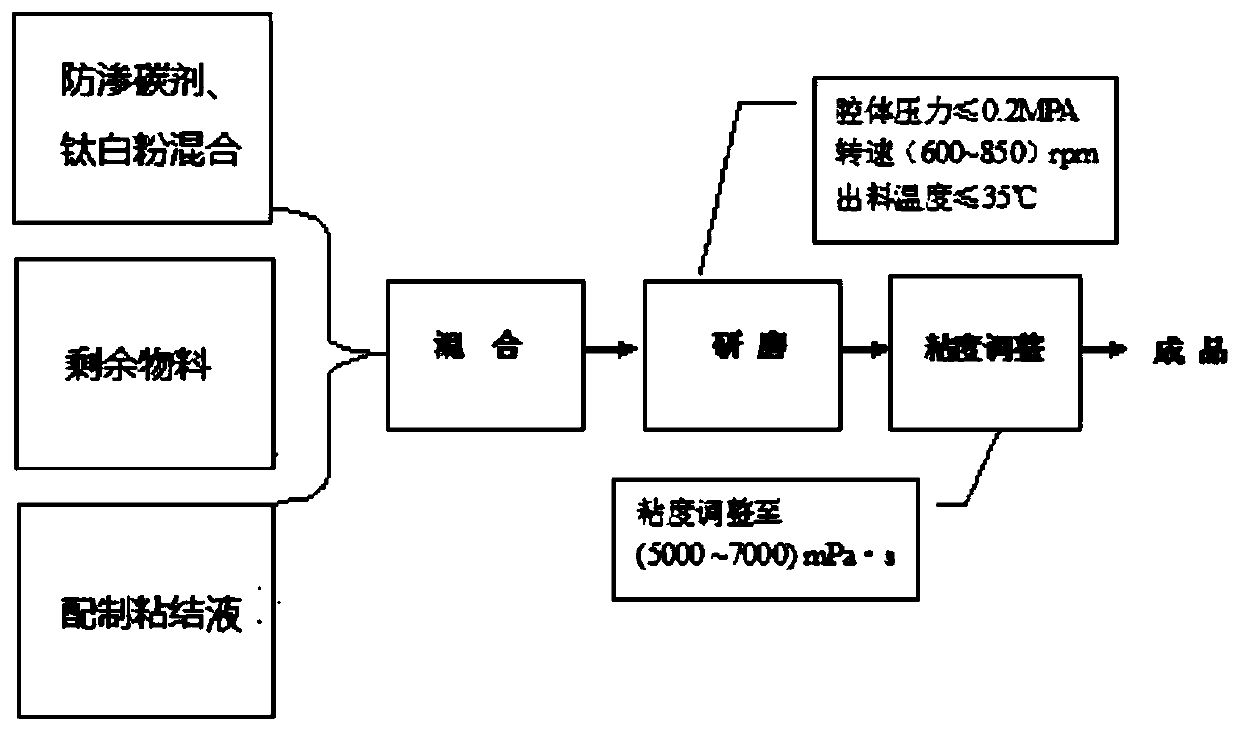

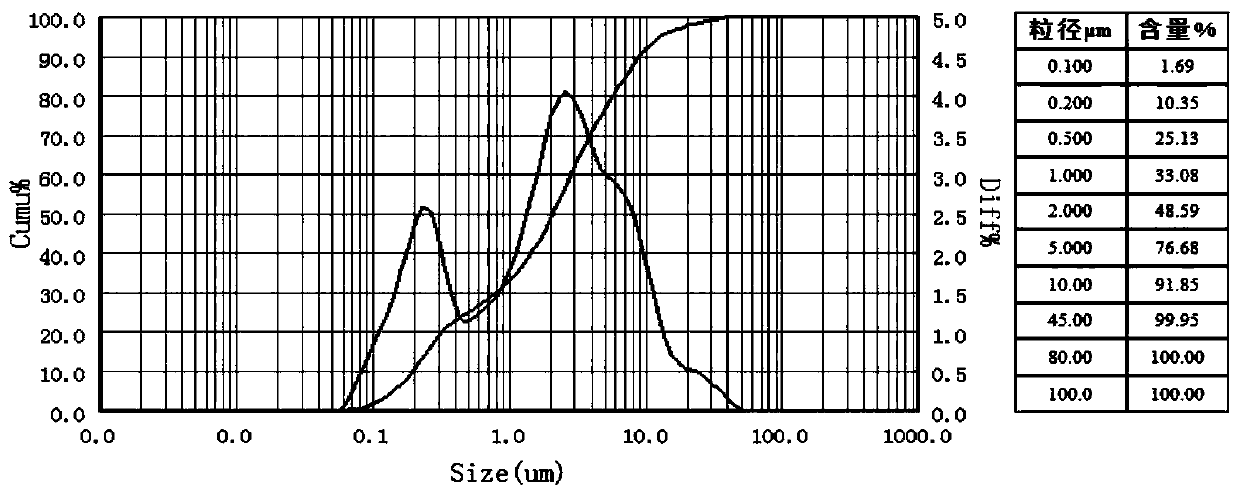

A kind of anti-carburization coating specially used for finishing parts and preparation method thereof

ActiveCN106521401BSmall particle sizeImprove wettabilitySolid state diffusion coatingPorosityPhosphate

Owner:NANJING KERUN NEW MATERIAL TECH

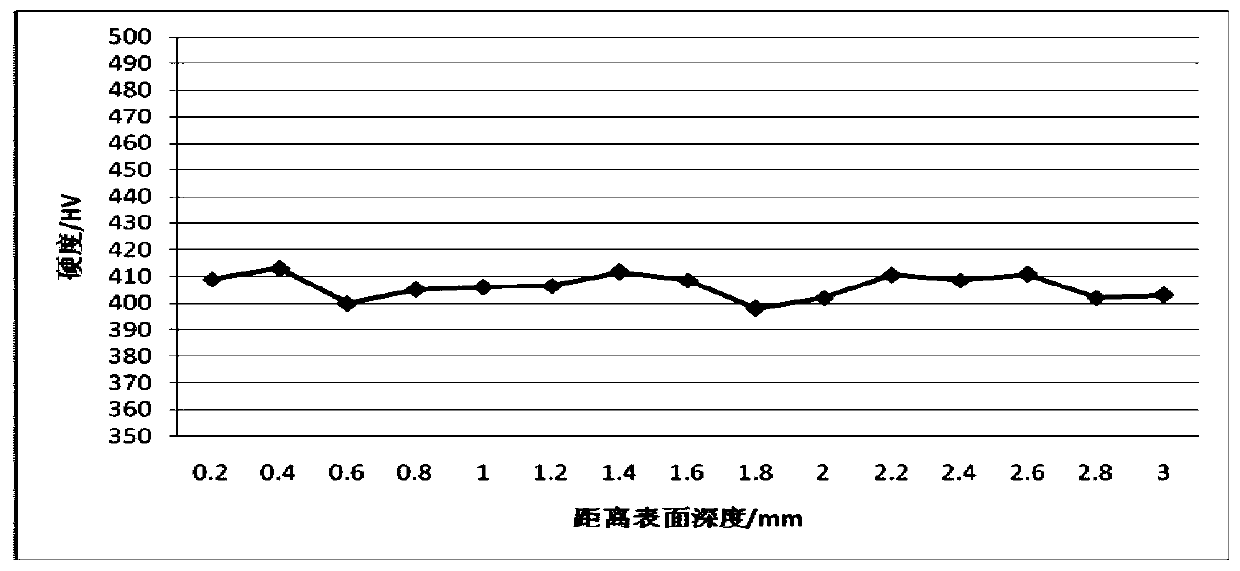

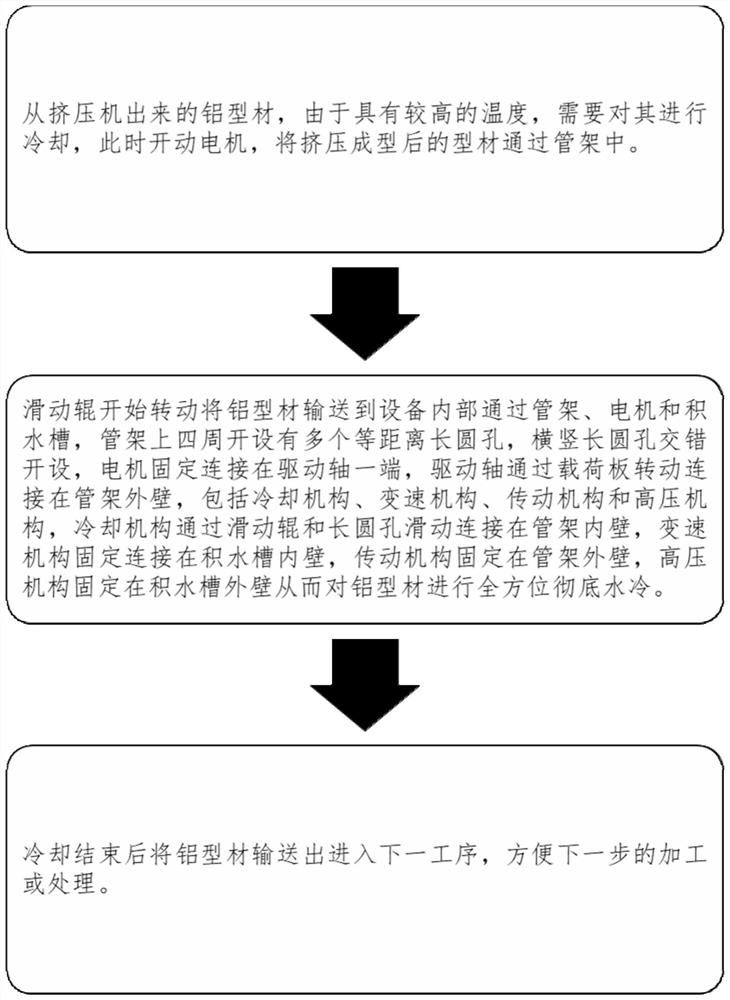

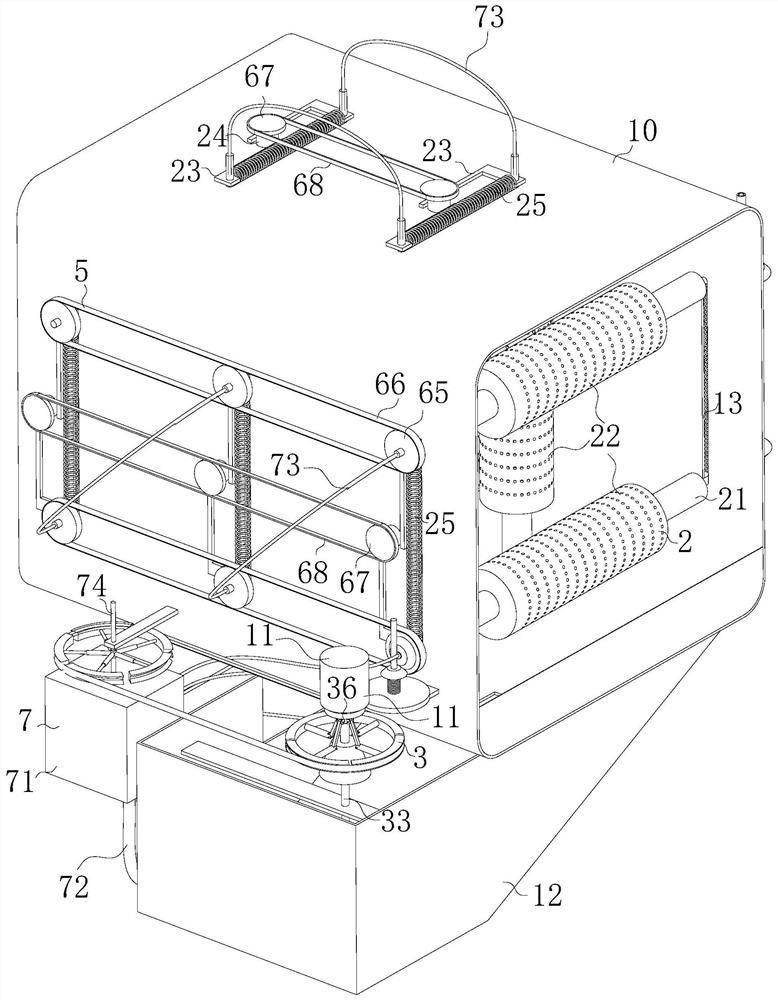

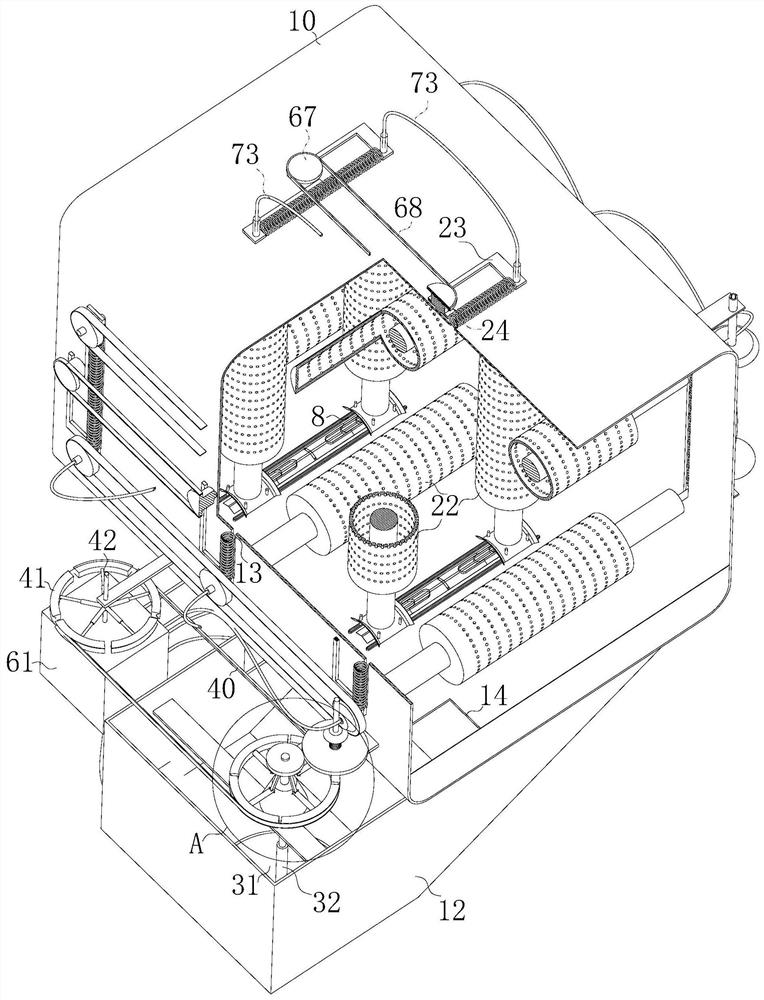

Aluminum profile cooling process

The invention discloses an aluminum profile cooling process in the technical field of aluminum profile cooling. A pipe frame, a motor and a water accumulation tank are included. A plurality of long round holes at equal intervals are formed in the periphery of the pipe frame, and the transverse long round holes and the vertical long round holes are formed in a staggered manner. The motor is fixedlyconnected to one end of a drive shaft, and the drive shaft is rotationally connected to the outer wall of the pipe frame through a load plate. A cooling mechanism, a speed change mechanism, a transmission mechanism and a high-pressure mechanism are included. The cooling mechanism is in sliding connection to the inner wall of the pipe frame through a sliding roller and the long round holes. The speed change mechanism is fixedly connected to the inner wall of the water accumulation tank. The transmission mechanism is fixed to the outer wall of the pipe frame. The high-pressure mechanism is fixed to the outer wall of the water accumulation tank. Aluminum profiles are formed in an extrusion manner, the aluminum profiles output from an extruder need to be cooled due to the high temperature, next-machining or treatment is facilitated, and the problems that under the common air cooling condition, the heat exchange coefficients of all parts of the profiles being in contact with air are equal,and due to different wall thicknesses or shapes, the heat dissipation speeds of all the parts are different are effectively solved.

Owner:吉安持凡电子科技有限公司

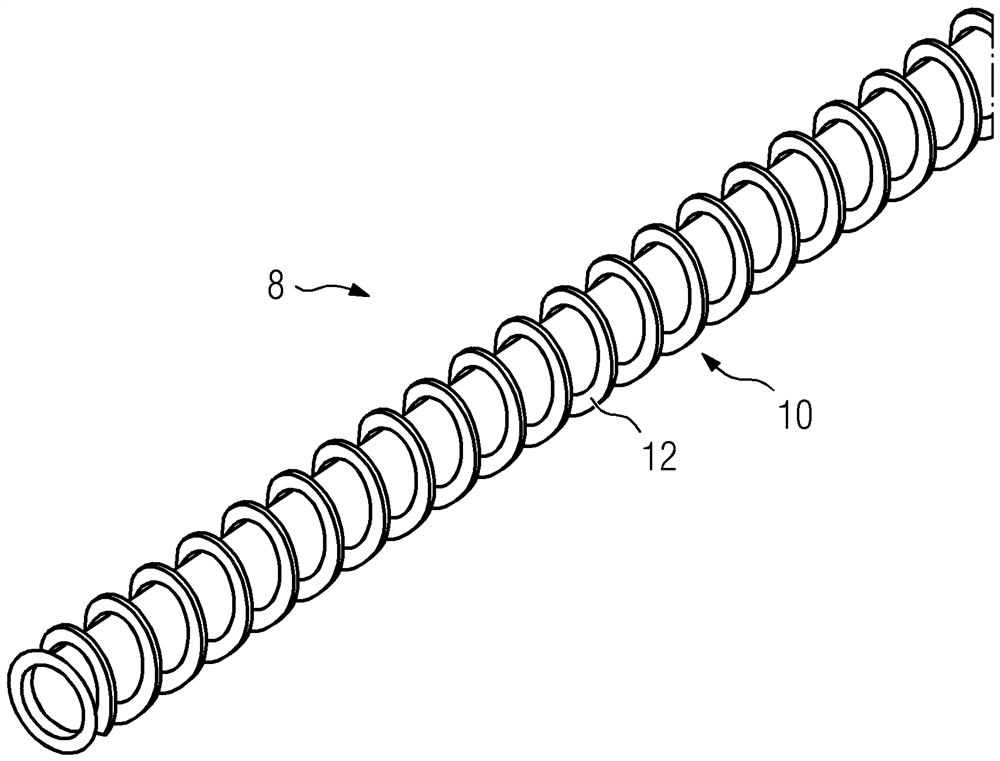

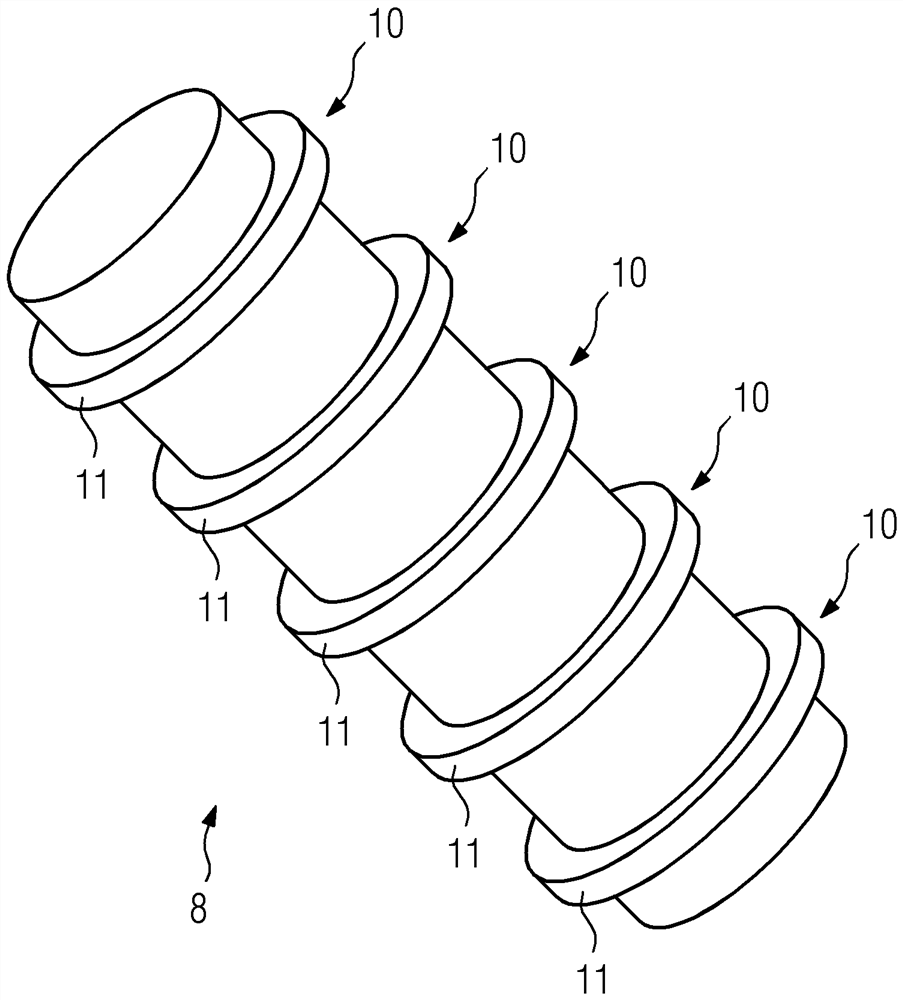

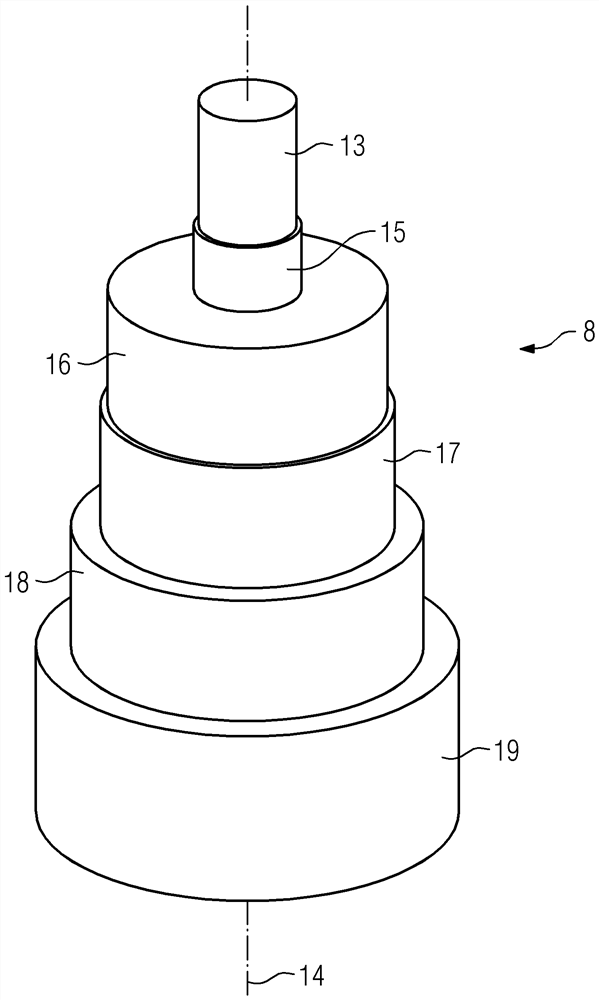

Electric cable for wind turbine and wind turbine

PendingCN111911369AChange cooling rateIncrease airflowEngine fuctionsInsulated cablesTurbineElectric cables

The invention relates to an electric cable for a wind turbine (1), and the cable is characterized in that the cable (8) comprises at least one cooling element (109 to cool the electric cable (8), wherein the cooling element (10) protrudes from the surface of the electric cable (8) .

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

A medical speed regulation and cooling device with communication function

ActiveCN107318827BIncreased vitrificationIncrease chances of survivalDead animal preservationFrozen storageEngineering

The invention discloses a novel medical speed regulation and temperature reduction device with a communication function. The medical speed regulation and temperature reduction device comprises an upper casing, a lower casing, a temperature regulating device, temperature and humidity probes, a temperature and humidity display panel, a WIFI (Wireless Fidelity) generator and a purpose made energy storage material, wherein a first casing sealing cavity, a first frozen storage pipe cavity, a first purpose made energy storage material cavity and a second purpose made energy storage material cavity are arranged inside the upper casing; the lower casing is connected with the upper casing through a metal rod; a plurality of second frozen storage pipe cavities, a second casing sealing cavity and a third purpose made energy storage material cavity are arranged inside the lower casing; the second frozen storage pipe cavities are used for storing frozen storage pipes; phase change materials are also stored in the second frozen storage pipe cavities; the temperature regulating device comprises four purpose made energy storage rods; the temperature and humidity probes are arranged at the outer side of one of the second frozen storage cavities; the temperature information is collected through the temperature probe; the humidity information is collected through a humidity probe; the temperature and humidity display panel is arranged on the front surface of the upper casing and is used for displaying the humidity information and the temperature information; the WIFI generator is used for sending temperature information; the purpose made energy storage material comprises a first purpose made energy storage material, a second purpose made energy storage material and a third purpose made energy storage material and is used for changing the temperature reduction speed.

Owner:上海理工资产经营有限公司

A power battery box cooling structure and its control method

ActiveCN108110370BChange cooling rateSave electricityCell temperature controlCell component detailsStructural deformationElectrical battery

Owner:HARBIN UNIV OF SCI & TECH

High pressure gas quenching cooling method of aerosol forced circulation

InactiveCN1492060AOvercome the shortcomings of uneven quenching and coolingImprove cooling effectQuenching agentsQuenching devicesEngineeringHigh pressure

The present invention belongs to the field of heat treatment of metal material. Gas and water fog is led into a container with forced stirring blower and heat exchanger for heat exchange with the hot workpiece, and the heat the gas and water fog absorb from the workpiece is taken away by the forced stirring blower and the heat exchanger to reach the aim of quickly cooling the quenched workpiece. The combination of gas and water fog can raise the heat exchange coefficient between the medium and the workpiece obviously and cooling capacity and the cooling capacity may be adjusted in certain range.

Owner:SHANGHAI JIAO TONG UNIV

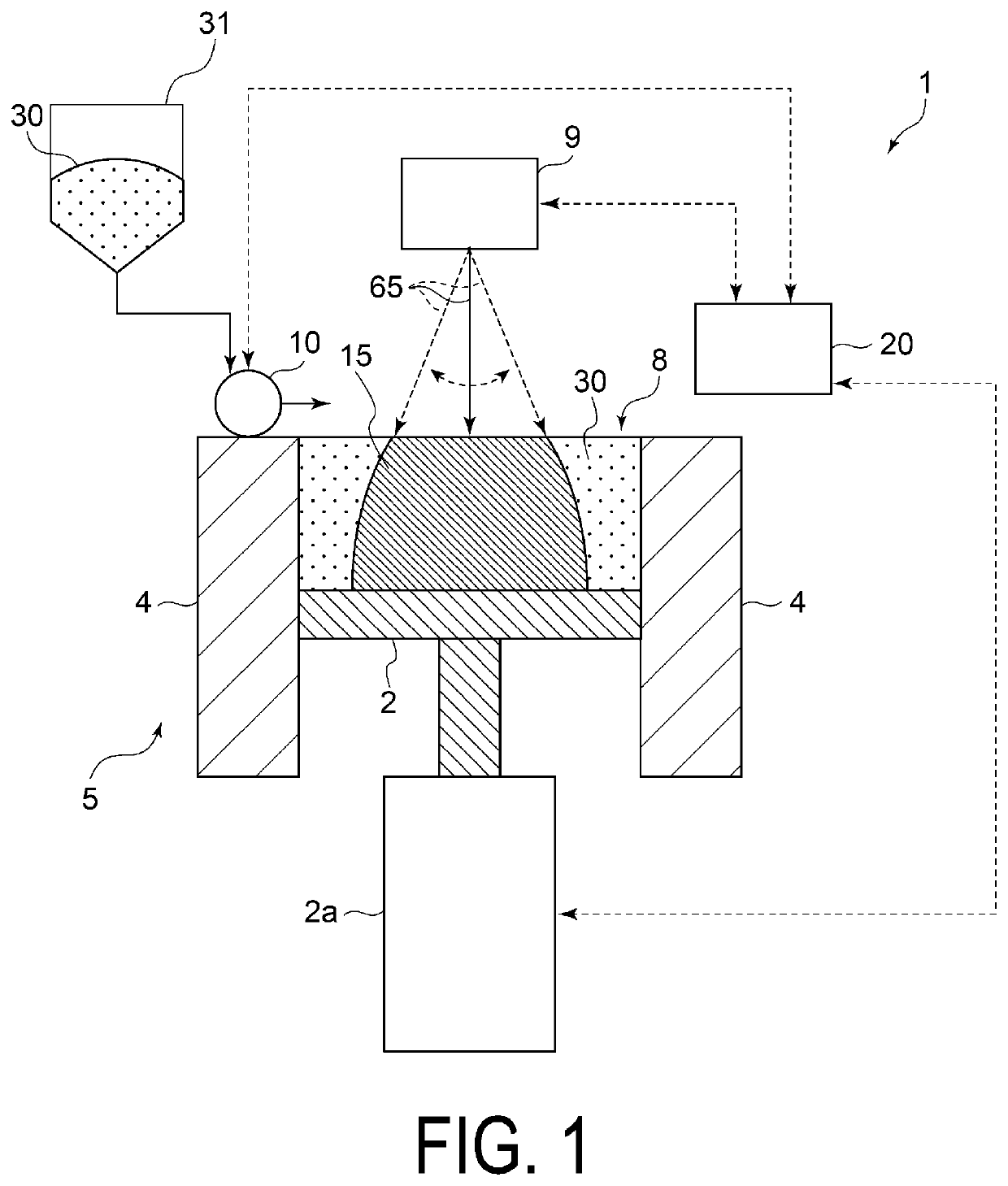

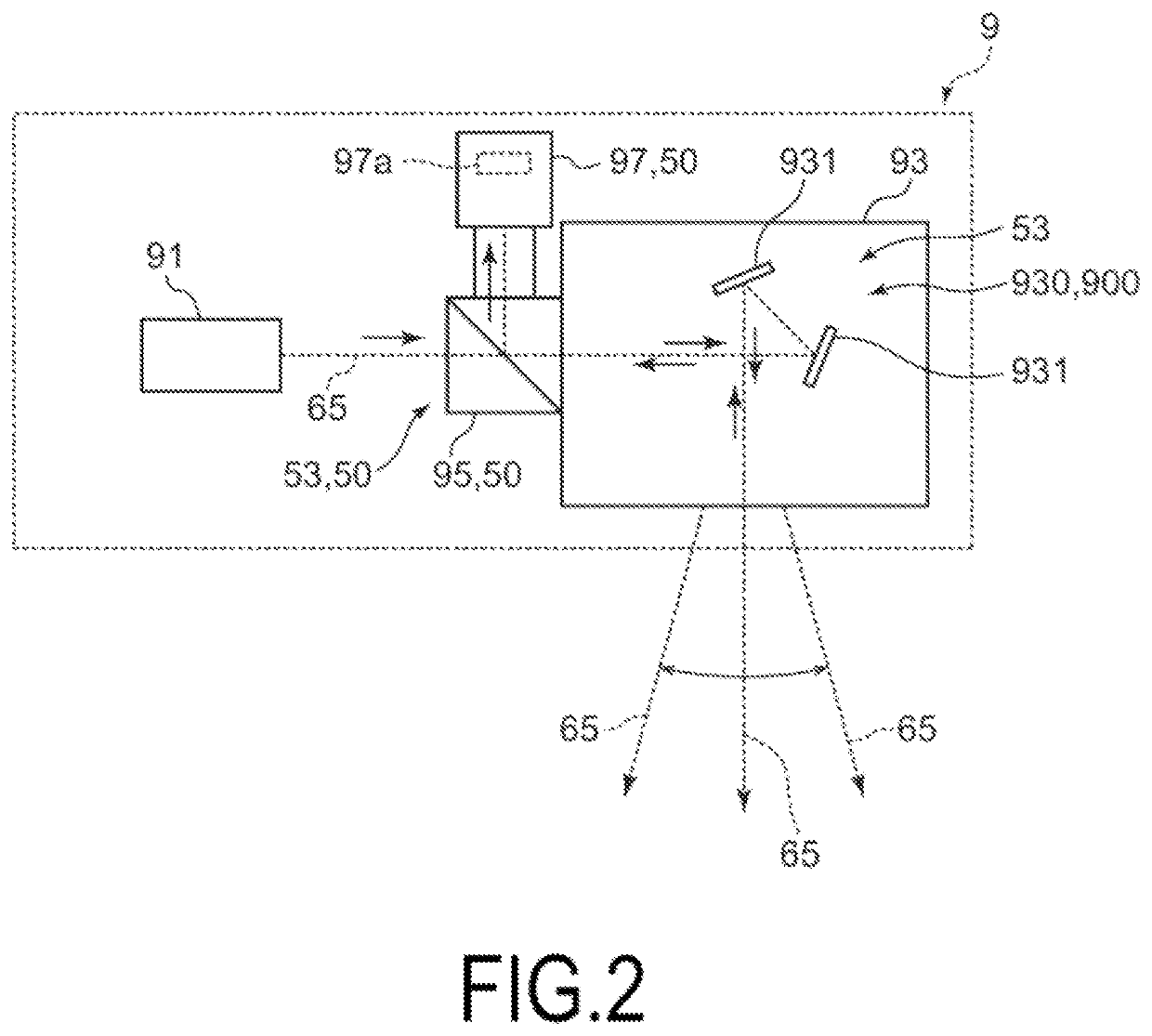

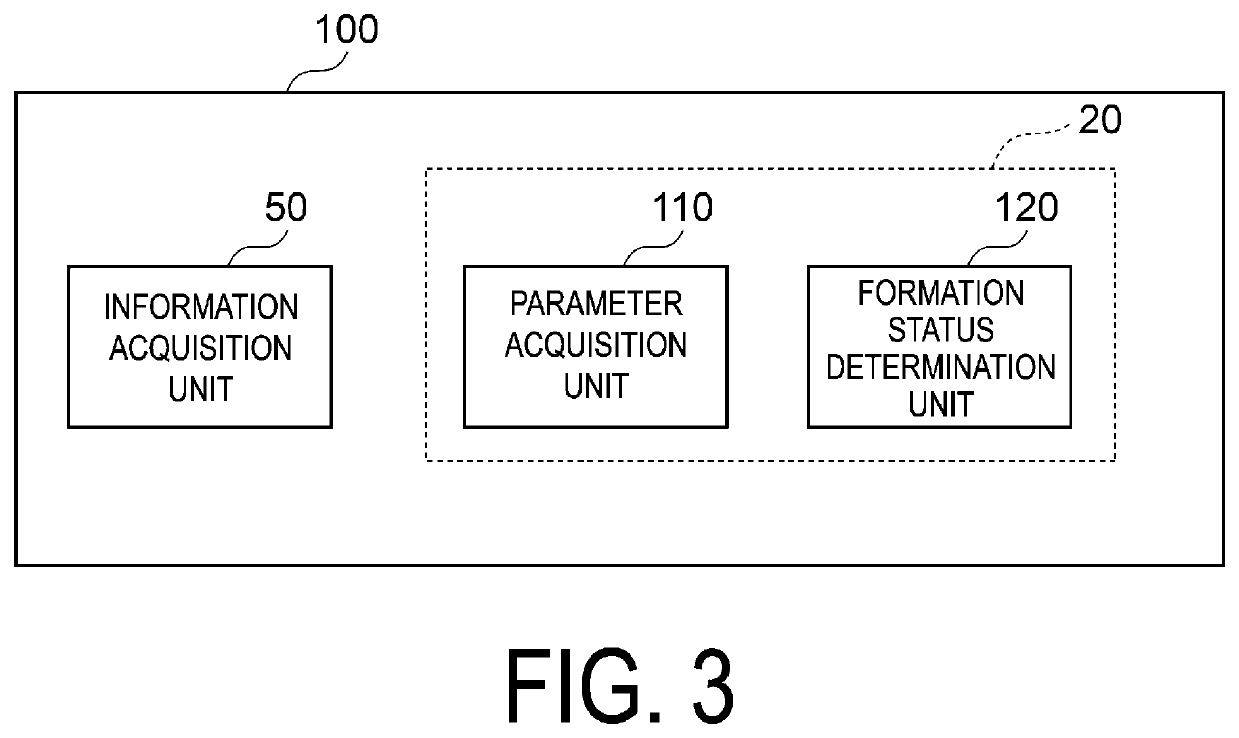

Method of monitoring an additive manufacturing process, additive manufacturing method, apparatus for monitoring an additive manufacturing process and additive manufacturing apparatus

PendingUS20210331245A1Quality improvementChange cooling rateAdditive manufacturing apparatusCeramic shaping apparatusProcess engineeringAdditive layer manufacturing

A method of monitoring an additive manufacturing process according to at least one embodiment of the present disclosure includes the steps of acquiring information on a temperature of a region upstream of a melt pool in a scanning direction of an energy beam, the melt pool being formed by irradiating a raw material with the energy beam, acquiring a parameter indicating a cooling rate of the region based on the information on the temperature, and determining a formation status based on the parameter.

Owner:MITSUBISHI HEAVY IND LTD

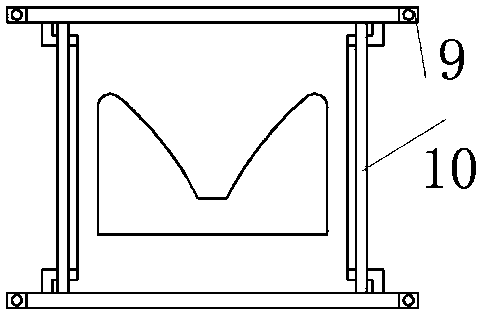

Strip cooling device

InactiveCN107901383AChange cooling rateFree to adjust the lengthFlat articlesEnvironment effectMechanical engineering

The invention discloses a strip cooling device. The strip cooling device comprises a plurality of stand plates arranged between a top plate and a bottom plate, the stand plates are parallel, and clearances exist between the stand plates. Through holes are formed in each stand plate, the shape of the sections of the through holes is matched with the shape of the section of a strip, and the throughholes cooperate with one another to form a strip conveying channel. According to the strip cooling device, the problem that when a composite pipe strip is cooled, the composite pipe strip is prone tobeing influenced by gravity or other external environments, and consequently a cavity in the strip collapses, and the appearances of the strip deforms can be solved.

Owner:张荣斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com