Power battery box cooling structure and control method thereof

A technology for cooling structure and power battery, applied in battery temperature control, battery, secondary battery and other directions, can solve the problems of rigid pipeline structure deformation, low cooling efficiency, etc., to increase the bonding area, improve cooling efficiency, and simple logic Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

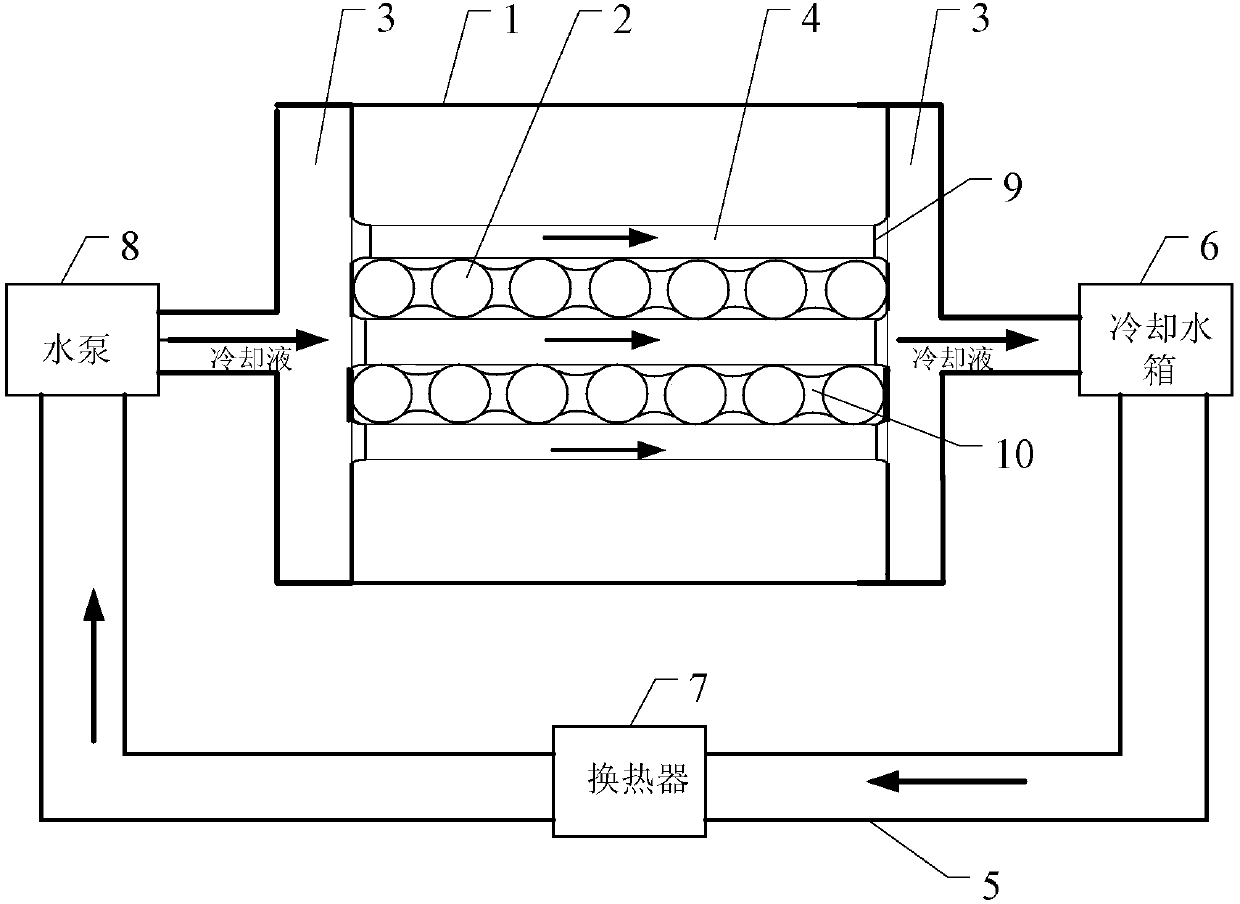

[0032] Specific implementation mode one: combine figure 1 Describe this embodiment in detail, the

[0033] A power battery box cooling structure for cooling the battery module 2 inside the battery box body 1, including two small water storage tanks 3, a flexible water jacket 4, a cooling water tank 6, a heat exchanger 7 and a water pump 8;

[0034] A small water storage tank 3 is respectively provided at both ends of the battery box body 1, and a plurality of battery modules 2 are arranged between the two small water storage tanks 3. The battery module 2 is formed by a plurality of battery arrays, adjacent to each other. A flexible water jacket 4 is provided between the battery modules 2, one end of the flexible water jacket 4 is used as a water inlet to communicate with a small water storage tank 3, and the other end of the flexible water jacket 4 is used as a water outlet to communicate with another small water storage tank 3 , outside the battery box body 1, two small wate...

specific Embodiment approach 2

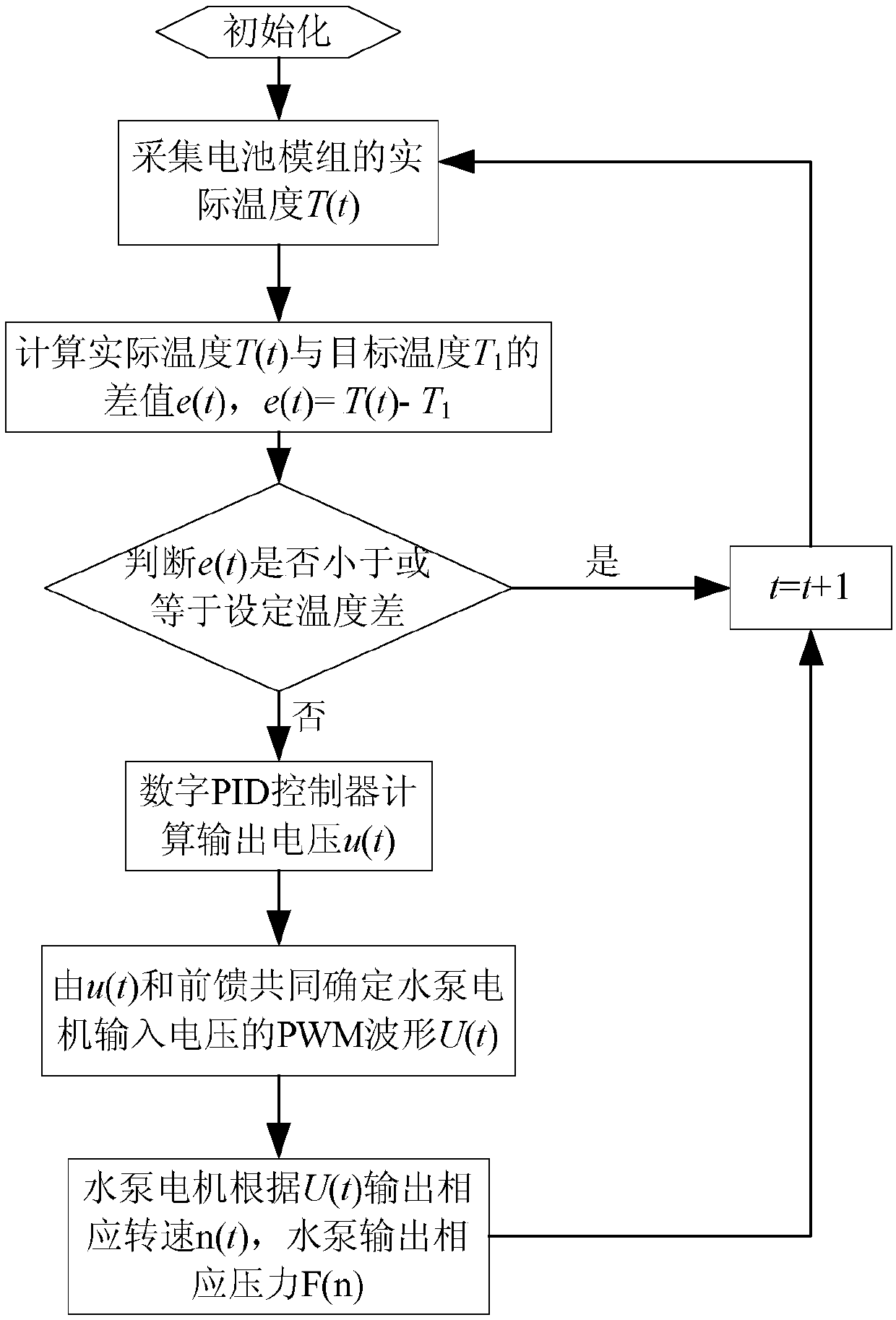

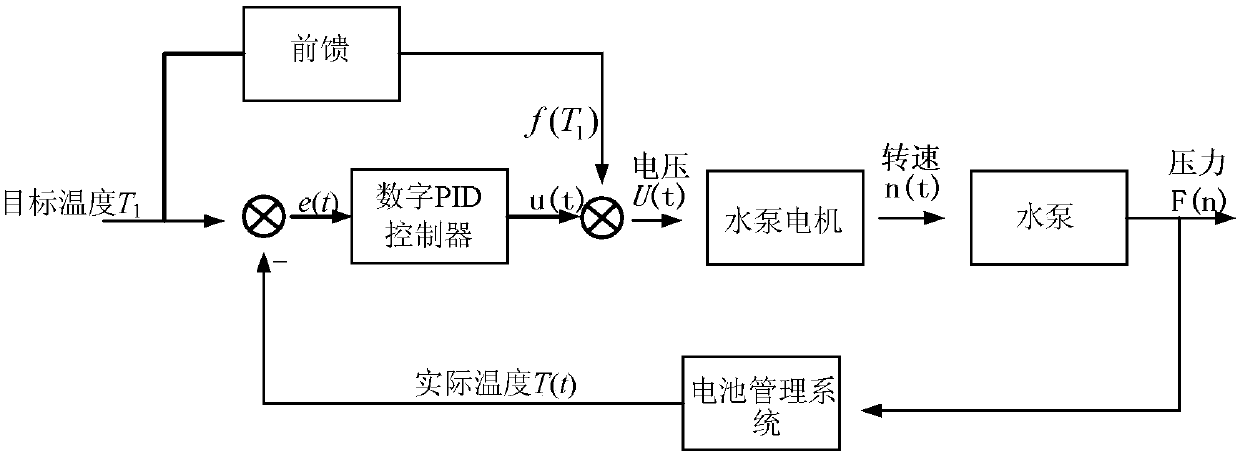

[0040] Specific implementation mode two: combination figure 2 with image 3 Specifically explain this embodiment, a method for controlling the cooling structure of a power battery box described in this embodiment, the method is to use the digital PID controller to receive the collected actual temperature of the battery module 2 to control the output speed of the water pump 8 and pressure, including the following steps:

[0041] Step 1, initialization, let t=2, u(1), e(1) and e(0) are all 0;

[0042] u(t), e(t) are the difference between the output voltage of the digital PID controller, the actual temperature and the target temperature;

[0043] Step 2, the battery management system collects the actual temperature T(t) of the battery module 2;

[0044] Step 3. Calculate the actual temperature T(t) and the target temperature T 1 The difference e(t), e(t)=T(t)-T 1 ;

[0045] Step 4. Determine whether e(t) is less than or equal to the set temperature difference T μ , if th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com