Improved Gravity Heat Pipe Heat Sink for High Power LEDs

A gravitational heat pipe, an improved technology, is used in semiconductor devices of light-emitting elements, cooling/heating devices for lighting devices, lighting and heating equipment, etc. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

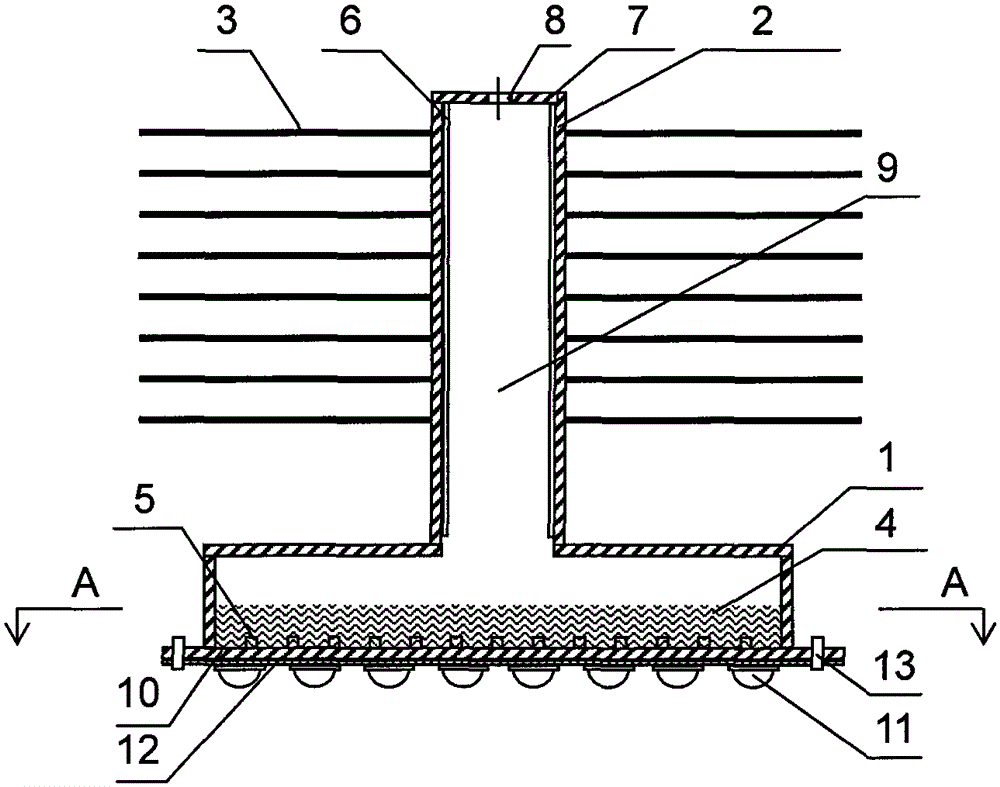

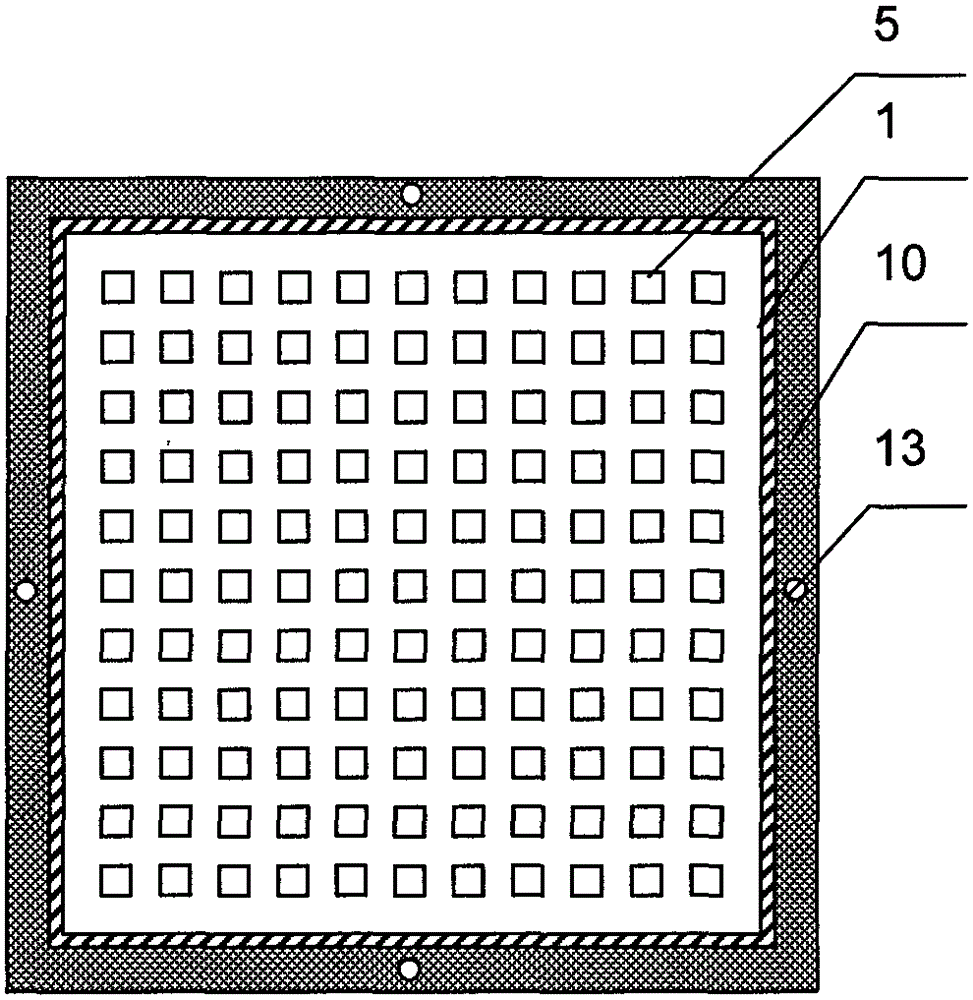

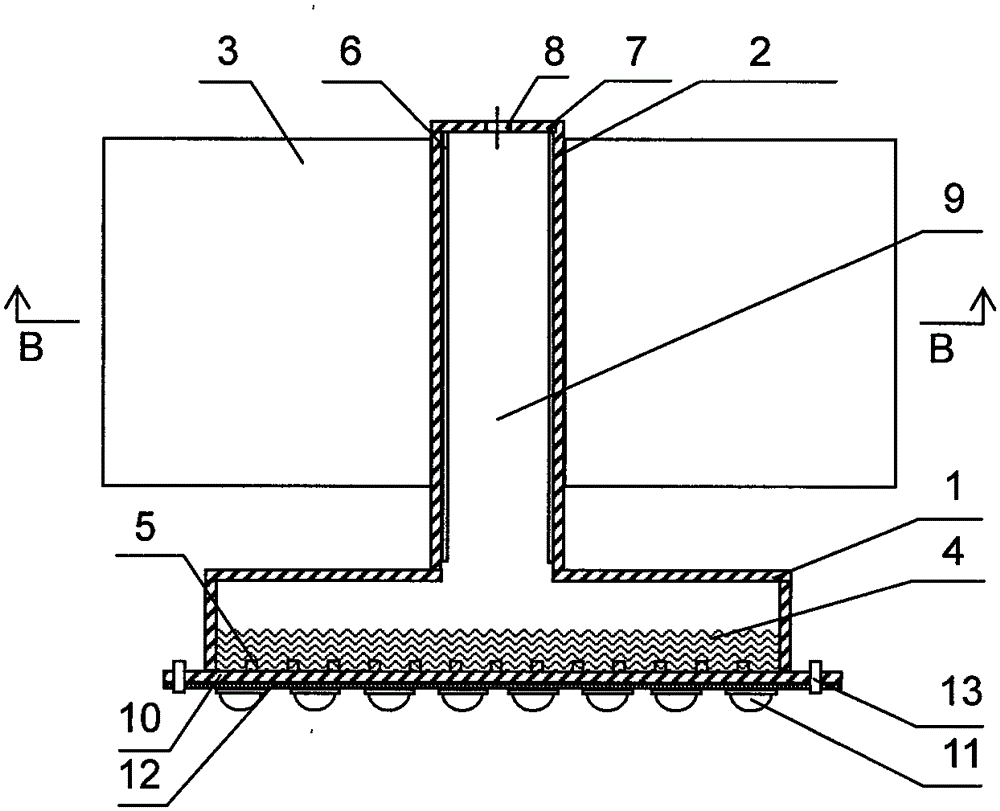

[0028] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

[0029] figure 1 It is a structural schematic diagram of Embodiment 1 of the improved gravity heat pipe radiator for high-power LEDs of the present invention. This embodiment includes: evaporation section 1, condensation section 2, and cooling fins 3, wherein: evaporation section 1 and condensation section 2 An improved gravity heat pipe is formed, that is, a closed vacuum chamber 9 filled with a heat transfer medium 4 , the lower surface of the evaporation section 1 is fixedly connected to the LED circuit substrate 10 , and a number of cooling fins 3 are connected to the outside of the condensation section 2 .

[0030] The condensing section and the evaporating section are hollow structures, made of red copper, aluminum or aluminum alloy, with a thickness of 2.0-5.0mm, and the two are connected through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com