Patents

Literature

35results about How to "Increase boiling heat transfer coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

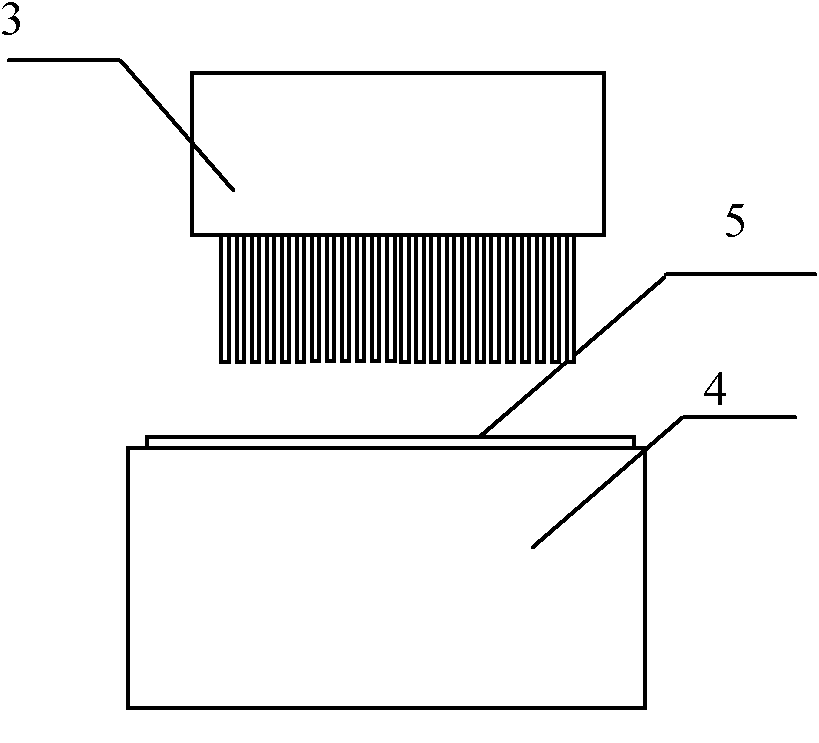

Improved gravity assisted heat pipe radiator used for high-power LED

InactiveCN103196116AEasy to processLow pricePoint-like light sourceLighting heating/cooling arrangementsRefluxHeat conducting

The invention discloses an improved gravity assisted heat pipe radiator used for a high-power LED, which comprises an improved gravity assisted heat pipe and radiating fins, and is characterized in that the improved gravity assisted heat pipe consists of a flat-plate-shaped evaporation section and a cylindrical condensation section, wherein the evaporation section is directly connected with an LED circuit baseplate; the condensation section is connected with the radiating fins; a heat conduction column is arranged on the inner wall of the lower end of the evaporation section; a reflux tank channel is axially arranged on the inner wall of the condensation section; the interior of the heat pipe is vaccumized and is filled with a heat-conducting medium; and the inner wall of the heat pipe is sandblasted for heat transfer enhancement. The improved gravity assisted heat pipe radiator used for the high-power LED transmits the heat to the radiating fins rapidly by the circulating convection with the participation of gravity, and has the benefits of flexibility, convenience, simplification, low cost, high start speed, capability of accelerating the radiating rate with the temperature rising of the high-power LED, and the like.

Owner:CHINA JILIANG UNIV

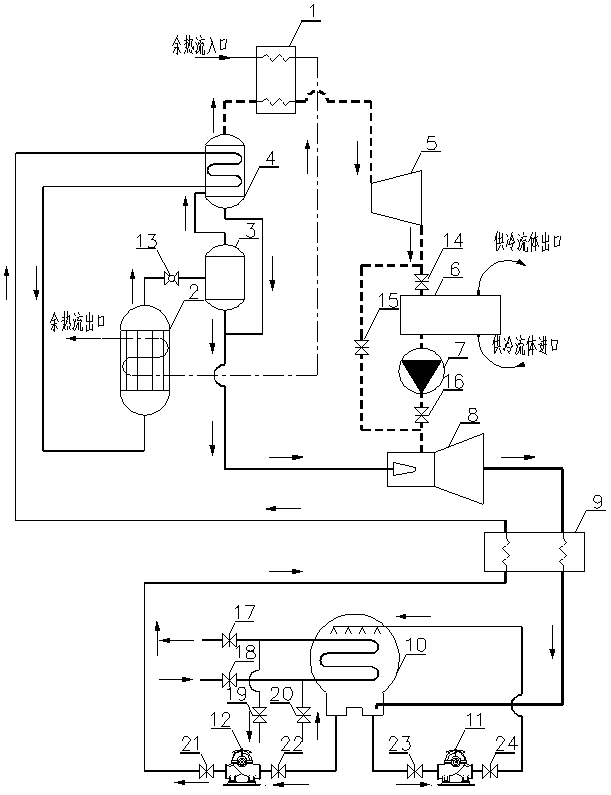

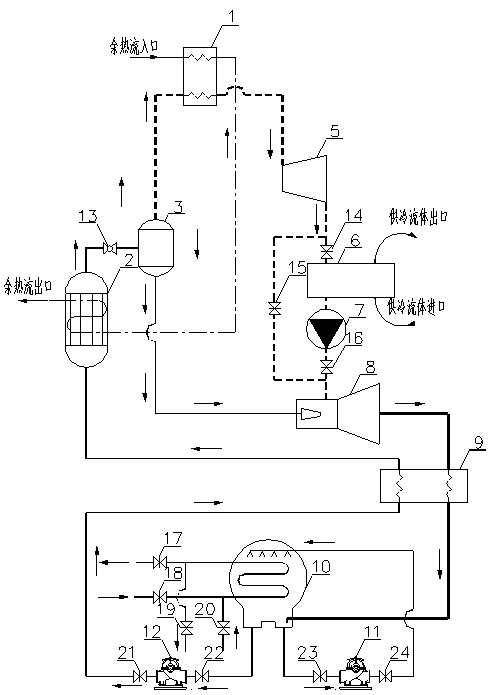

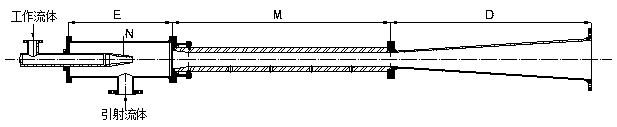

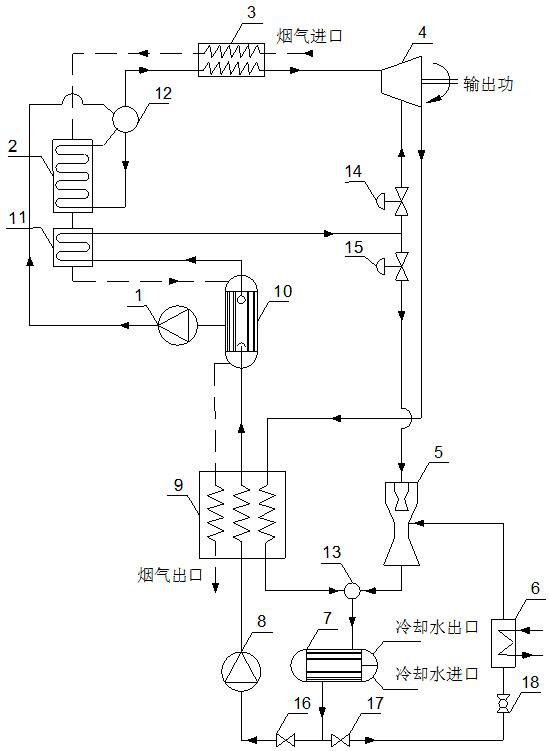

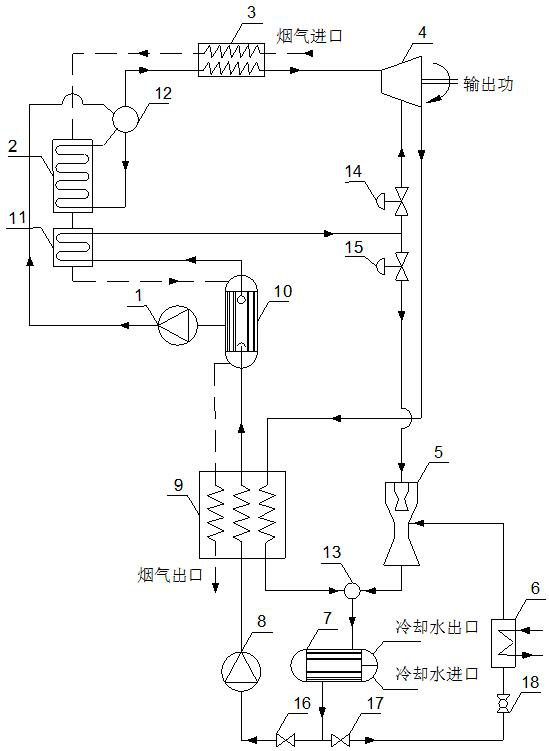

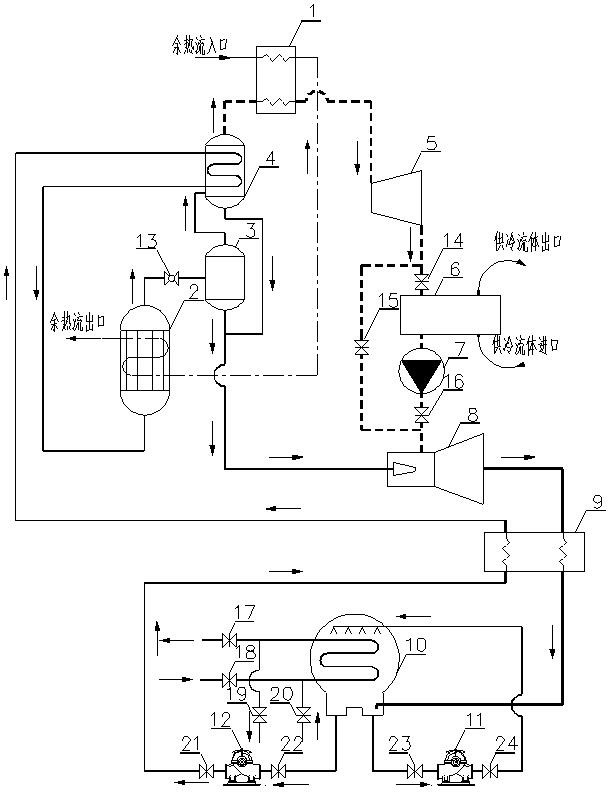

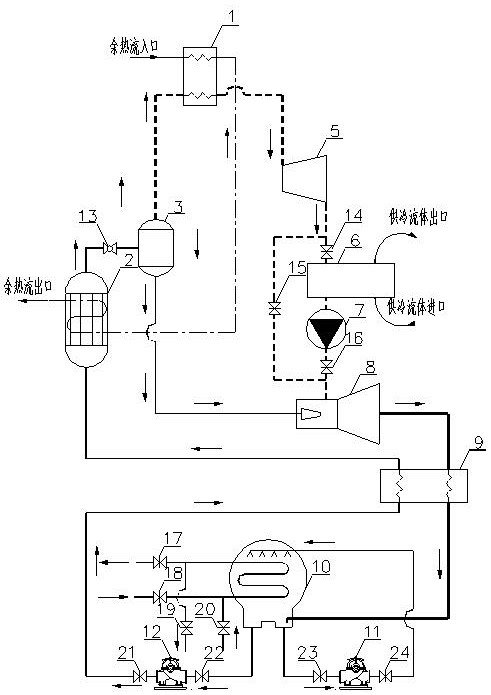

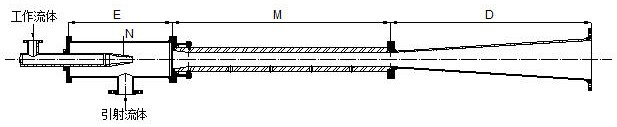

Medium and low-temperature waste heat driven flat evaporation-injection-absorption combined cycle combined cold-heat power supply system

ActiveCN110185511AHigh power outputReduce cold end pressureSteam engine plantsRefrigeration machinesNew energyEvaporation

The invention relates to a medium and low-temperature waste heat driven flat evaporation-injection-absorption combined cycle combined cold-heat power supply system and belongs to the technical field of new energy and energy conservation. The medium and low-temperature waste heat driven flat evaporation-injection-absorption combined cycle combined cold-heat power supply system comprises a superheater, a waste heat heater, a flash evaporator, a rectifier, an expansion machine, a cooling heat exchanger, a booster compressor, an injection ejector, a regenerator, an absorber, an absorption pump, asolution pump, a throttling valve and a stop valve. The medium and low-temperature waste heat driven flat evaporation-injection-absorption combined cycle combined cold-heat power supply system can achieve combined cold-heat power supply or heat and power cogeneration according to requirements of users. Regardless of operating in a cold-heat power supply mode or in a heat and power cogeneration mode, the combined cycle system only has a small part of external discharge heat loss and can make use of energy to the maximum extent.

Owner:KUNMING UNIV OF SCI & TECH

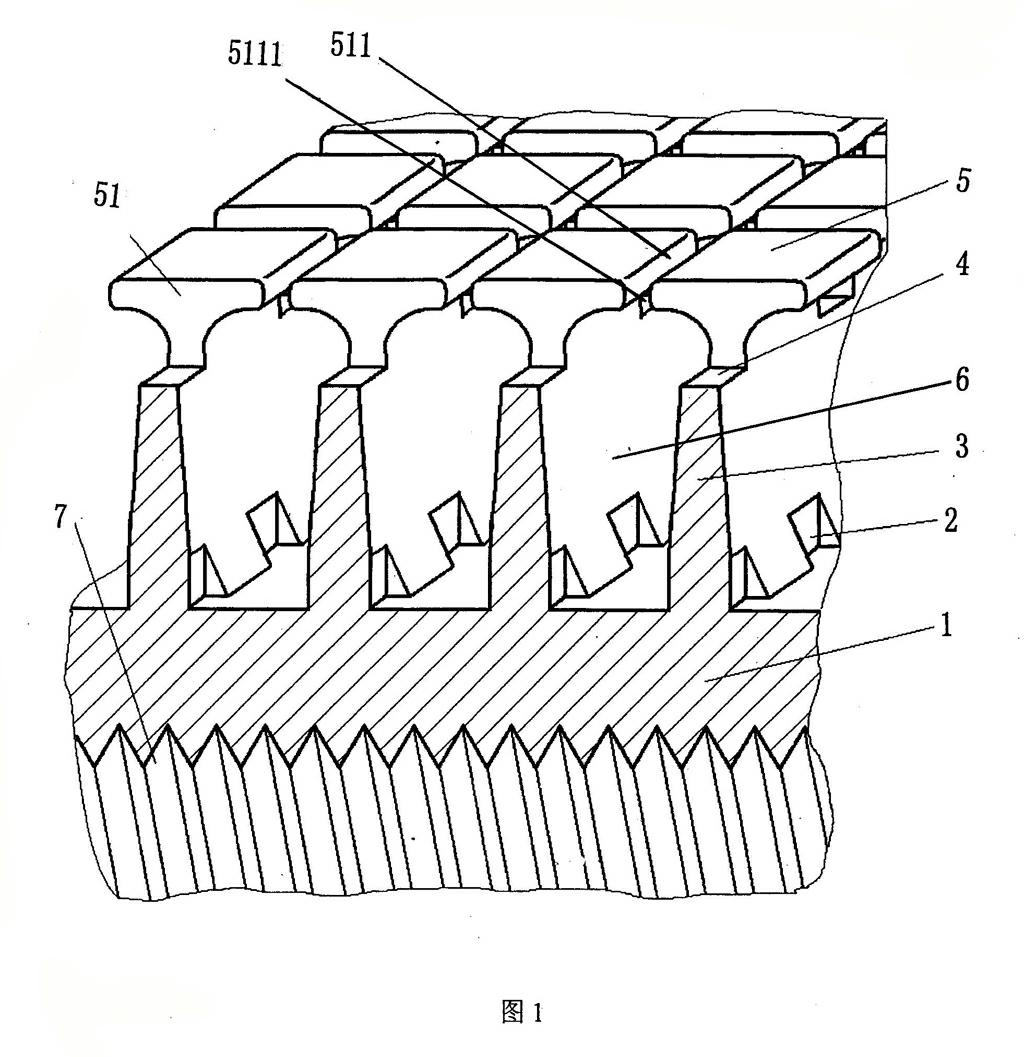

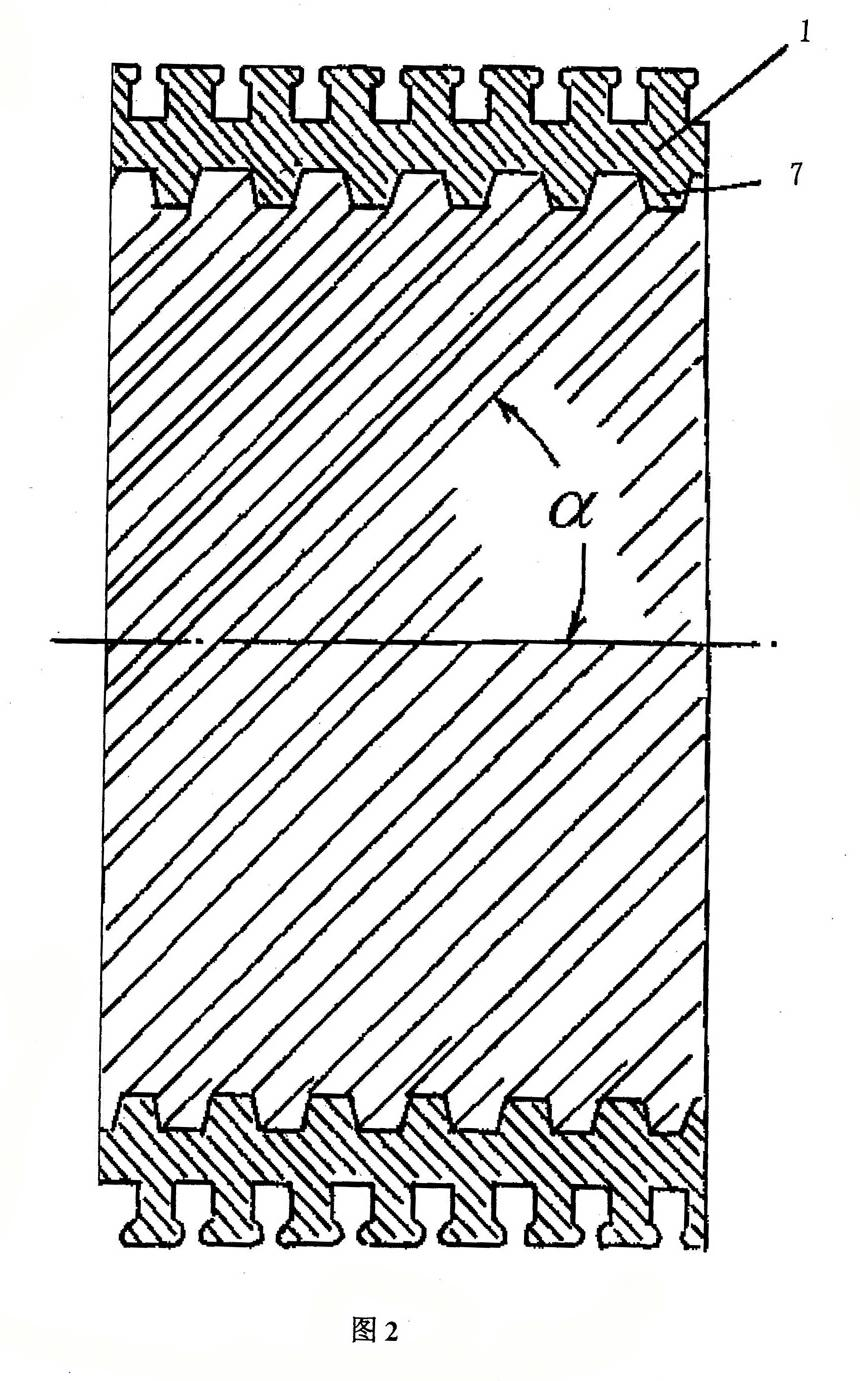

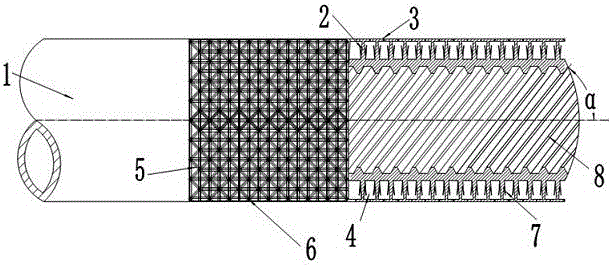

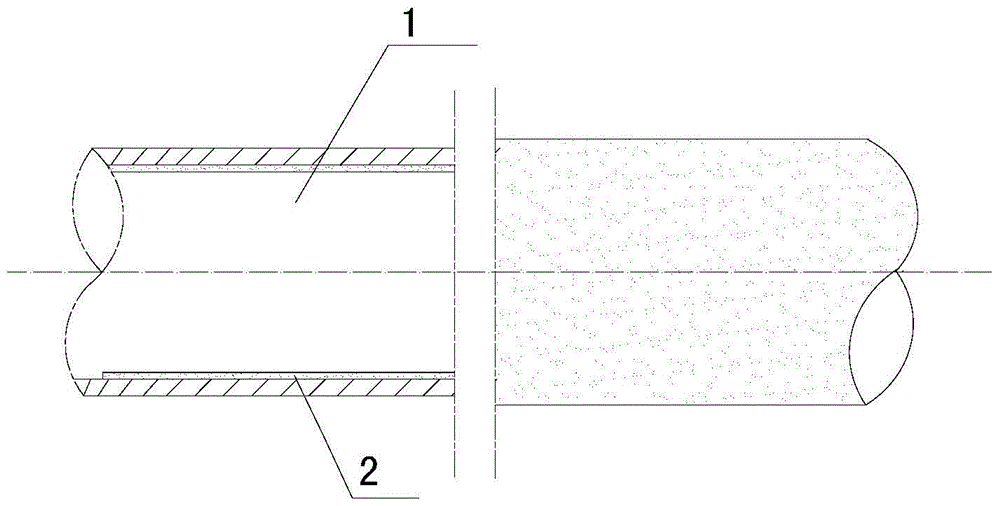

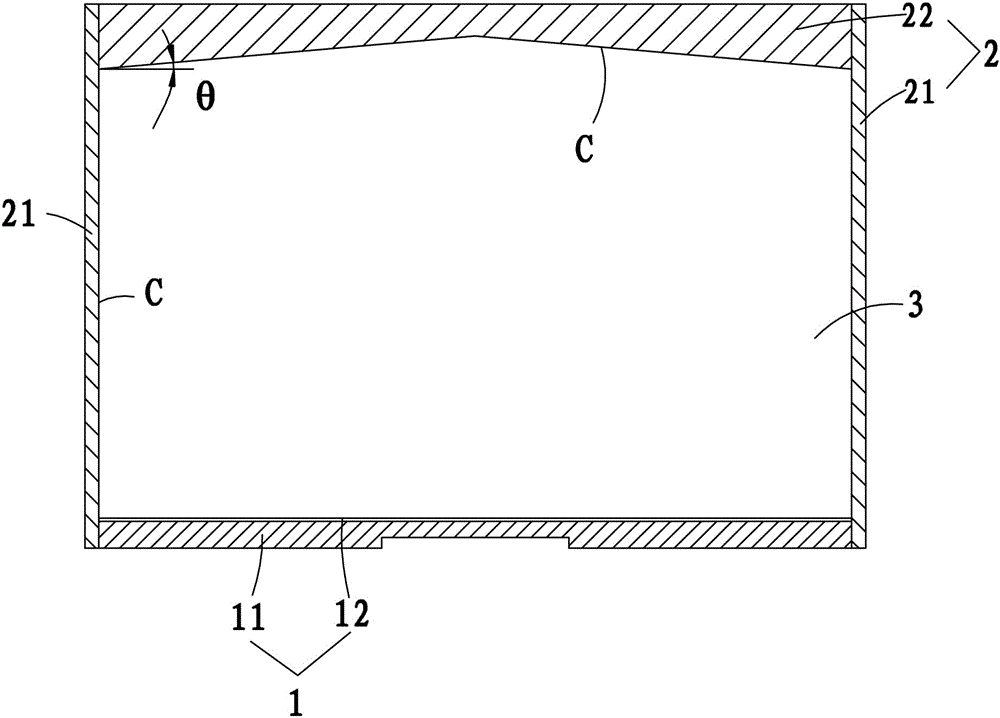

Heat exchanger tube used for evaporator

InactiveCN102305569AHigh activityIncrease boiling heat transfer coefficientHeat transfer modificationTubular elementsEvaporation heat transferEngineering

The invention relates to a heat exchanger tube used for an evaporator, belonging to the technical field of heat exchange parts. The heat exchanger tube comprises a tube body and an external fin formed on the external wall surface of the tube body, wherein at least one side of the root of the external fin is provided with grooves which are used for retaining residue steam and is of small-scale hollow cavity structures at intervals. The heat exchanger tube provided by the invention has the advantages that the grooves with small-scale hollow cavity structures are formed on the side surface of at least one side of the root of the external fin at intervals, thus the grooves with small-scale hollow cavity structures are provided for a chamber with a large-scale hollow cavity structure in the existing technology so as to retain the residue steam which is used as the gasifying center for generating the next bubble, thereby improving the activity of the chamber with the large-scale hollow cavity structure and obviously improving the boiling heat transfer coefficient; and the weight of the tube body is reduced because the grooves with the small-scale hollow cavity structures are designed, which is in favor of saving materials and dose not cause the reduction of the strength of the tube body.

Owner:JIANGSU CUILONG PRECISION COPPER TUBE CORP

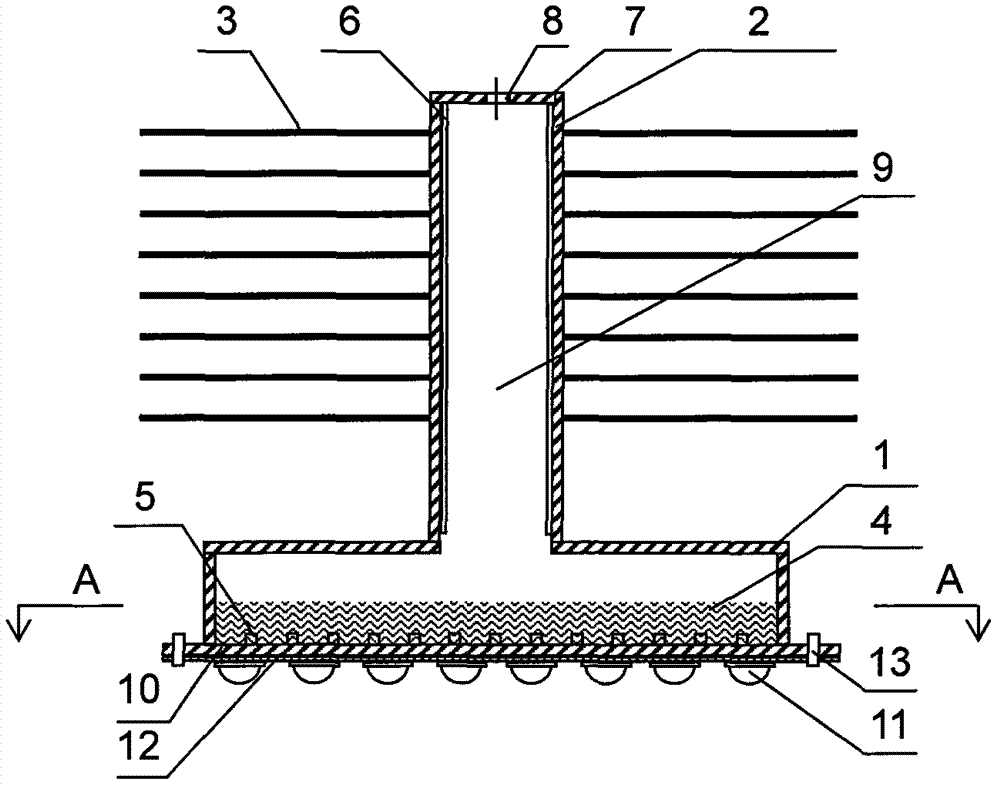

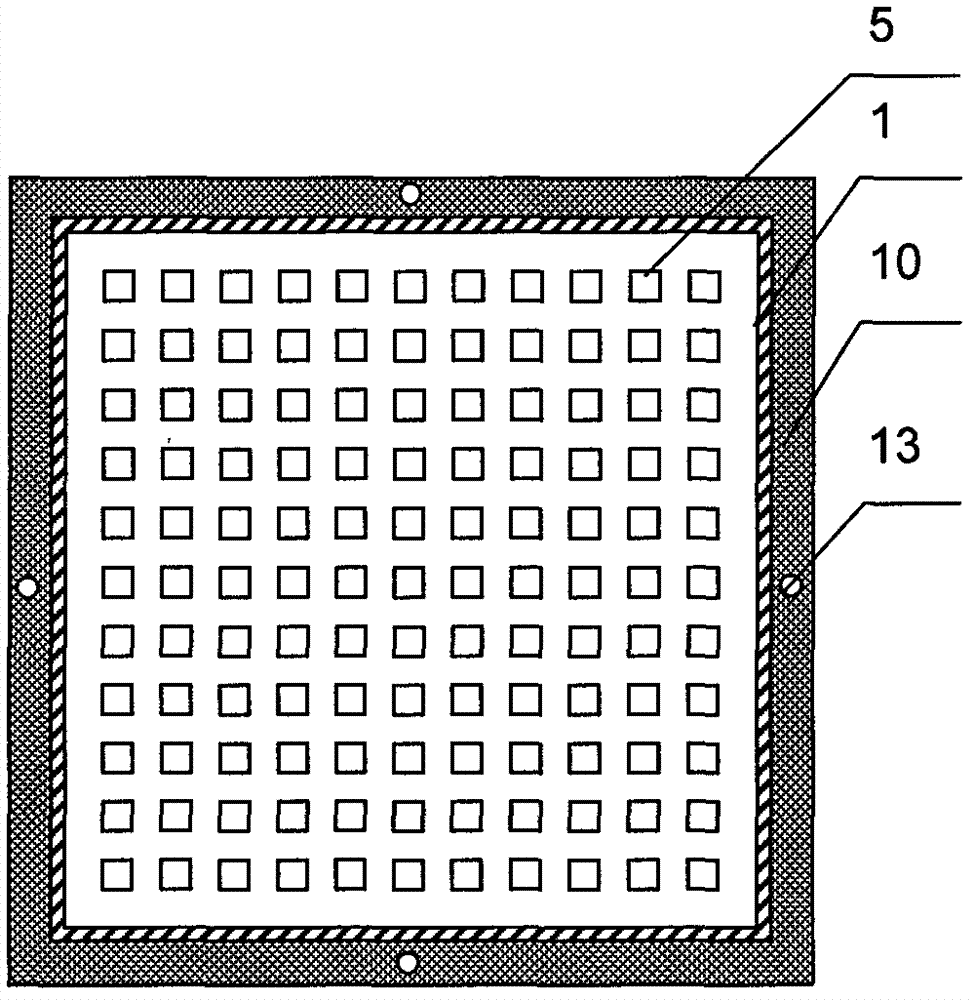

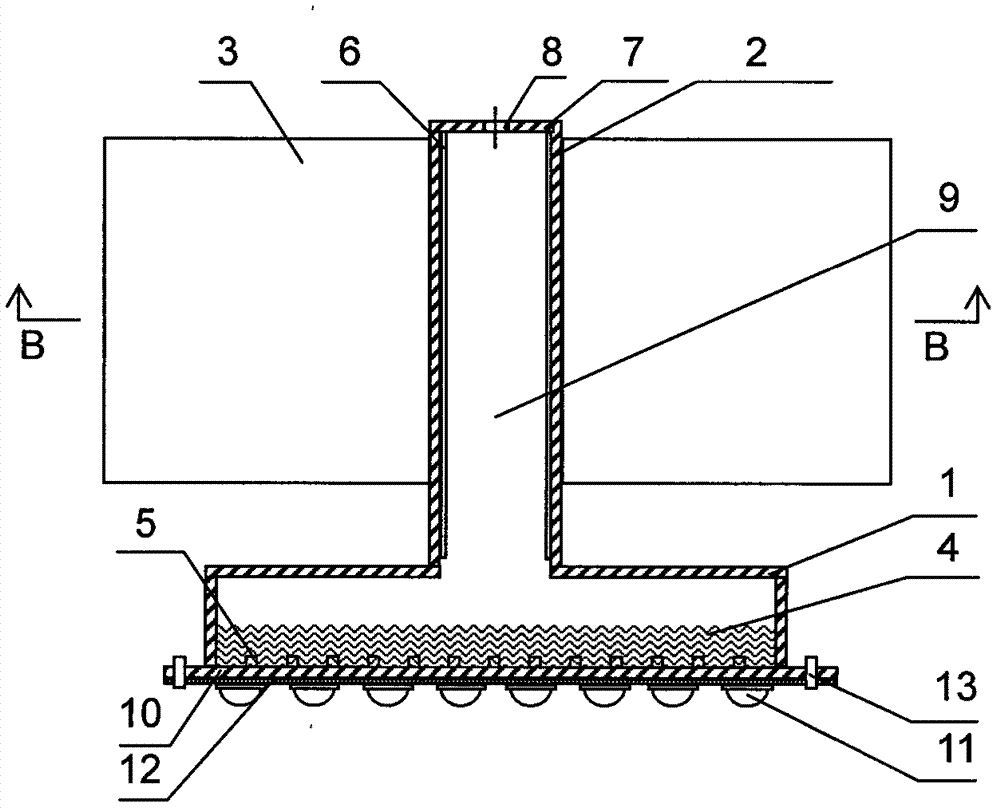

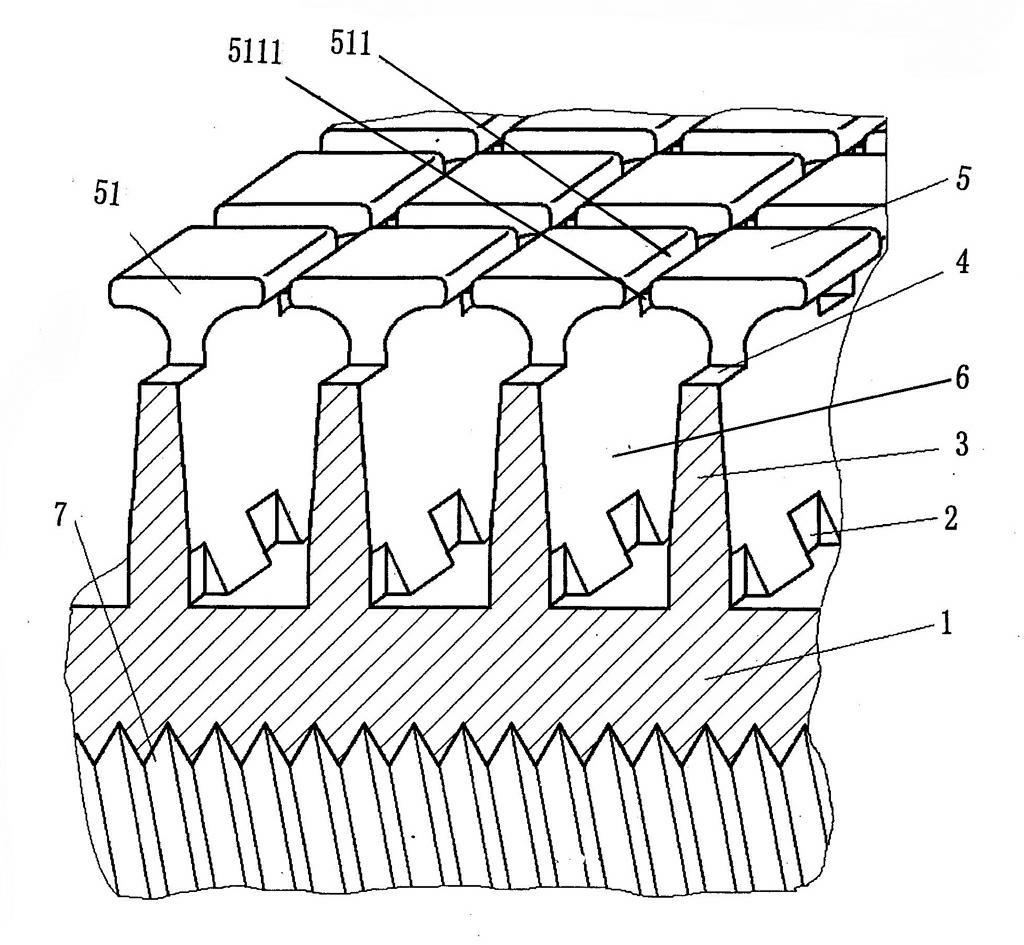

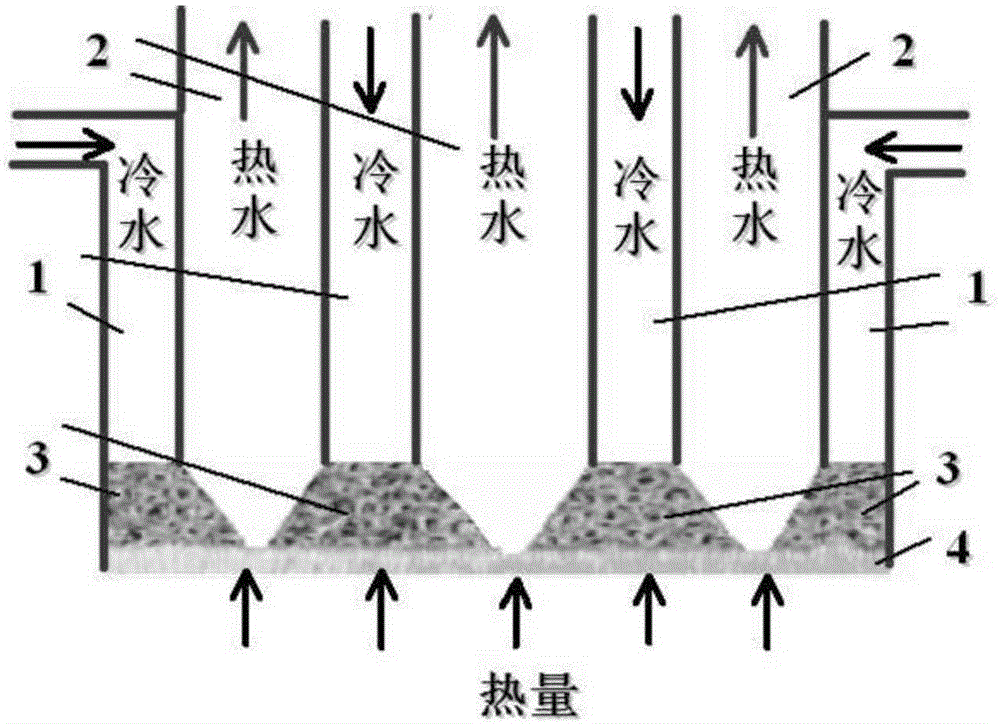

High-hole-density through hole metal foam electronic element heat-dissipation device based on impact jet flow

ActiveCN103117258ALarge specific surface areaStrong disruptive abilityDigital data processing detailsSemiconductor/solid-state device detailsJet flowWater pipe

A high-hole-density through hole metal foam electronic element heat-exchanging device based on impact jet flow comprises a heat-exchanging substrate, through hole metal foam sintered on the heat-exchanging substrate, a cooling water inlet pipe and a water drainage pipe, wherein main bodies of the cooling water inlet pipe and the water drainage pipe are vertical arranged at intervals, heat-exchanging parts at the bottoms of the two water pipes are provided with the through hole metal foam, and a heat-exchanging structure is arranged in the position wherein the through hole metal foam is connected with the water drainage pipe. According to the high-hole-density through hole metal foam electronic element heat-dissipation device based on the impact jet flow, the through hole metal foam is used for separating the flowing route of supplement liquid and the escape route of bubbles, and largely reduces the resistance when the bubbles escape. The heat-exchanging device is high in heat-exchanging efficiency, and is capable of being widely used in the heat-exchanging field of electronic elements.

Owner:SHANGHAI JIAO TONG UNIV

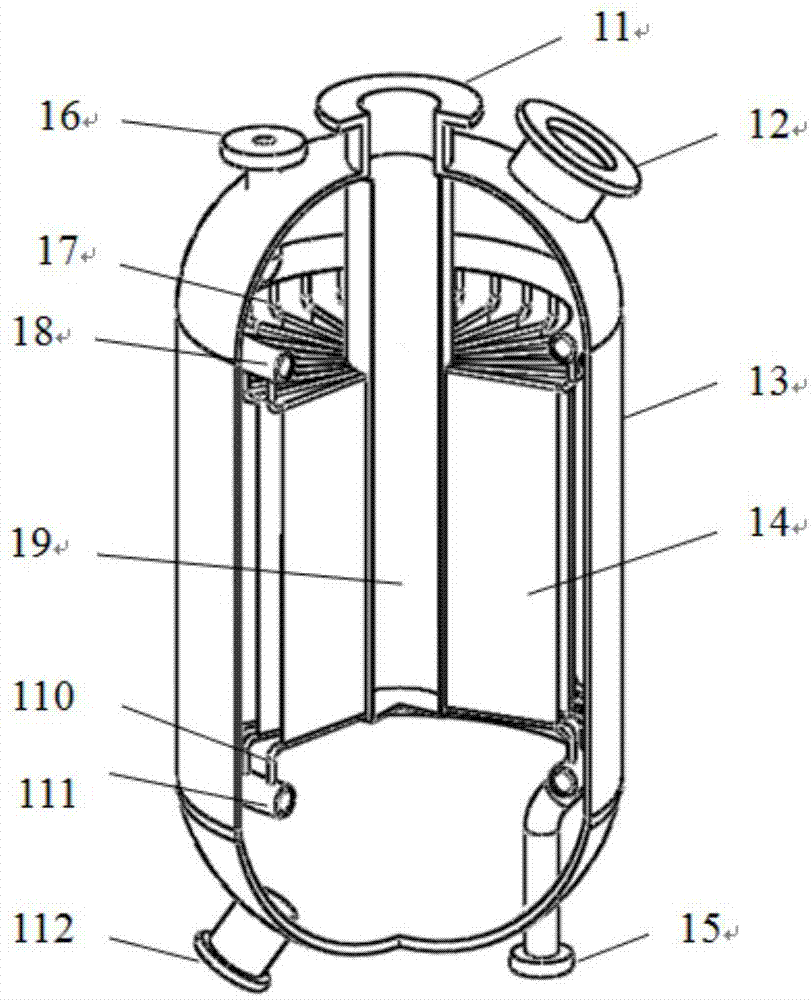

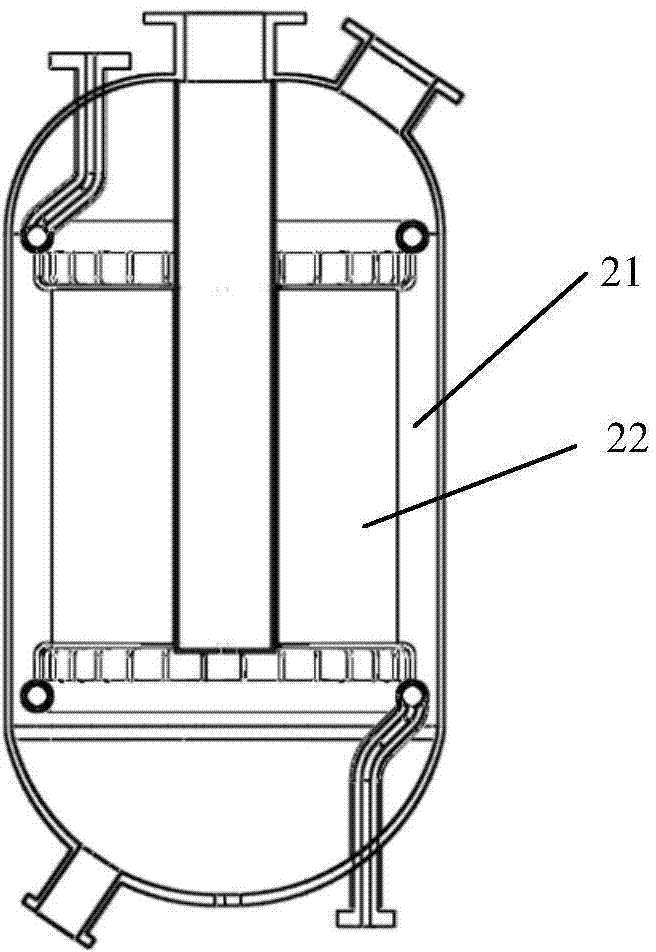

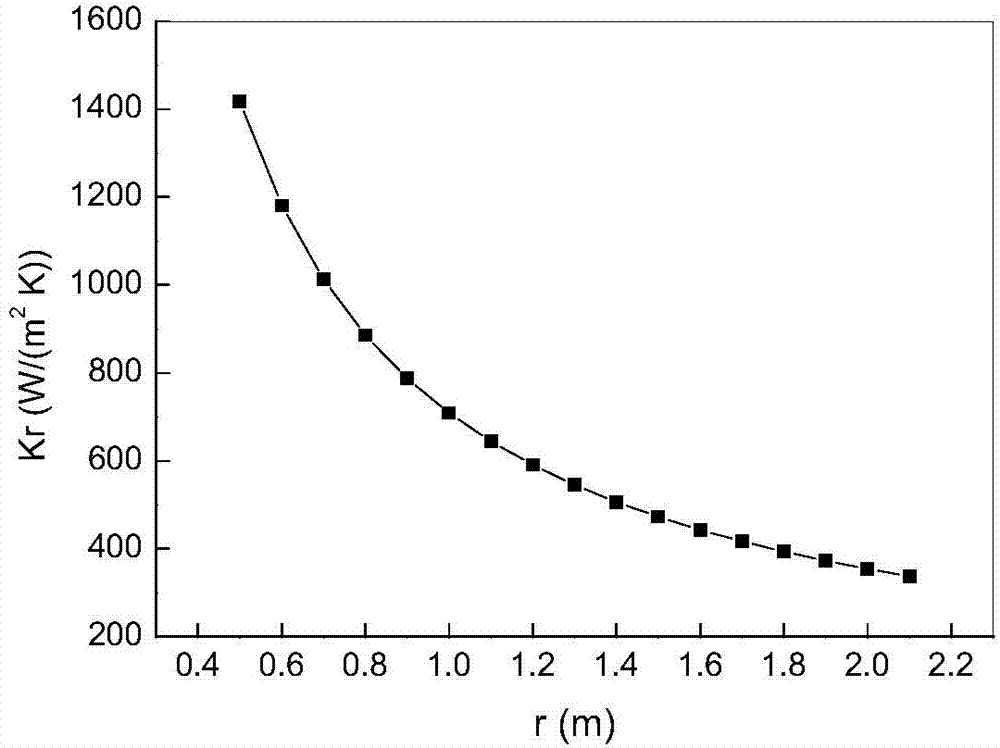

Novel carbonylation reactor for process of producing glycol through synthesis gas

InactiveCN104841340AFast updateWell formedOrganic compound preparationHydroxy compound preparationProcess engineeringCarbonylation

The invention relates to a novel carbonylation reactor for a process of producing glycol through synthesis gas. The reactor is a radial reactor and comprises a reactor shell, a heat exchange component, a flow dividing pipe, a flow collecting pipe and catalyst, wherein the flow dividing pipe is located in the center of the reactor; the heat exchange component is arranged between the flow dividing pipe and the flow collecting pipe; the heat exchange component is arranged in a catalyst bed layer, and the reactor shell comprises a cylinder, an upper seal head, a lower seal head, a reaction gas inlet, a reaction gas outlet, a cooling medium inlet, a cooling medium outlet, a catalyst unloading port and the like; the reaction gas inlet and the reaction gas outlet are arranged on the upper seal head; reaction gas enters the reactor from the reaction gas inlet, then flows downwards along the flow dividing pipe in the center, radially passes through the catalyst bed layer for reaction, and reaction product gas enters the flow collecting pipe, flows upwards along the flow collecting pipe and flows out from the reaction gas outlet. Compared with the prior art, the novel carbonylation reactor for the process of producing glycol through synthesis gas has the advantages of high heat exchange efficiency, small equipment size, high catalyst using efficiency and convenience in loading and unloading.

Owner:WUHUAN ENG +2

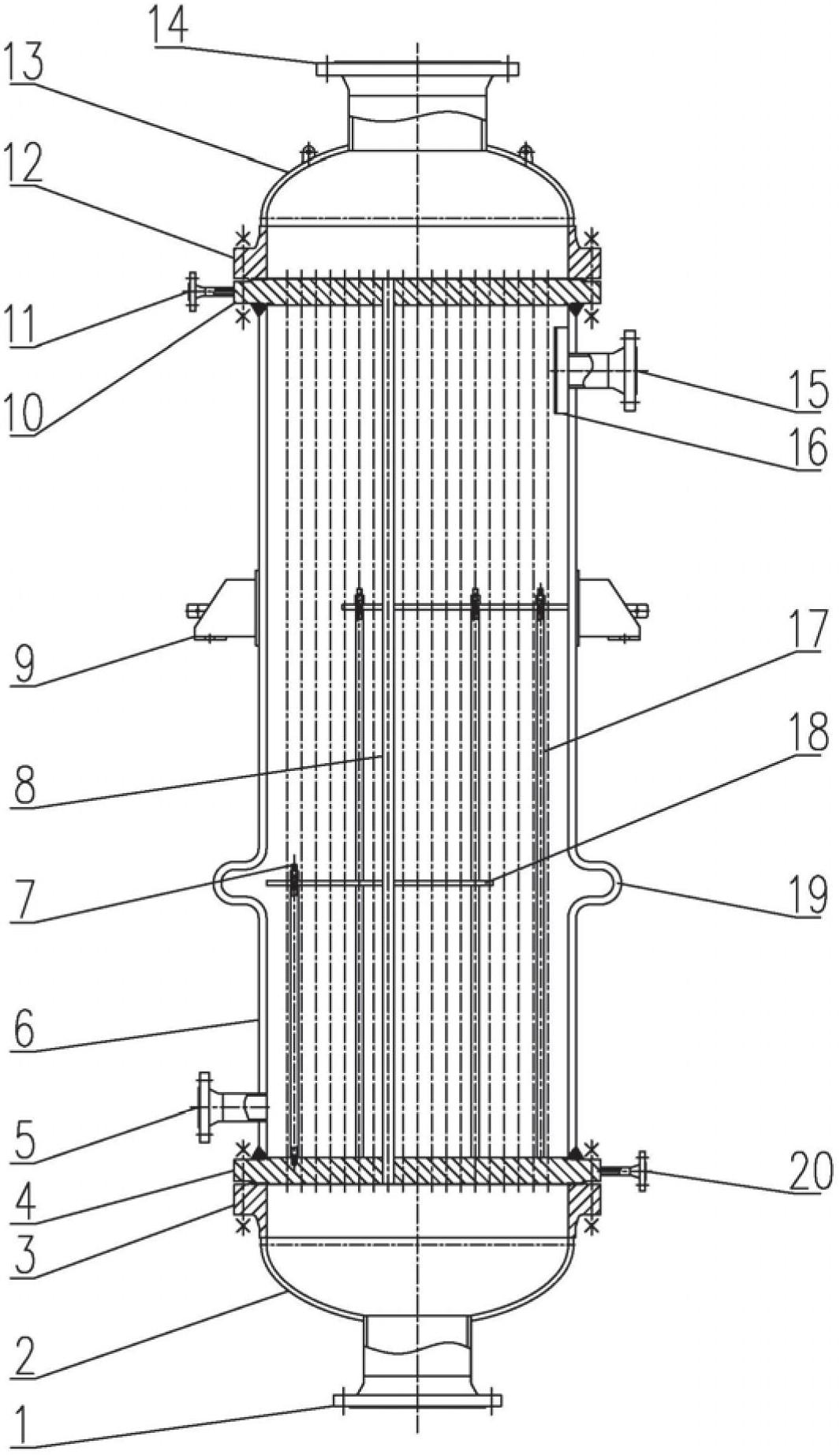

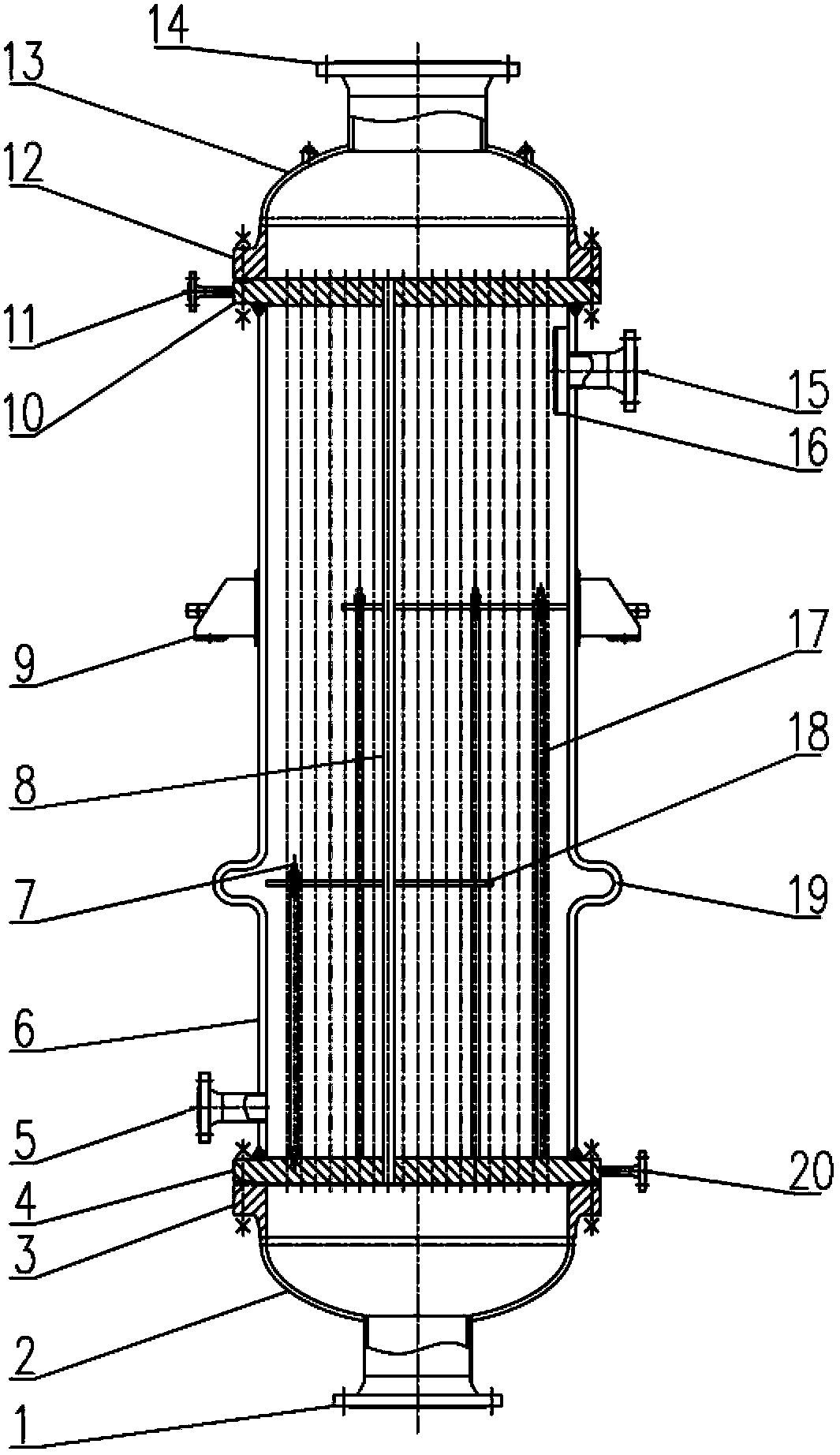

Reboiler

ActiveCN102671399AExtended cleaning cycleImprove heat transfer efficiencyBoiling apparatusReboilerPorous layer

The invention discloses a reboiler which comprises a cylinder and a plurality of heat exchange tubes, wherein a material inlet and a material outlet are arranged at two ends of the cylinder respectively; a steam inlet is arranged on the cylinder on the side of the material outlet; and a condensate outlet is arranged on the cylinder on the side of the material inlet. According to the reboiler, a porous layer is processed on inner surfaces of heat exchange tube substrates and the porous layer has a heating surface with increased roughness so as to form an artificial evaporating core, so that the heat transfer efficiency of the heat exchange tubes is increased. Meanwhile, longitudinal grooves are processed on the outer surfaces of the heat exchange tube substrates, circular bulges are arranged in the longitudinal grooves, longitudinal nicks are arranged on a teeth part, the thickness of a liquid film is reduced by utilizing a surface tension and then the condensation effect on the exteriors of the heat exchange tubes is improved. According to the invention, the total coefficient of heat transfer of the reboiler is above 3 times of that of a light tube reboiler; anti-scaling capacity of boiling sides of the heat exchange tubes is increased; the dirt deposition rate is less than that of a smooth tube, so that the cleaning period of the reboiler is prolonged.

Owner:CHINA ELEVENTH CHEM CONSTR +1

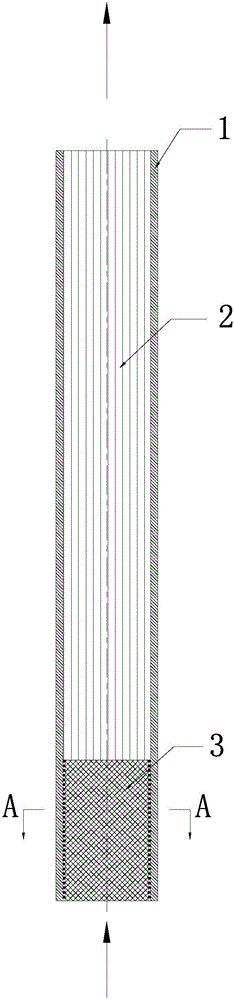

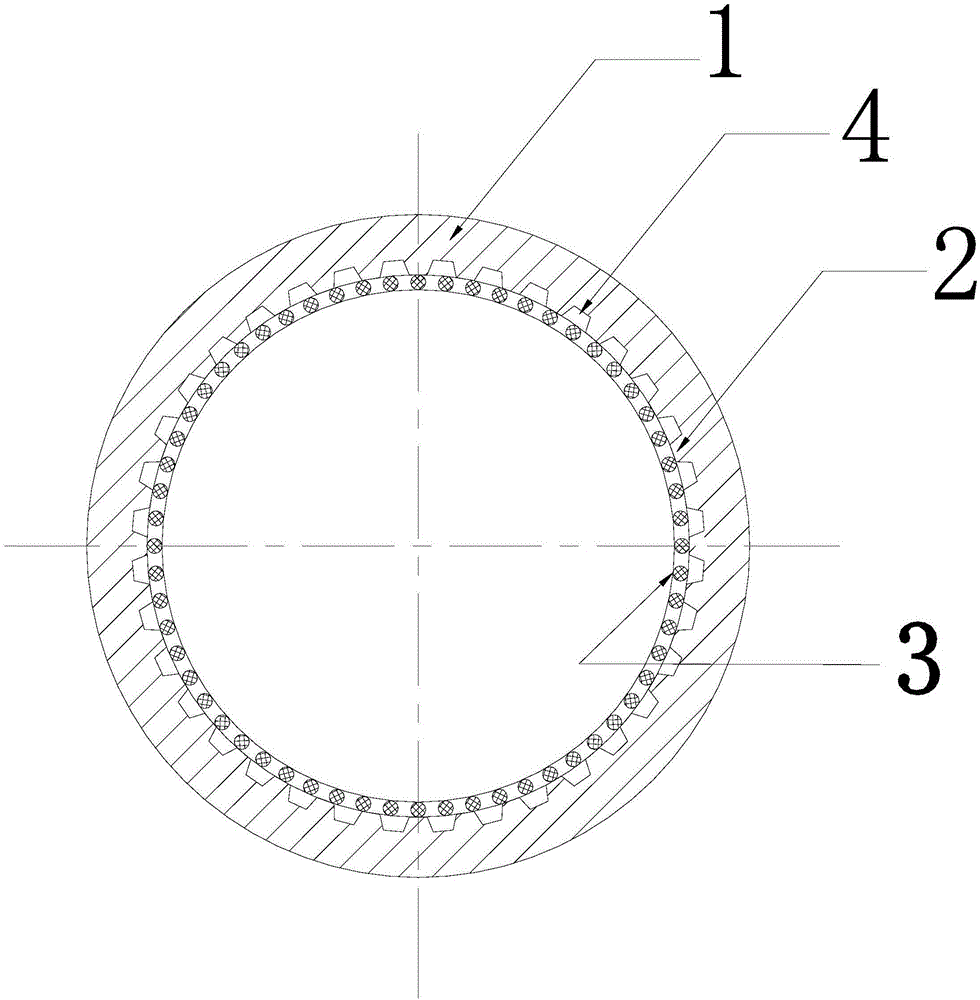

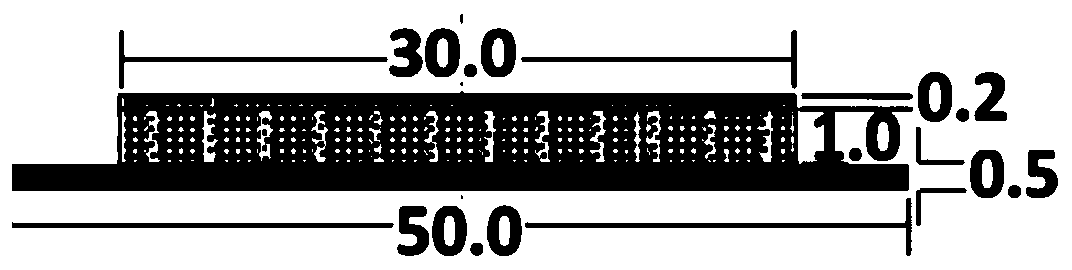

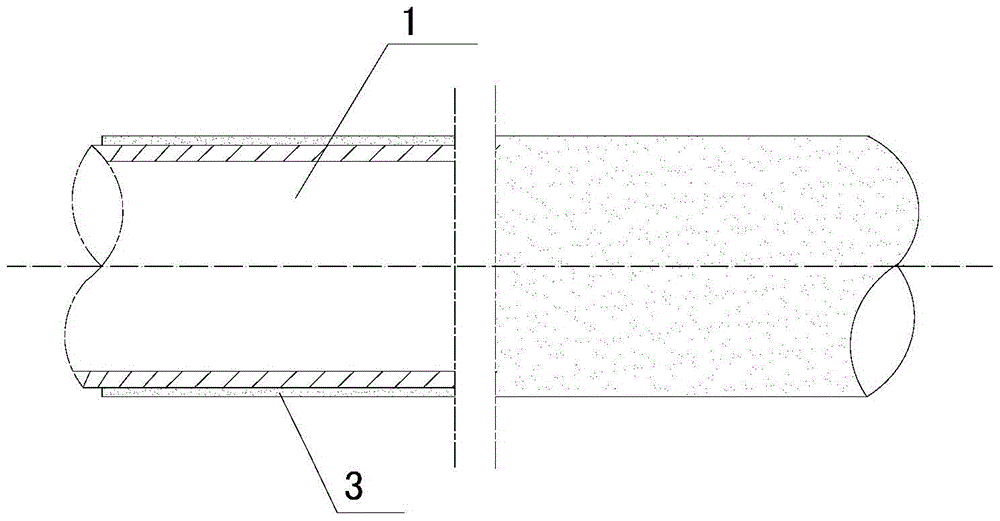

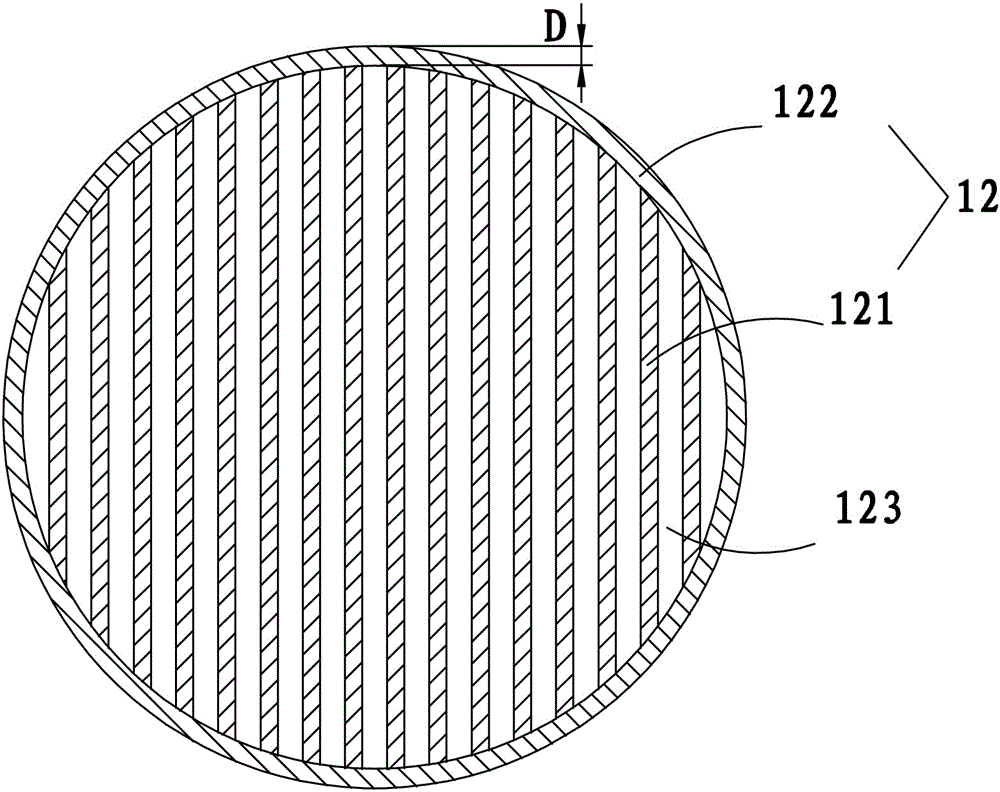

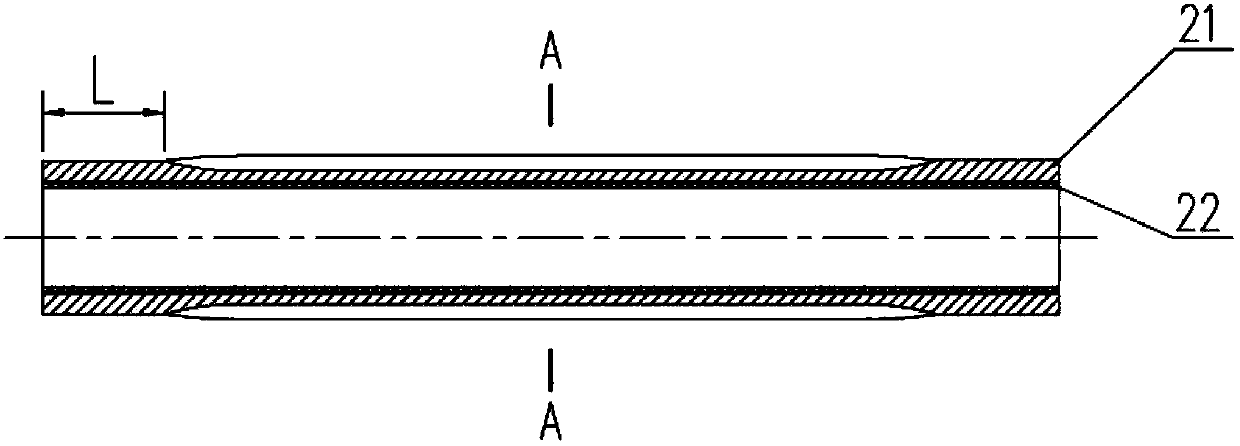

Internally-threaded evaporation heat exchange tube inlayed with wire mesh on inner surface

InactiveCN105157464AIncrease boiling heat transfer coefficientImprove heat transfer effectTubular elementsEngineeringMetal

The invention discloses an internally-threaded evaporation heat exchange tube inlayed with a metal wire mesh on the inner surface. The internally-threaded evaporation heat exchange tube comprises a tube body provided with an inlet end and an outlet end, wherein a plurality of linear ribs peripherally distributed at intervals and extending in the axial direction of the tube body and linear channels formed among the linear ribs are arranged on the inner surface of the tube body, at least one layer of cylindrical metal wire mesh is arranged in the tube body, and the peripheral face of the metal wire mesh is in contact with the tops of the linear ribs to cover the linear channels, so that a channel separated from a central tube cavity of the tube body is formed between the metal wire mesh and the linear channels. The heat exchange efficiency of the threaded heat exchange tube can be further improved.

Owner:苏州新太铜高效管有限公司

Waste heat recovery and power cooling combined supply system for ship gas turbine

ActiveCN112160808AImprove efficiencyReduce total irreversible lossRecuperative heat exchangersSteam engine plantsEngineeringSuperheater

The invention relates to a waste heat recovery and power cooling combined supply system for a ship gas turbine, and belongs to the technical field of ships and energy conservation. The waste heat recovery and power cooling combined supply system for the ship gas turbine comprises an ORC liquid supply pump, an ORC steam generator, an ORC superheater, an ORC turbine, an ejector, a refrigeration evaporator, a condenser, a low-pressure liquid supply pump, a low-pressure preheater, a low-pressure steam generator, a low-pressure superheater, a steam pocket, a mixer, a regulating valve, a stop valveand a throttle valve. According to the system, temperature matching of heat exchange fluid and self-adaption of a high-temperature and low-temperature two-stage cycle working media are achieved by fully utilizing the characteristic of temperature change and phase change of a non-azeotropic mixed working media and the characteristic that the thermodynamic property difference of a vapor phase and aliquid phase is large during balance, the total irreversible loss of the system is reduced, and the total efficiency of composite cycle is improved.

Owner:KUNMING UNIV OF SCI & TECH

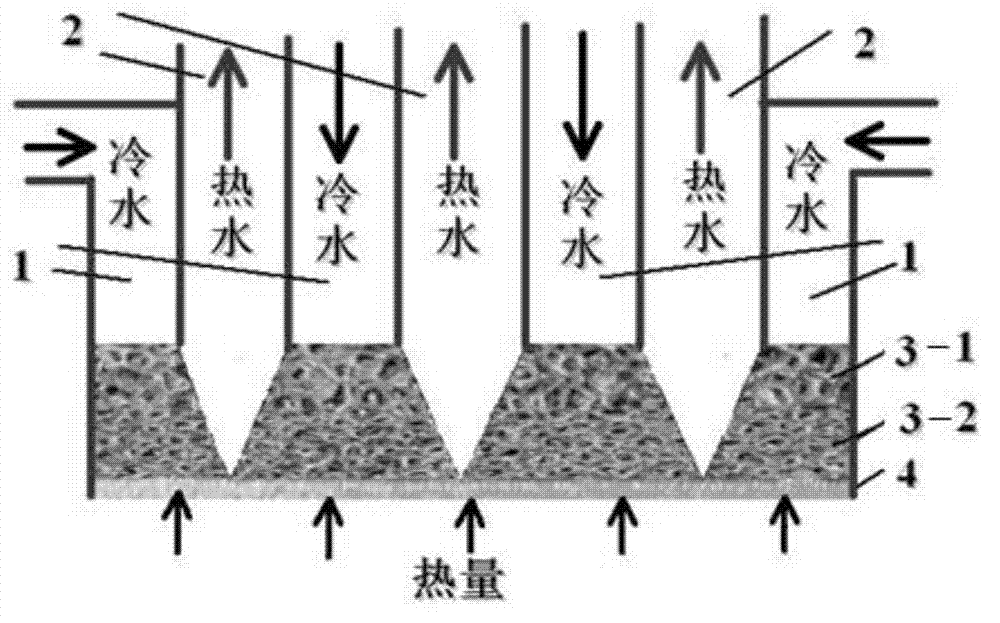

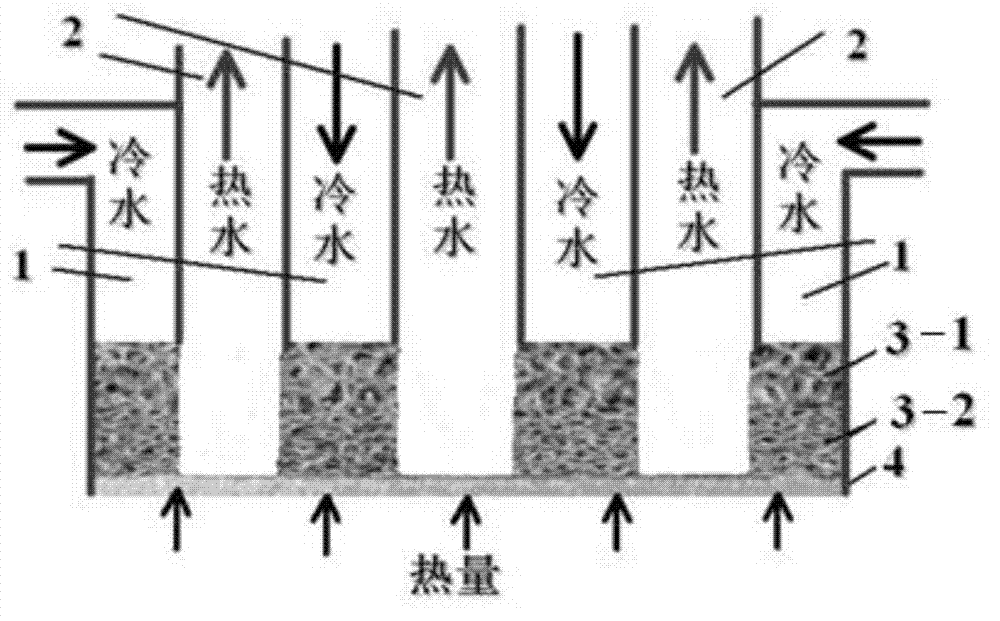

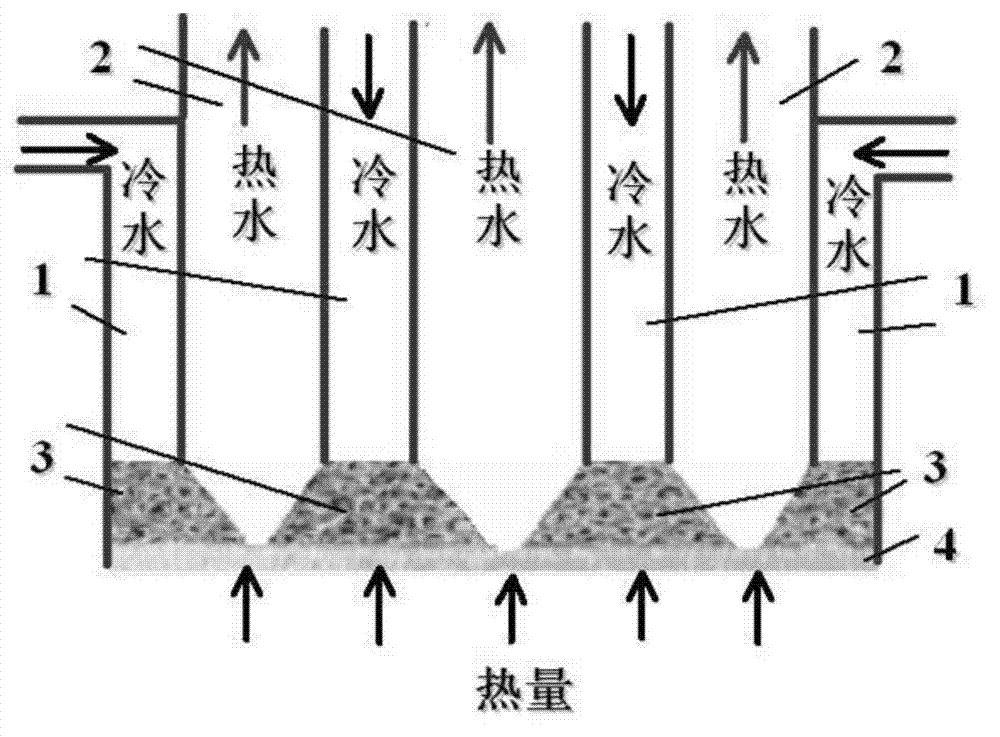

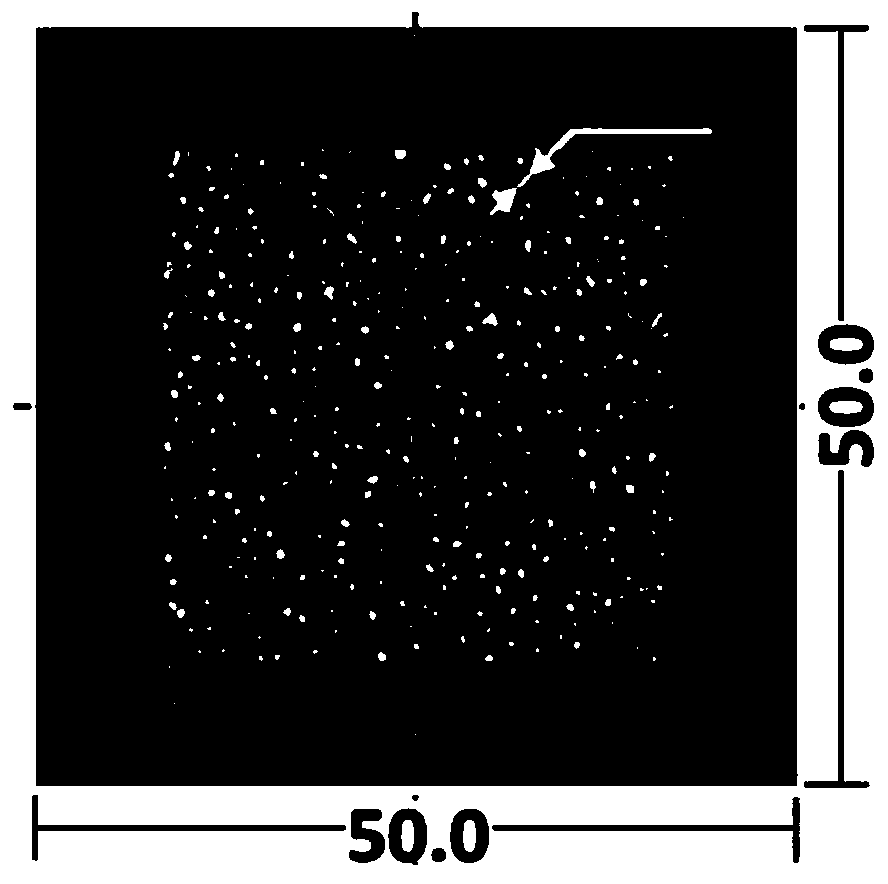

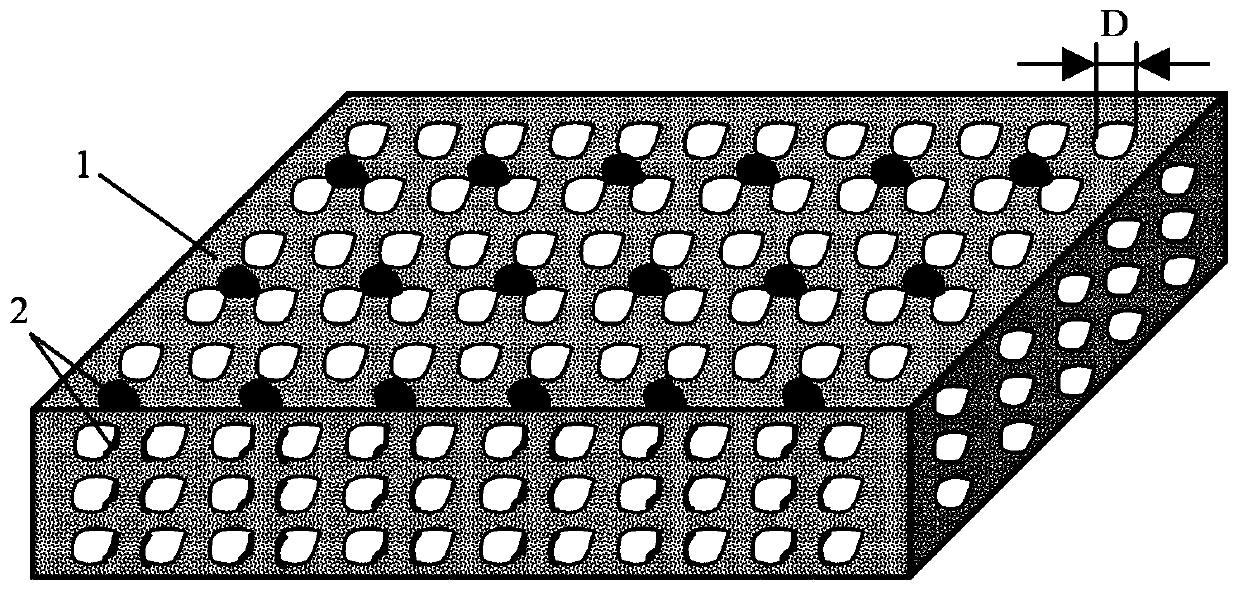

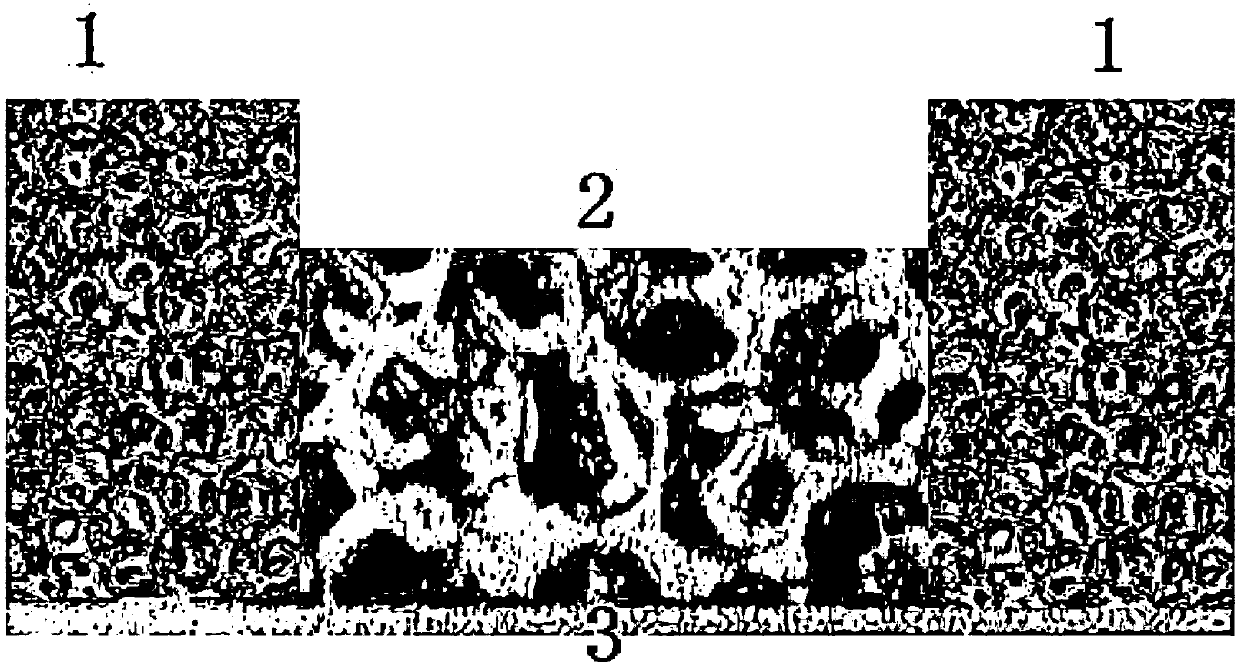

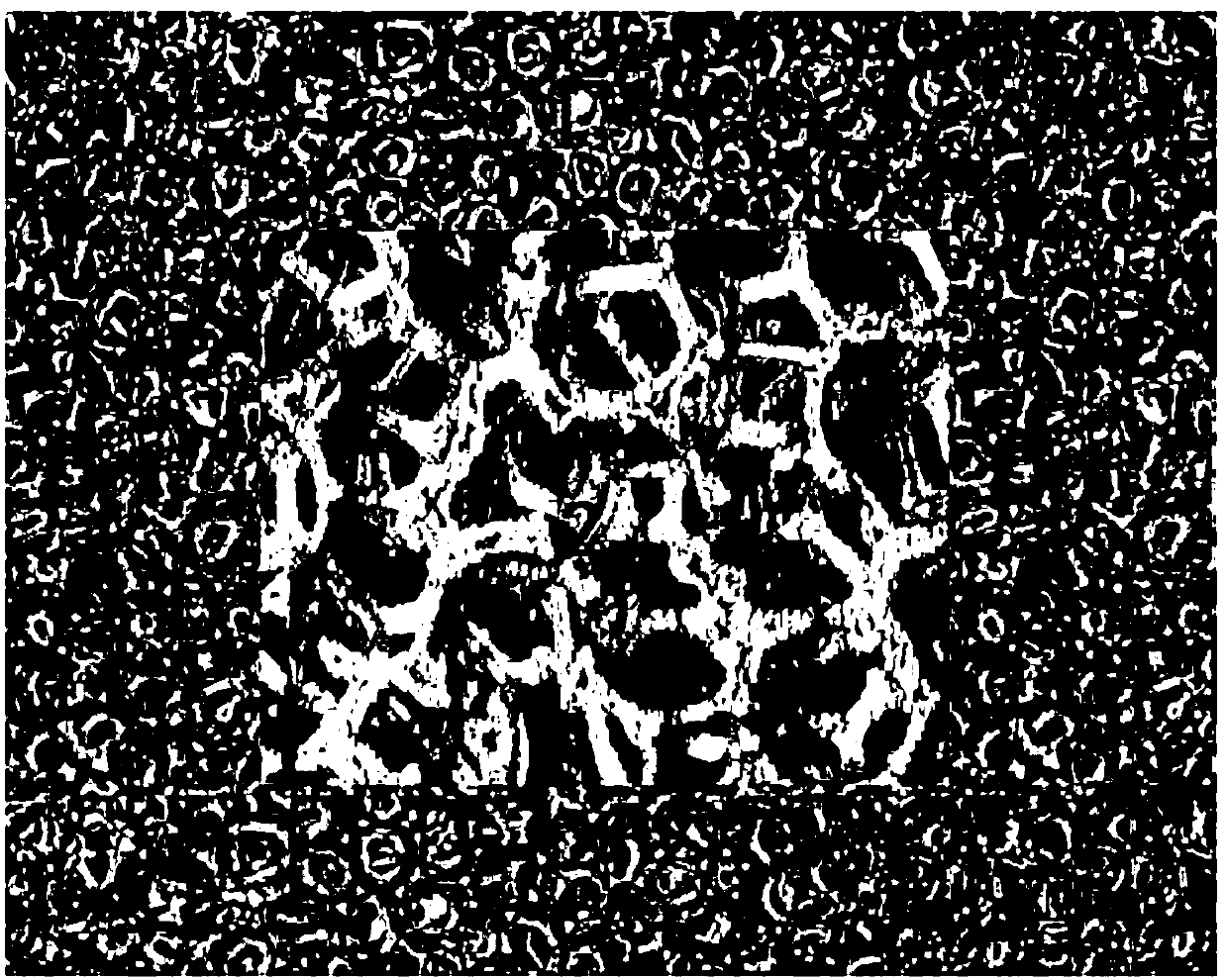

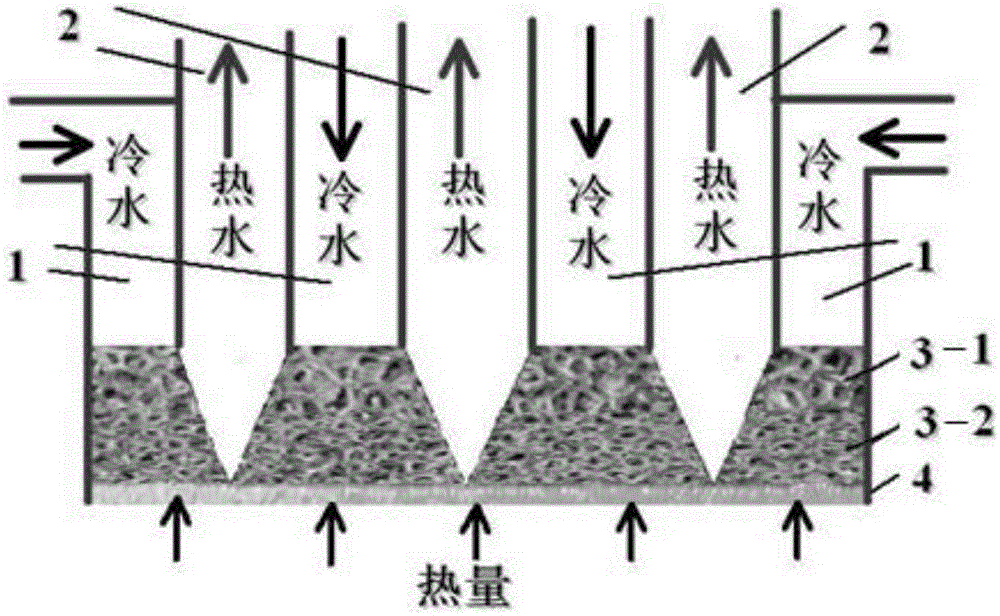

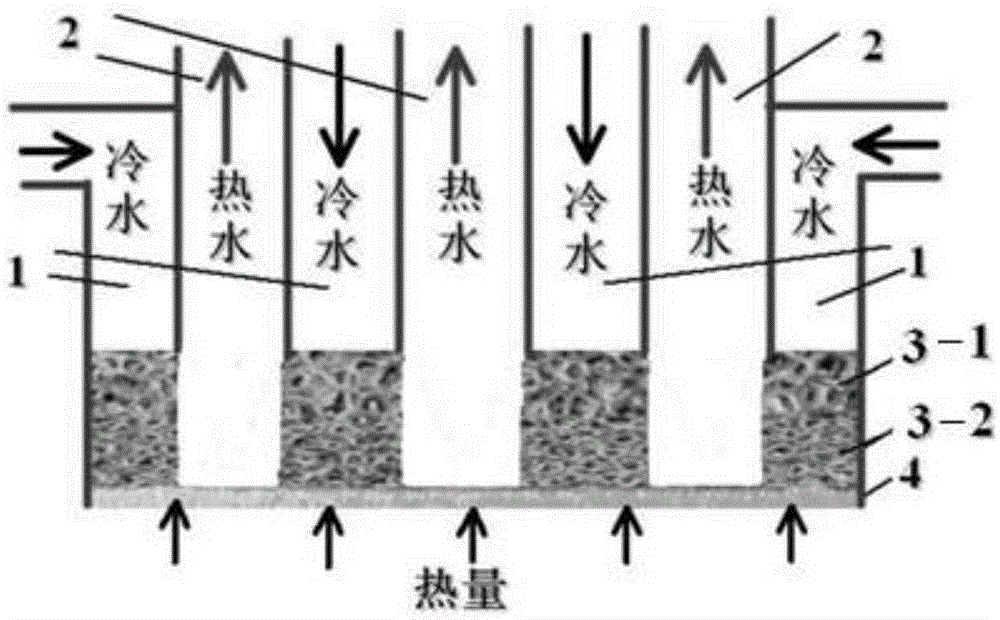

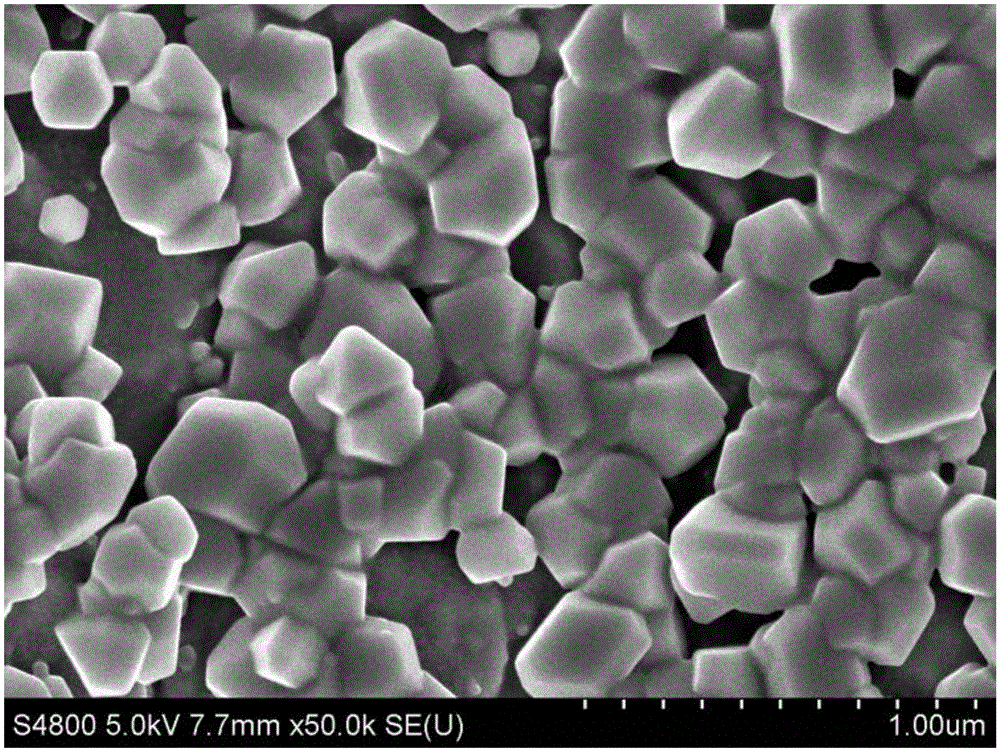

Free particle/porous medium composite enhanced boiling structure and preparation method thereof

ActiveCN110842202AAdd spoilersFast heat conductionHeat transfer modificationThermodynamicsPorous medium

The invention discloses a free particle / porous medium composite enhanced boiling structure. The structure comprises a substrate and a porous matrix structure formed on the surface of the substrate, aplurality of pore cavities are formed in the porous matrix structure, and free particles capable of moving in the pore cavity are dispersed in the pore cavity. When the free particle / porous medium composite enhanced boiling structure is prepared, metal particles are sintered to prepare a porous material matrix, the porous material matrix is drilled to form the pore cavity, and then the pore cavityis filled with free particles and sealed. The structure is based on the enhancing characteristics of nucleation activation in the boiling heat transfer process and liquid supply of a liquid absorbingcore to a nucleation site, bubbles are prevented from being mixed and the liquid backflow resistance is reduced by means of bubble nucleation and liquid supply partition. Meanwhile, the free particles collide with one another in the boiling process, so that heat transfer, microlayer evaporation and convective heat transfer in working fluid are enhanced, bubble nucleation is easy, the growth speedis high, the separation frequency is high, and therefore the enhanced boiling heat transfer is realized.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Evaporating pipe with narrow-gap steam exhaust opening

ActiveCN105066761ADisengagement speed reducedReduced exit speedEvaporators/condensersTubular elementsChinese charactersAcute angle

The invention discloses an evaporating pipe with a narrow-gap steam exhaust opening. T-shaped fins are arranged on the outer surface of the evaporating pipe; a hole is formed between the adjacent fins; spiral channels are formed in the inner surface of a heat transfer pipe. The evaporating pipe is characterized in that a plurality of grooves which extend along the axial direction, the radial direction and the directions which form different included angle together with the axial direction are formed in the outer surface; the intersection of the grooves which extend in different directions is in a shape like a Chinese character 'mi'; a channel which is communicated with the holes outside the pipe is formed in the intersection, i.e., an exhaust opening for steam in the holes is formed; the exhaust opening is in a narrow-gap shape; meanwhile, triangular bulges are formed in the side surfaces of the T-shaped fins, and are protruded on the side surfaces, which are close to the fins as much as possible; the included angles of the triangular bulges and the surfaces of the fins are acute angles. The evaporating pipe with the narrow-gap steam exhaust opening disclosed by the invention works with a low-pressure refrigerant medium, evaporation cores are easy to nucleate and large in number; the bubble detachment frequency is high; the heat exchange effect is good.

Owner:山东恒辉节能技术集团有限公司

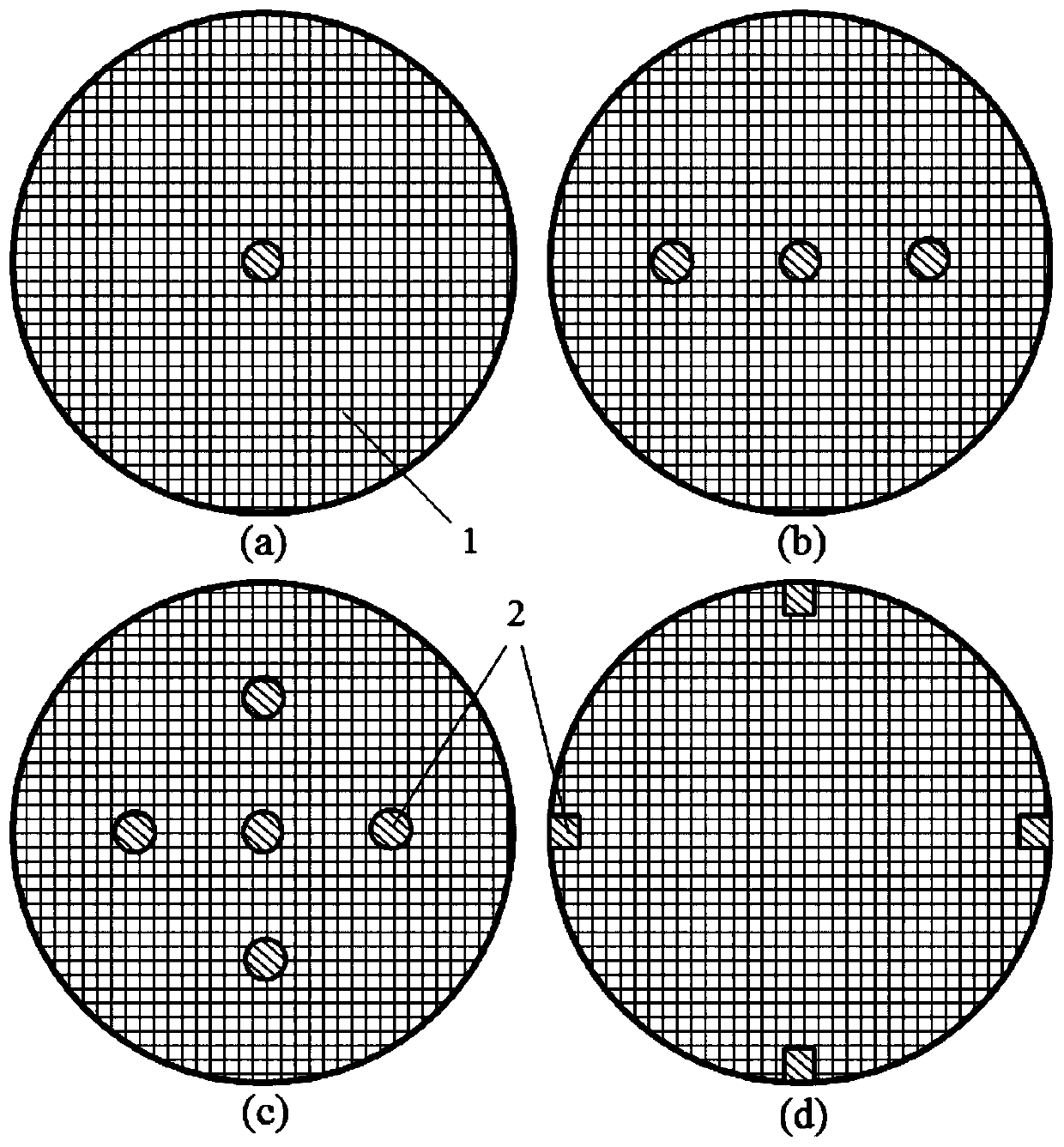

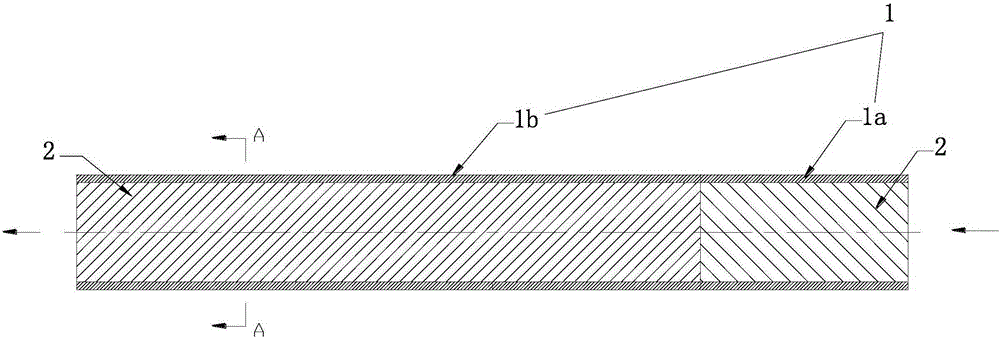

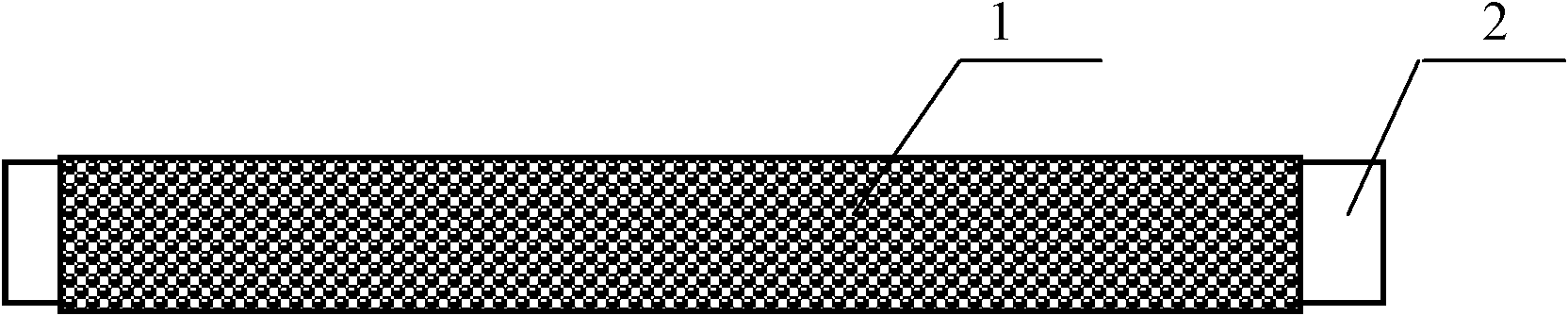

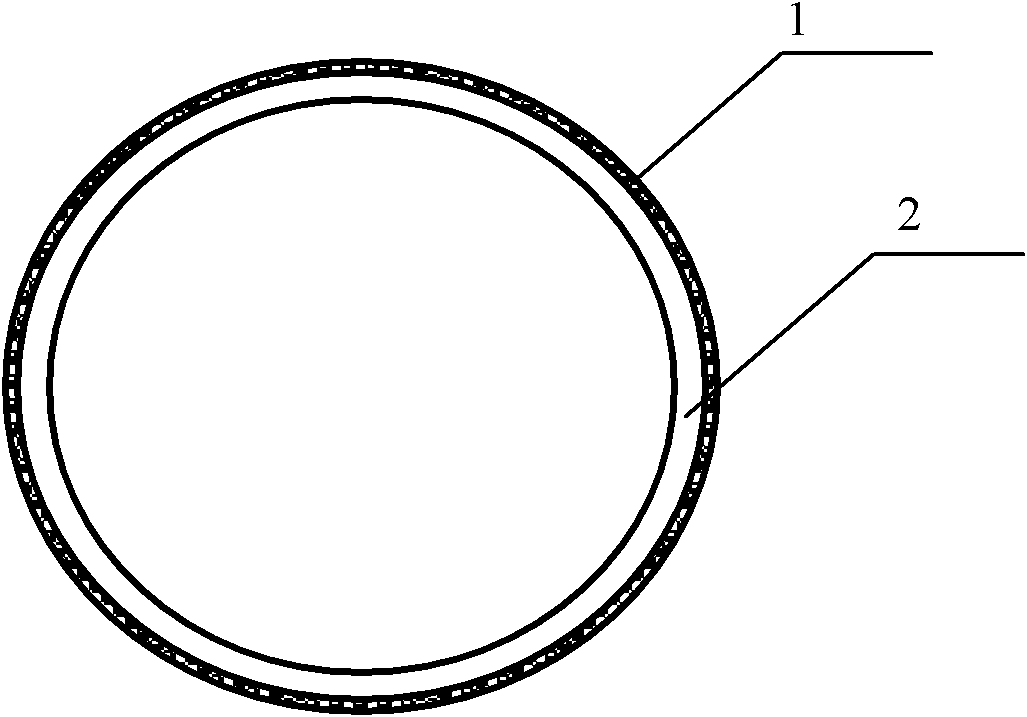

Foam metal with mixed wet surface and preparation method thereof

InactiveCN110551998AEnhanced Capillary SuctionReduce disengagement resistanceMetallic material coating processesMicro nanoElectronic component

The invention discloses foam metal with a mixed wet surface and a preparation method thereof. The foam metal comprises a super-hydrophilic surface (1) obtained through a chemical oxidization process and a foam meal surface locally covered by a super-hydrophilic film (2). The foam metal is characterized in that the super-hydrophilic surface (1) is provided with a micro-nano binary surface structure, wherein the main component of the super-hydrophilic film (2) is a high-molecular compound with a hydrophobic group. The foam metal is used in strengthening of boiling heat transfer, can improve boiling heat transfer property, and meets heat dissipation needs of high-integration electronic components and parts and heat exchange equipment with high heat exchange amount. The super-hydrophilic surface (1) in the foam metal has extremely strong lyophilic property, reduces gas bubble separating resistance, improves capillary liquid-absorbing ability, and obviously improves boiling heat transfer property; the super-hydrophilic film (2) which can be locally distributed can quicken a nucleation process of gas bubbles, a boiling start point is reduced, and boiling heat transfer property of foam metal is further strengthened.

Owner:SOUTHEAST UNIV

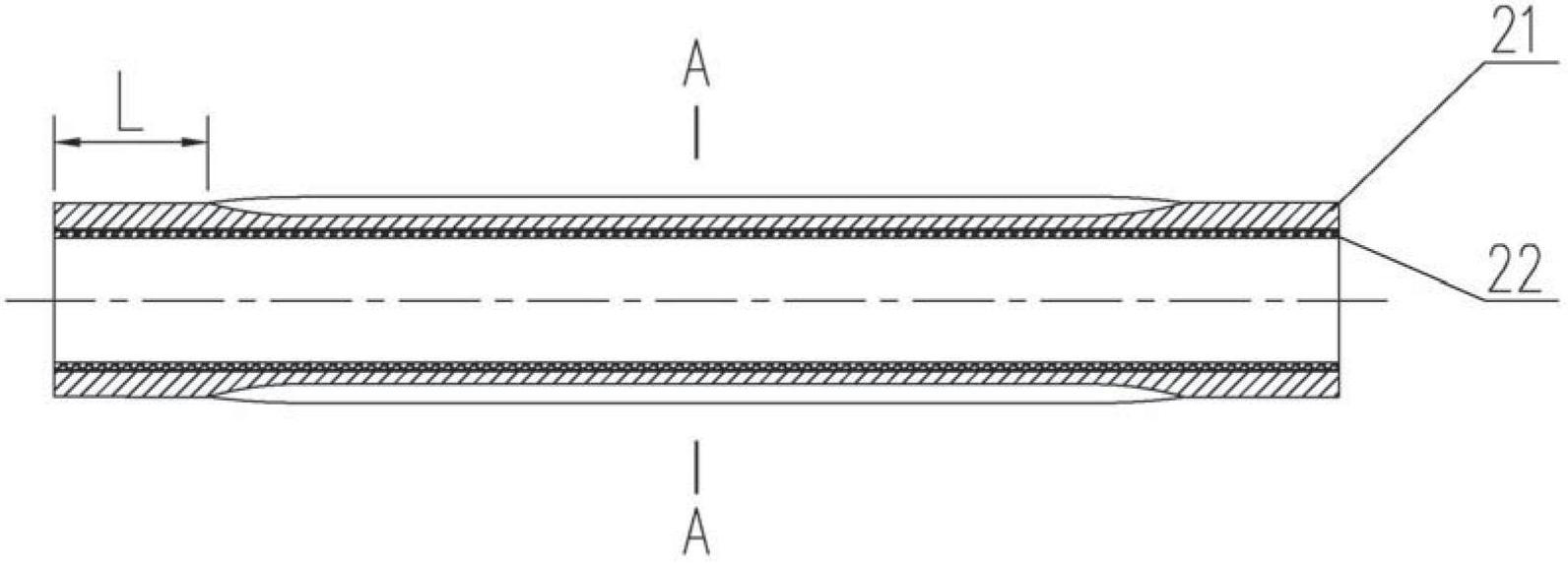

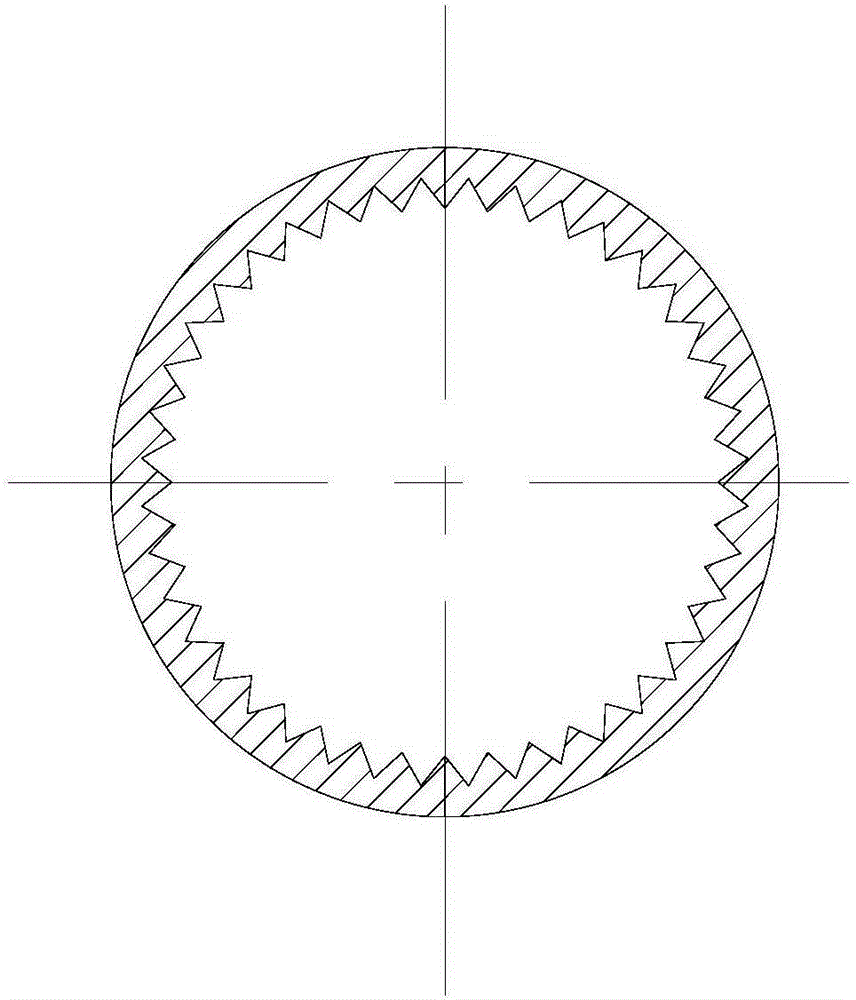

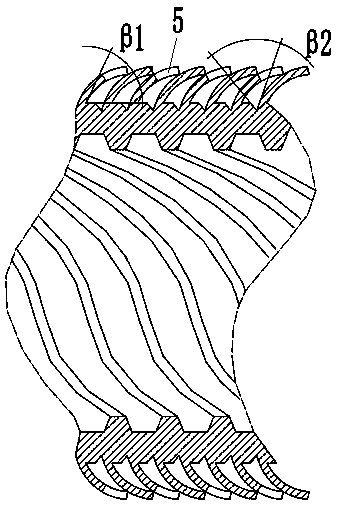

Inner-thread evaporation heat exchange pipe with two sections of different spiral tooth-shaped structures

InactiveCN105202961AIncrease boiling heat transfer coefficientTubular elementsEvaporationEngineering

The invention discloses an inner-thread evaporation heat exchange pipe with two sections of different spiral tooth-shaped structures. The inner-thread evaporation heat exchange pipe comprises a pipe body, wherein the inner surface of the pipe body is provided with a plurality of spiral racks with a certain spiral lead angle and a groove channel formed between the spiral racks; the pipe body is composed of a first heat exchange pipe section and a second heat exchange pipe section; and the spiral racks in the first heat exchange pipe section and the spiral racks of the second heat exchange pipe section have different rack quantities, different rack heights, different spiral lead angles and different spiral directions. The inner-thread evaporation heat exchange pipe is divided into two heat exchange sections in the same inner-thread heat exchange pipe along the flowing direction of a refrigerating agent; and each section of the spiral racks have the different rack quantities, different rack heights, different spiral lead angles and different spiral directions, so that the high-boiling heat exchange coefficient can be greatly improved and the heat exchange efficiency is improved.

Owner:苏州新太铜高效管有限公司

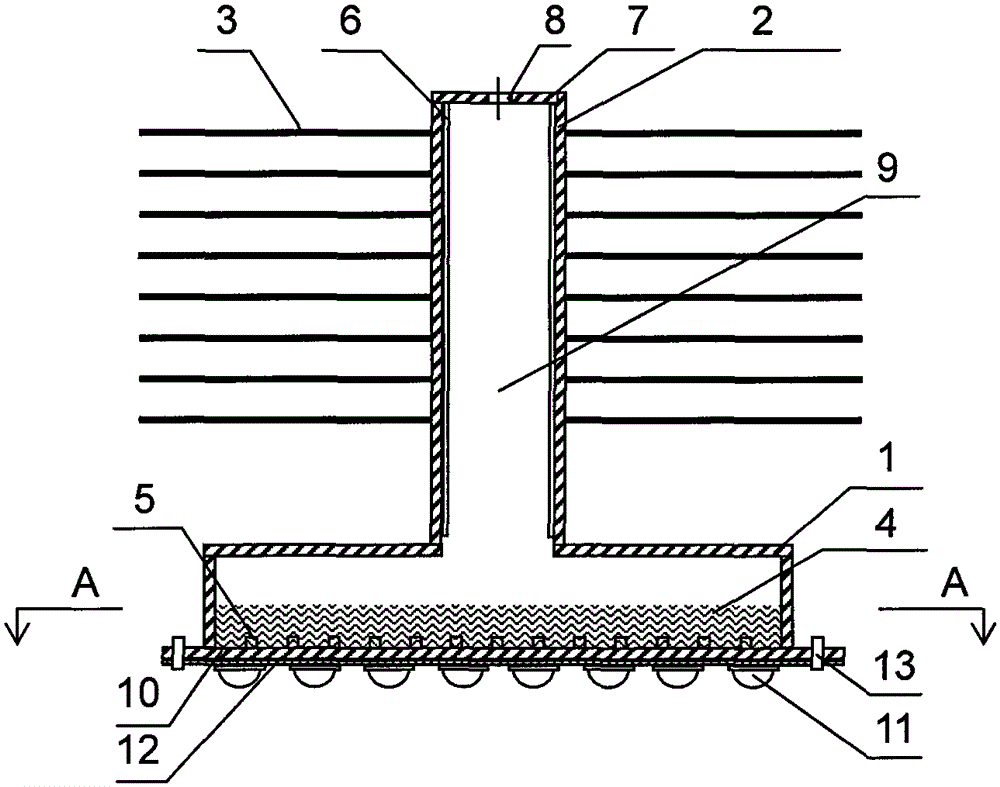

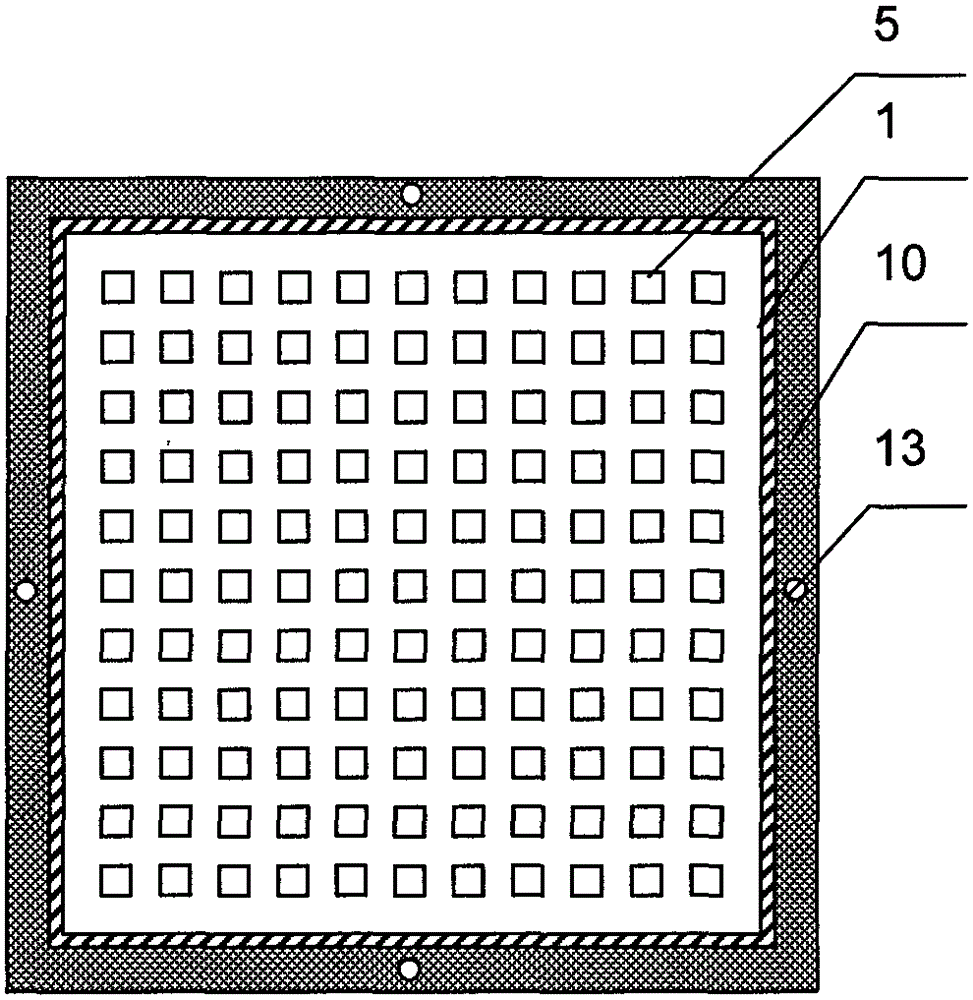

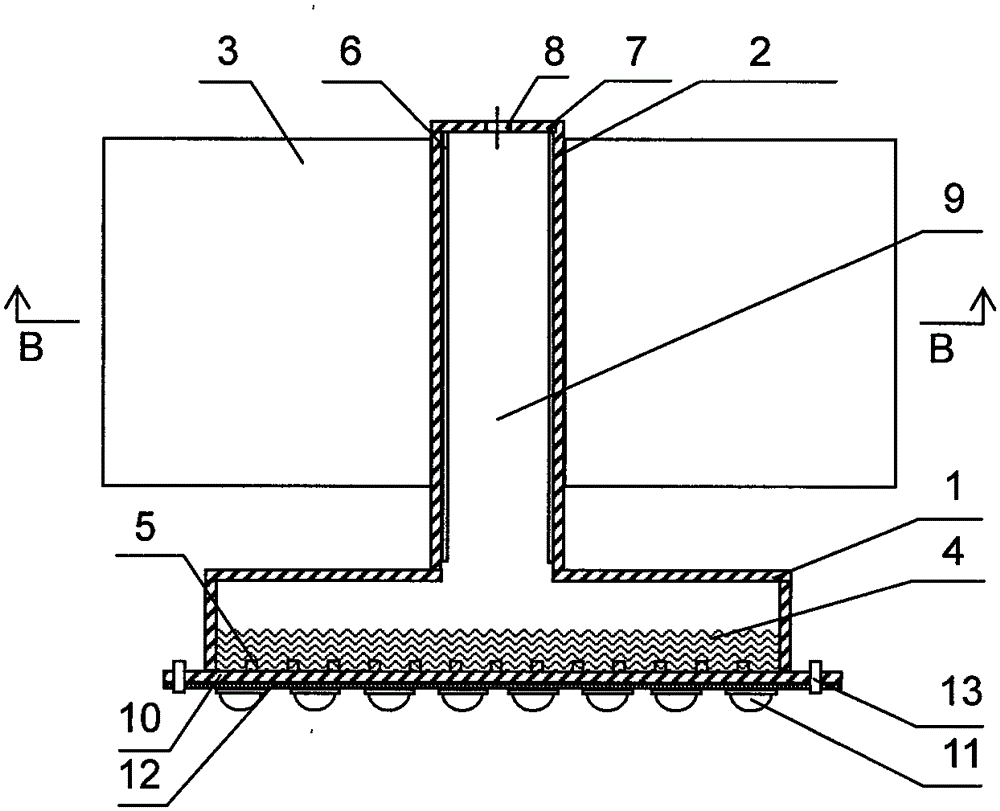

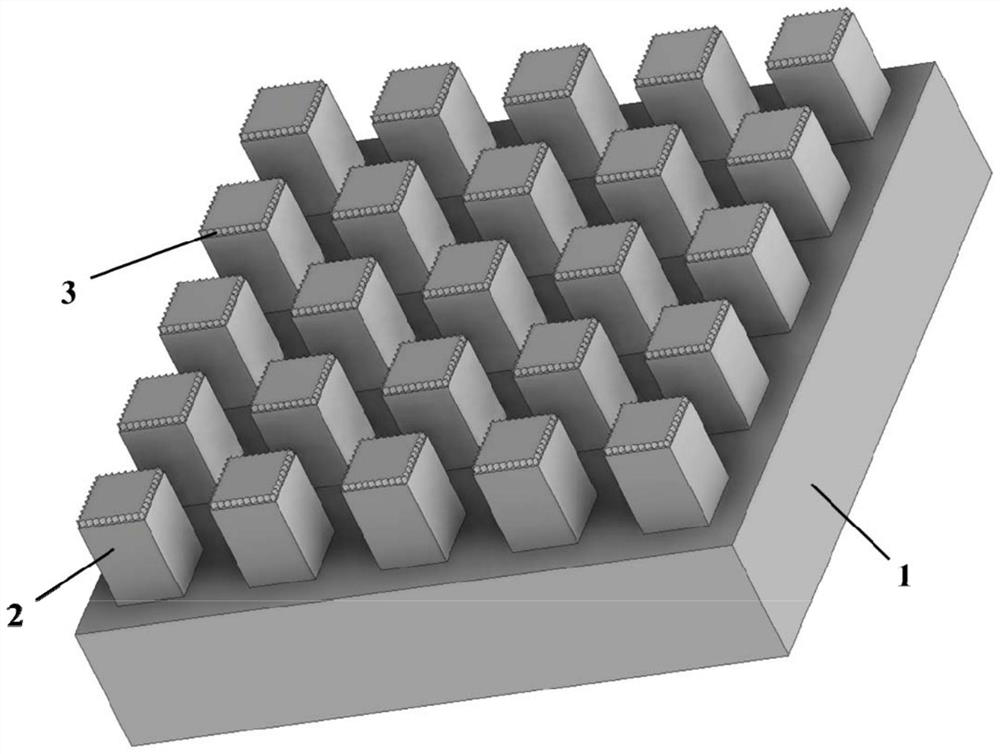

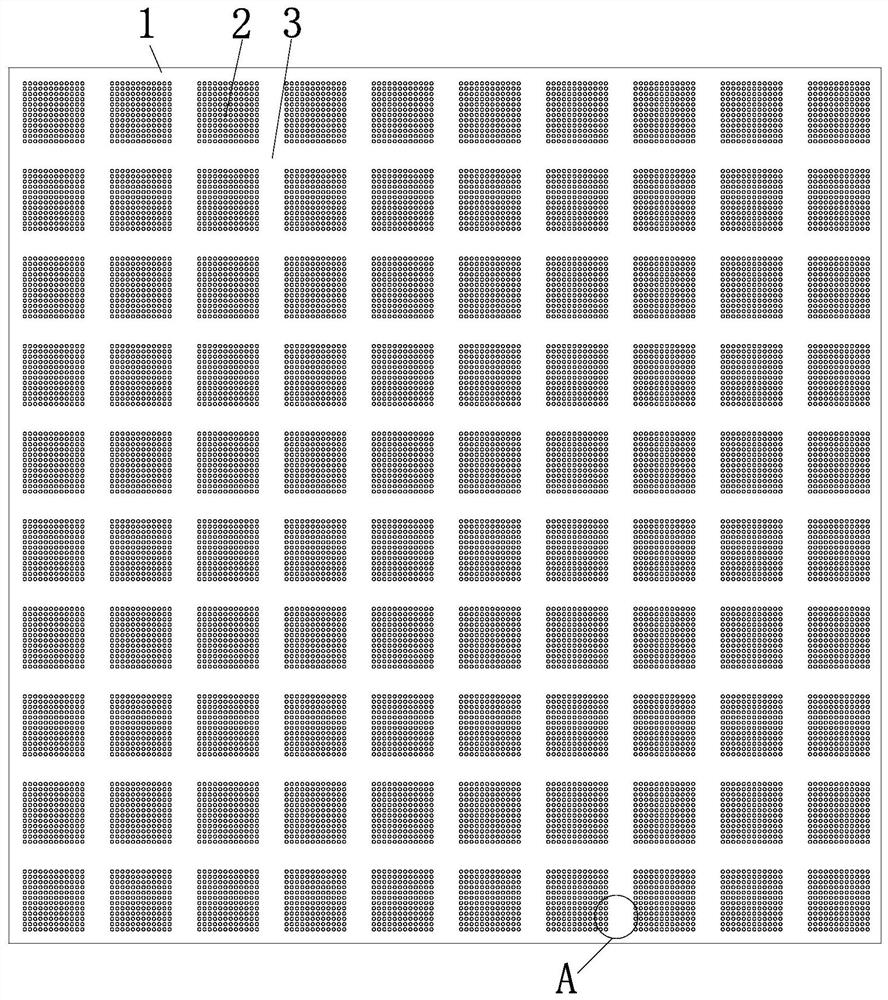

Mixed wettability micro-nano composite enhanced heat exchange structure and preparation method thereof

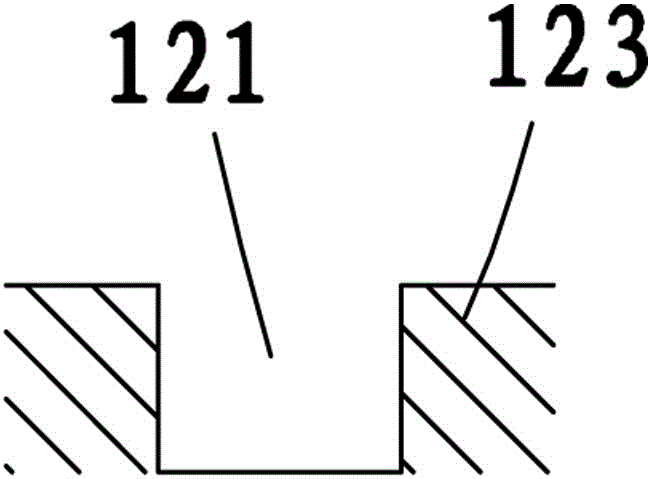

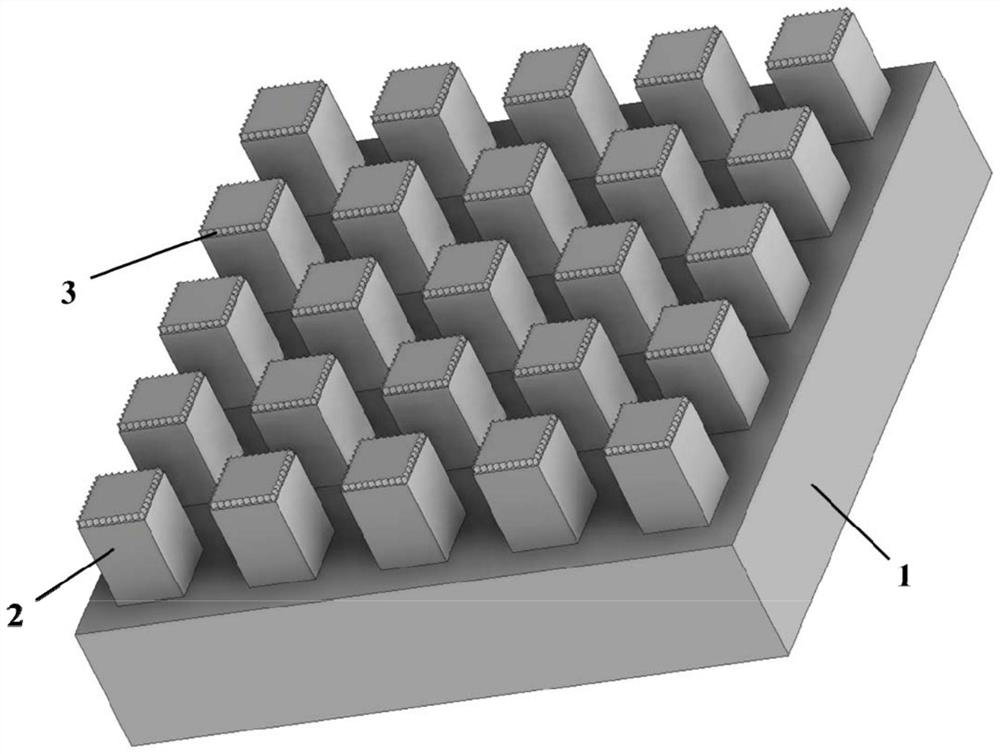

ActiveCN111834309AEfficient separationLeave in timeSemiconductor/solid-state device detailsSolid-state devicesPhysicsChemistry

The invention discloses a mixed wettability micro-nano composite enhanced heat exchange structure. The structure comprises a heat dissipation substrate, wherein a plurality of square micro-cylindricalarray units and groove channels arranged among the micro-cylindrical array units are etched on the heat dissipation substrate. Each micro-cylinder array unit comprises a plurality of micro-cylinderswhich are arranged in order, nanowires are arranged on the groove channels and the micro-cylinders, the diameter of the nanowires ranges from 200 nm to 500 nm, and the height of the nanowires ranges from 10 micrometers. The invention further discloses a manufacturing method of the mixed wettability micro-nano composite enhanced heat exchange structure. The micro-cylindrical array unit and the nanowire structure adopted by the invention can effectively enhance the boiling heat transfer coefficient of high heat flux and delay the boiling dry burning phenomenon.

Owner:XIAN UNIV OF SCI & TECH

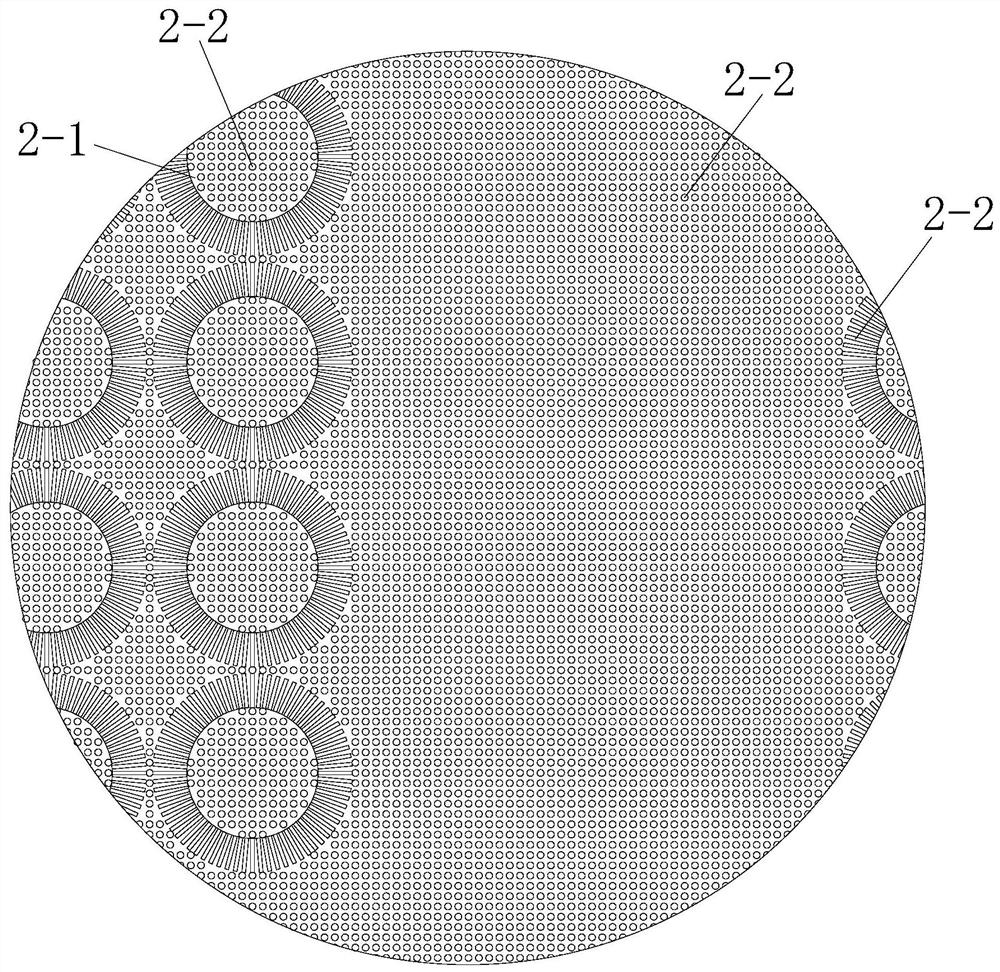

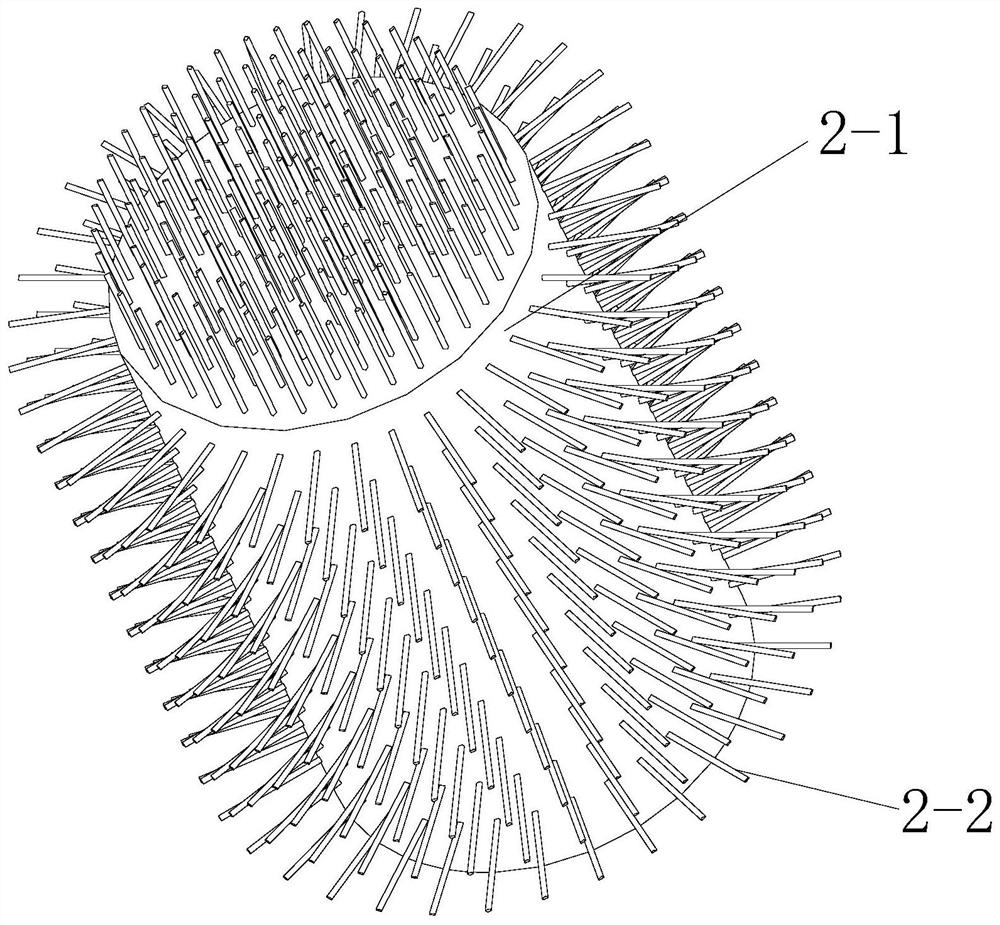

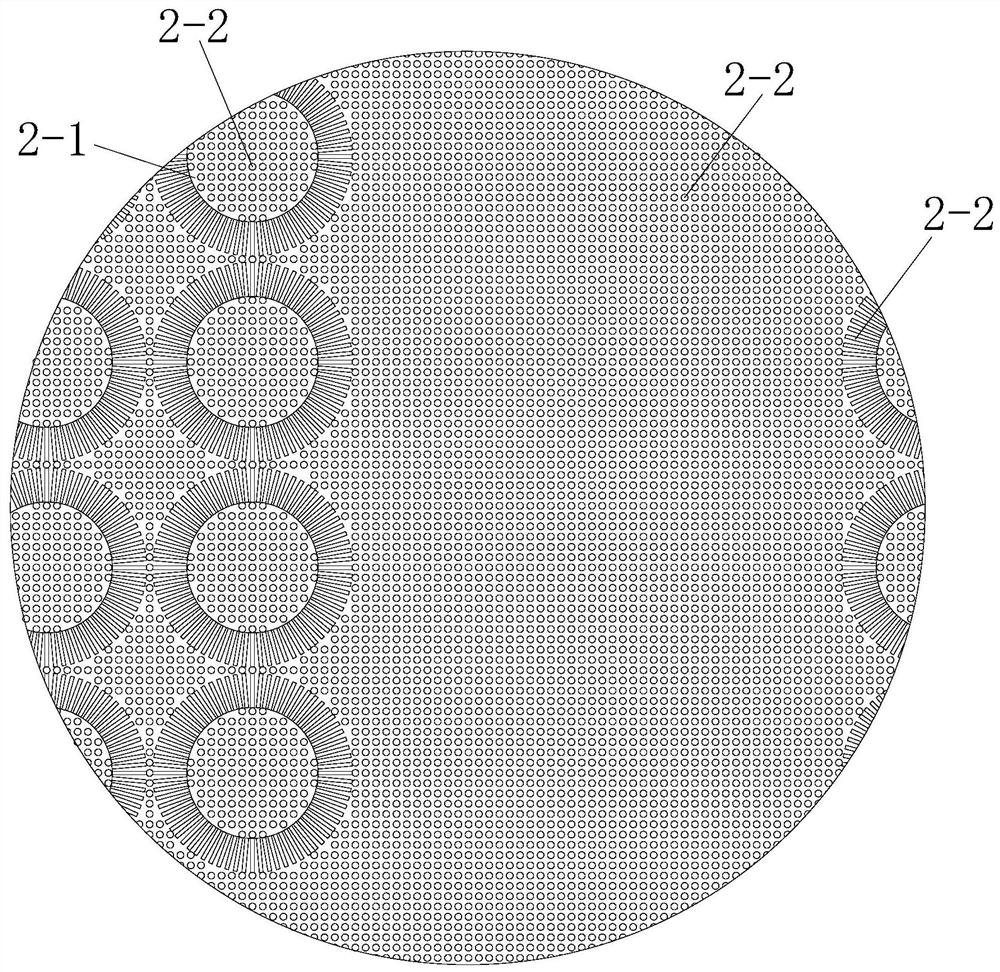

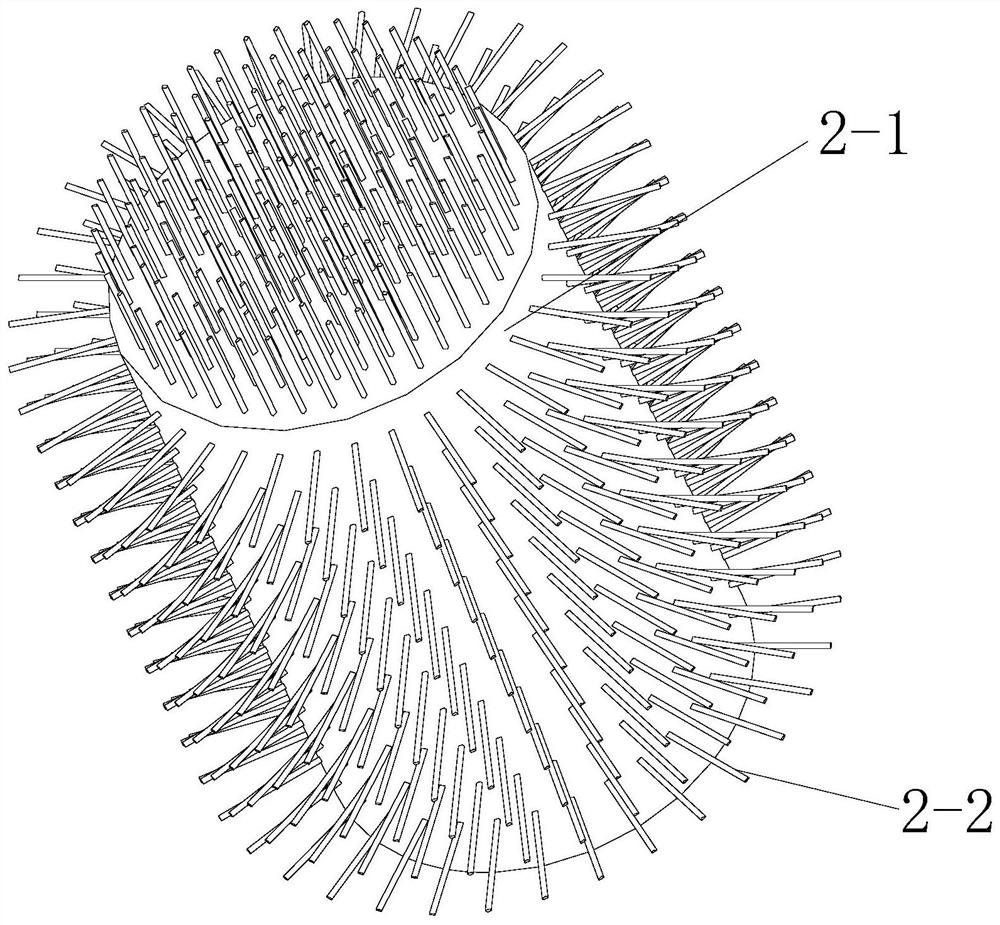

Variable density metal foam radiator

InactiveCN107706161ALarge specific surface areaStrong turbulenceSemiconductor/solid-state device detailsSolid-state devicesEvaporationElectronic chip

A variable density metal foam radiator comprises a heat transfer substrate and through-hole metal foams of different sizes respectively sintered on the heat transfer substrate. The square through-holemetal foams are located in the middle part of the heat transfer substrate, and the annular through-hole metal foams are located in the outer periphery of the square through-hole metal foams and havesmaller pores. According to the invention, the through-hole metal foams with the smaller pores have larger capillary force, as a circulation way to supplement a liquid required for evaporation, the through-hole metal foams with the larger pores are more conducive to the escape of bubbles so that the through-hole metal foams can separate the circulation path of the supplement liquid from the bubbleescape path, the resistance encountered when the bubbles escape is greatly reduced, and thus the boiling heat transfer coefficient is increased. The maximum boiling heat transfer coefficient is 3 times more than that of a smooth copper plate. The boiling initial wall superheat degree is reduced to 2K. The special structure in the invention makes the temperature distribution of the heat transfer substrate more uniform and more suitable for the heat radiation of an electronic chip. Therefore, the heat transfer device of the invention has high heat transfer efficiency and can be widely used in the field of heat radiation of electronic devices.

Owner:SHANGHAI JIAO TONG UNIV

Organic mixed working medium of steam turbine

InactiveCN103694962AImprove heat transfer effectIncrease boiling heat transfer coefficientHeat-exchange elementsCondensation processBoiling point

The invention belongs to the technical field of organic working mediums and in particular relates to an organic mixed working medium of a steam turbine. The sum of the mass percentage of the components is 100%; the working medium consists of R245fa and R123; the mass percentage of the R245fa to the R123 is (60-70) : (30-40). The working medium has different-temperature thermodynamic characteristics in a constant-pressure evaporation or condensation process. The working medium is optimally matched with cold / heat source temperature in evaporation equipment or condensation equipment by selecting the components of the mixed organic working medium and optically selecting the proportion of the components. Bubbles generated by the low-boiling-point organic working medium in the pipe generates perturbation action on the mixed organic working medium by utilizing the non-azeotropic characteristic of the mixed working medium, so that a heat transfer enhancement effect is achieved, the boiling heat transfer coefficient is increased, the optimal region of the heat transfer coefficient is enlarged, the heat transfer coefficient is increased by 6 to 10% through experimental test, and the area of heat transfer equipment is reduced.

Owner:ZIBO SANGTE POWER EQUIP

A power-cooling combined power supply system for marine gas turbine waste heat recovery

ActiveCN112160808BImprove efficiencyReduce total irreversible lossRecuperative heat exchangersSteam engine plantsWorking fluidSuperheater

Owner:KUNMING UNIV OF SCI & TECH

High-density through-hole metal foam heat sink for electronic devices based on impinging jet

ActiveCN103117258BPromote escapeReduce resistanceDigital data processing detailsSemiconductor/solid-state device detailsHeat sinkMetal foam

Owner:SHANGHAI JIAOTONG UNIV

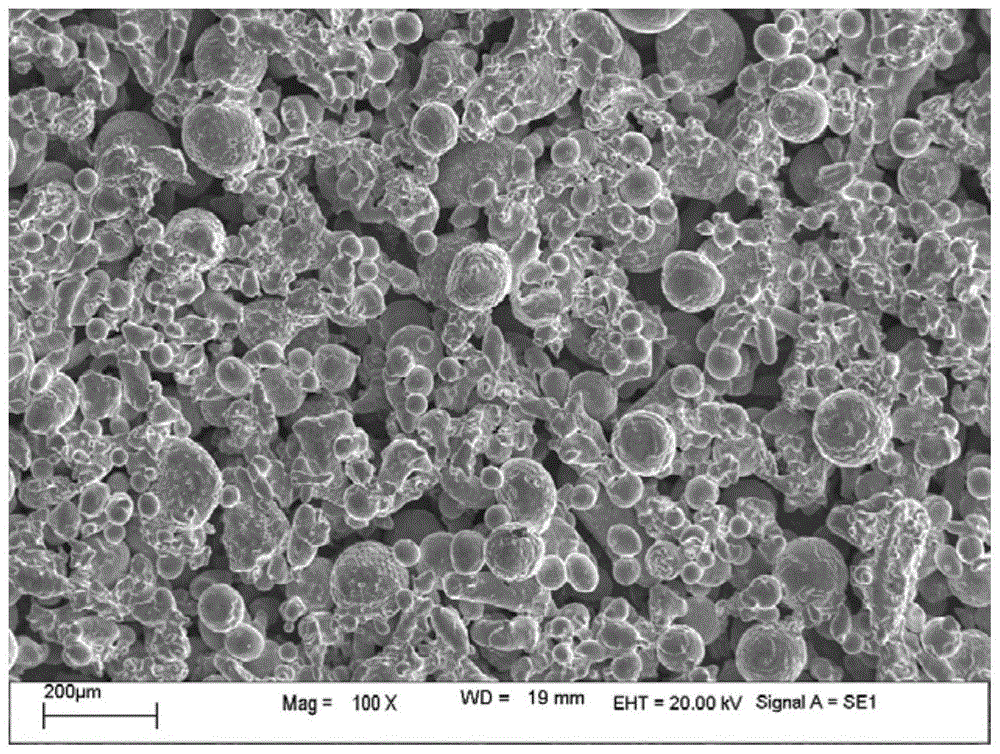

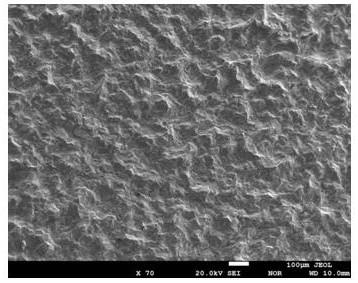

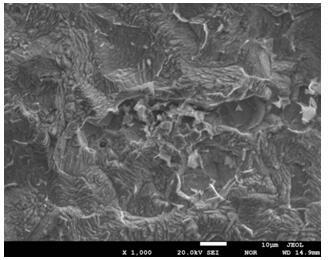

A kind of metal alloy material and its use

ActiveCN104263993BMeet the requirements of the national standardNo sheddingTransportation and packagingMetal-working apparatusMetal alloyPorous layer

A metal alloy material, which contains 2-10wt% of Ni, 10-20wt% of Zn, 5-10wt% of Sn, the balance of Cu and unavoidable impurities. The material provided by the invention can be used to prepare copper-nickel alloy surface porous tubes. The metal alloy material provided by the invention can make the porous layer on the surface of the porous tube achieve metallurgical bonding with the base tube at a suitable temperature, which can not only avoid damage to the performance of the base tube at an excessively high sintering temperature, but also solve the problem of excessively low sintering temperature. Problems such as poor bonding strength of the porous layer, poor corrosion resistance, and short life occur at the sintering temperature.

Owner:北京广厦环能科技股份有限公司

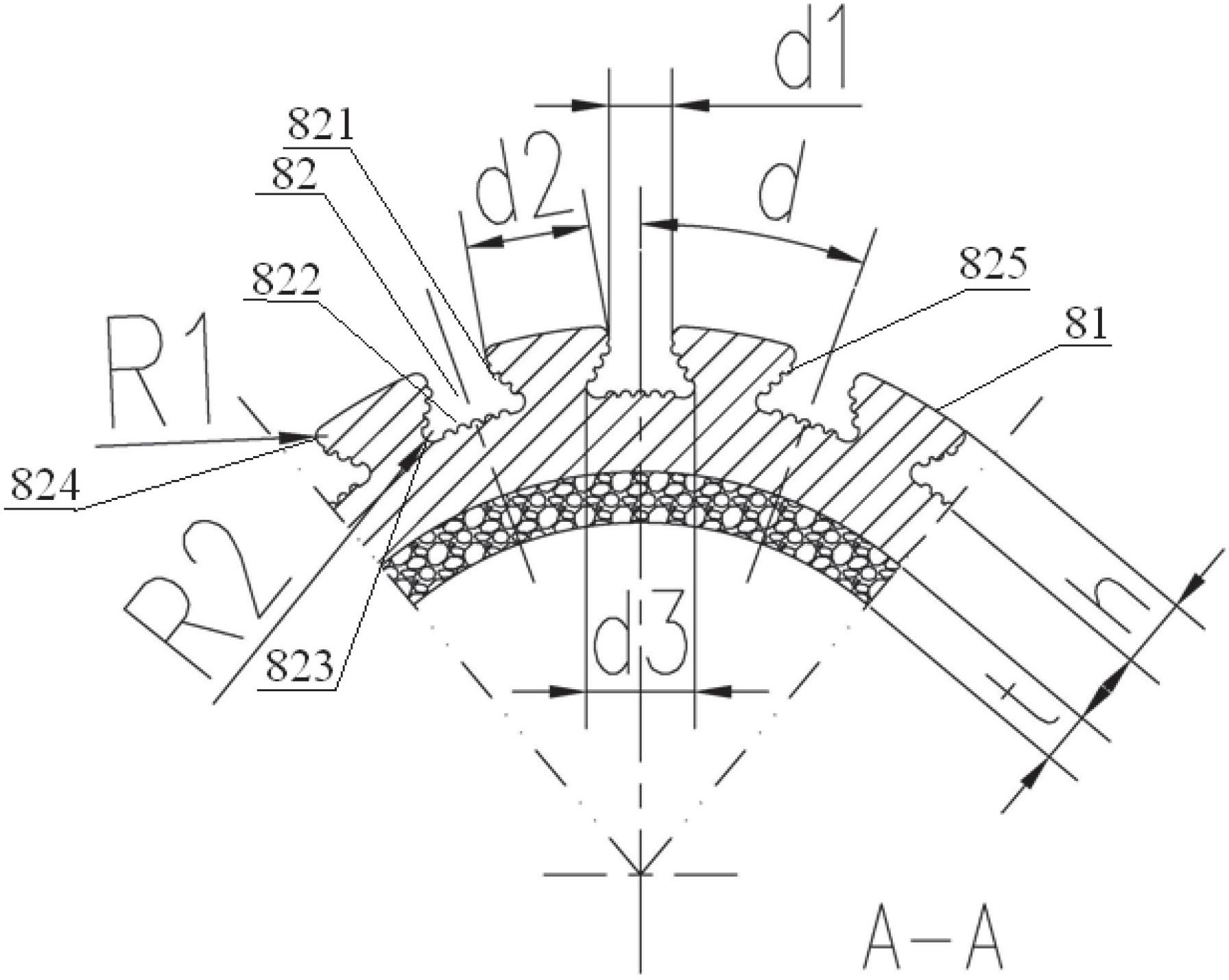

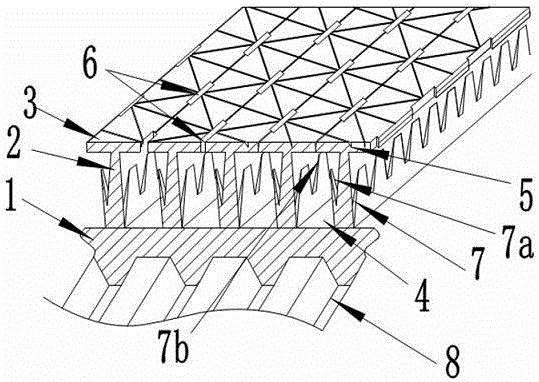

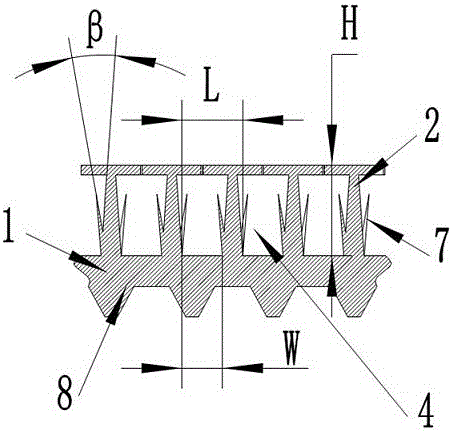

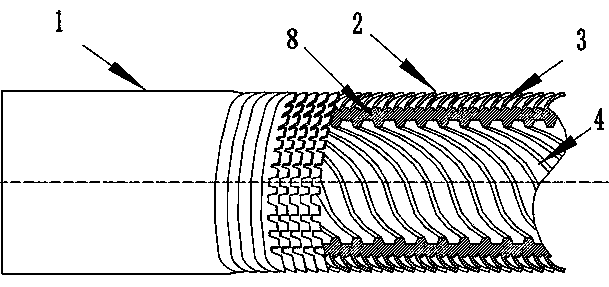

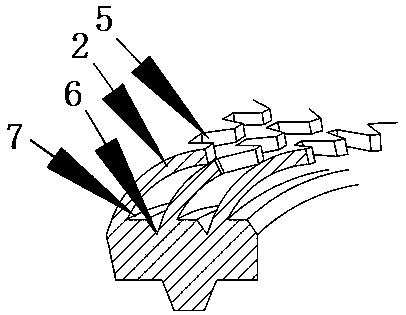

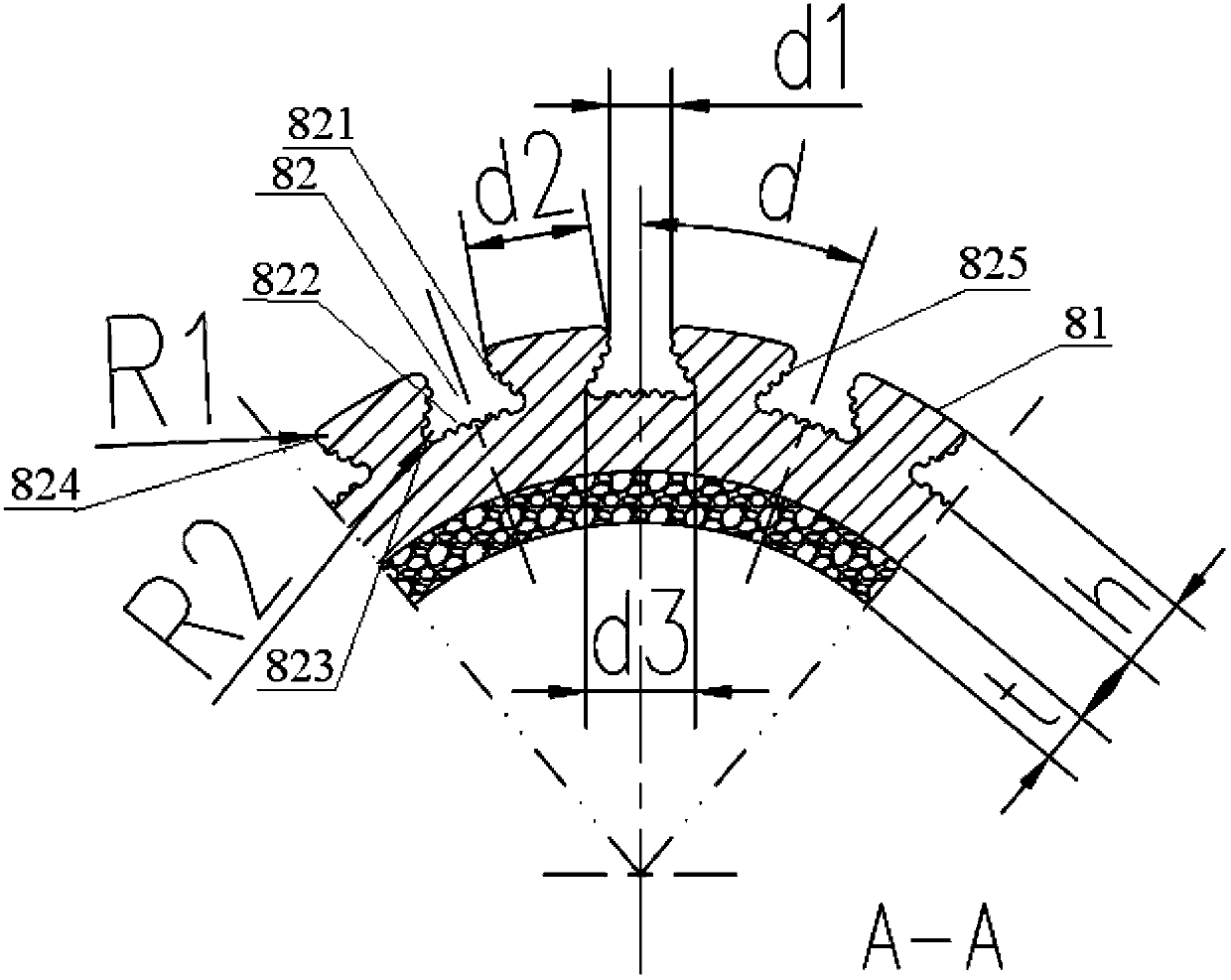

Novel flooded type evaporating heat exchange tube

ActiveCN109307389AIncrease boiling heat transfer coefficientPromote growthEvaporators/condensersHeat transfer modificationEngineeringExchange coefficient

The invention discloses a novel flooded type evaporating heat exchange tube. The novel flooded type evaporating heat exchange tube comprises a light section and an evaporating surface section, whereinthe evaporating surface section comprises a heat exchange tube body (8). The novel flooded type evaporating heat exchange tube is characterized in that inclined bent fins (2) which are spirally distributed along the axis of the heat exchange tube are arranged on the outer surface of the heat exchange tube body (8), wherein the surfaces of the fins (2) are in the shapes of curved surfaces, and thefins tilt in the same direction; the tops of adjacent fins (2) are in tight contact with each other without a seam, and the fins (2) cover a channel between the fins to define a triangular cavity (3); a trapezoidal notch (5) is formed in the top of each fin (2) as a steam discharge hole / liquid inlet of the cavity; and bulged ribs which are uniformly distributed in the peripheral direction are arranged on the inner surface of the heat exchange tube body (8), and a spiral channel is formed between every two adjacent ribs. The novel flooded type evaporating heat exchange tube is simple in processing, and is high in yield; and within a practical common wall surface superheat degree range, a heat exchange coefficient is slightly affected by the wall surface superheat degree, and is kept stable, so that variable working conditions of a heat exchanger are adapted.

Owner:山东恒辉节能技术集团有限公司

A self-excited phase change thermal control cooling system

ActiveCN105222629BRealize savingsImprove heat transfer effectIndirect heat exchangersSelf excitedEvaporation

The invention provides a self-excitation type phase change thermal control cooling system. The system comprises a heat taking evaporation module and a condensation cooling module, wherein a closed cavity for filling a working medium is formed therebetween; the heat taking evaporation module is positioned at one end part of the closed cavity, and consists of a heat taking baseplate and an evaporation end surface microstructure; and the evaporation end surface microstructure is arranged on an inner end surface of the heat taking baseplate. The system further comprises a capillary micro straight groove and a liquid accumulation and liquid supply groove ring; the condensation cooling module comprises a condensation side part and a condensation top plate; the condensation side part is positioned at the side edge of the closed cavity; the condensation top plate is positioned at the other end part of the closed cavity; and the inner end surfaces of the condensation side part and the condensation top plate are combined surfaces having a film liquid area and a dropping liquid area. As the capillary micro straight groove having high-strength phase change heat taking under fine scale is introduced, the critical heat flux density and the heat exchange coefficient are promoted, and the heat exchange capacity of a heat end is strengthened; and meanwhile, the drop type condensation is built at a condensation end for timely and effectively falling and updating drops, so that the condensation heat exchange effect is reinforced and promoted.

Owner:FUJIAN CAS CERAMIC OPTOELECTRONICS TECH CO LTD

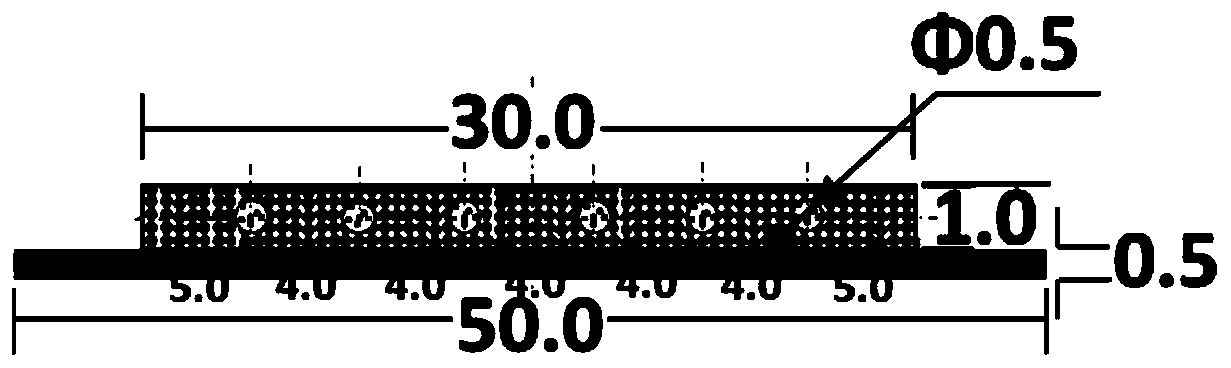

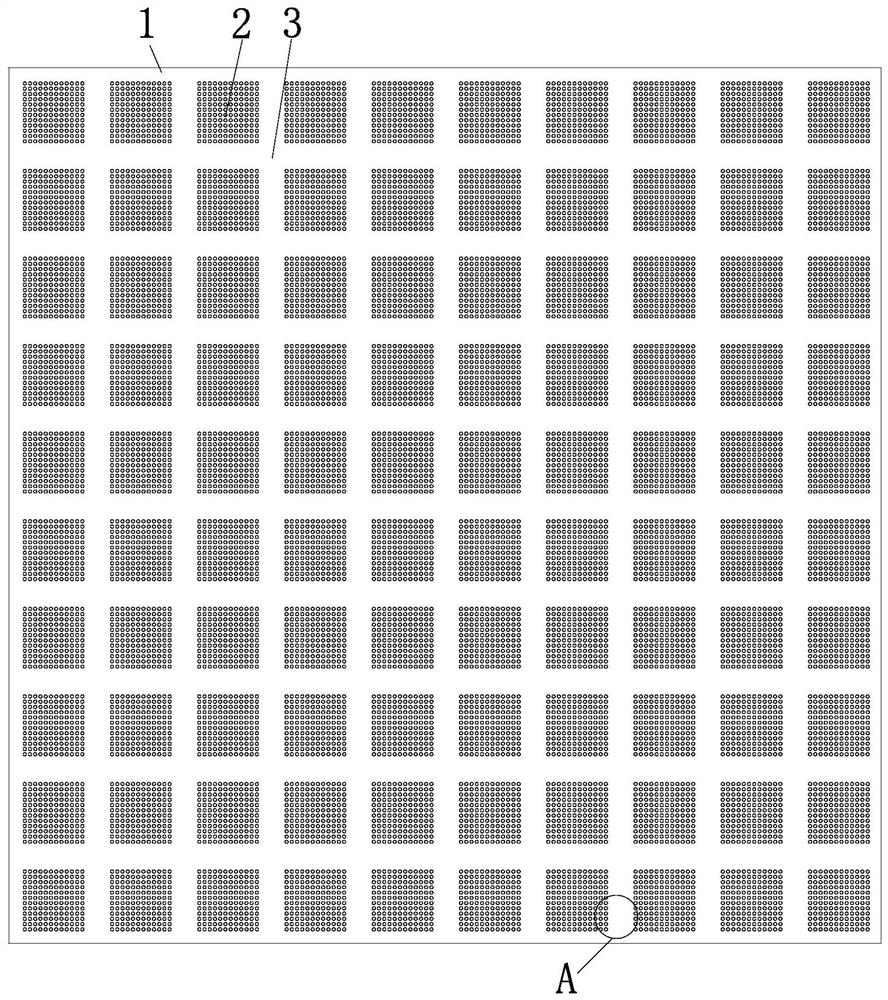

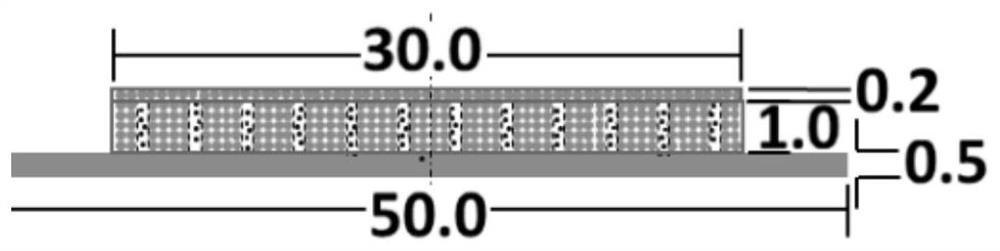

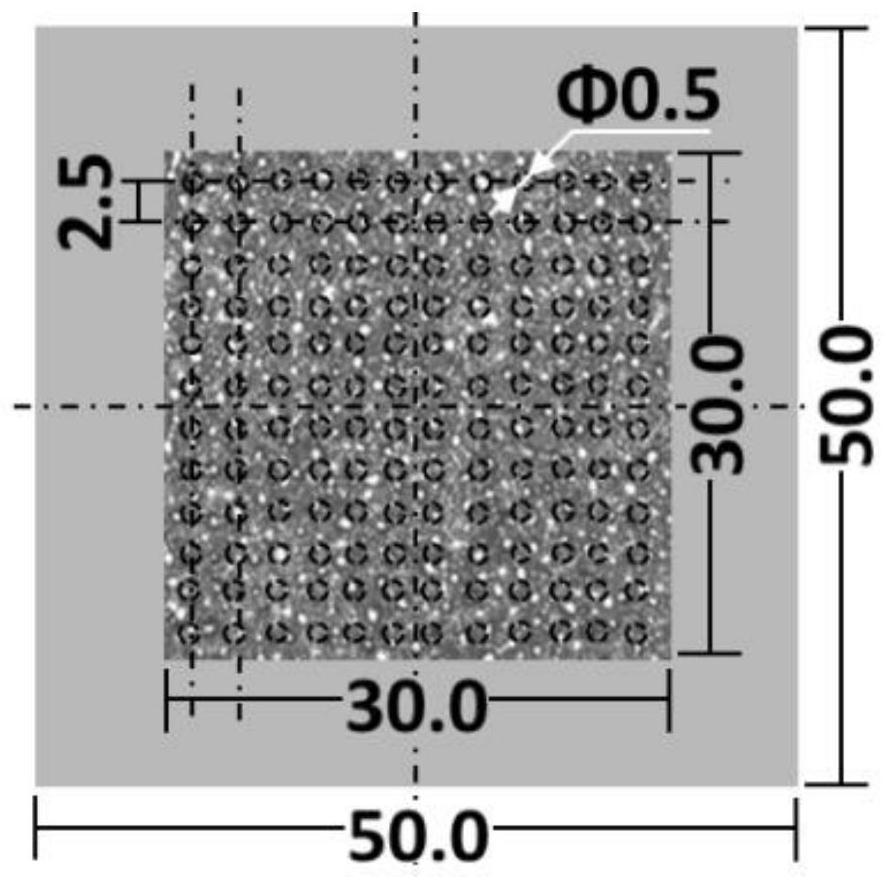

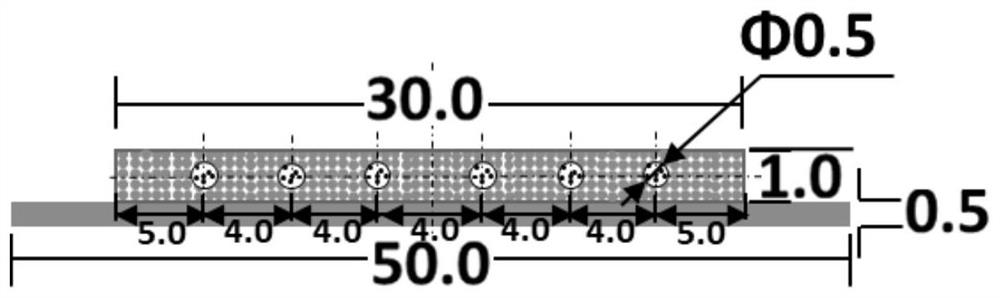

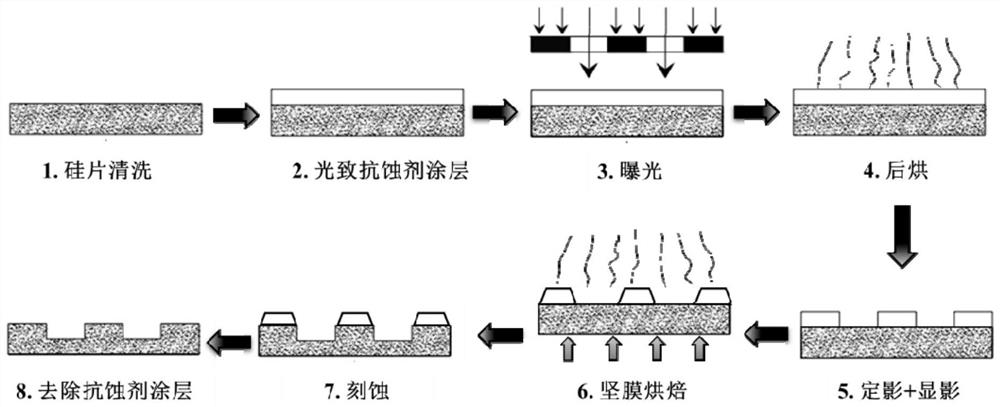

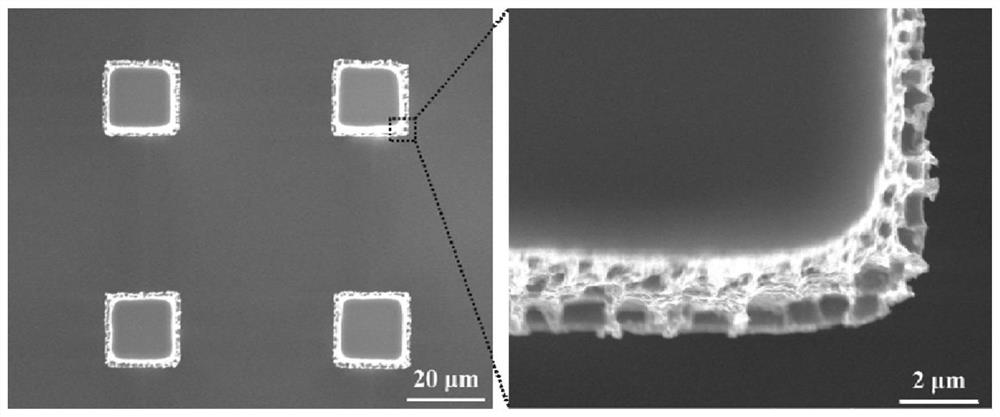

Layered micro-nano composite structure for enhancing boiling heat transfer, and processing method thereof

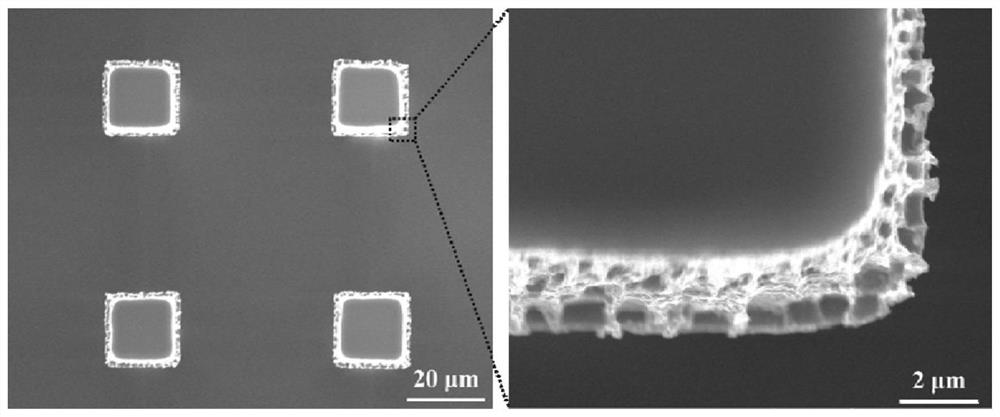

ActiveCN113825365AIncrease the actual heat transfer areaIncreased fluid refill speedSemiconductor/solid-state device detailsSolid-state devicesMicrostructureHeat flow

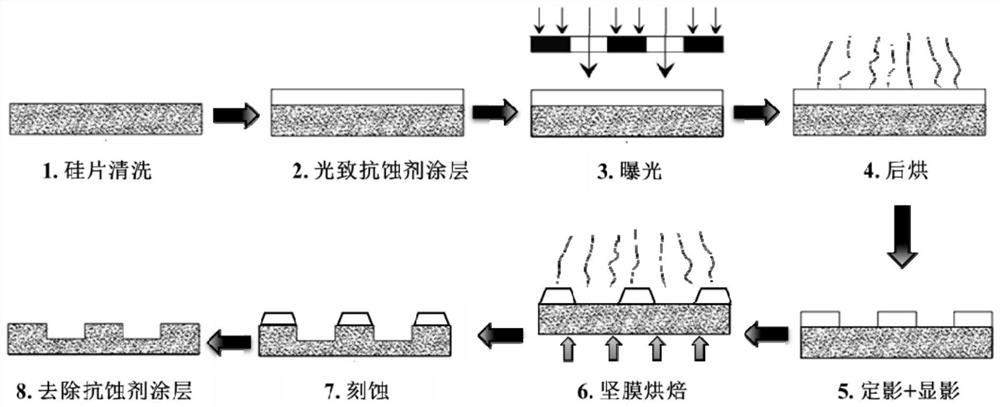

The invention discloses a layered micro-nano composite structure for enhancing boiling heat transfer, and a processing method thereof. The layered micro-nano composite structure comprises a silicon substrate, a cylindrical microstructure grown on the silicon substrate and nano holes around the top surface of the cylindrical microstructure. The composite structure is based on the cylindrical microstructures arranged in an array mode, and the liquid supply speed of a heat flux density area can be effectively increased; and the nano holes generated on the periphery of the top surface of the cylindrical microstructure can effectively improve the vaporization core density, so that the boiling heat transfer coefficient is improved. The nano holes are only distributed around the top surface of the cylindrical microstructure, so that large-area transverse merging of bubbles in a high-heat-flux area at the bottom of the cylindrical microstructure is effectively prevented, heat transfer deterioration is effectively delayed, and it is ensured that the liquid supply capacity cannot be weakened due to introduction of the nano-structure. The layered micro-nano composite structure is machined and formed at a time through a dry corrosion method, accurate regulation and control of the micro-structure are achieved, and the machining method is easy to operate and low in manufacturing cost.

Owner:CENT SOUTH UNIV

A medium and low temperature waste heat driven flash-injection-absorption combined cooling, heating and power system

ActiveCN110185511BHigh power outputReduce cold end pressureSteam engine plantsRefrigeration machinesNew energySuperheater

The invention relates to a medium-low temperature waste heat driven flash-injection-absorption combined cooling, heating and power supply system, which belongs to the technical field of new energy and energy saving. The medium and low temperature waste heat-driven flash-injection-absorption combined cooling, heating and power system includes superheater, waste heat heater, flash evaporator, rectifier, expander, cooling heat exchanger, booster compressor, injection Ejectors, regenerators, absorbers, absorption pumps, solution pumps, throttle and shut-off valves. This system can realize combined cooling, heating and power supply or combined heating and power supply according to the needs of users. No matter whether the compound cycle system constructed by the present invention is operated under the combined cooling, heating and power supply or combined heating and power supply mode, only a small part of the external heat loss can be realized. Maximum utilization of energy.

Owner:KUNMING UNIV OF SCI & TECH

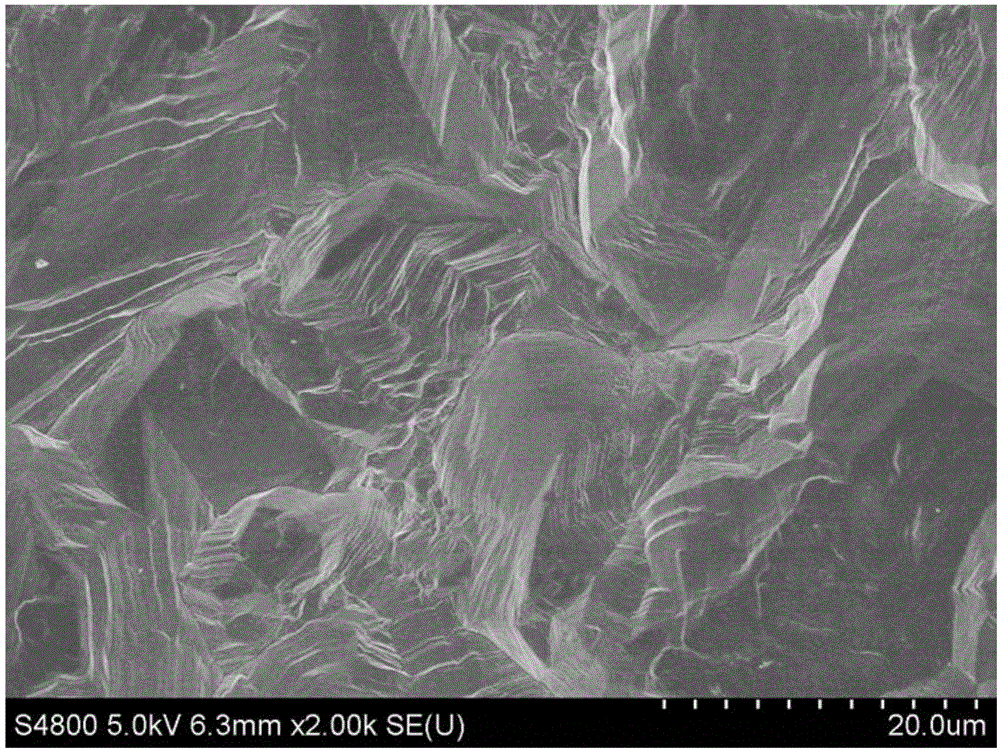

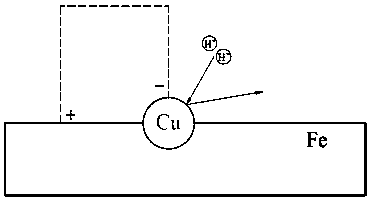

A preparation method of porous Cu surface for heat exchange

ActiveCN103469216BSimple preparation processLower requirementSolid state diffusion coatingAnhydrous ethanolEtching

The invention discloses a preparation method of a porous Cu surface for heat exchange. The method comprises the following steps: 1) placing a Cu substrate in ethanol for ultrasonic degreasing, then placing into an HCl solution for ultrasonic etching, further washing with deionized water and then naturally air-drying; 2) flatly placing the Cu substrate after natural air-drying on a polytetrafluoroethylene platform, placing into a hydrothermal reaction kettle with a tetrafluoroethylene inner liner, adding anhydrous ethanol into a gap between the hydrothermal reaction kettle and the polytetrafluoroethylene platform and performing steam heat treatment to get a Cu-based porous CuO thin film; and 3) performing reduction heat treatment on the Cu-based porous CuO thin film under a hydrogen atmosphere to get the Cu-based porous Cu surface for heat exchange. The Cu-based porous Cu surface prepared by the preparation method disclosed by the invention has an excellent boiling heat transfer effect; compared with a smooth base, the Cu-based porous Cu surface has the advantage that the boiling heat transfer coefficient at the initial stage of boiling can be increased by 8-12 times.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A free particle/porous medium composite enhanced boiling structure and its preparation method

ActiveCN110842202BAdd spoilersFast heat conductionHeat transfer modificationPorous mediumMetal particle

The invention discloses a free particle / porous medium composite enhanced boiling structure, which comprises a substrate and a porous matrix structure formed on the surface of the substrate. Several pores are distributed in the porous matrix structure, and dispersed in the cavity There are free particles able to move within the cavity. When preparing the free particle / porous medium composite enhanced boiling structure, metal particles are first sintered to obtain a porous material matrix, holes are formed in the porous material matrix, and then free particles are filled into the cavity and closed. The present invention is based on the activation of nucleation points during the boiling heat transfer process and the enhanced characteristics of the liquid-absorbing core supplying liquid to the nucleation site. The collision in the process strengthens the internal heat conduction, micro-layer evaporation and convective heat transfer of the working fluid, which makes the bubbles easy to nucleate, the growth rate is fast, and the detachment frequency is high, thus realizing the enhanced boiling heat transfer.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Improved Gravity Heat Pipe Heat Sink for High Power LEDs

InactiveCN103196116BEasy to processLow pricePoint-like light sourceLighting heating/cooling arrangementsRefluxHeat conducting

Owner:CHINA JILIANG UNIV

Reboiler

ActiveCN102671399BImprove boiling heat transferStrong scale resistanceBoiling apparatusPorous layerEngineering

Owner:CHINA ELEVENTH CHEM CONSTR +1

Method for machining porous-surface heat-exchange pipe for boiling heat-transfer equipment

The invention discloses a method for machining a porous-surface heat-exchange pipe for boiling heat-transfer equipment, aiming at providing a heat-exchange pipe and a machining method with the advantages of simple process, convenience for machining, no falling of a machined porous surface and capability of machining various complex structural forms. The method comprises the steps of: cutting an aluminum alloy sheet according to developed dimensions of a base pipe and a porous layer of a heat-exchange pipe respectively to obtain aluminum alloy sheets which are respectively used for machining the base pipe and the porous layer and have the same dimensions as the developed dimensions of the base pipe and the porous layer of the heat-exchange pipe; respectively evening out; placing the evened-out aluminum alloy sheet for machining the porous layer in the middle of a terrace die and a hollowing die, and punching the aluminum alloy sheet for machining the porous layer by using the terrace die and the hollowing die; superposing and thermally pressing a porous layer substrate and the evened-out aluminum alloy sheet for machining the base pipe so that the porous layer substrate and the evened-out aluminum alloy sheet for machining the base pipe are integrated; and then, machining the evened-out aluminum alloy sheet for machining the base pipe into a pipe shape, and welding both the machined aluminum alloy sheets to obtain the aluminum alloy heat-exchange pipe with the porous surface.

Owner:TIANJIN UNIV OF COMMERCE

A layered micro-nano composite structure for enhancing boiling heat transfer and its processing method

ActiveCN113825365BIncrease the heat exchange areaIncrease heat transfer rateSemiconductor/solid-state device detailsSolid-state devicesHeat fluxNanohole

The invention discloses a layered micro-nano composite structure for enhancing boiling heat transfer and a processing method thereof. The layered micro-nano composite structure includes a silicon substrate, a columnar microstructure grown on the silicon substrate, and a surface around the top surface of the columnar microstructure. Nanoholes. The composite structure is based on the columnar microstructure arranged in an array, which can effectively improve the liquid replenishment rate in the heat flux density region; the nano-cavities generated around the top surface of the columnar microstructure can effectively improve the vaporization core density, thereby increasing the Boiling heat transfer coefficient. The nano-scale holes are only distributed around the top surface of the columnar microstructure, which can effectively prevent the large-area lateral merger of bubbles in the high heat flux area at the bottom of the columnar microstructure, effectively delay the occurrence of heat transfer deterioration, and ensure that the liquid replenishment capacity will not weakened by the introduction of nanostructures. The layered micro-nano composite structure is formed by one-time processing by a dry etching method, so as to realize precise regulation of the micro-structure, and the processing method is simple to operate and has a low manufacturing cost.

Owner:CENT SOUTH UNIV

A surface treatment method for improving heat transfer coefficient of heat exchanger

ActiveCN109023318BDensity distribution can be adjustedLarge specific surface areaLiquid/solution decomposition chemical coatingPhysical chemistryBoiling heat transfer

The invention relates to a surface treatment method capable of increasing the heat exchange coefficient of a heat exchanger, and belongs to the technical field of heat exchangers. The surface treatment method comprises the steps that copper salt is added into water to be prepared into a copper salt solution, and silver salt is added into water to be prepared into a silver salt solution; acid is added into the copper salt solution to obtain a copper salt-acid surface treatment solution, and acid is added into the silver salt solution to be prepared into silver salt-acid surface treatment solution; under the condition of the temperature of 20-90 DEG C, the heat exchanger is placed into the copper salt-acid surface treatment solution or the silver salt-acid surface treatment solution to be treated for 0.5-8 h, and then the heat exchanger porous surface is obtained; or an acid solution is prepared, under the condition of the temperature of 20-90 DEG C, the heat exchanger is placed into thecopper salt solution or the silver salt solution to be soaked and react for 0.1-30 s and then placed into the acid solution with the temperature of 20-90 DEG C to be soaked and react for 0.5-8 h, andthen the heat exchanger porous surface is obtained. According to the surface treatment method, the heat exchange coefficient of the heat exchanger can be effectively increased through a replacement reaction, and boiling heat transfer of a working medium is enhanced.

Owner:KUNMING UNIV OF SCI & TECH

Mixed wettability micro-nano composite enhanced heat transfer structure and preparation method of the structure

ActiveCN111834309BEfficient separationLeave in timeSemiconductor/solid-state device detailsSolid-state devicesNanowireHeat flow

The invention discloses a mixed wettability micro-nano composite enhanced heat exchange structure, which includes a heat dissipation substrate, and the heat dissipation substrate is etched with a plurality of square micro-cylindrical array units and grooves arranged between the micro-cylindrical array units The channel and the micro cylinder array unit include a plurality of neatly arranged micro cylinders, the grooved channels and the micro cylinders are provided with nanowires, the diameter of the nanowires is 200nm-500nm, and the height of the nanowires is 10 μm. The invention also discloses a manufacturing method of the mixed wettability micro-nano composite enhanced heat exchange structure. The micro-cylindrical array unit and the nanowire structure adopted in the invention can effectively enhance the boiling heat transfer coefficient of high heat flux and delay the phenomenon of boiling and dry burning.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com