Variable density metal foam radiator

A metal foam and heat sink technology, which is applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problem that the specific surface area of through-hole metal foam is large, the advantages have not been fully utilized, and the overall boiling heat transfer is increased Coefficient and other issues, to achieve the effect of large specific surface area, reduced resistance, and increased boiling heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

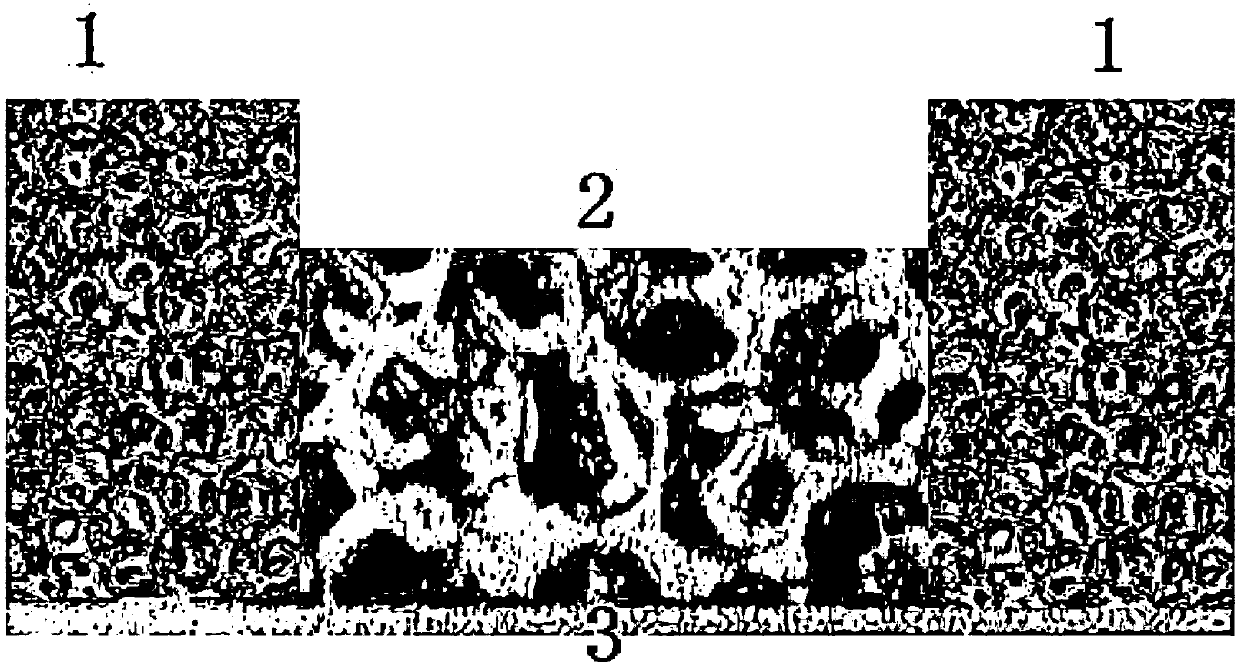

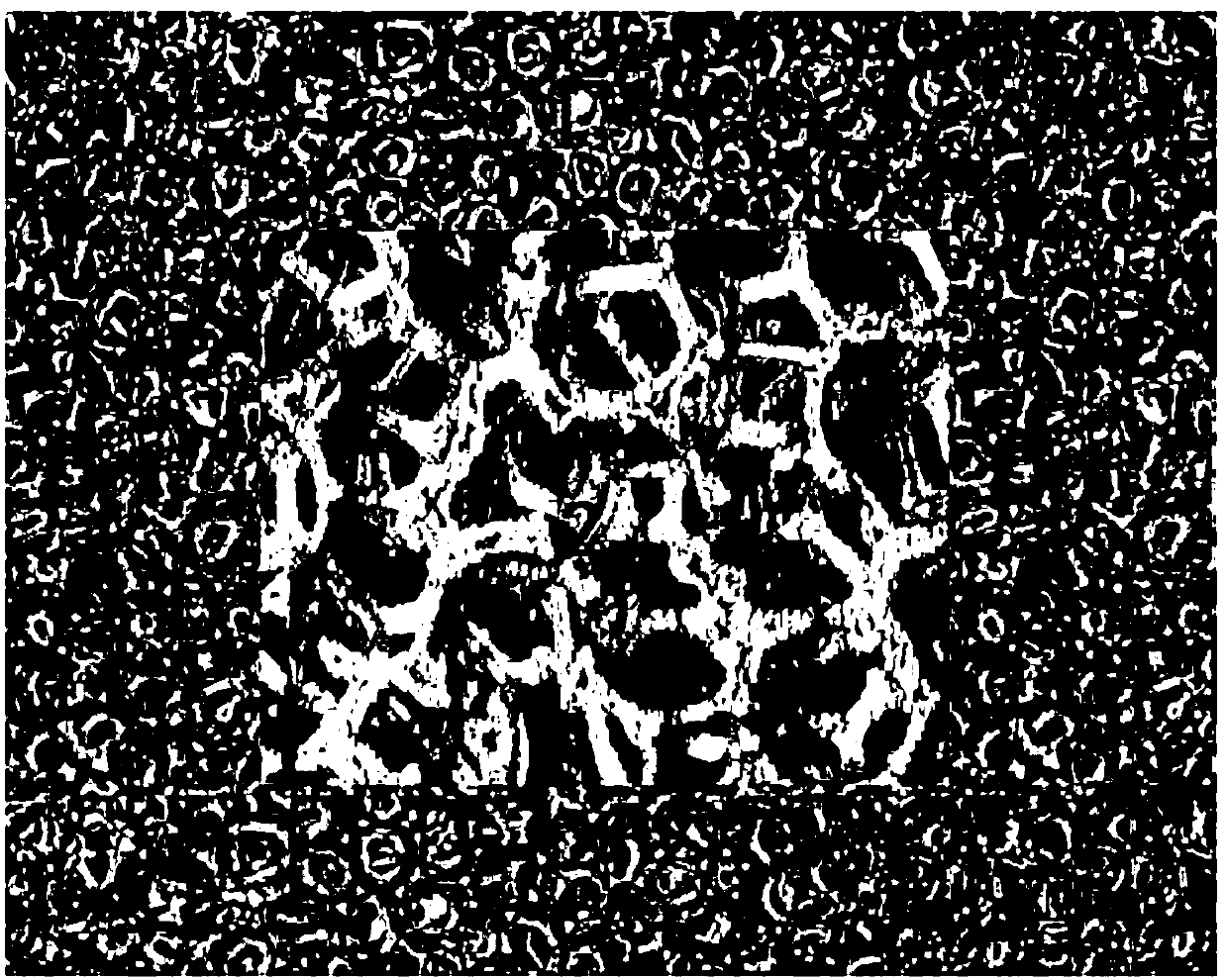

[0017] Such as figure 1 As shown, this embodiment includes: a heat exchange substrate 3 , an annular through-hole metal foam 1 sintered on the heat exchange copper substrate 3 , and a square through-hole metal foam 2 sintered on the heat exchange substrate 3 .

[0018] The described annular through-hole metal foam 1 is a structure with smaller pores, and the range of the described hole density is

[0019] 60PPI-130PPI, the range of the porosity is 0.8-0.9, and the thickness of the foam is 3mm-6mm.

[0020] The square through-hole metal foam 2 is a structure with relatively large pores, the range of the pore density is 5PPI-40PPI, the range of the porosity is 0.92-0.98, and the thickness of the foam is 1mm-3mm .

[0021] The through-hole metal foam 1 and the through-hole metal foam 2 described in this embodiment are connected by brazing to reduce thermal contact resistance.

[0022] The metal foam with through holes is prepared by investment casting method, wherein the metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com