Foam metal with mixed wet surface and preparation method thereof

A foamed metal and wettability technology, applied in the field of foamed metal, can solve the problems of air bubble escaping obstruction, etc., and achieve the effects of reducing waiting time, improving boiling heat transfer coefficient, and reducing detachment resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

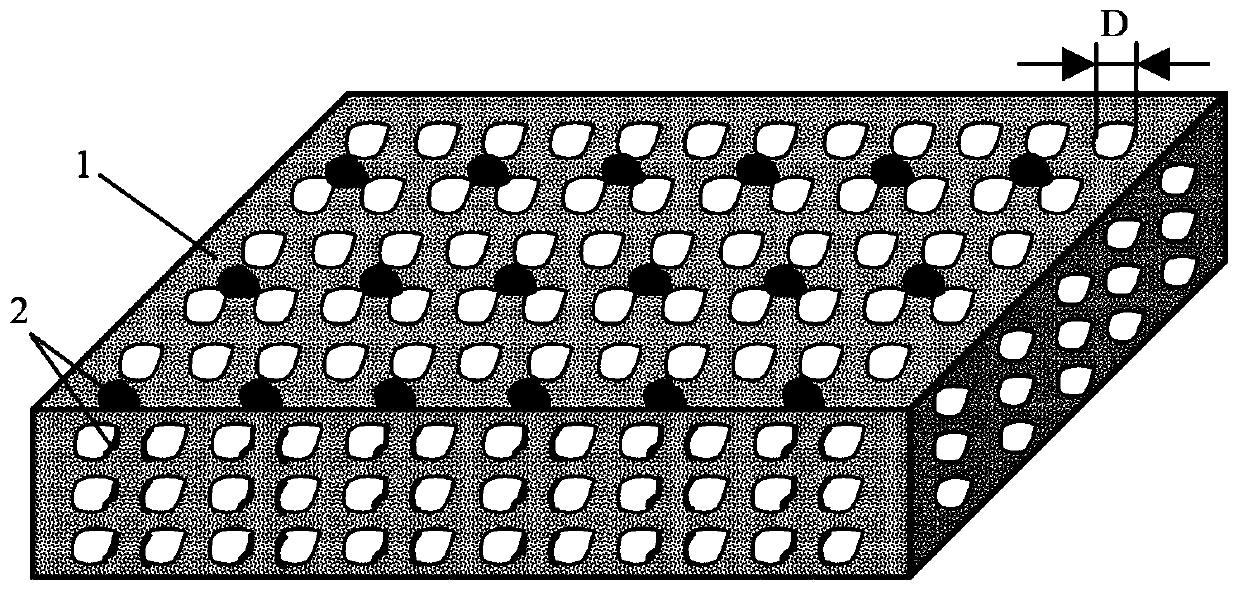

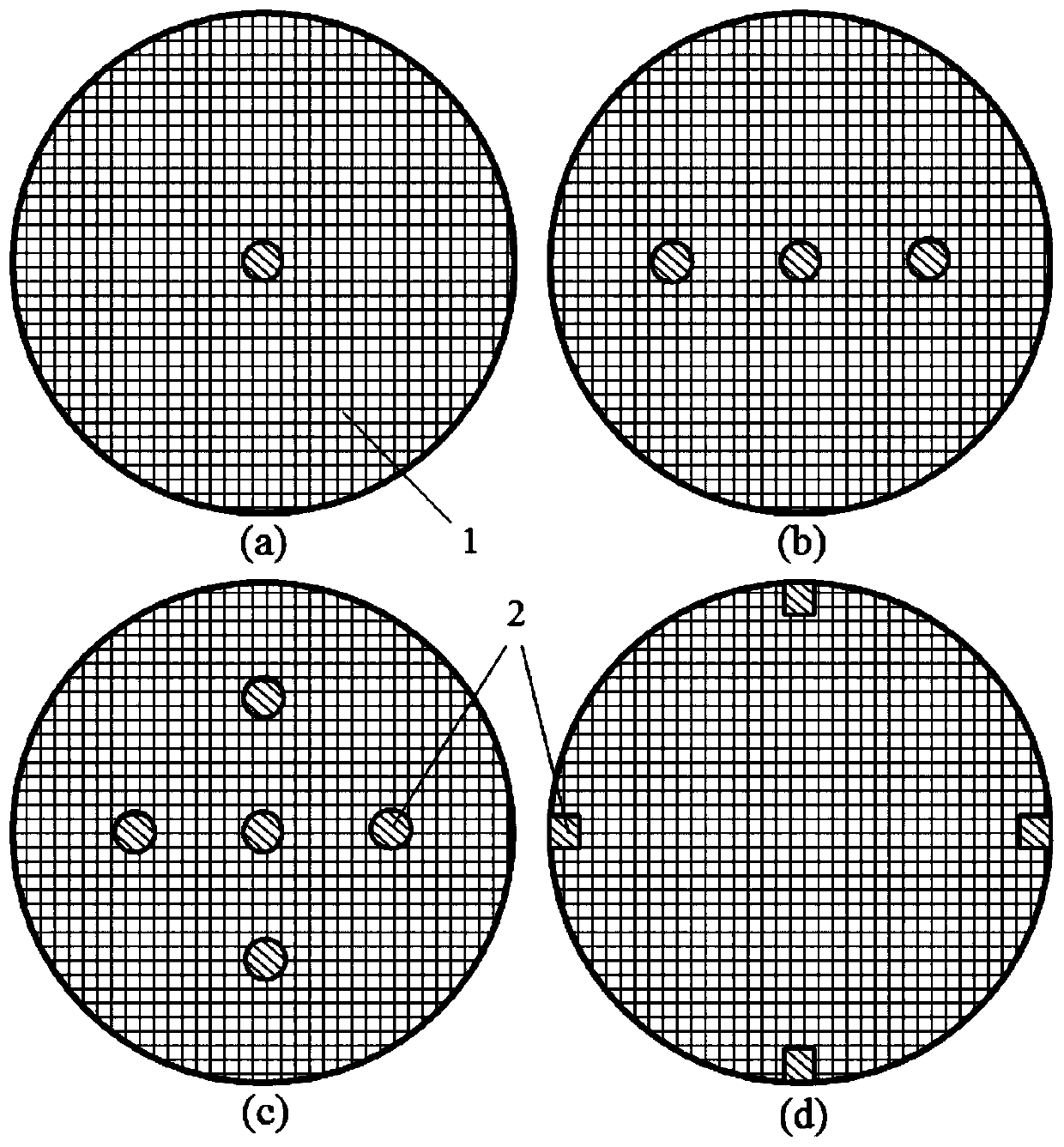

[0026] A metal foam with a mixed wettability surface (such as figure 1 shown), the metal foam has a super-hydrophilic surface 1, and the super-hydrophilic surface 1 is figure 2 The way shown in (a) is distributed with superhydrophobic film 2 (hydrophobic point area is 0.5~20mm 2 ), and due to the penetration of the liquid in the metal foam for preparing the film, the surface of the skeleton inside the metal foam is also attached to this super-hydrophobic film.

[0027] The foam metal material is copper, its shape is circular, its diameter is 20mm, its height H is 2mm, and its pore equivalent diameter D is 1mm. The apparent contact angle can reach 0°.

[0028] Its preparation method is as follows:

[0029] 1) Put metal foam into K 2 S 2 o 8 and KOH mixed solution (where K 2 S 2 o 8 The concentration of KOH is 0.08mol / L, and the concentration of KOH is 0.8mol / L. ) for 60 minutes to completely oxidize the surface, rinse with deionized water and dry completely after tak...

Embodiment 2

[0033] A metal foam with a mixed wettability surface (such as figure 1 shown), the metal foam has a super-hydrophilic surface 1, and the super-hydrophilic surface 1 is figure 2 (b) shows that the super-hydrophobic film 2 is uniformly distributed in a linear arrangement at equal intervals (the spacing of the hydrophobic points is 1-20mm, and the area of the hydrophobic points is 0.5-20mm 2 ), and due to the penetration of the liquid in the metal foam for preparing the film, the surface of the skeleton inside the metal foam is also attached to this super-hydrophobic film.

[0034] The foam metal material is copper, its shape is circular, its diameter is 20mm, its height H is 2mm, and its pore equivalent diameter D is 1mm. The apparent contact angle can reach 0°.

[0035] Its preparation method is as follows:

[0036] 1) Put metal foam into K 2 S 2 o 8 and KOH mixed solution (where K 2 S 2 o 8 The concentration is 0.09mol / L, and the concentration of KOH is 0.9mol / L) f...

Embodiment 3

[0040] A metal foam with a mixed wettability surface (such as figure 1 shown), the metal foam has a super-hydrophilic surface 1, and the super-hydrophilic surface 1 is figure 2The inner side of the metal foam shown in (c) is center-symmetrical and annularly distributed with super-hydrophobic films 2 (the spacing between the hydrophobic points is 1-20mm, and the area of the hydrophobic points is 0.5-20mm 2 ), and due to the penetration of the liquid in the metal foam for preparing the film, the surface of the skeleton inside the metal foam is also attached to this super-hydrophobic film.

[0041] The foam metal material is copper, its shape is circular, its diameter is 20mm, its height H is 2mm, and its pore equivalent diameter D is 1mm. The apparent contact angle can reach 0°.

[0042] Its preparation method is as follows:

[0043] 1) Put metal foam into K 2 S 2 o 8 and KOH mixed solution (where K 2 S 2 o 8 The concentration is 0.11mol / L, and the concentration of K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com