Pneumatic tire

A technology for pneumatic tires and treads, applied in tire parts, wheels, tire treads/tread patterns, etc., can solve the problems of poor ground contact, partial wear, insufficient edge effect, etc., to improve edge effect, improve The effect of braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

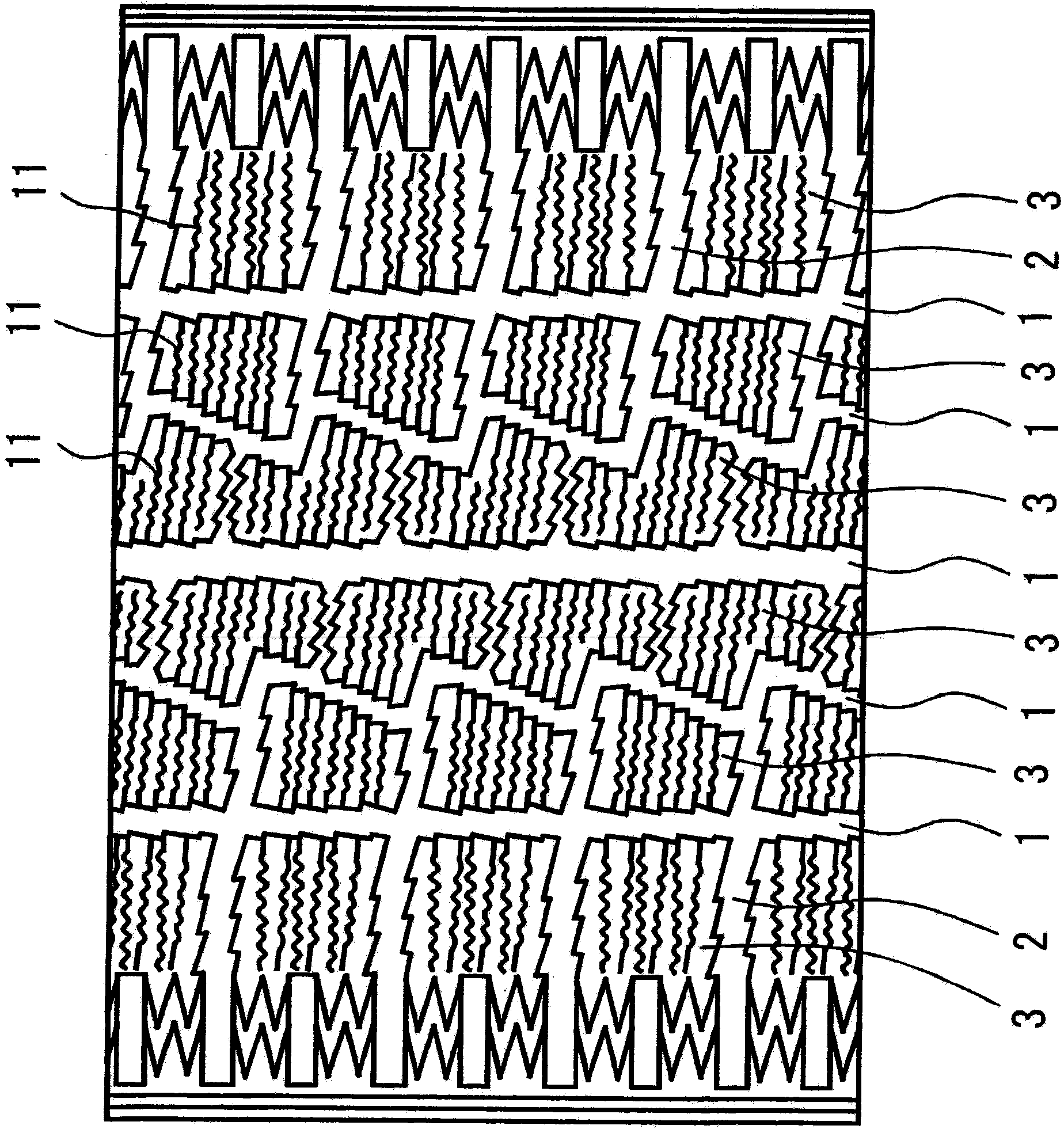

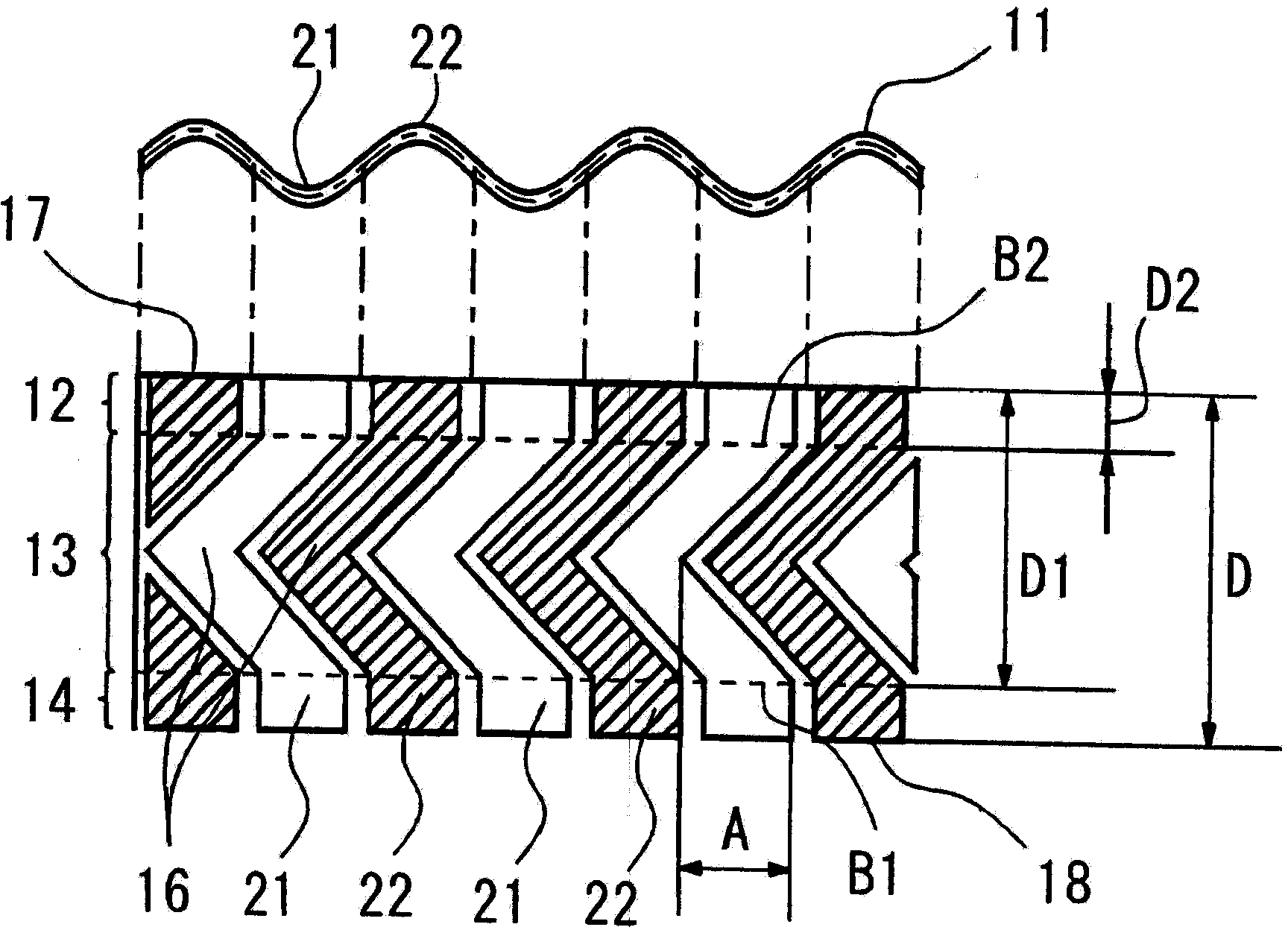

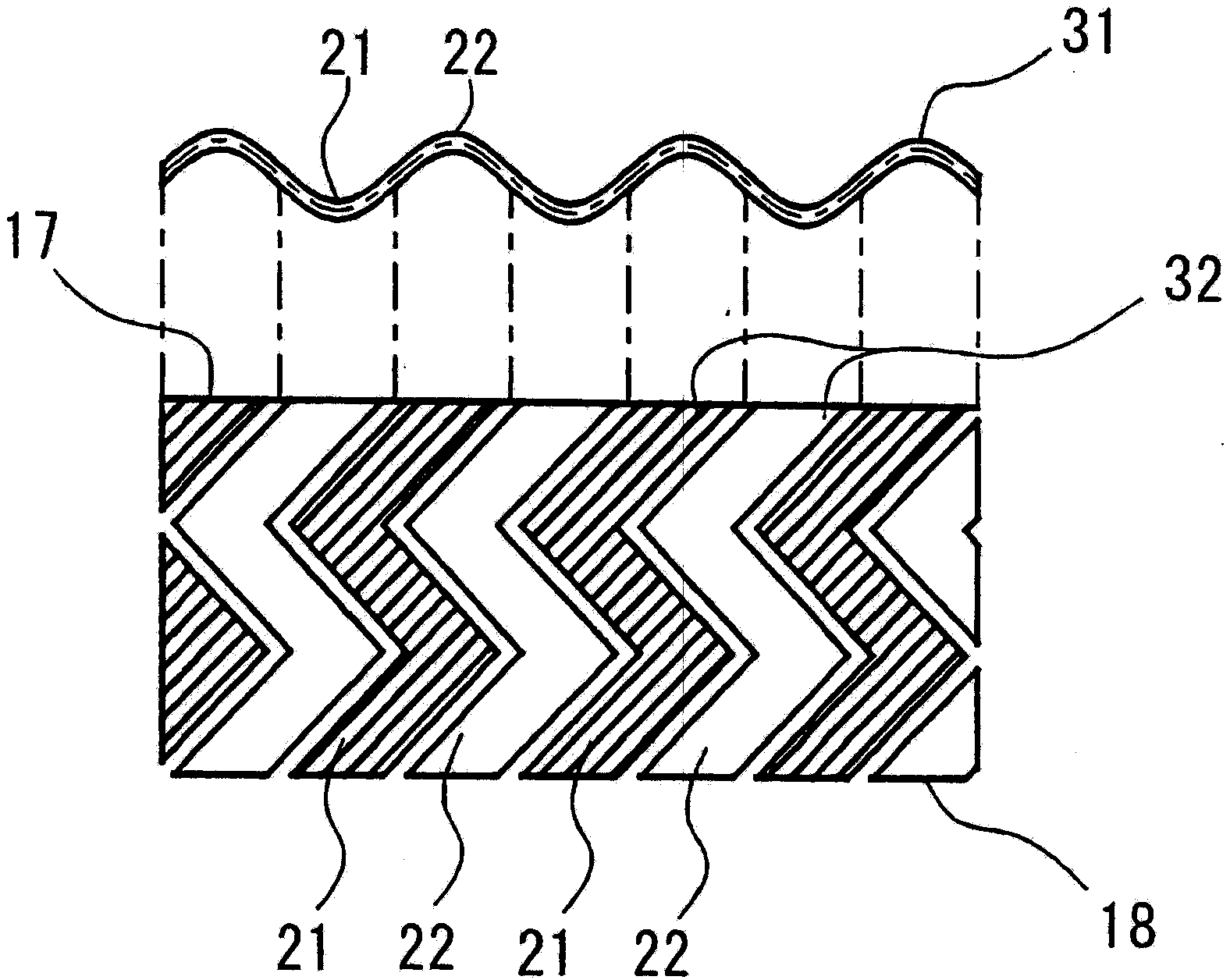

[0040] As an example, the pneumatic tire of the present invention and the pneumatic tire of the conventional example were tested and evaluated for performance. Any 1 tire has figure 1 The tread pattern shown, examples have figure 2 The zigzag pattern shown in the previous example has image 3 The zigzag pattern shown in . The depth D of any one zigzag pattern is 7 mm, and in the example, D1 is 5.5 mm, D2 is 1.5 mm, and A is 2 mm. The tire size is 195 / 65R15, and the performance is evaluated on a 2000ccFF van.

[0041] In Table 1, ice braking is the inverse of the ABS braking distance at a speed of 40 km / h on icy roads. The conventional tire when new is represented as an index of 100, and the larger the number, the better the performance. In addition, the term "wear time" refers to the time when the tread is worn to 60% of the zigzag depth D.

[0042] [Table 1]

[0043]

[0044] According to Table 1, since the peaks and valleys of the waveform are not zigzag, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com