Patents

Literature

35results about How to "Lower boiling point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

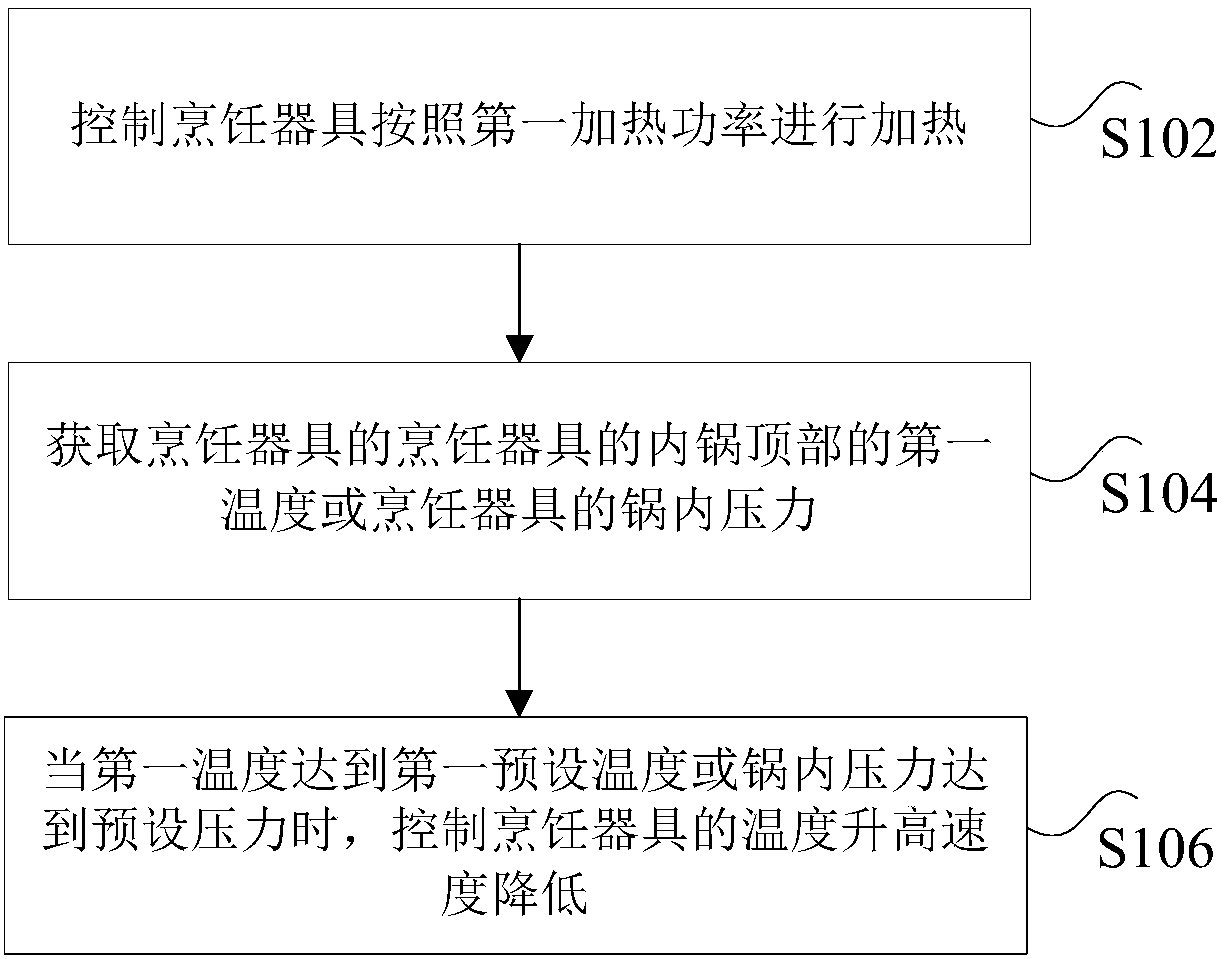

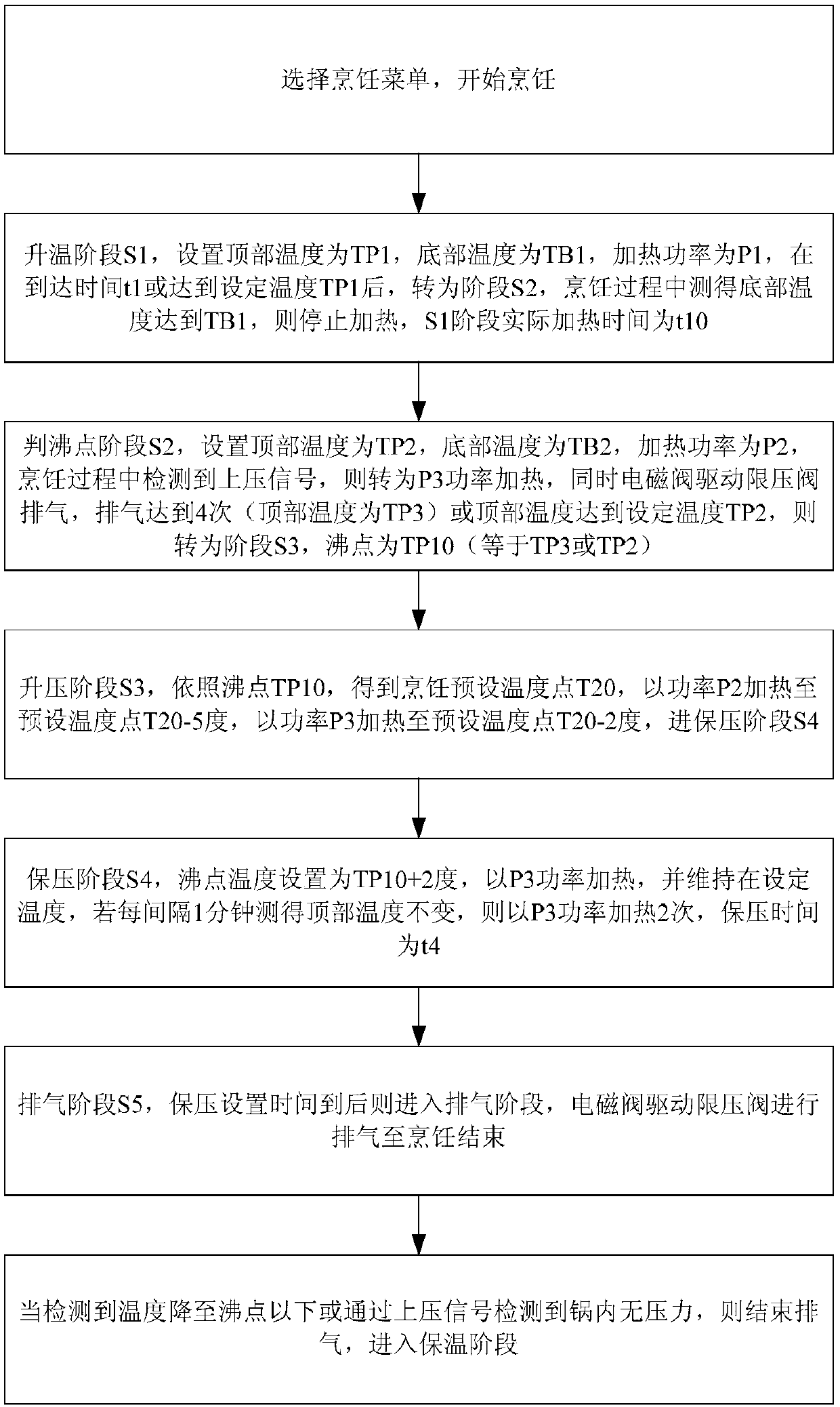

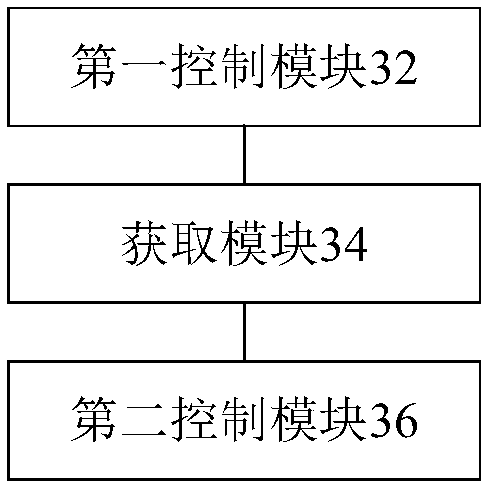

Cooking appliance and control method and device thereof, storage medium and processor

The invention discloses a cooking appliance and a control method and device thereof, a storage medium and a processor. The control method includes the steps that the cooking appliance is controlled toperform heating according to first heating power; the first temperature of the top of an inner pot of the cooking appliance or the in-pot pressure of the cooking appliance is acquired; when the firsttemperature reaches a first preset temperature or the in-pot pressure reaches a preset pressure, the temperature rising speed of the cooking appliance is controlled to be reduced. The control methodsolves the technical problem that in the prior art, the accuracy of detecting the temperature through a temperature collecting column arranged on the outer surface of a pot cover is low.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

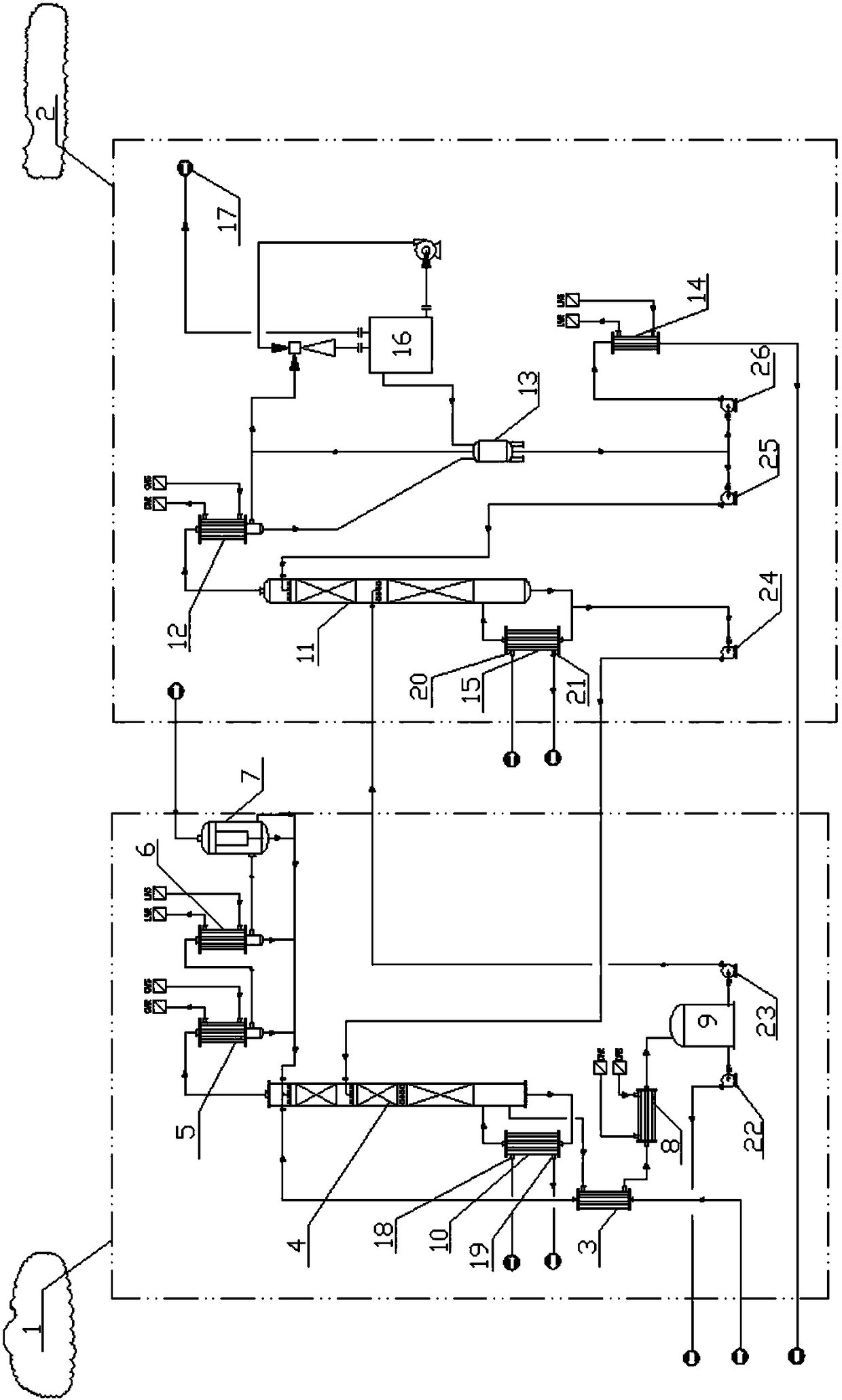

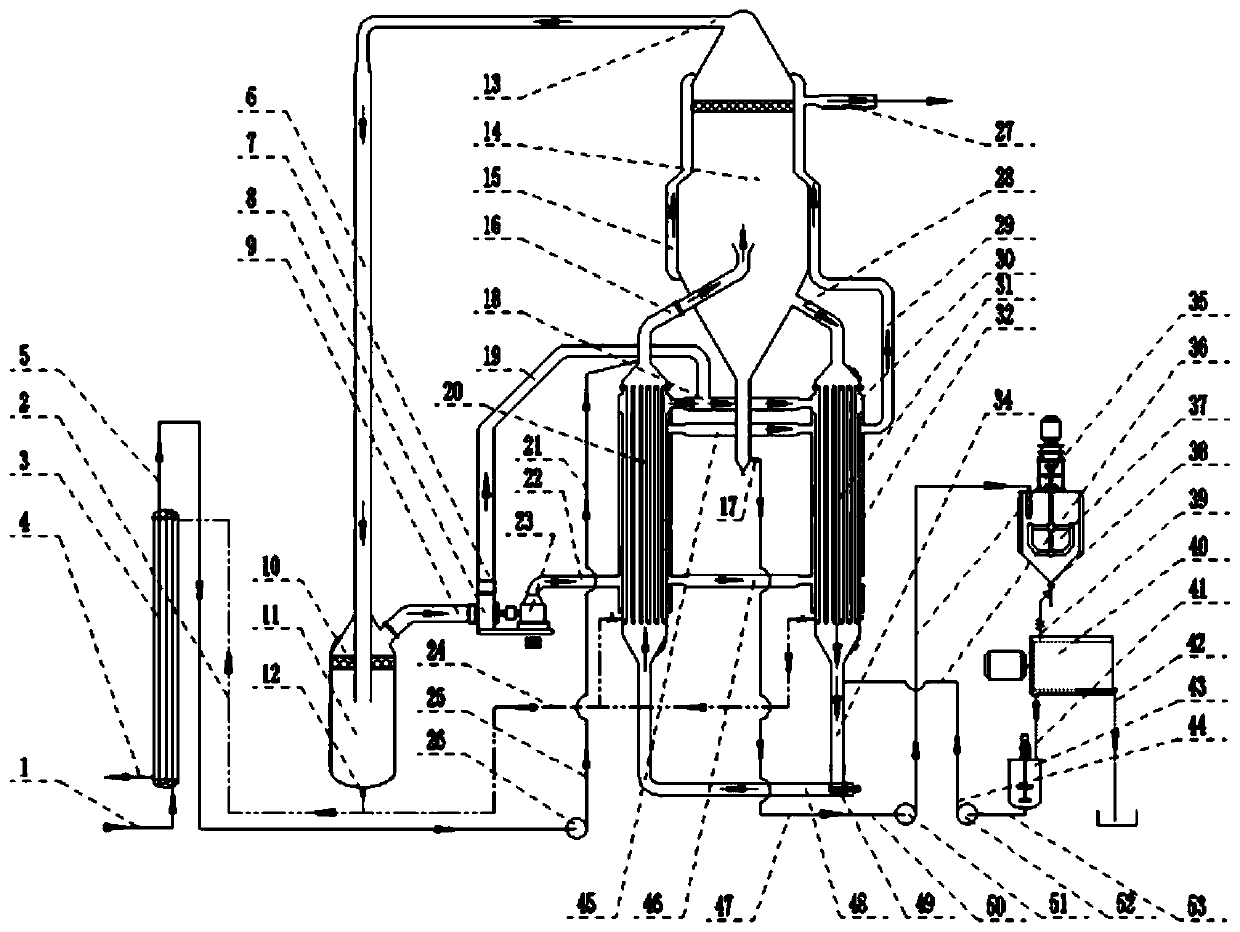

VCM purification hydrochloric acid full-resolution device and process

PendingCN108483399ALow device failure rateSolving Reliability IssuesChlorine/hydrogen-chloride purificationSmall footprintCalcium

The invention relates to a VCM purification hydrochloric acid full-resolution device and process. The VCM purification hydrochloric acid full-resolution device comprises a concentrated hydrochloric acid resolution system and a dilute hydrochloric acid vacuum concentration system, wherein the concentrated hydrochloric acid resolution system comprises a two-way heat exchanger, a concentrated hydrochloric acid resolution tower, a first-stage hydrogen chloride cooler, a second-stage hydrogen chloride cooler and an acid mist separator which are in communication with each other in sequence, and thelower part of the two-way heat exchanger is in communication with a dilute acid intermediate tank through a dilute acid cooler; the dilute hydrochloric acid vacuum concentration system comprises a dilute hydrochloric acid concentration tower, a water vapor condenser, a waste water intermediate tank and a waste water cooler, the dilute acid intermediate tank is in communication with the dilute hydrochloric acid concentration tower, the bottom of the dilute hydrochloric acid concentration tower is in communication with the concentrated hydrochloric acid resolution tower, and the dilute hydrochloric acid concentration tower is connected with the water vapor condenser and the waste water intermediate tank sequentially, and the waste water intermediate tank is in communication with the dilute hydrochloric acid concentration tower and the waste water cooler. The VCM purification hydrochloric acid full-resolution device is free of waste liquid containing mercury-diluted calcium chloride, andhas the advantages of low failure rate, long-term continuous operation, short process flow, small occupied area and small investment and the like.

Owner:杭州东日节能技术有限公司

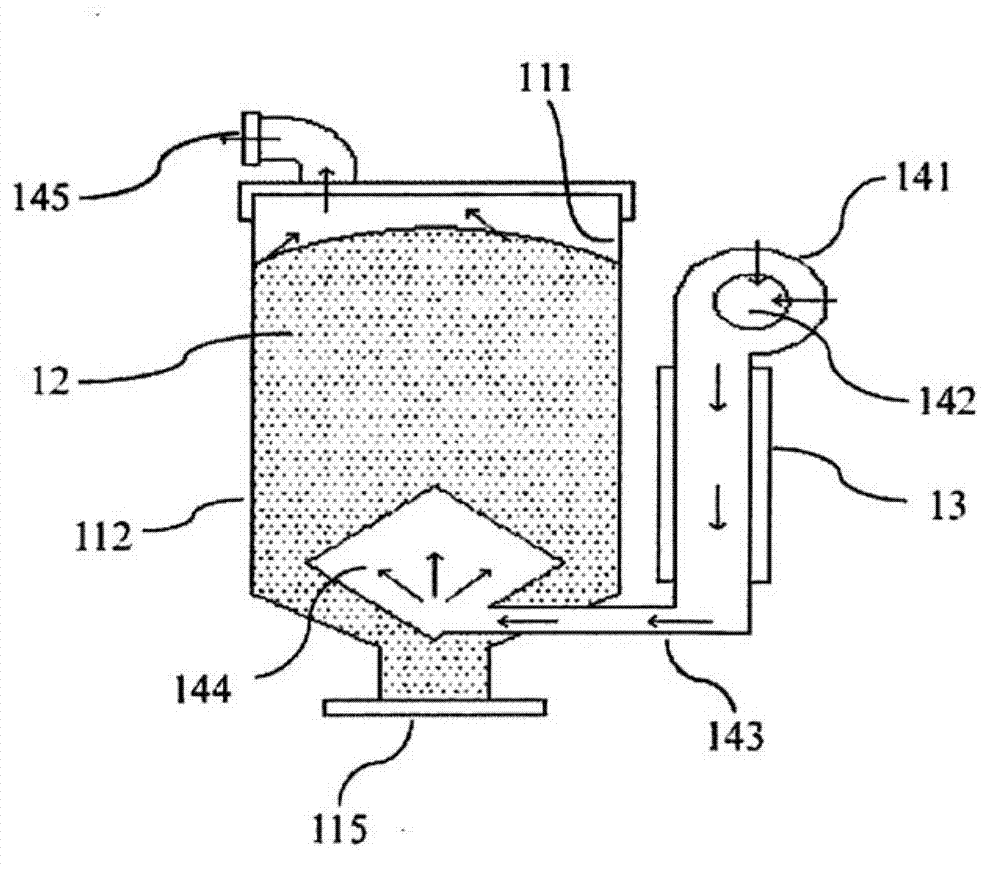

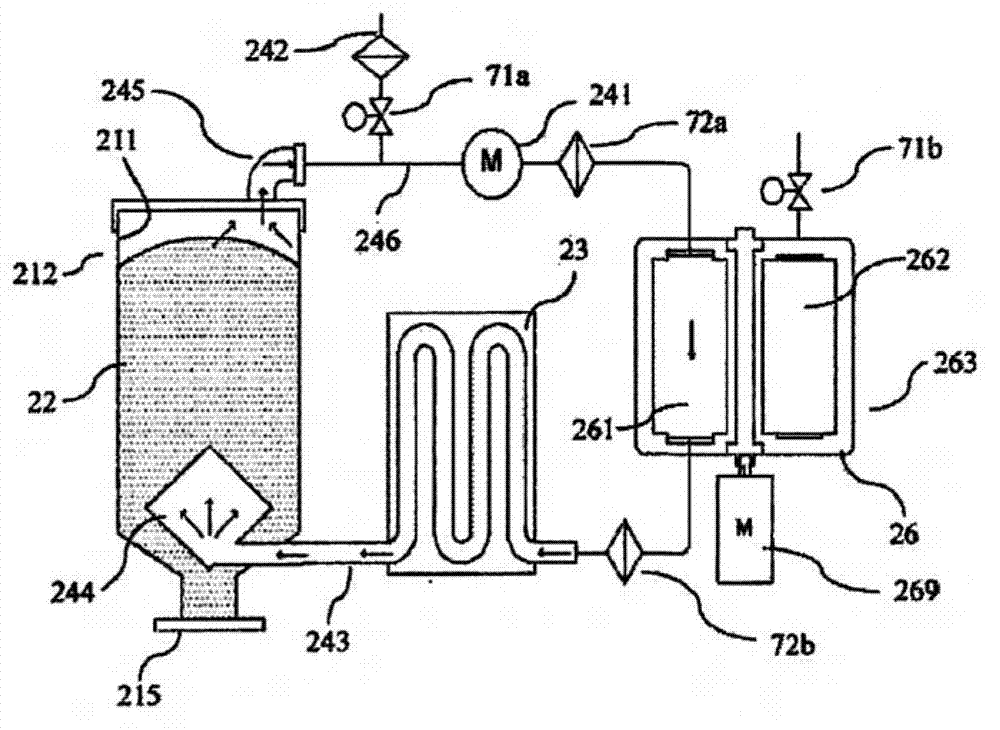

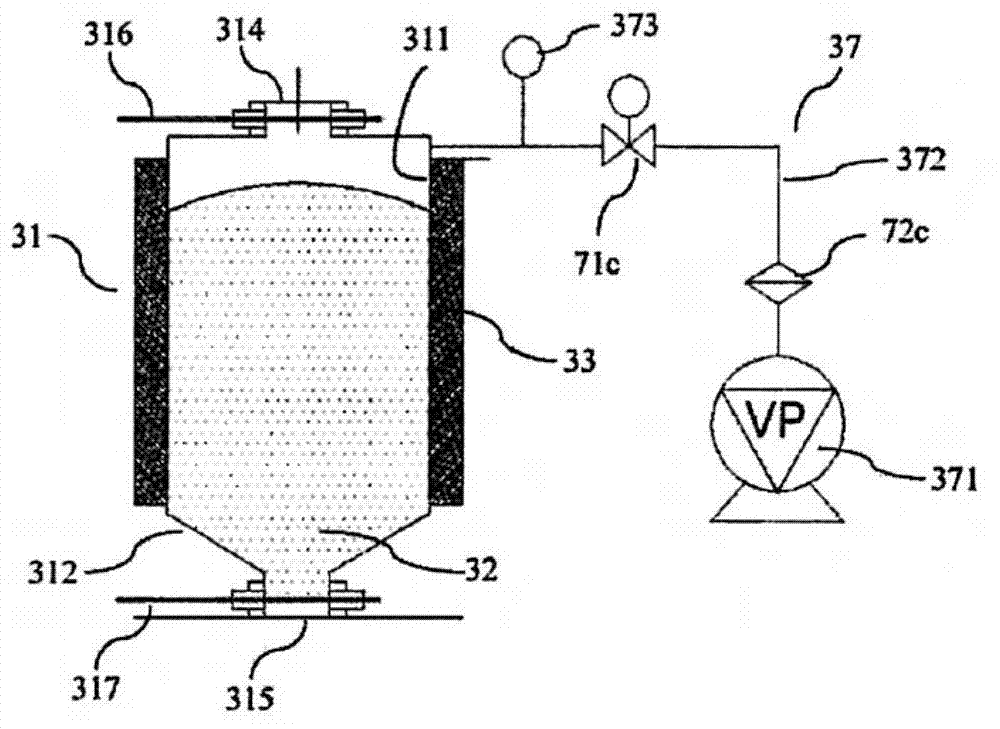

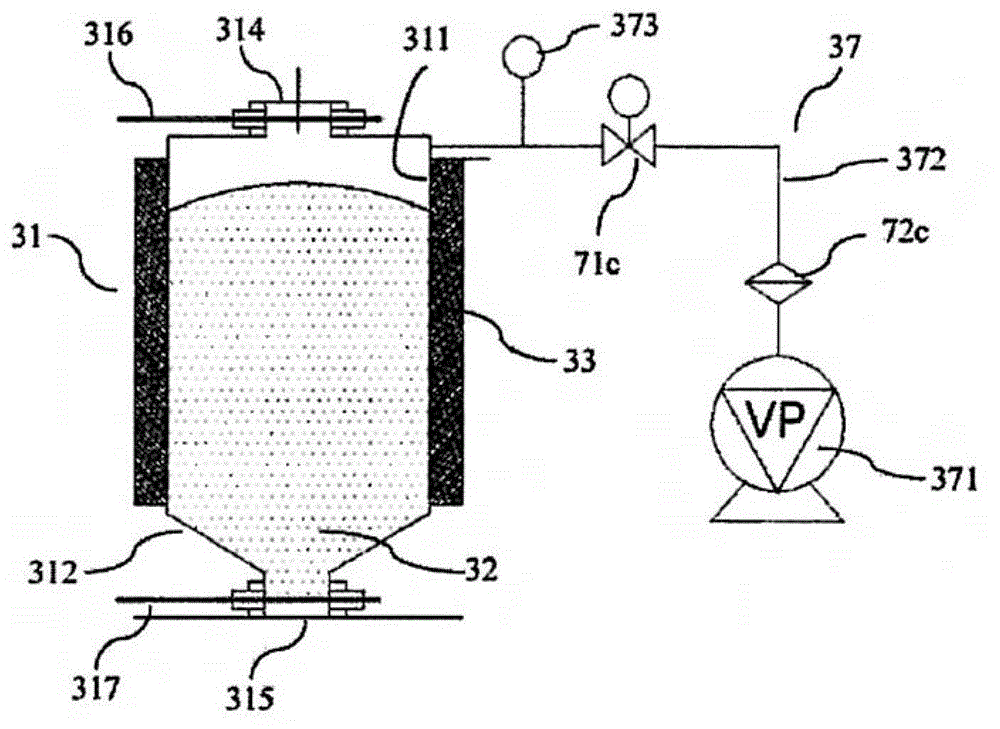

Infrared air exhaust and pressure reduction material-drying device

InactiveCN102967122ADrying smoothlyAchieve dryingDrying using combination processesDrying chambers/containersInfraredVacuum pressure

The invention discloses an infrared air exhaust and pressure reduction material-drying device comprising a tank body than can be enclosed inside. An infrared lighting source emits infrared to the inside of the device. The tank body that can be enclosed is connected with an air exhaust and pressure reduction assembly. Material requiring drying is disposed in the tank body that can be enclosed. Under the irradiation of the infrared, the internal water molecules of the irradiated substance can generate resonance energy because of absorption of the infrared and the temperature of the irradiated substance rises. The heating management of the irradiated substance is controlled through intensity of illumination of the infrared and interval of on-off irradiation time. The material requiring drying is heated to a predetermined temperature and achieves specific vacuum pressure through air exhaust and pressure reduction via communication of a vacuum pump pipeline together with the tank body that can be enclosed, so that the boiling temperature of the water can be reduced to be below the specific temperature according to physical characteristics and the internal water molecules of the substances can vaporize through boiling. Vaporized moisture can be exhausted during the air exhaust and pressure reduction. The infrared air exhaust and pressure reduction material-drying device is formed by the tank body, which can be enclosed and can employ the vacuum pump for the air exhaust and pressure reduction, and the infrared lighting source.

Owner:陈淑姿 +1

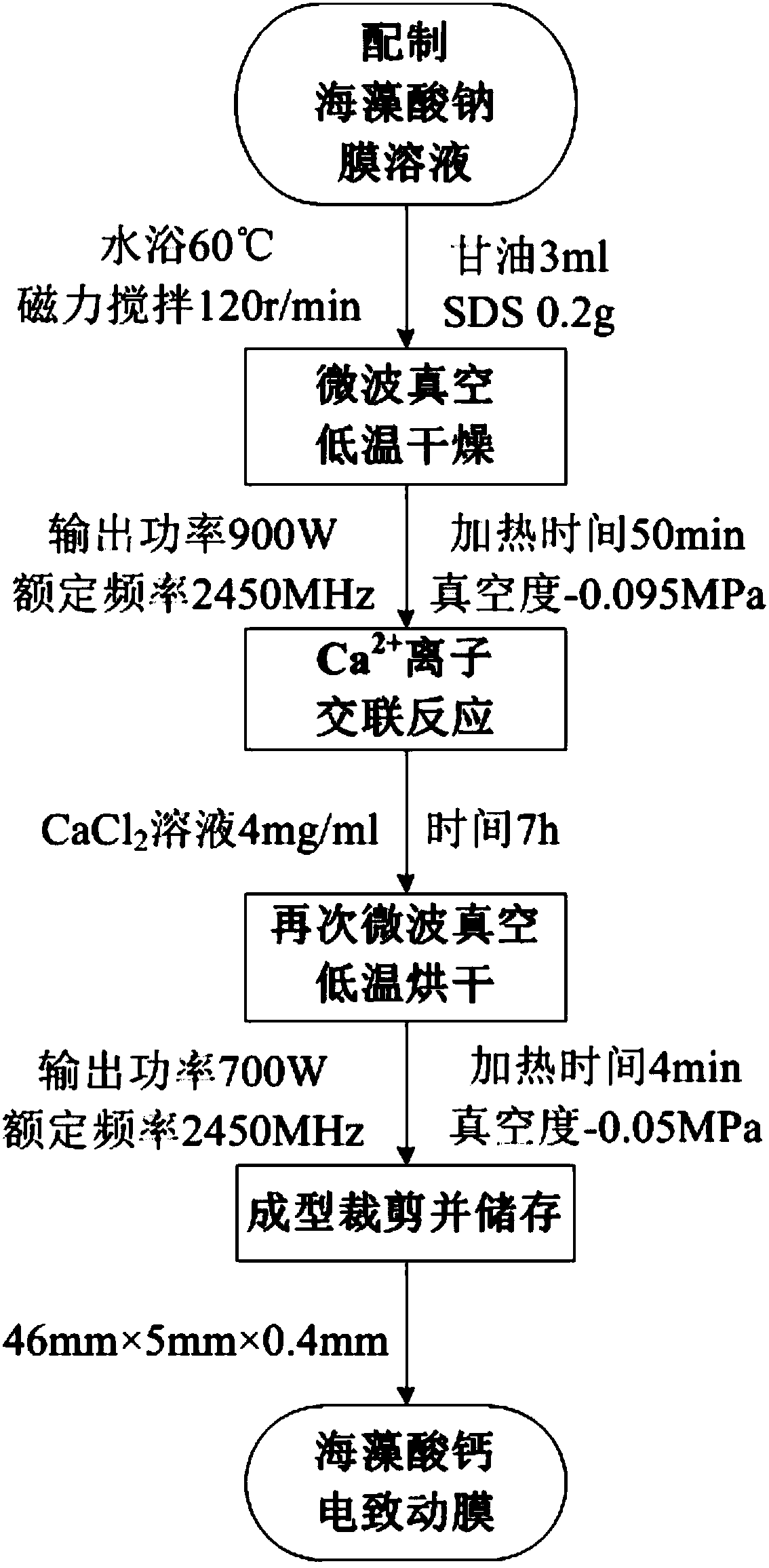

Preparation method of calcium alginate electrically-driven film adopting microwave vacuum low-temperature drying technology

InactiveCN108484955AFlat surfaceReduced diffusion rateProgramme-controlled manipulatorChemical industryCross-linkPolymer science

The invention provides a preparation method of a calcium alginate electrically-driven film adopting a microwave vacuum low-temperature drying technology. The microwave vacuum low-temperature drying technology is adopted, and through the combination with the two technologies of microwave drying and vacuum drying, the advantages of the two technologies are sufficiently and comprehensively developed.The preparation method comprises the following steps: using natural macromolecular biological materials of sodium alga acid as a film forming main material and a cross-linking agent CaCl2, and addingplasticizer glycerinum and plastic assisting agent lauryl sodium sulfate so as to prepare the calcium alginate electrically-driven film of a three-dimensional network gel structure. The raw materialsare wide in sources and low in cost, and the obtained electrically-driven film is non-toxic, tasteless and biodegradable. After microwave vacuum drying, hierarchical pore structures are connected with one another and are regular, the ionic cross-linking of Ca<2+> on the inner layer and the outer layer is comprehensive and uniform, and the electrically-driven film is excellent and controllable inelectrically-driven performance and long in service life. The microwave vacuum low-temperature drying technology of the calcium alginate electrically-driven film prepared in the invention is energy-saving, efficient and free of pollution, and is mostly beneficial for high molecular material synthesis and curing reaction with extremely high requirement for heating rate and uniformity.

Owner:HARBIN ENG UNIV

Continuous evaporative crystallization device and method for 4-cyanopyridine

ActiveCN112691403ALower crystallization temperatureSimplified crystallization stepsOrganic chemistryEvaporator accessoriesPhysical chemistryOrganosolv

The invention discloses a continuous evaporative crystallization device and method for 4-cyanopyridine. The device comprises a pressurizing assembly, a connecting pipe and an evaporation reaction kettle, and is characterized in that the pressure in the evaporation reaction kettle is increased by the pressurizing assembly so as to the crystallization temperature of the 4-cyanopyridine and the boiling point temperature of other organic solvents, after pressurization is completed, a heating resistor is used for heating and crystallizing part of the solution to ensure that only water and other organic solvents are vaporized and the 4-cyanopyridine is heated and crystallized in the evaporation and crystallization process of the 4-cyanopyridine, and meanwhile, water vapor, the other organic solvents and part of the 4-cyanopyridine are absorbed and liquefied again by a condensation reflux box, and drop on the right side of the evaporation reaction kettle, and the heating resistor on the right side carries out evaporative crystallization operation under normal pressure again, so that the 4-cyanopyridine is separated out after being crystallized and is attached to the inner wall of the right side of the evaporation reaction kettle, the crystallization operation steps of the 4-cyanopyridine are simplified, and the crystallization amount of the 4-cyanopyridine separated out is effectively increased.

Owner:ANHUI COSTAR BIOCHEM CO LTD

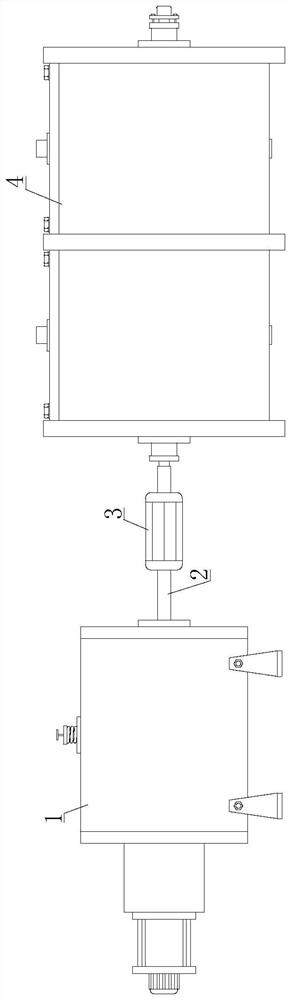

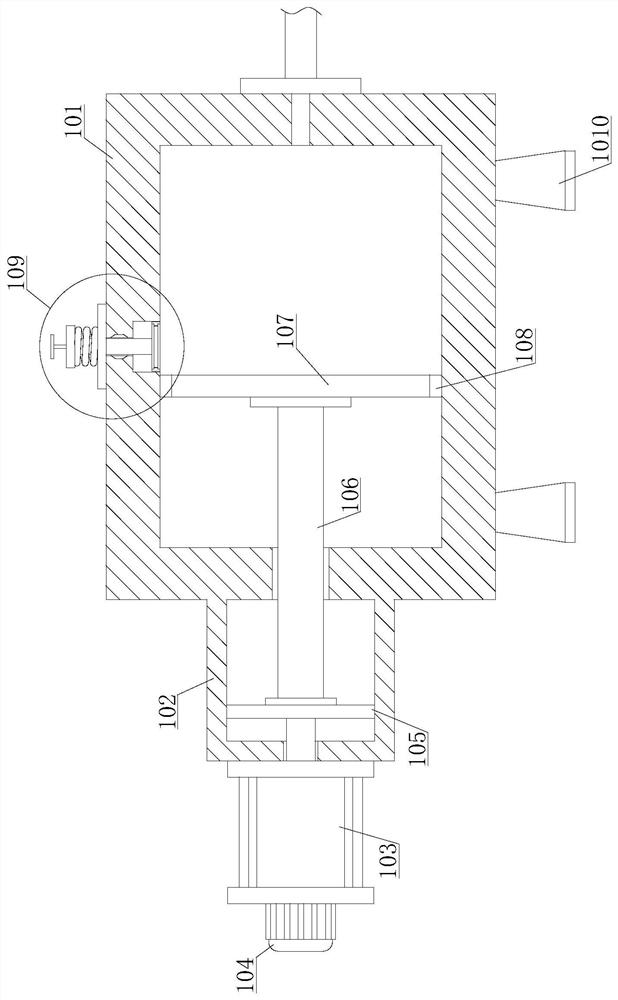

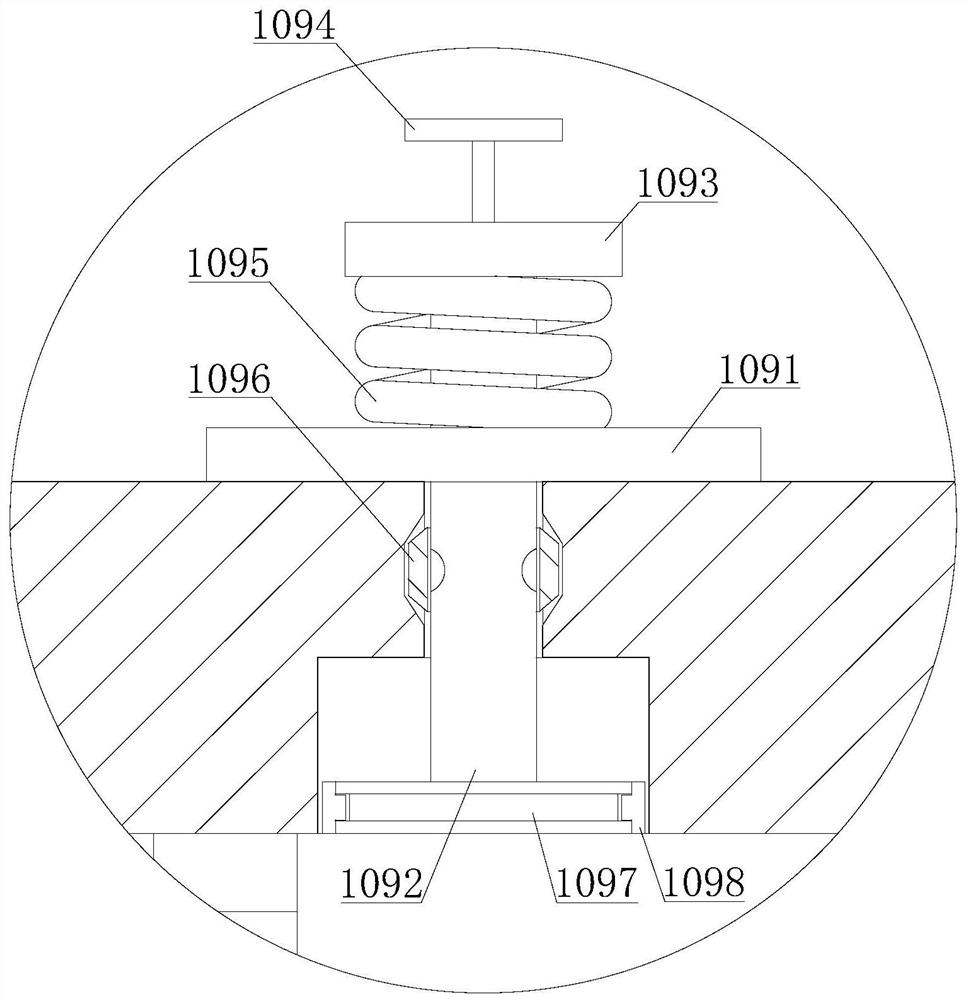

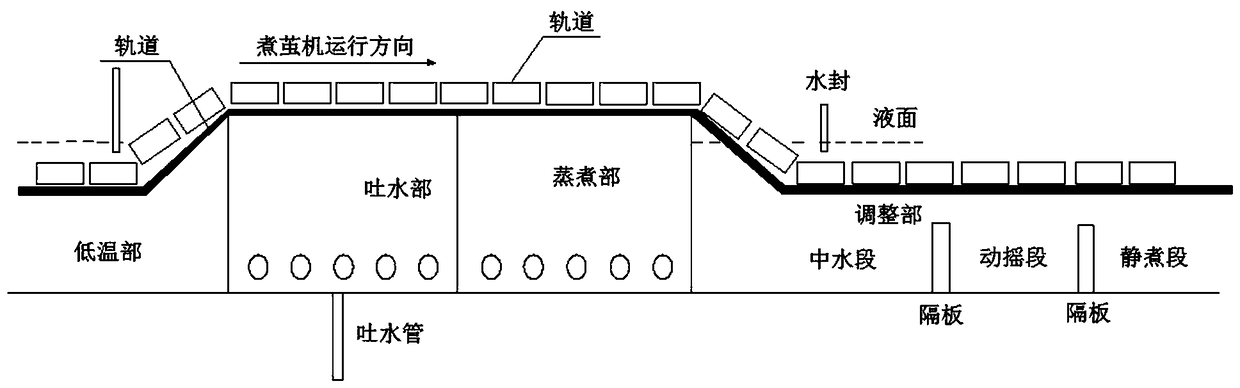

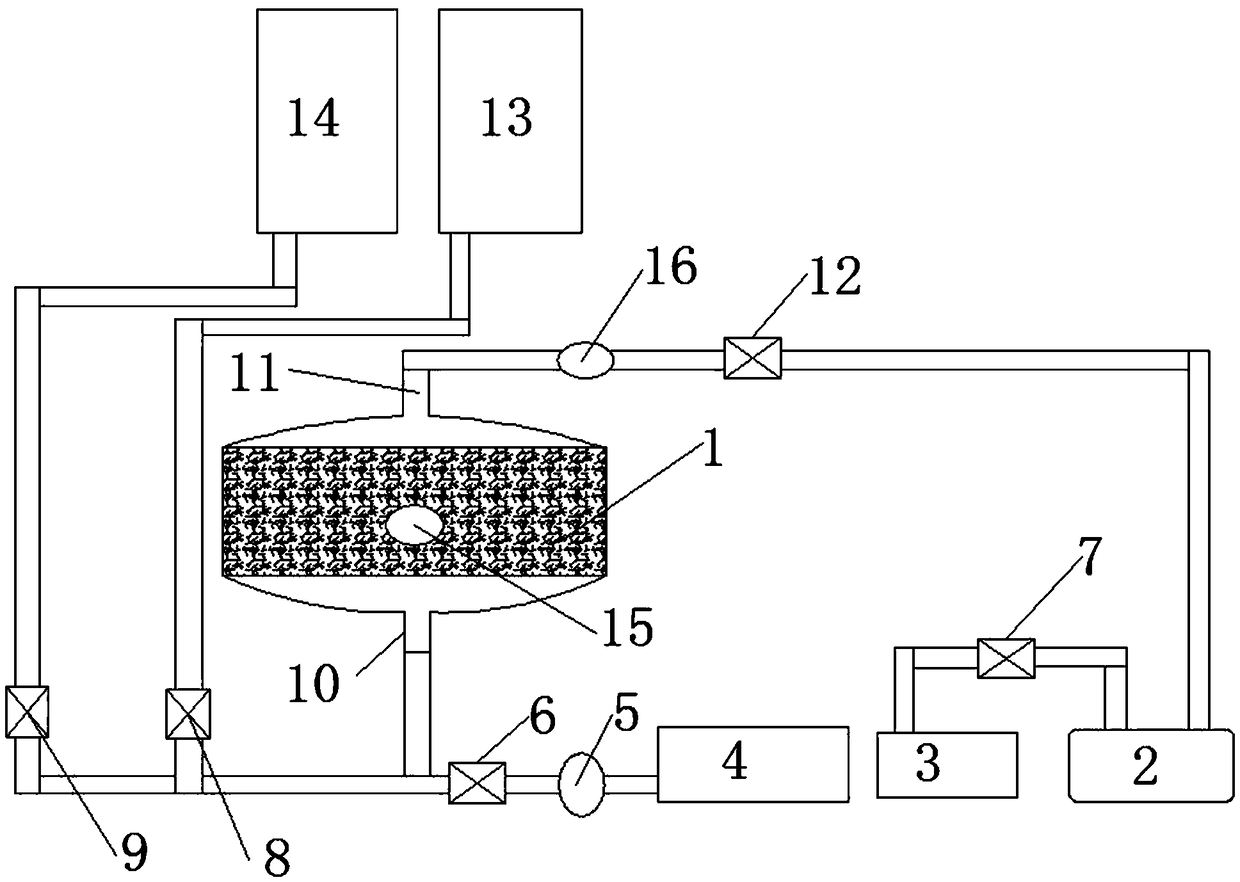

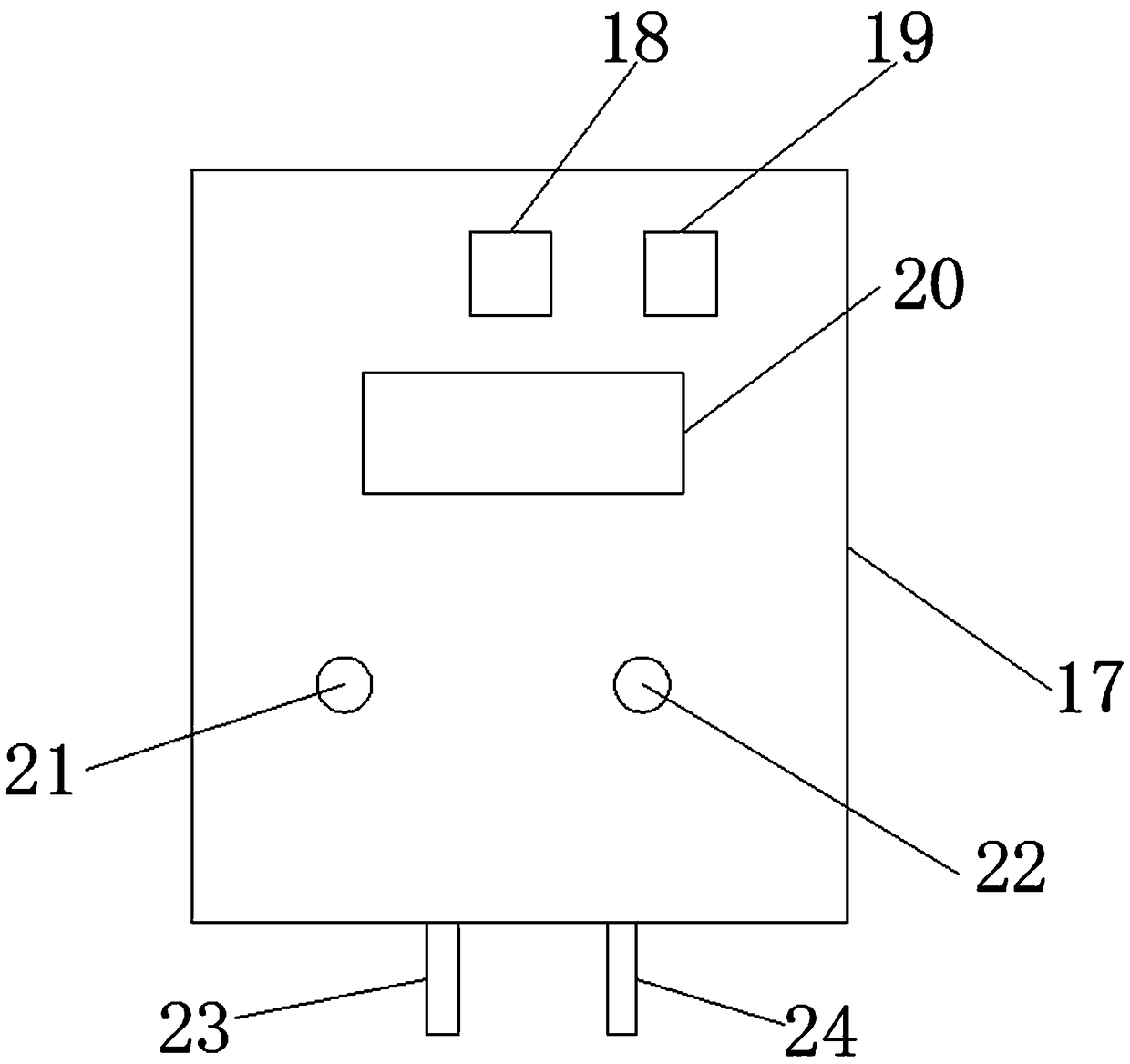

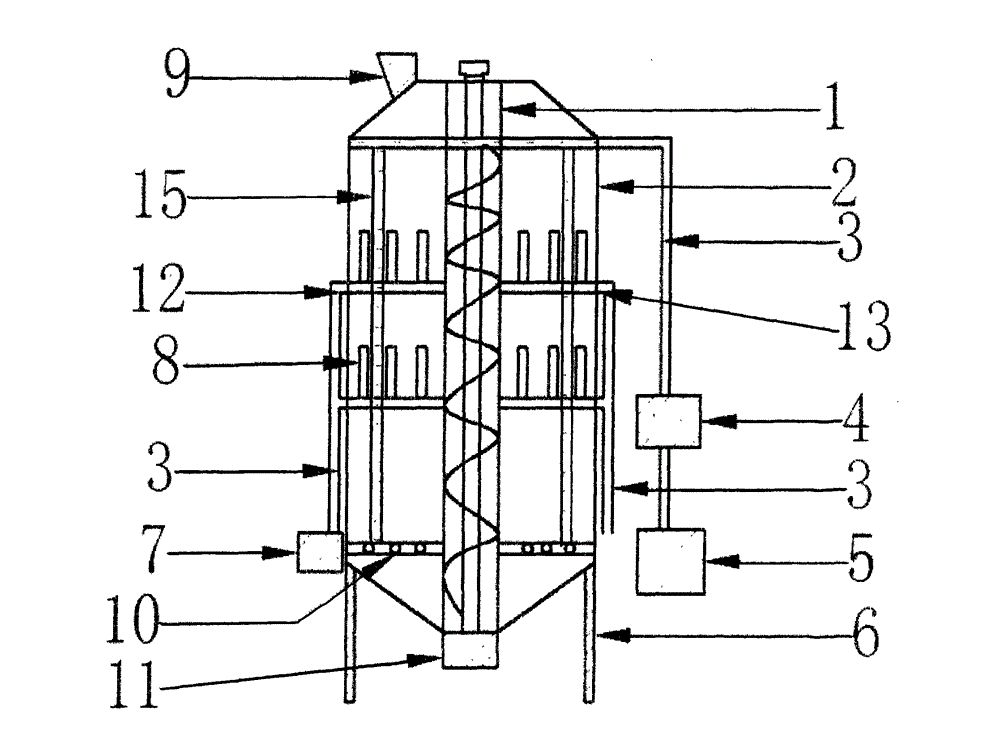

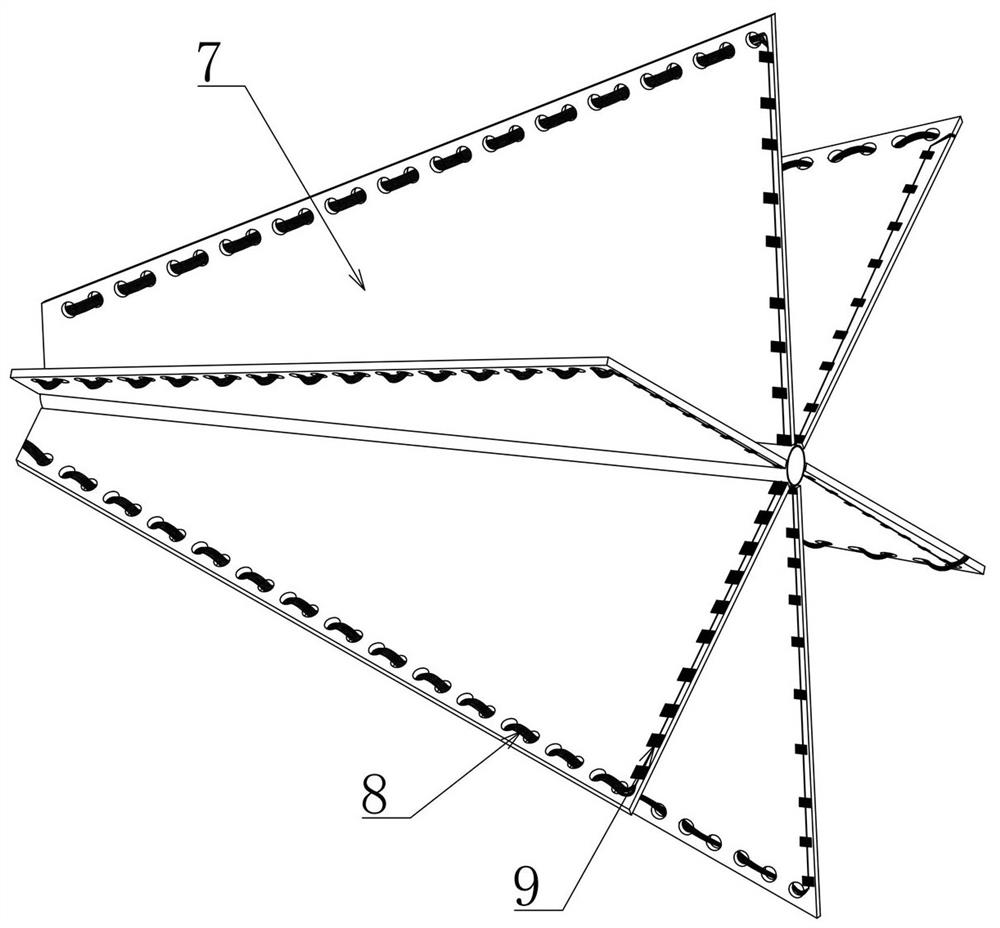

Cocoon cooking water absorption adjusting device in vacuum state and control technology thereof

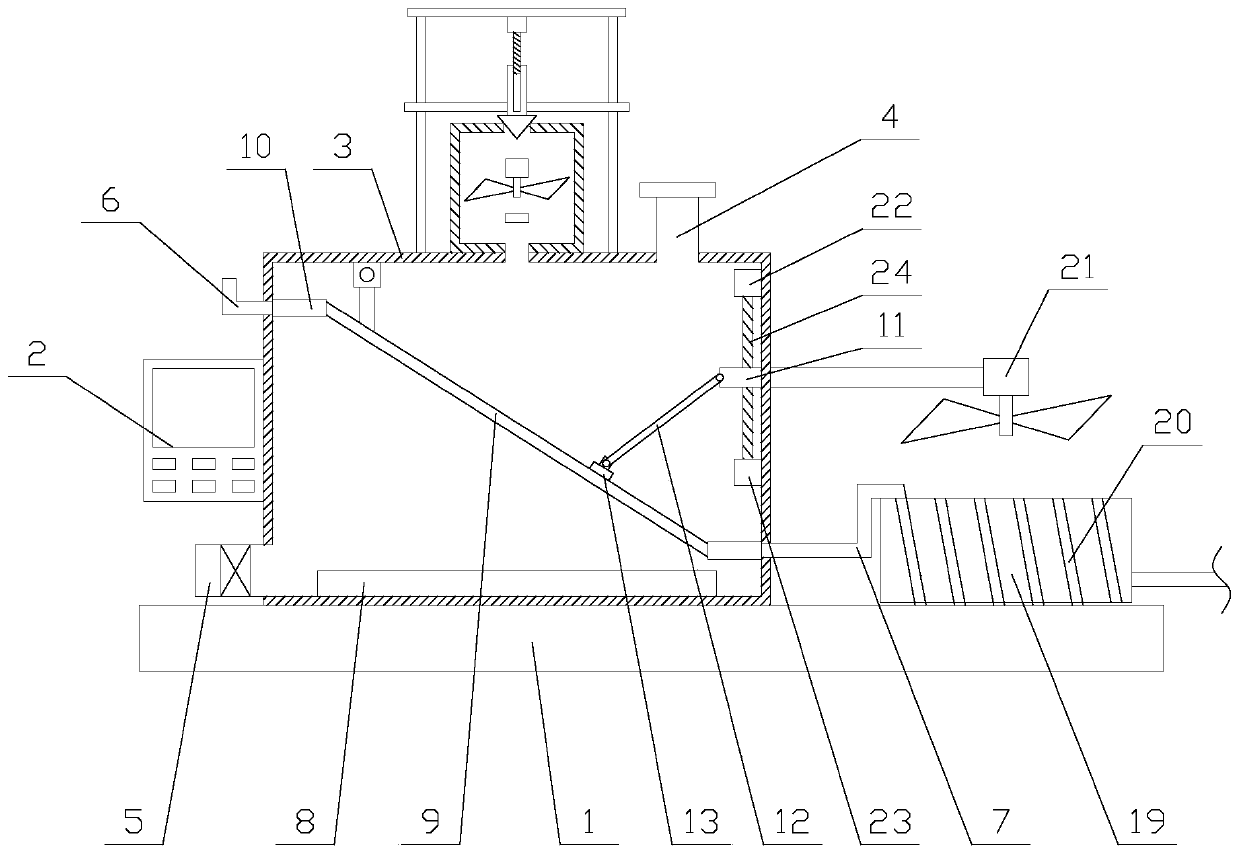

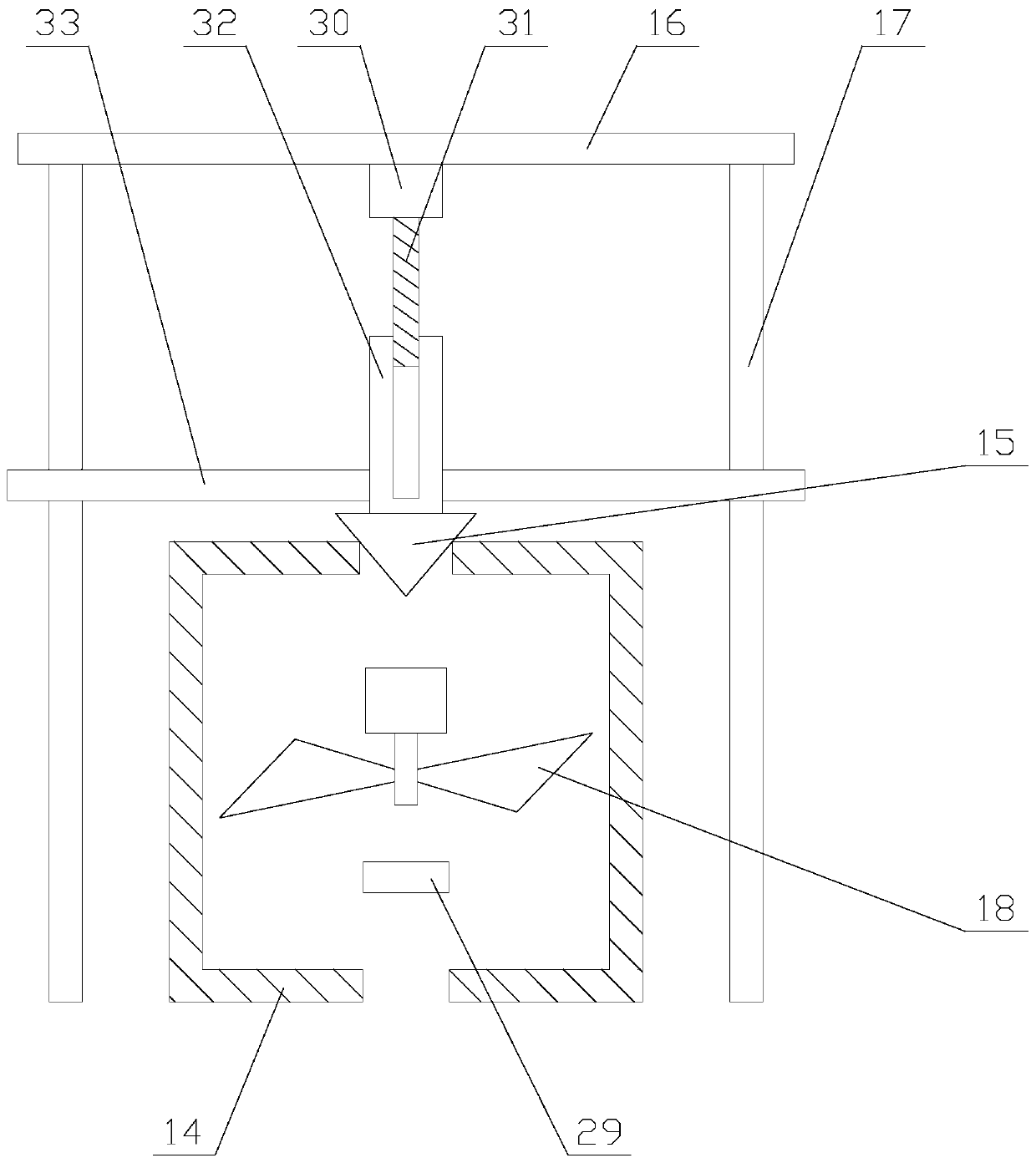

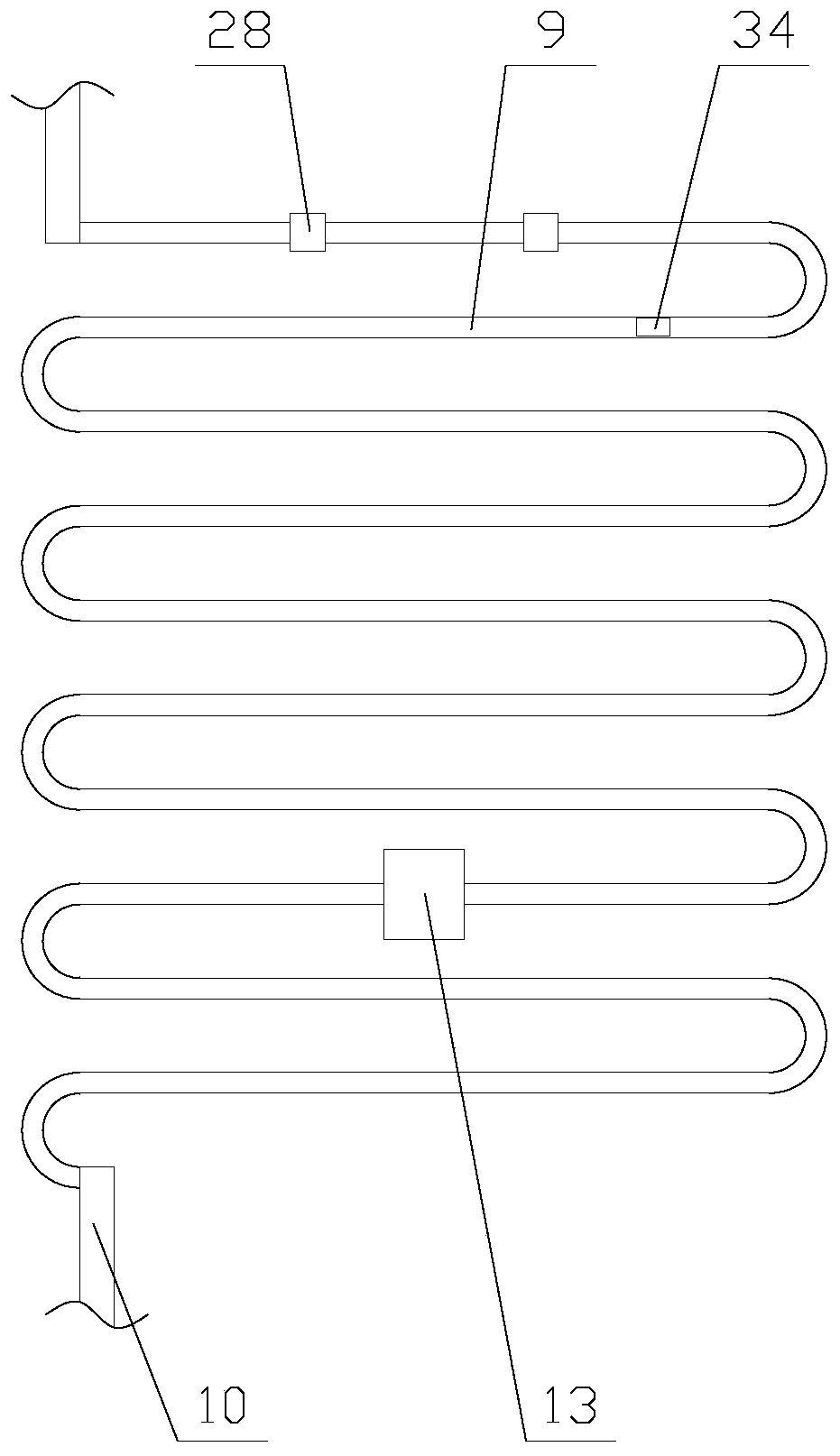

InactiveCN108754627AReduces the chance of shriveled cocoonsImprove the uniformity of water absorptionSilk reelingEngineeringElectromagnetic valve

The invention discloses a cocoon cooking water absorption adjusting device in a vacuum state and a control technology thereof. The device comprises a vacuum water absorption adjusting device and an electric control cabinet control device in control connection with the vacuum water absorption adjusting device, and the vacuum water absorption adjusting device comprises a temperature probe, a water tank, a pipeline, a main tank, an auxiliary tank and electric control equipment composed of a one-way valve, a water pump, a vacuum pump and a plurality of electromagnetic valves; the electric controlcabinet control device comprises an electric control cabinet body, a PLC main board is arranged in the electric control cabinet body, a PLC text displaying screen, an automatic running switch and an automatic / manual change-over switch are arranged on the electric control cabinet body; the control technology comprises the steps that vacuumizing is conducted, and high-temperature water is sucked; vacuumizing is conducted, and low-temperature water is sucked; vacuumizing is conducted, and normal-temperature water is sucked; vacuumizing is conducted, and the normal-temperature water is continuously sucked; air releasing and re-pressing are conducted, and silkworm cocoon water absorption adjusting temperature reducing protection is completed; the device is in a closed cocoon cooking container,water absorption adjusting for cocoons is completed in the vacuum state, and the control technology can make the cocoons uniformly absorb water and reduce the generation rate of shriveled cocoons.

Owner:SICHUAN RES INST OF SILK SCI

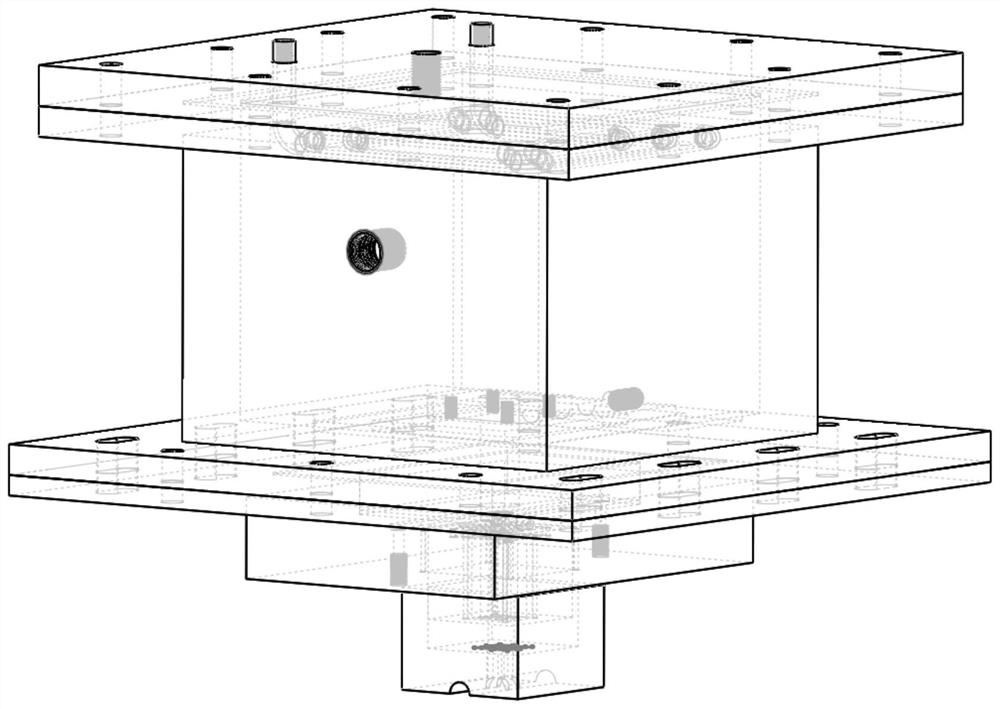

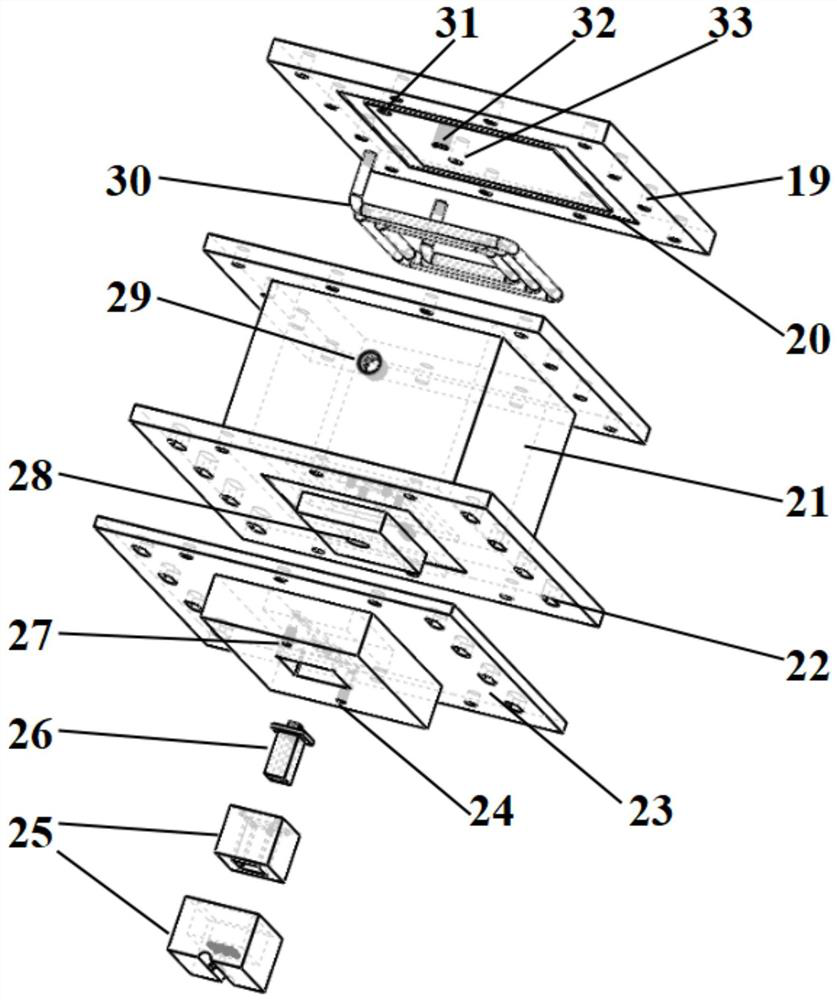

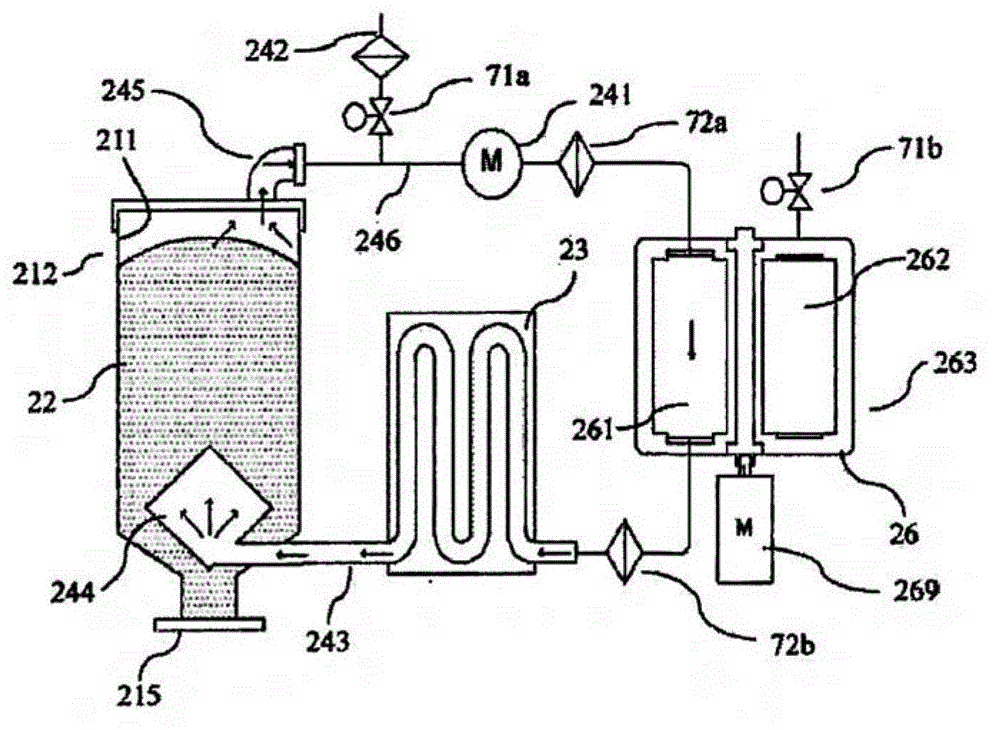

Negative-pressure phase-change heat dissipation device and high-heat-flux electronic chip simulation heat dissipation system

ActiveCN112702889AAvoid separationBreak away quicklyModifications by conduction heat transferEvaporation heat transferHeat flow

The invention discloses a negative-pressure phase-change heat dissipation device and a high-heat-flux electronic chip simulation heat dissipation system, which utilize boiling coupling film evaporation to use a water working medium to generate phase change in a negative pressure environment, so as to realize efficient heat dissipation of a chip, and solve the problems that a liquid supply channel and a gas separation channel of an existing chip cold plate are mixed and the heat transfer capacity is low. A negative pressure environment is generated on one side of an evaporation waterproof breathable film, the pressure difference between the two sides of the film is increased, on one hand, mutual interference of traditional boiling heat exchange gas separation and liquid supply is avoided, on the other hand, the evaporation power and speed of the liquid are enhanced, the working efficiency of the cold plate is remarkably improved by utilizing a film evaporation mechanism, and the heat dissipation requirement that the heat flux density exceeds 1 kW / cm<2> can be met.

Owner:XI AN JIAOTONG UNIV

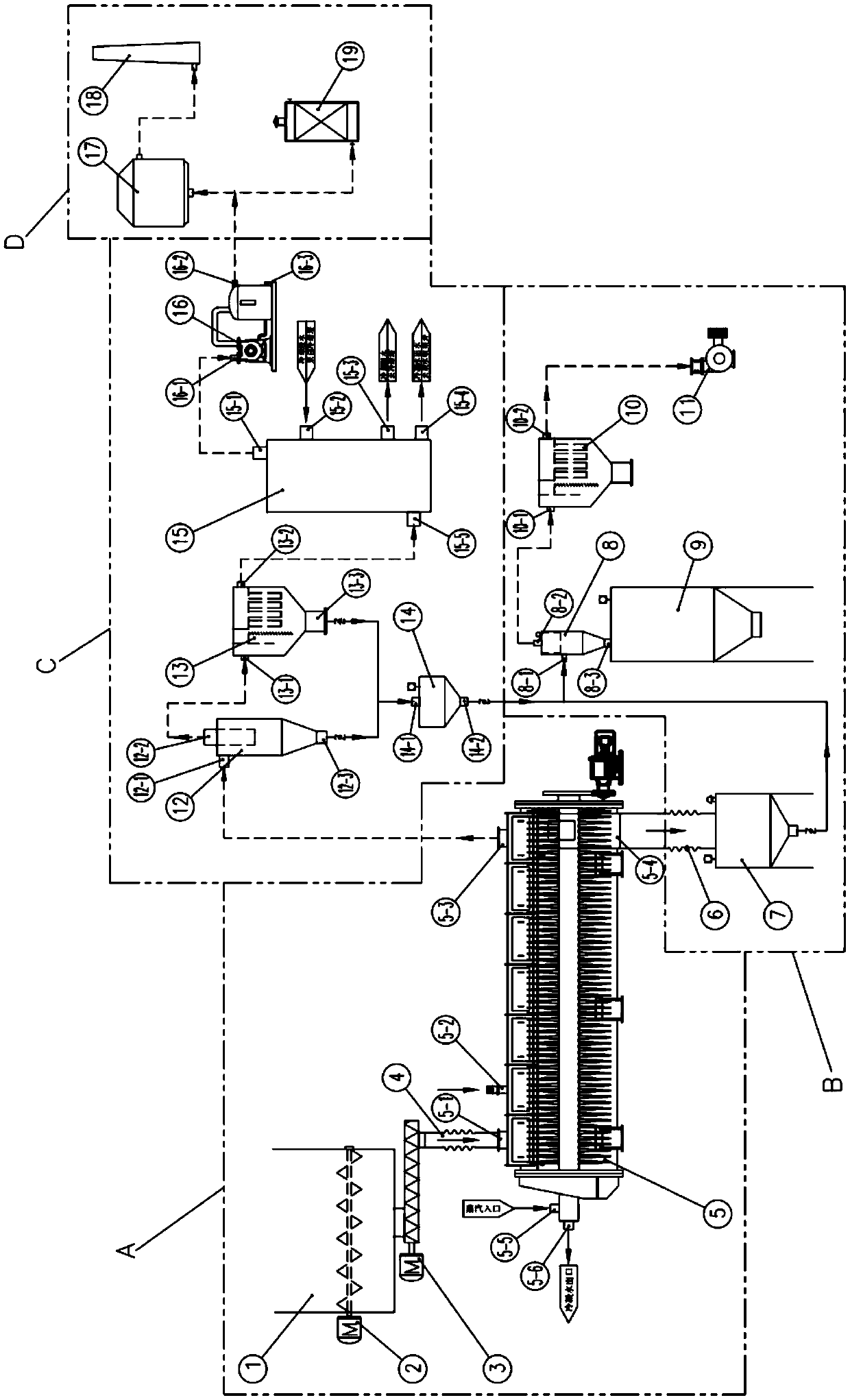

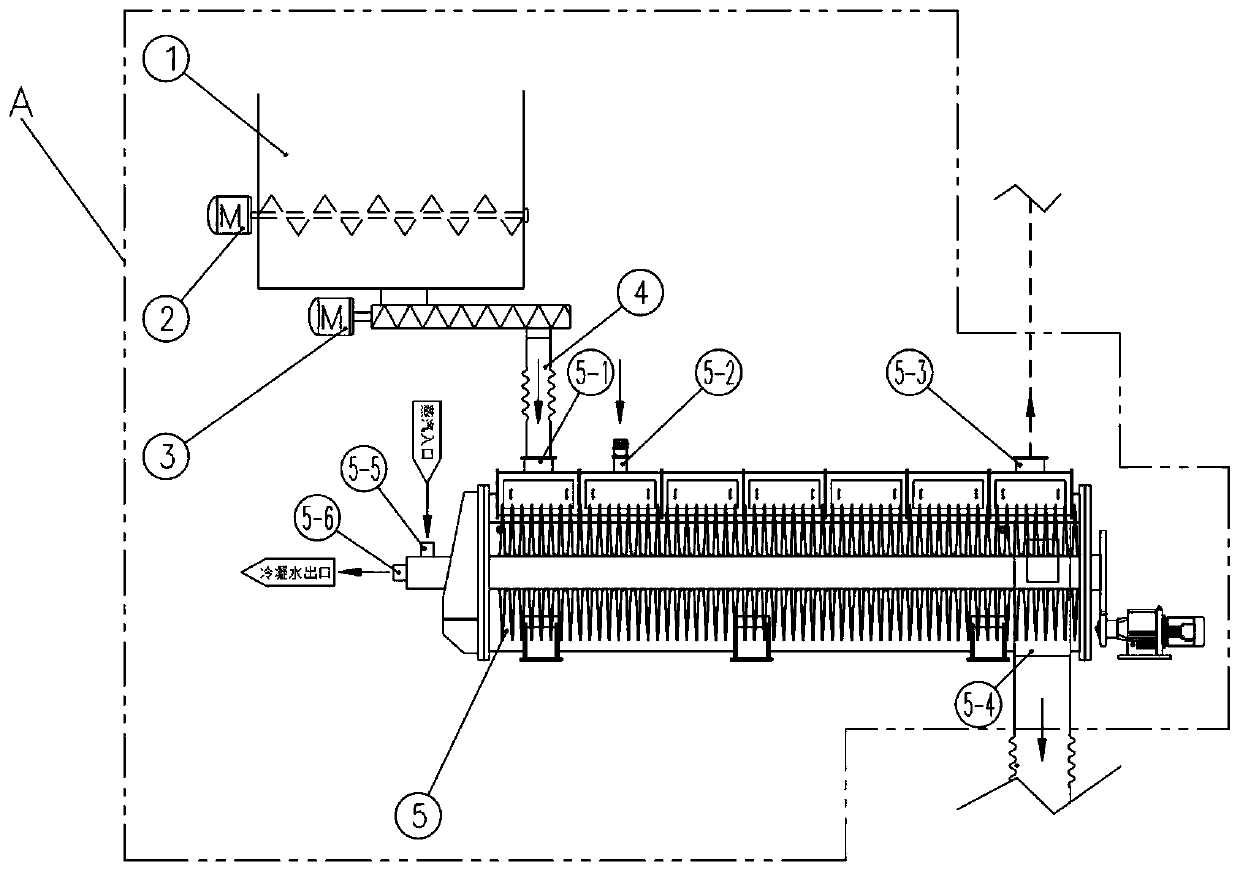

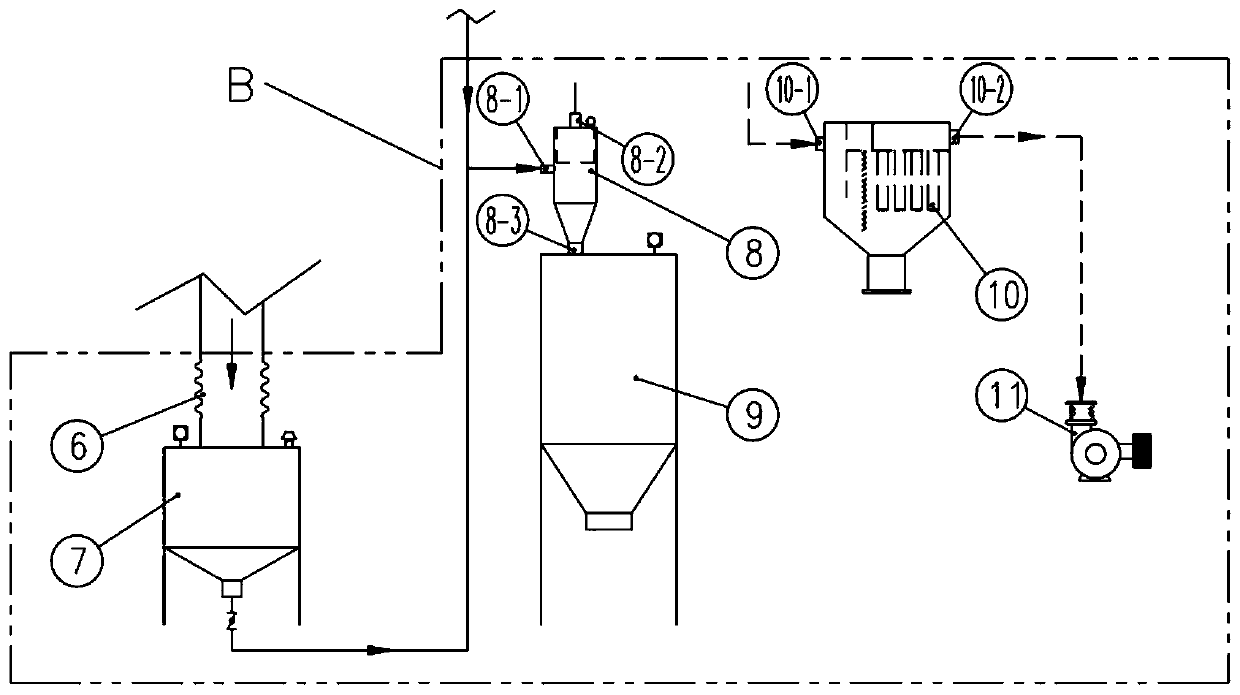

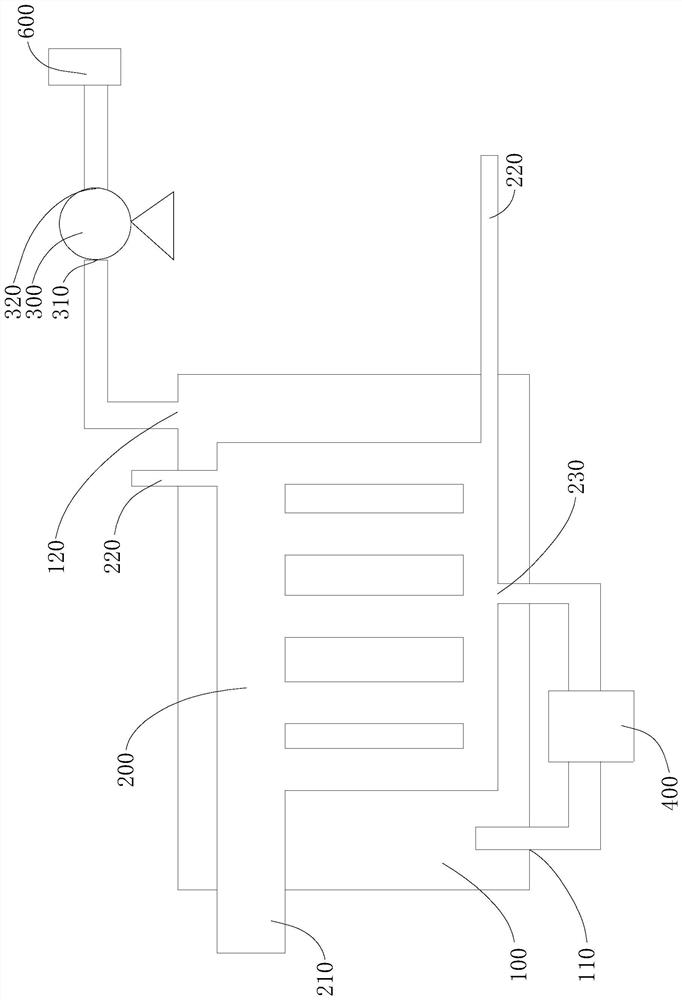

Low-vacuum sludge drying system

PendingCN111470749ALower boiling pointIncrease water evaporation rateCombination devicesSludge treatment by de-watering/drying/thickeningSludgeBaghouse

The invention discloses a low-vacuum sludge drying system, and relates to the technical field of sludge drying. The system comprises a wet sludge bin, an arch breaking device, a conveying device, a feeding flexible connecting section, a low-vacuum sludge drying device, a discharging flexible connecting section, a buffer bin, a vacuum conveying device, a dry sludge bin, an efficient bag type dust removal device, a Roots blower, a cyclone dust removal device, an efficient bag type dust remover, a storage bin, a condenser, a vacuum system, an incineration device, a chimney and a deodorization device, wherein the arch breaking device is mounted on the wet sludge bin. The low-vacuum sludge drying system provided by the invention is of a fully-sealed structure, the sludge drying device is subjected to space air exhaust through the vacuum system, so that a certain negative pressure state is formed in the sludge drying device, and sludge drying is carried out in the negative pressure state environment; not only is the boiling point temperature reduced, but also the water evaporation speed is increased; and the overall operation energy consumption of the equipment is directly reduced, so that the energy-saving effect is achieved.

Owner:上海净泥新能源科技有限公司

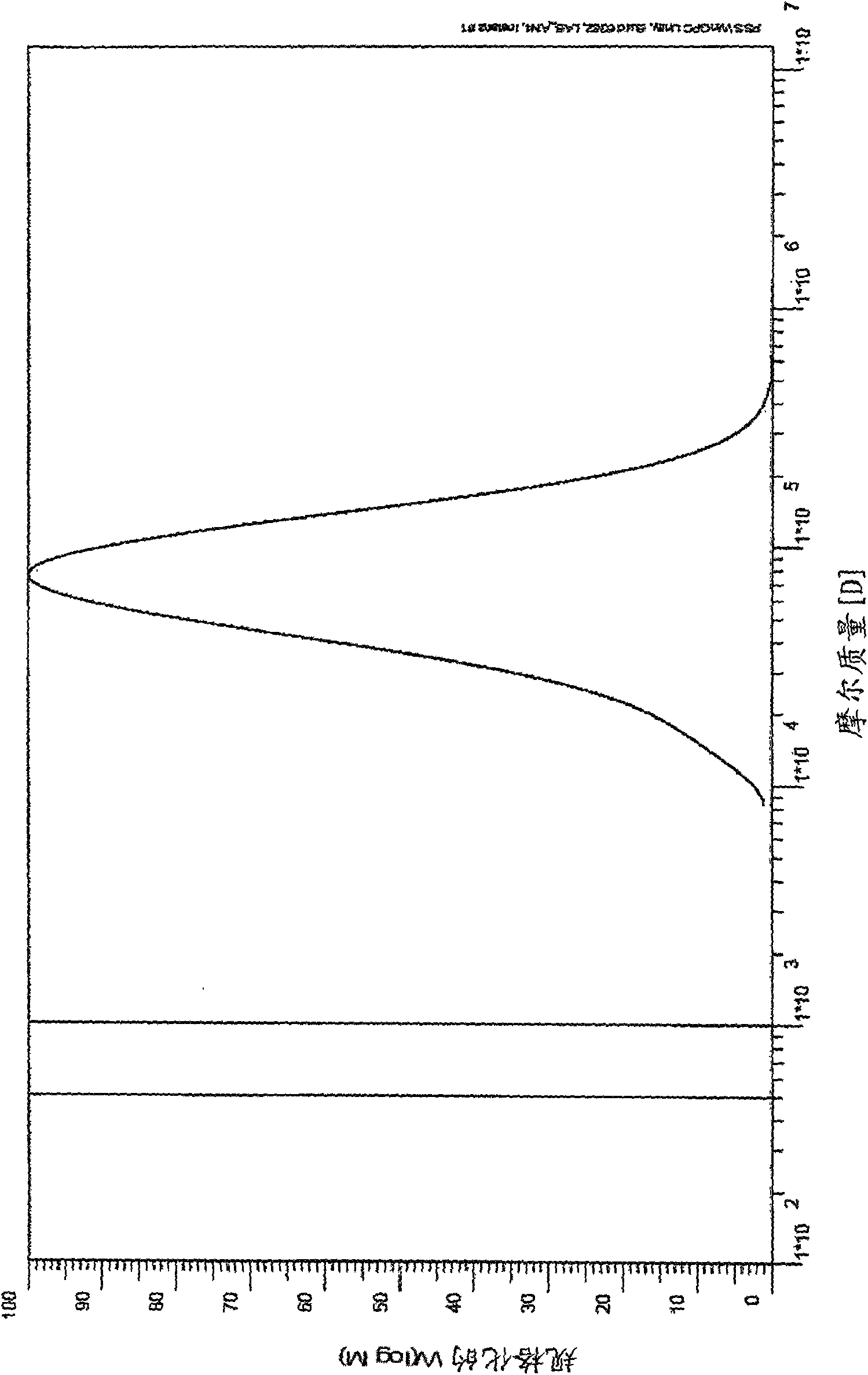

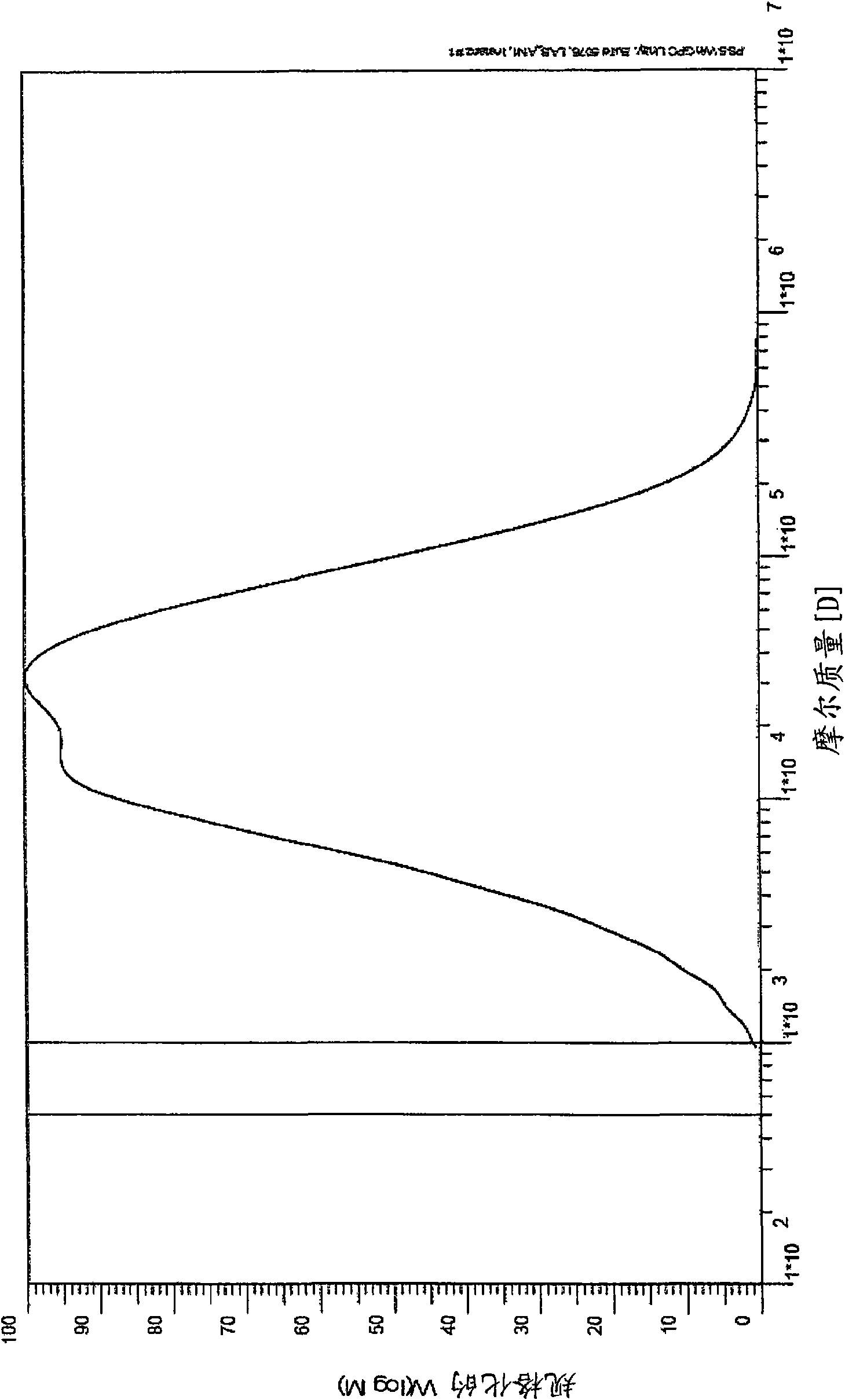

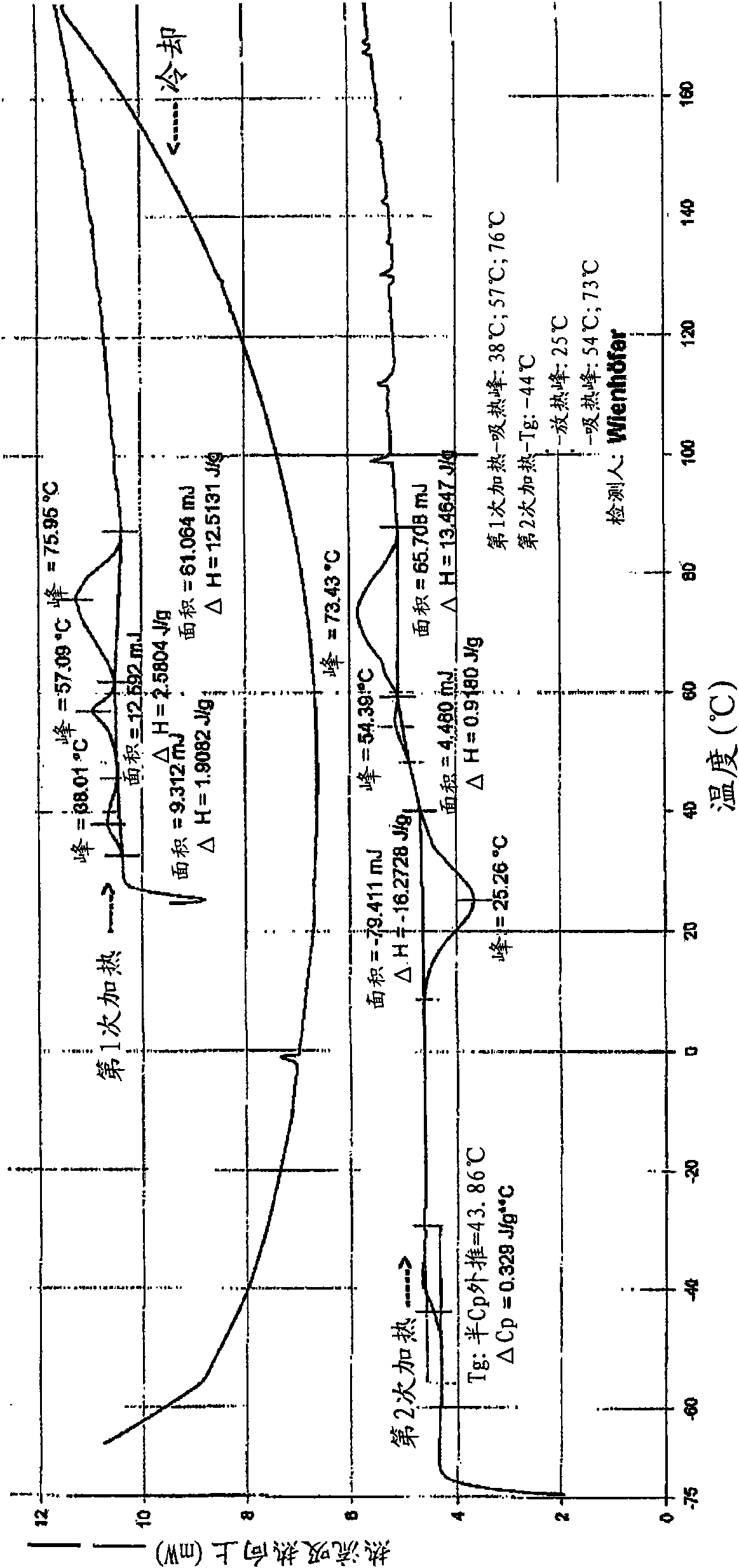

Use of polyolefins comprising atactic structural elements in floor coverings

InactiveCN101555303AEasy to implantReduce melt viscosityConstructions elementsCoatingsChemistryPolyolefin

The present invention relates to the use of polyolefins comprising atactic structural elements in floor coverings, in particular in rugs or artificial lawns. The polyolefins contain at most 30 mass % of ethylene, 70 to 100 mass % of or at most 30 mass % of propylene, and / or 70 to 100 mass % of or at most 25 mass % of 1-butene or other straight-chain 1-olefin. The total amount is 100 mass %. A triad distribution of propylene triad measured through <13>C-NMR method has 20 to 55 mass % of atactic structure, 40 to 80 mass % of isotactic structure and at most 30 mass % of syndiotaxy; and / or a triad distribution of 1-butene measured through <13>C-NMR method has 2 to 85 mass % of atactic structure and at most 20 mass % of syndiotaxy.

Owner:EVONIK DEGUSSA GMBH

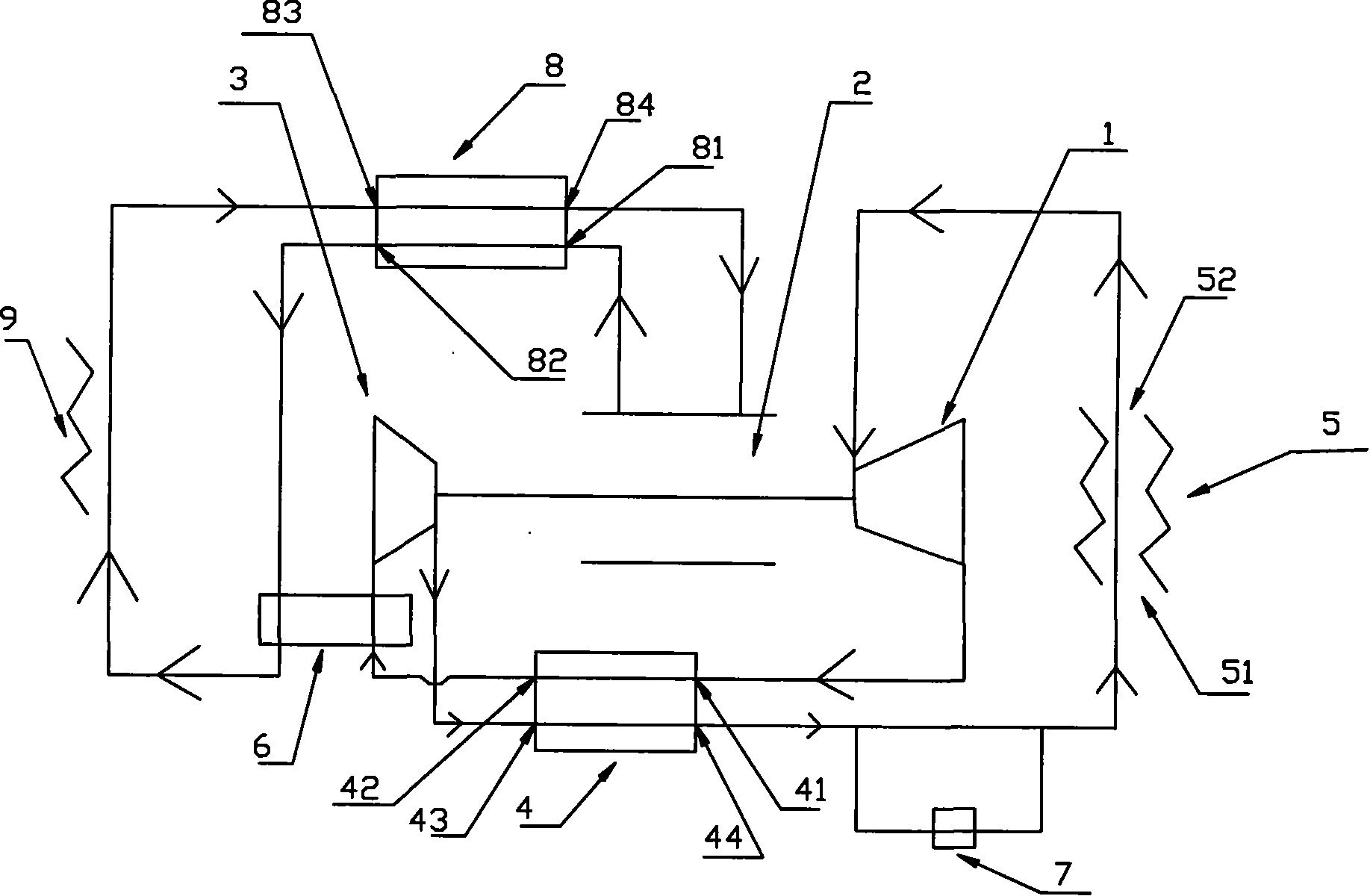

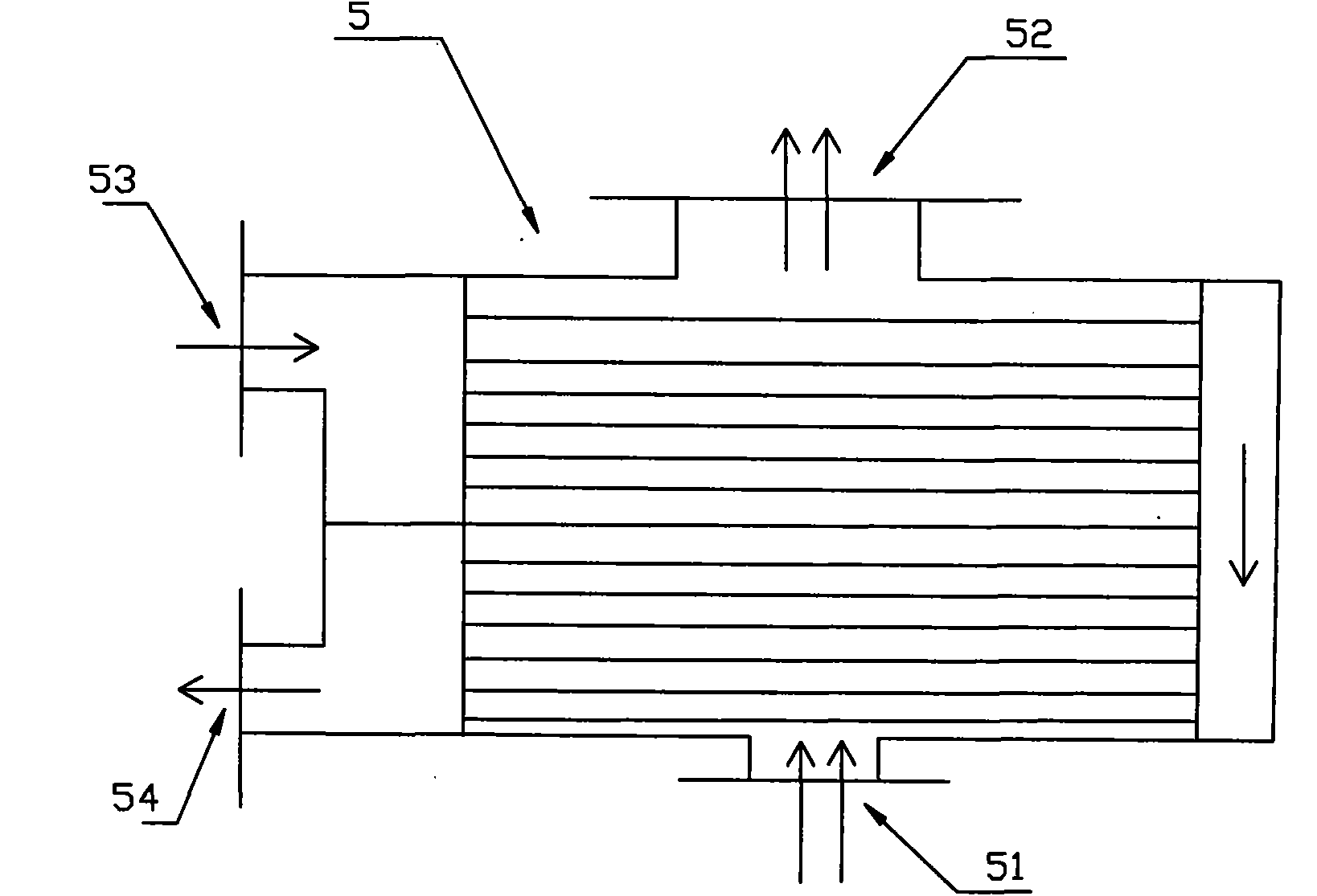

Vacuum circulating drying machine for grain

InactiveCN106288748ADry evenly at low temperatureFast dryingDrying solid materialsDrying machines with local agitationAtmospheric airBoiling point

The invention discloses a vacuum circulating drying machine for grain. The machine comprises a lifting device, a drying bin, a condenser, a vacuum pump, a heating device, a heat exchanger, a feeding valve, a discharging valve, a grain discharging device, a ventilation device, a support and air ducts; the lower end of the drying bin is fixedly supported by the support; the discharging valve is mounted at one end below the drying bin; the feeding valve is mounted on the side surface of the upper end of the drying bin; the lifting device is mounted in the center of the upper end of the drying bin; the heat exchanger, the grain discharging device and an exhaust device are mounted in a bin body of the drying bin; and after an outlet of the exhaust device extends out of the drying bin, moisture in the drying bin is exhausted into the atmosphere via the outlet of the exhaust device by the aid of the air duct I, the condenser, the air duct II and the vacuum pump. With the machine, continuous lifting stirring can be realized, the thermal conversion efficiency of heat internal circulation is high, the loss is low, heat conduction and heat dissipation speeds are increased, the drying temperature is increased, the boiling temperature of the moisture is reduced, and the quality of the dried grain is further improved.

Owner:张家鑫

Negative pressure concentration total heat type evaporation recovery system

PendingCN111974015AEfficient recyclingEmission reductionHeat recovery systemsEvaporation with vapour compressionPlate heat exchangerProcess engineering

The invention provides a negative pressure concentration total heat type evaporation recovery system. The negative pressure concentration total heat type evaporation recovery system comprises a high-temperature heat pump, an air energy heat pump, a circulating heat preservation and storage box, a heater, an evaporator, a preheating tank, a condenser, a plate heat exchanger and a finished product device. The high-temperature heat pump is connected with the circulating heat preservation and storage box and the heater; the air energy heat pump is connected between the high-temperature heat pump and the circulation heat preservation and storage box; the heater is connected with the evaporator and the preheating tank; the evaporator is connected with the condenser and the finished product device; the preheating tank is connected with the plate heat exchanger and the finished product device; the plate heat exchanger is connected with the condenser; and the condenser is connected with the circulating heat preservation and storage box. The reverse Carnot cycle principle is utilized to condense and recover the heat required to be discharged in the concentration technique process, and the heat is used for heating the solution, thereby implementing cyclic utilization of the heat, greatly lowering the energy consumption, lowering the evaporation boiling point and further lowering the energy consumption; and equipment is simple and efficient, a boiler is not needed, and a large amount of carbon emission and operation cost can be reduced.

Owner:江西臻强新能源有限公司

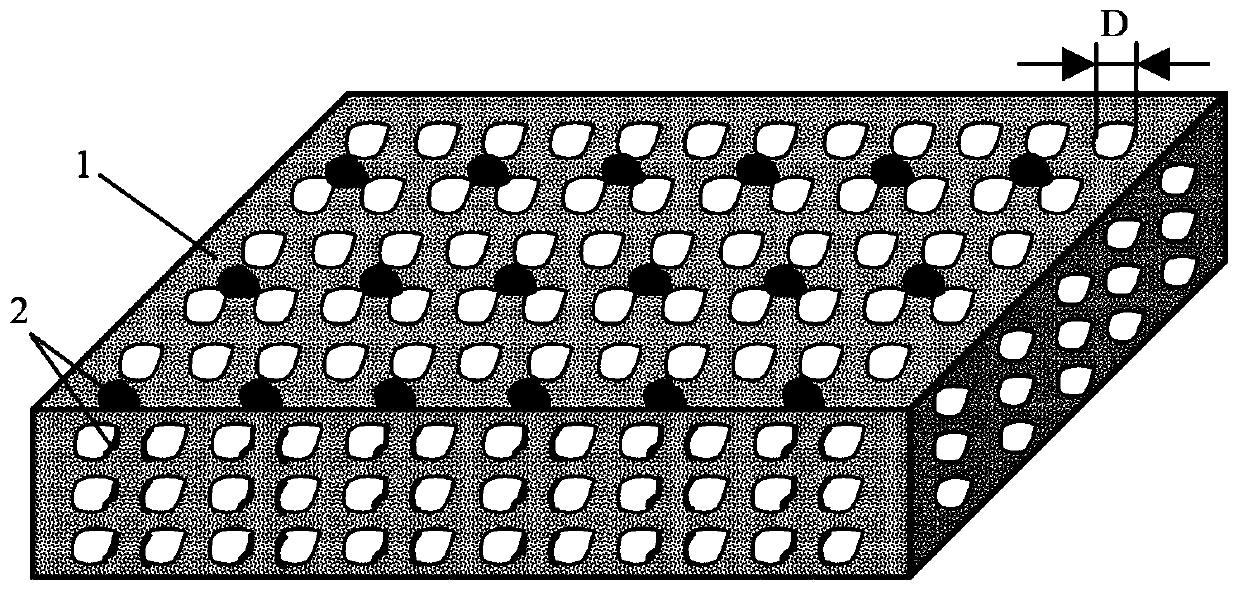

Foam metal with mixed wet surface and preparation method thereof

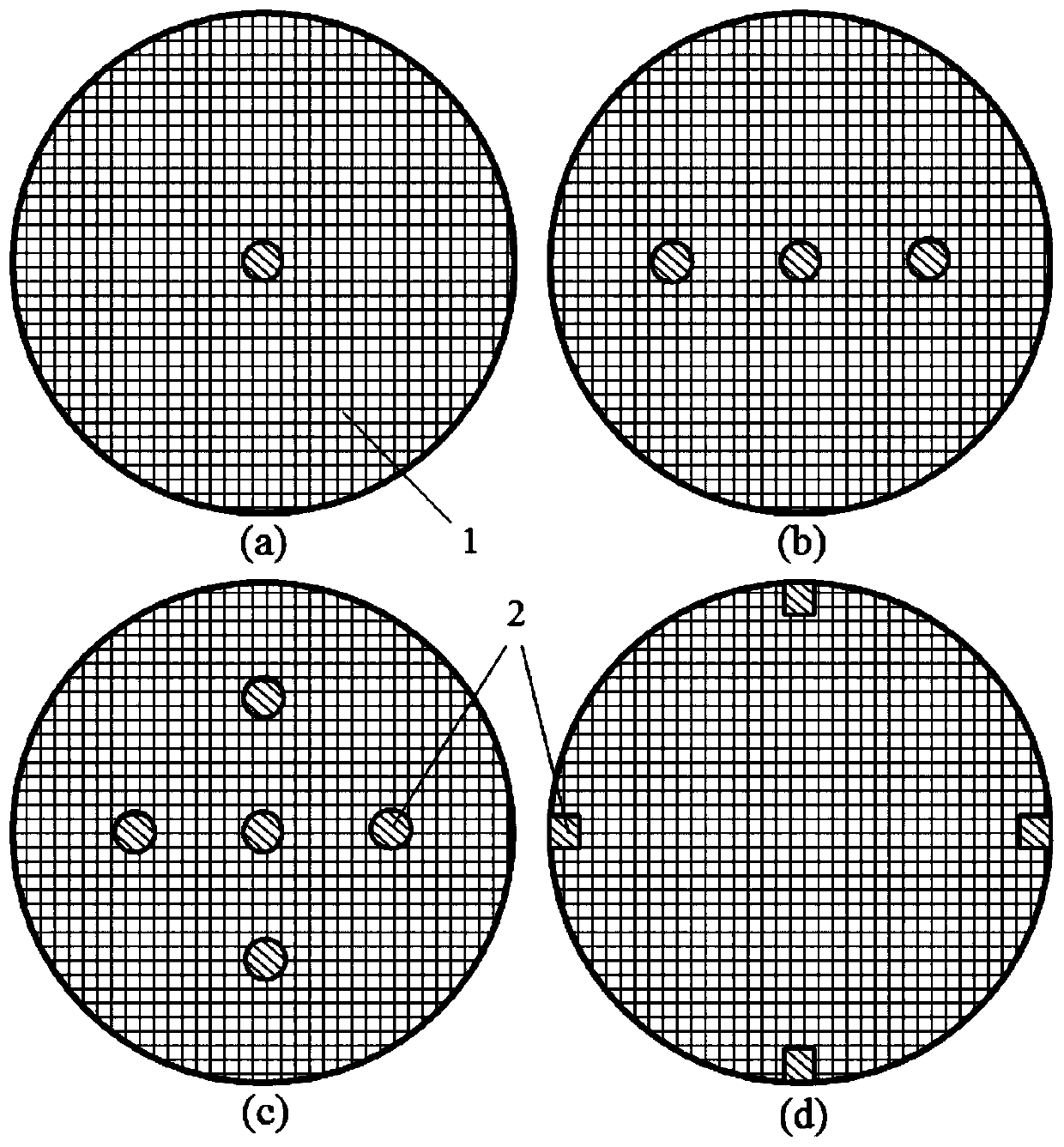

InactiveCN110551998AEnhanced Capillary SuctionReduce disengagement resistanceMetallic material coating processesMicro nanoElectronic component

The invention discloses foam metal with a mixed wet surface and a preparation method thereof. The foam metal comprises a super-hydrophilic surface (1) obtained through a chemical oxidization process and a foam meal surface locally covered by a super-hydrophilic film (2). The foam metal is characterized in that the super-hydrophilic surface (1) is provided with a micro-nano binary surface structure, wherein the main component of the super-hydrophilic film (2) is a high-molecular compound with a hydrophobic group. The foam metal is used in strengthening of boiling heat transfer, can improve boiling heat transfer property, and meets heat dissipation needs of high-integration electronic components and parts and heat exchange equipment with high heat exchange amount. The super-hydrophilic surface (1) in the foam metal has extremely strong lyophilic property, reduces gas bubble separating resistance, improves capillary liquid-absorbing ability, and obviously improves boiling heat transfer property; the super-hydrophilic film (2) which can be locally distributed can quicken a nucleation process of gas bubbles, a boiling start point is reduced, and boiling heat transfer property of foam metal is further strengthened.

Owner:SOUTHEAST UNIV

Pasteurization equipment for milk disinfection, having function of accurate regulating

InactiveCN110037106APrecise control of heating timeReduce pressureMilk preservationHeating timePasteurization

The invention relates to pasteurization equipment for milk disinfection, having a function of accurate regulating. The pasteurization equipment comprises a base, a controller, a water tank, a water filling pipe, a drain pipe, a pressure reducing mechanism, a liquid inlet pipe, a liquid outlet pipe and a heat dissipation mechanism, wherein a speed regulating mechanism and a heater are arranged in the water tank; the speed regulating mechanism comprises a heating pipe, a hinging assembly, a steering assembly and two hoses; the steering assembly comprises a lifting unit, a lifting block, a connecting rod and a connecting plate; and the pressure reducing mechanism comprises a pressure reducing box, a blocking block, a seal assembly, a top plate and two supporting rods. According to the pasteurization equipment for milk disinfection, having the function of accurate regulating disclosed by the invention, through the pressure reducing mechanism, the pressure intensity in the water tank is reduced, so that the boiling point temperature of water in the water tank is reduced, and the situation that the water temperature is too high, and nutrient substances of the milk run off is avoided; moreover, the flow rate of the milk in the heating pipe is regulated by the speed regulating mechanism, so that the heating time of the milk is accurately controlled, favorable sterilization and disinfection effect is guaranteed, and the practicality of the equipment is improved.

Owner:齐宽宽

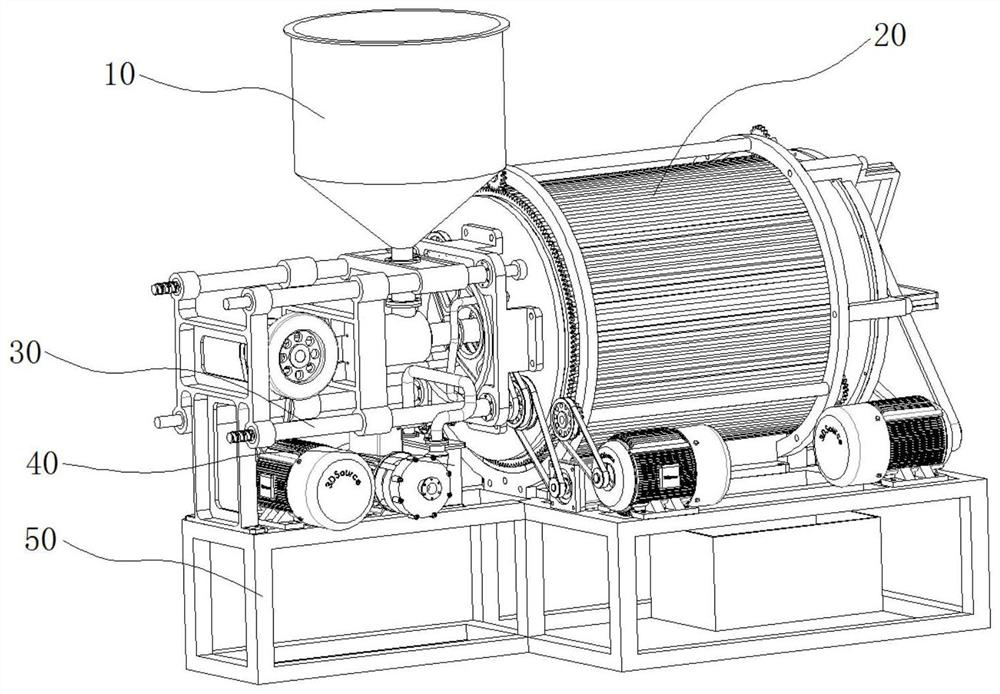

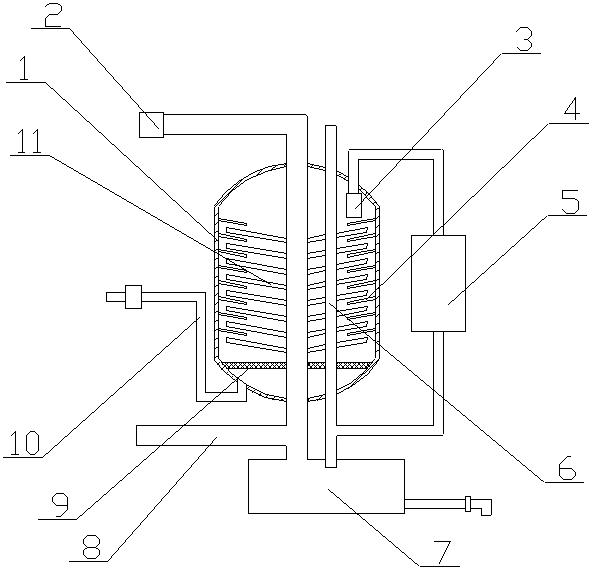

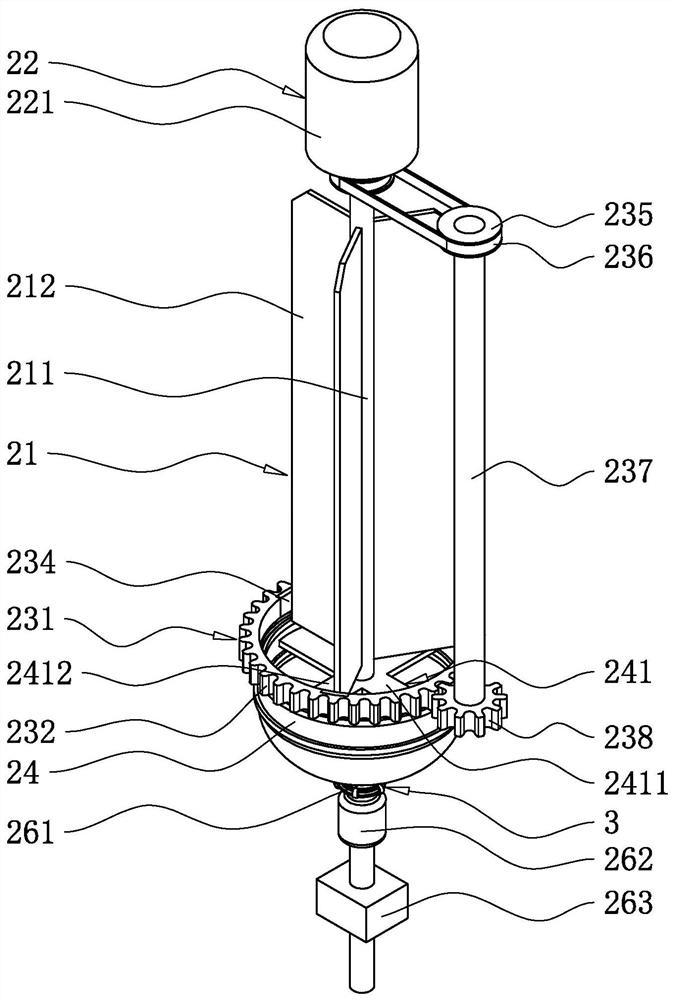

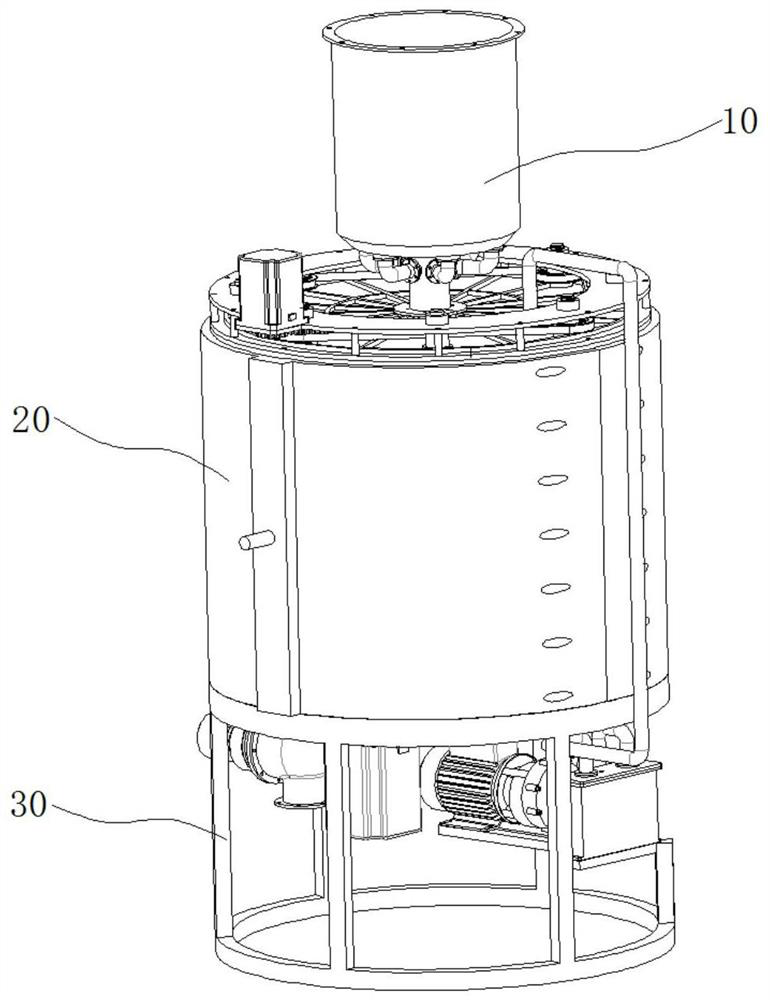

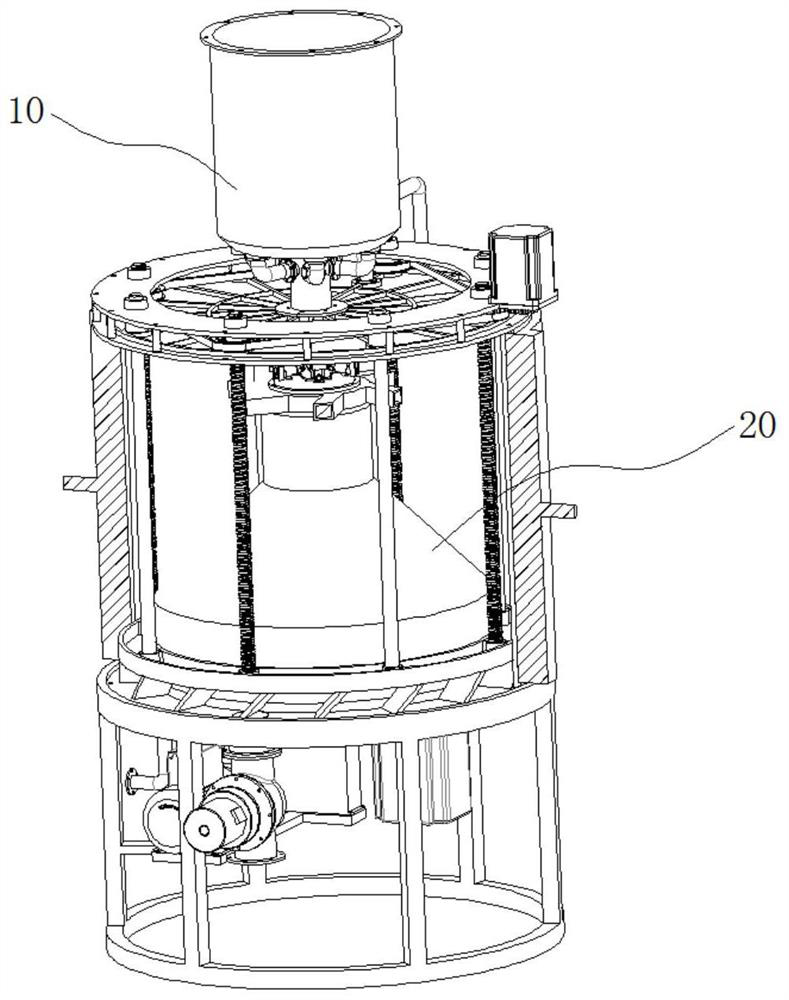

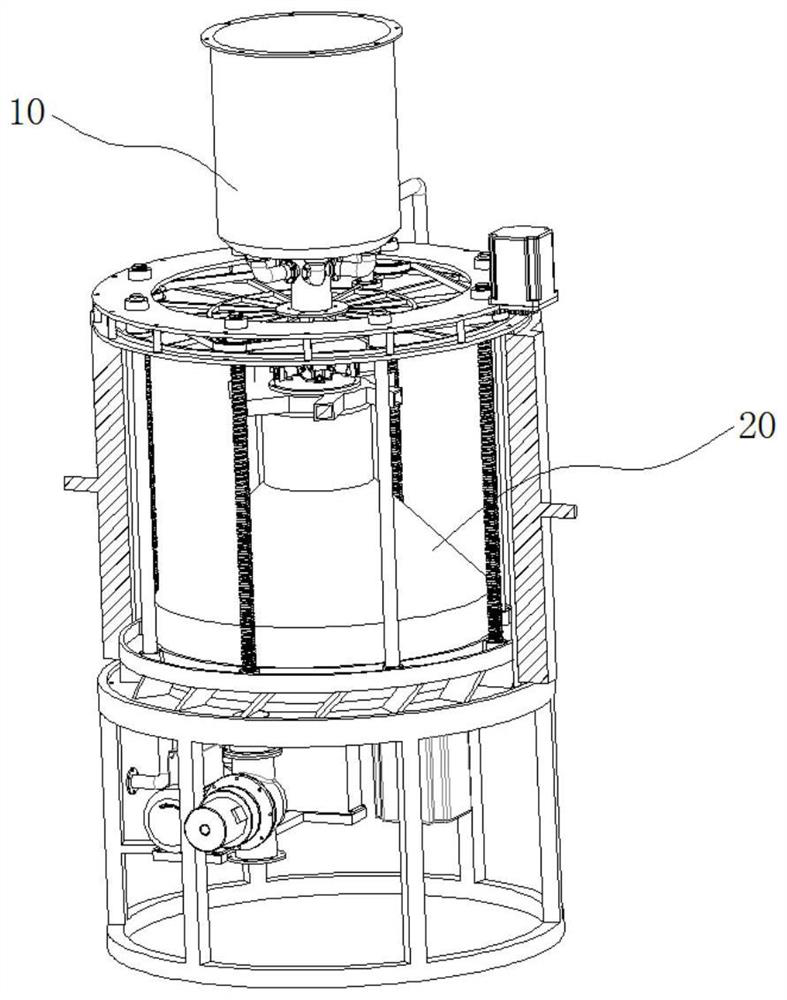

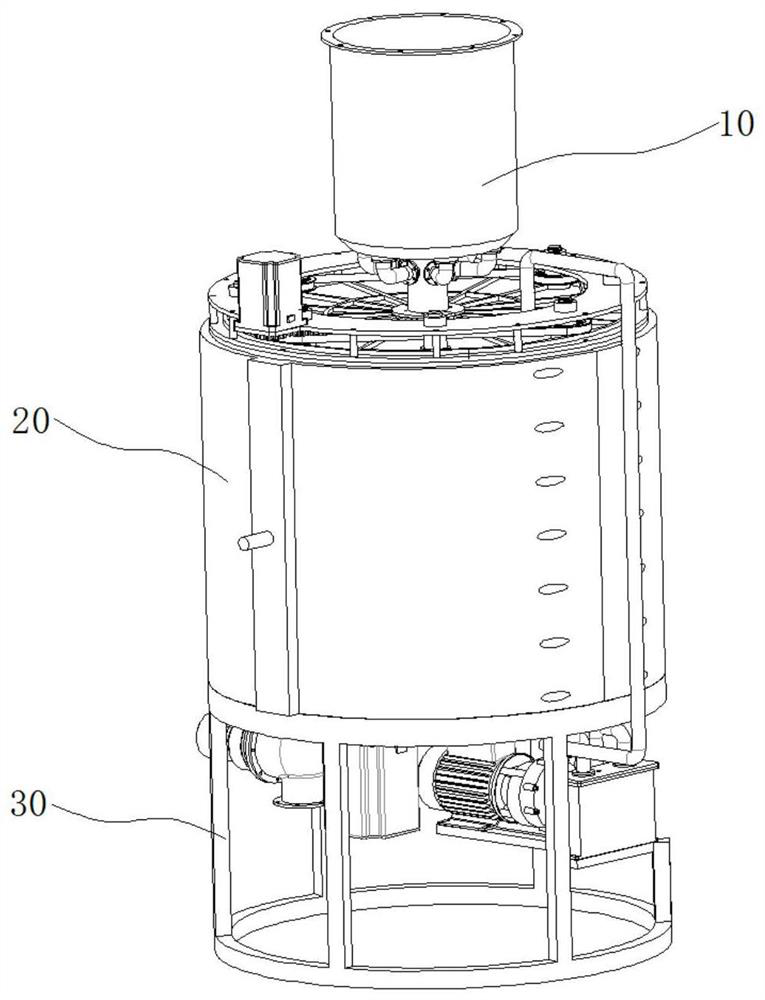

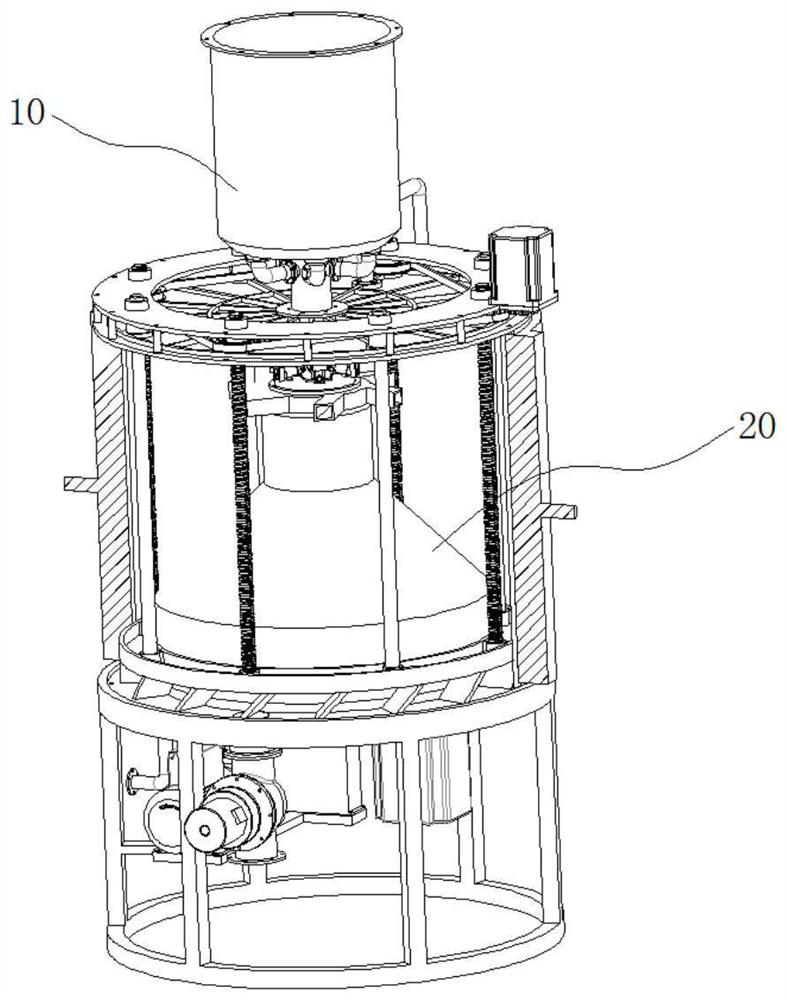

Concentration component for heating and concentrating donkey-hide gelatin liquid

The invention discloses a concentration component for heating and concentrating donkey-hide gelatin liquid, the concentration component comprises a bottom frame (50) and a concentration device (20), the concentration device (20) comprises a concentration mechanism (21) and a guiding mechanism (22), the concentration mechanism (21) is used for heating and concentrating the donkey-hide gelatin liquid, the guiding mechanism (22) is used for outputting the concentrated donkey-hide gelatin liquid outwards, the concentration mechanism (21) comprises a concentration power assembly (211) and a concentration assembly (212), the concentration assembly (212) comprises a heating cylinder (2121), a concentration cylinder (2122), a mounting ring (2123) and a concentration base, the concentration base is mounted on the bottom frame (50), the heating cylinder (2121) is of a circular cylinder structure with two open ends, the heating cylinder (2121) is horizontally and fixedly mounted on the concentration base, and the heating cylinder (2121) is used for providing heat for the concentration cylinder (2122). A full-automatic treatment mode is adopted, the working efficiency is greatly improved, the donkey-hide gelatin liquid can be fully concentrated through the unique design, and therefore high-quality raw materials are provided for subsequent medicinal material processing.

Owner:合肥方洛信息科技有限公司

Seawater desalination system using solar in air

PendingCN110182879AShort processReduce volumeGeneral water supply conservationSeawater treatmentSeawaterEnvironmentally friendly

The invention discloses a seawater desalination system using solar in air and relates to a water desalination device which is used for continuously feeding hot air radiated by the sun through an openventilation system, exchanging heat with seawater in a closed distillation tank, and performing condensation extraction in combination with a condensing system and extracting water from the seawater.The system is clean and environmentally friendly, low in cost, and suitable for nautical vessels, salvage fishing boats, areas with scarce fresh water resources, can be used to cool and humidify indoors in combination with an exhaust fan, and is characterized by including a closed distillation tank, a condensing system and a ventilation system, wherein the loop of the ventilation system penetratesinto the closed distillation tank, one end of the loop of the condensing system is communicated with the top of the closed distillation tank, and the other end is bypassed from the outside of the closed distillation tank to the bottom of the closed distillation tank, and then penetrates the bottom of the closed distillation tank and penetrates through the top of the closed distillation tank; thecondensing system and the ventilation system are of open loops.

Owner:XUZHOU BLUE LAKE INFORMATION TECH CO LTD

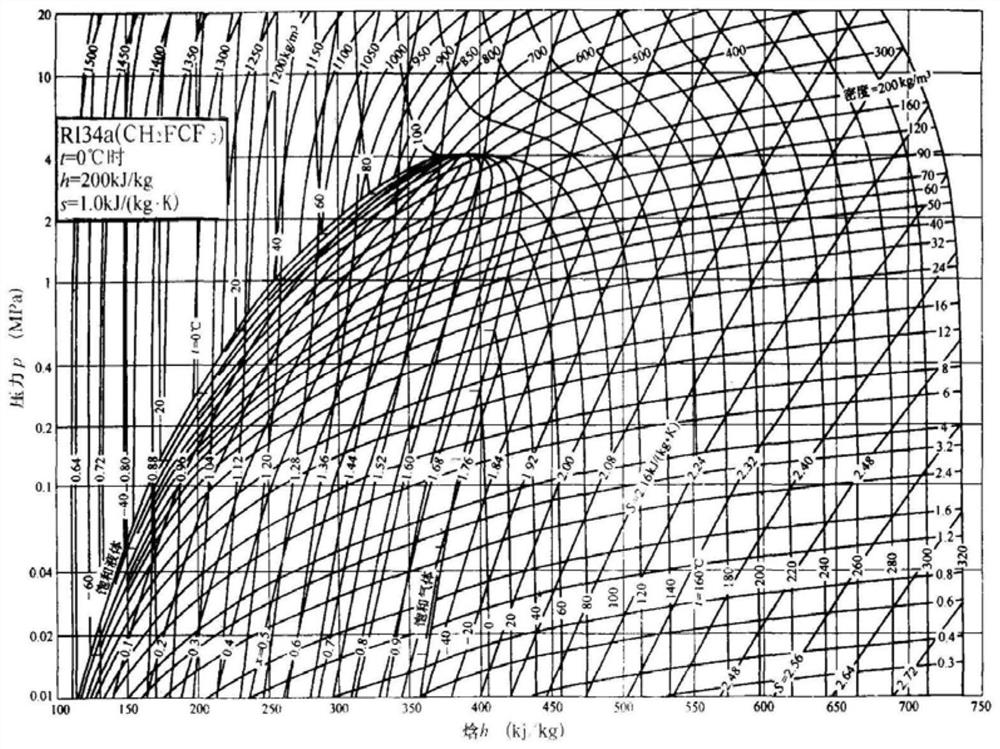

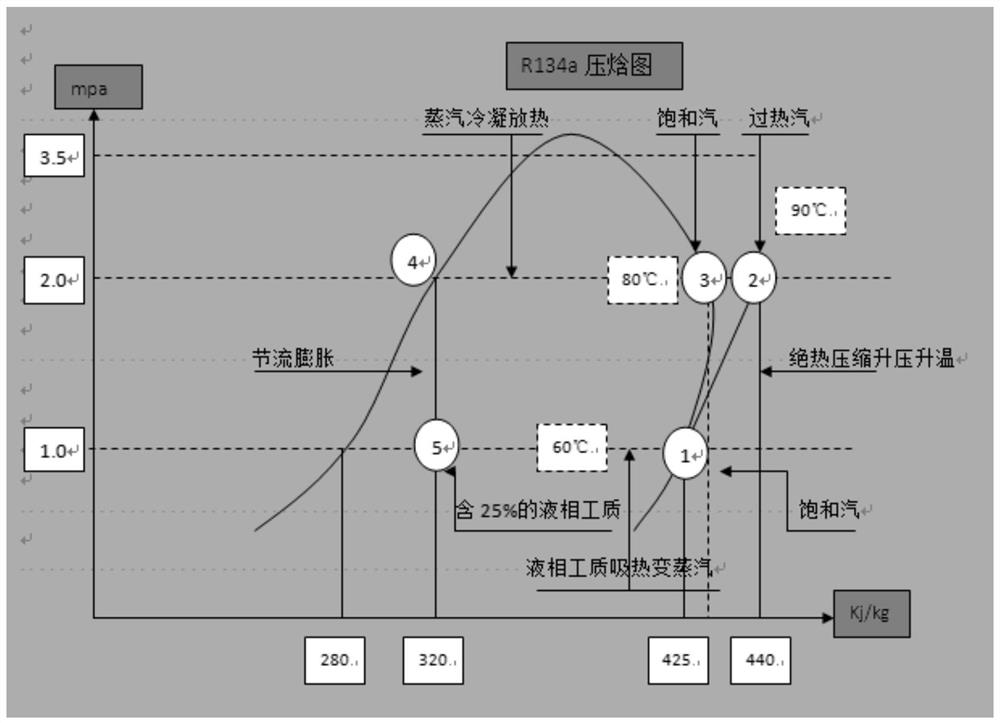

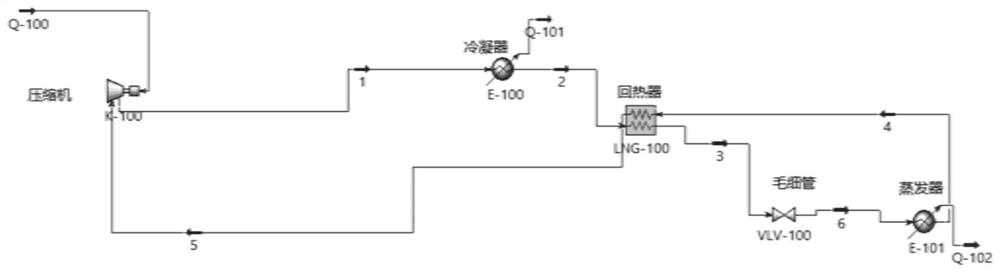

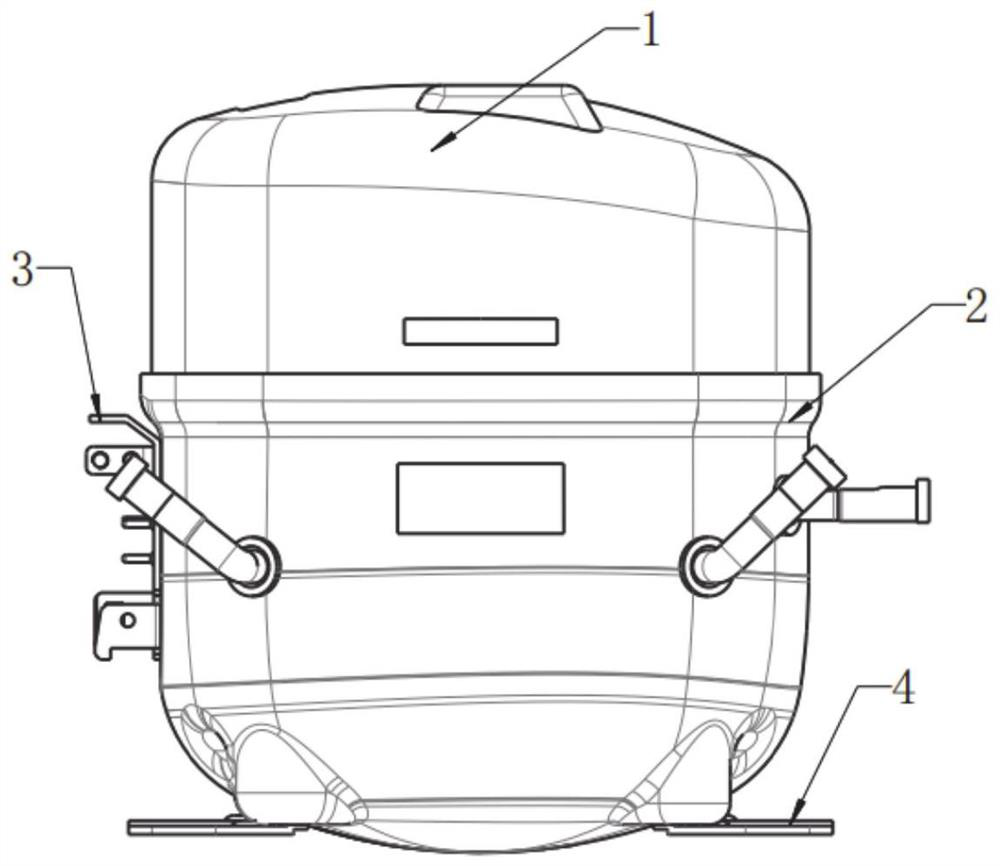

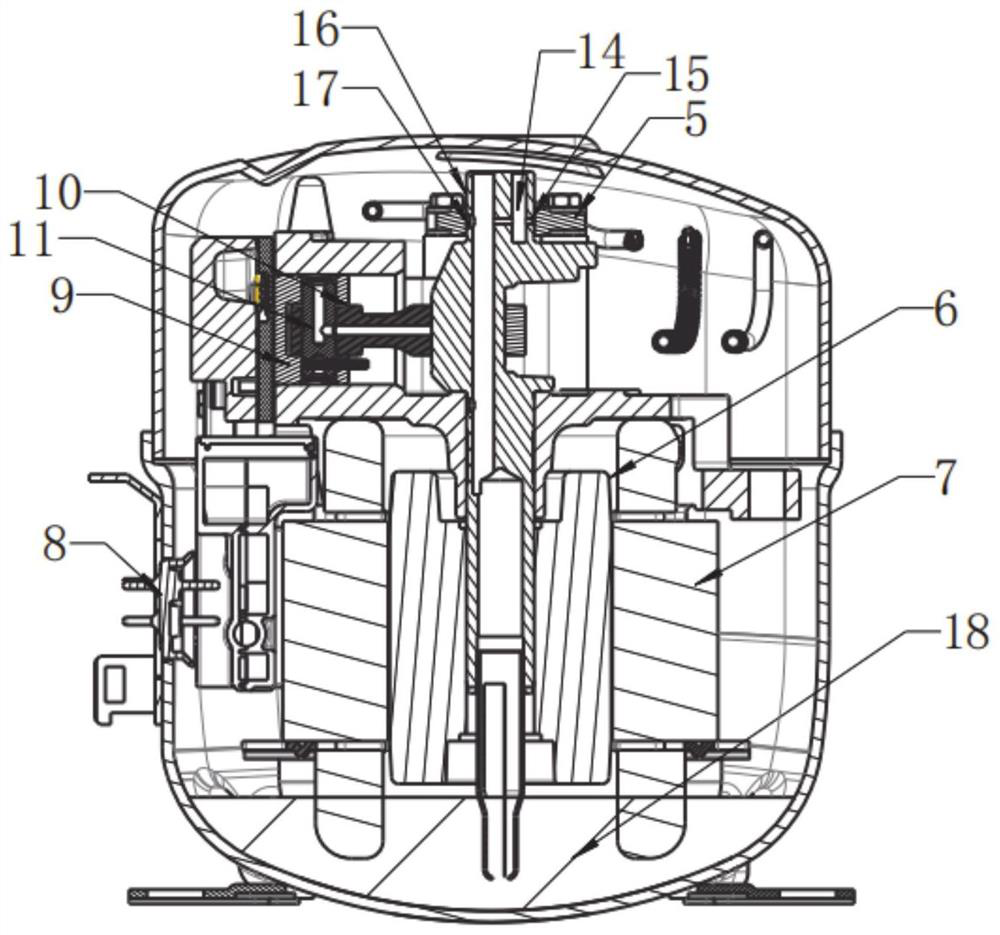

A compressor suitable for linde-hampson throttling refrigerator

ActiveCN112940682BLower boiling pointLow cooling temperaturePositive displacement pump componentsCompression machinesRefrigeration temperatureEngineering

The disclosure provides a refrigerant composition, a mixed working medium and a compressor, which relate to the technical field of refrigeration, and are physically mixed with ethylene and butane at room temperature. Component 1: ethylene, whose content is 20% by weight or less based on the weight of the composition 50 wt%; component two: butane, the content of which is 50 wt% to 80 wt% based on the weight of the composition; the component two is at least one of n-butane and isobutane. The corresponding refrigerant composition is obtained, and the boiling point temperature of the system can be lowered in the single-stage compressor, so that a lower refrigeration temperature can be achieved.

Owner:QINGDAO WANBAO COMPRESSOR

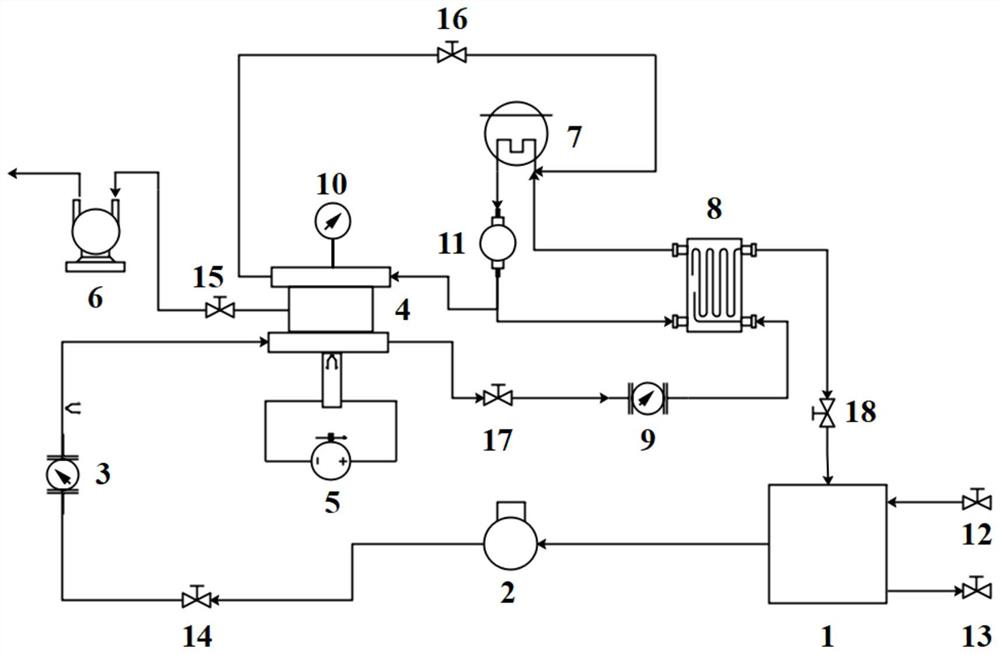

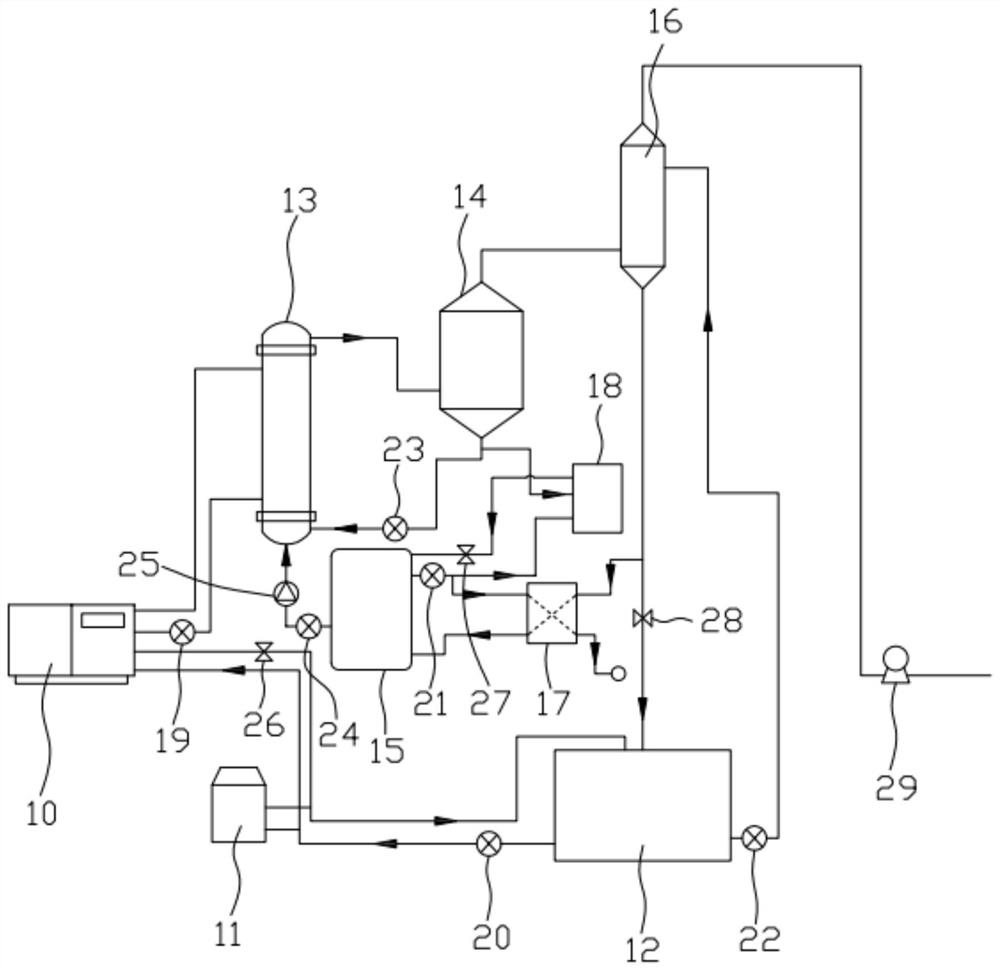

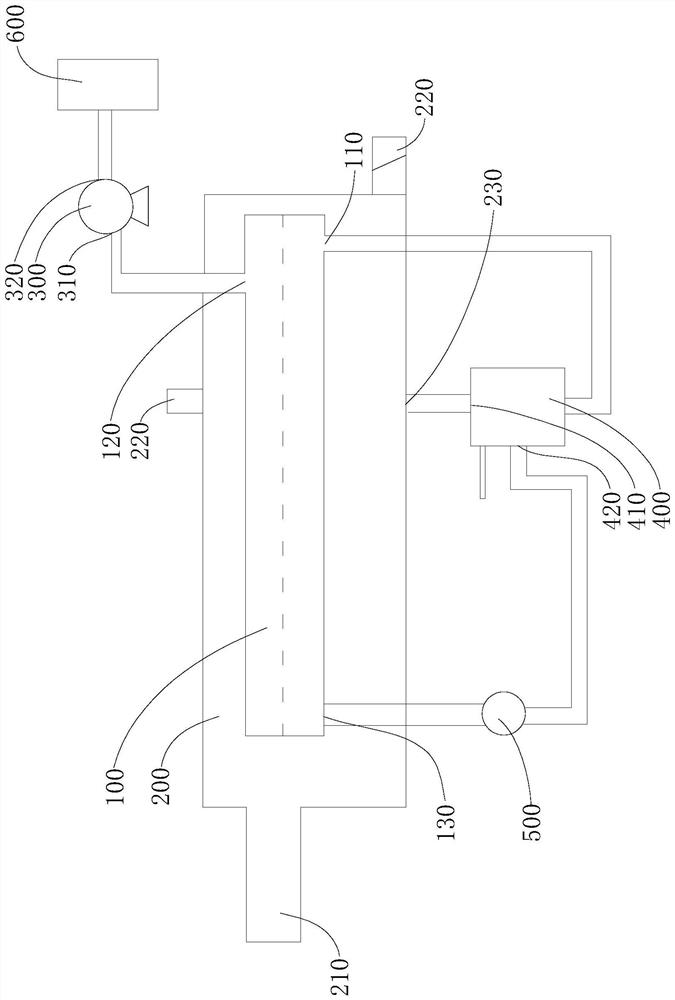

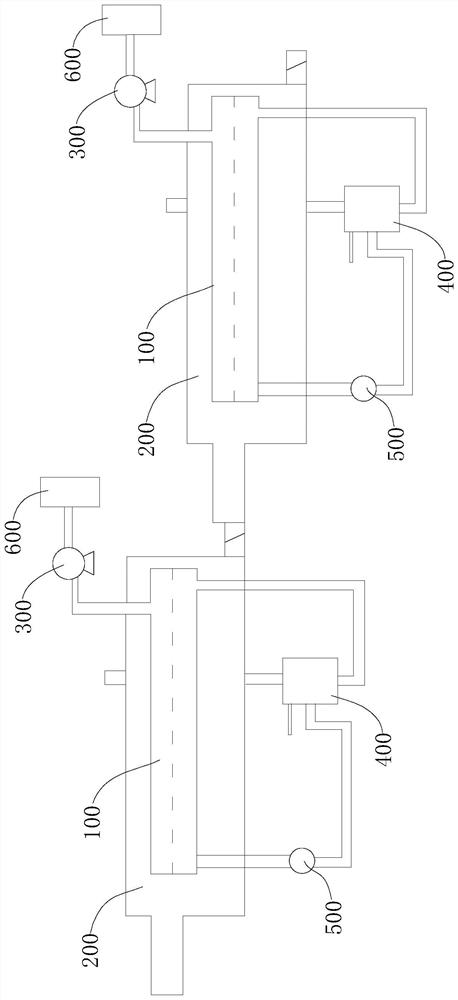

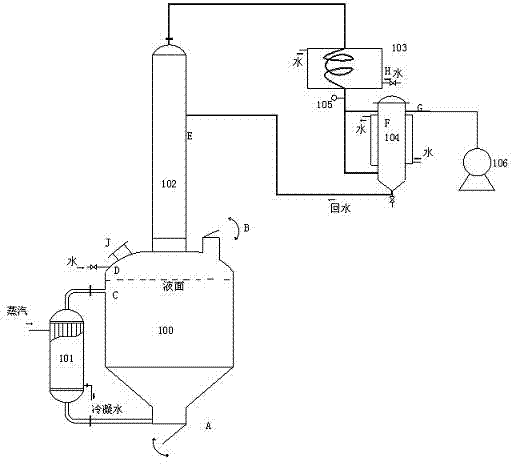

Gas-fired internal combustion engine type mechanical steam recompression system and control method thereof

ActiveCN110357188AImprove evaporation efficiencyRelieve pressureCombustion enginesGaseous engine fuelsBoiling pointCentrifugal compressor

The invention belongs to the field of sewage treatment, and relates to a steam compression system, particularly to a gas-fired internal combustion engine type mechanical steam recompression system anda control method thereof. The gas-fired internal combustion engine type mechanical steam recompression system comprises a gas-fired internal combustion engine and a sewage treatment system, wherein the 1# heater (20) of the sewage treatment system is connected to the gas discharge of the gas-fired internal combustion engine (23), and a steam compressor (8) is additionally arranged between the buffer tank (11) of the sewage treatment system and the high temperature and high pressure steam branch pipeline (18) on the 1# heater (20). According to the present invention, the gas-fired internal combustion engine uses natural gas as the fuel, and the power output shaft of the gas-fired internal combustion engine drives the steam compressor; the steam compression system uses the centrifugal compressor to reduce the pressure inside the evaporator so as to lower the boiling temperature of the water and increase the evaporation efficiency; and the gas-fired internal combustion engine type mechanical steam recompression system uses high-temperature tail gas to heat the sewage so as to achieve the evaporation of sewage.

Owner:HARBIN DONGAN ENGINE GRP

Gas waste heat recovery and purification device and system thereof

PendingCN114459008ARealize waste heat recovery functionReduce pressureFeed water supplyVapor condensationWater collectionEvaporation chamber

The invention discloses a gas waste heat recovery and purification device and system, and the device comprises an evaporation chamber which is provided with a first water inlet and a first exhaust port; the condensation chamber is connected with the evaporation chamber, and the condensation chamber is provided with a first air inlet, a second air outlet and a first water outlet; the air extracting device is communicated with the first exhaust port, and the air extracting device can be used for extracting air from the evaporation chamber; and the condensate water collector is respectively communicated with the first water outlet and the first water inlet, and the condensate water collector is used for collecting condensate water condensed in the condensation chamber and supplying the condensate water into the evaporation chamber. The boiling point of water in the evaporation chamber is lower than the continuous condensation point of the condensation chamber, waste heat recovery of exhaust gas is achieved, pure condensate water is generated in the condensation heat release process of the exhaust gas, and therefore separation of non-condensable gas in the exhaust gas is achieved.

Owner:FOSHAN KINGXUNENG COLD CHAIN TECH CO LTD

Infrared air exhaust and pressure reduction material-drying device

InactiveCN102967122BDrying smoothlyAchieve dryingDrying using combination processesDrying chambers/containersInfraredVacuum pressure

The invention discloses an infrared air exhaust and pressure reduction material-drying device comprising a tank body than can be enclosed inside. An infrared lighting source emits infrared to the inside of the device. The tank body that can be enclosed is connected with an air exhaust and pressure reduction assembly. Material requiring drying is disposed in the tank body that can be enclosed. Under the irradiation of the infrared, the internal water molecules of the irradiated substance can generate resonance energy because of absorption of the infrared and the temperature of the irradiated substance rises. The heating management of the irradiated substance is controlled through intensity of illumination of the infrared and interval of on-off irradiation time. The material requiring drying is heated to a predetermined temperature and achieves specific vacuum pressure through air exhaust and pressure reduction via communication of a vacuum pump pipeline together with the tank body that can be enclosed, so that the boiling temperature of the water can be reduced to be below the specific temperature according to physical characteristics and the internal water molecules of the substances can vaporize through boiling. Vaporized moisture can be exhausted during the air exhaust and pressure reduction. The infrared air exhaust and pressure reduction material-drying device is formed by the tank body, which can be enclosed and can employ the vacuum pump for the air exhaust and pressure reduction, and the infrared lighting source.

Owner:陈淑姿 +1

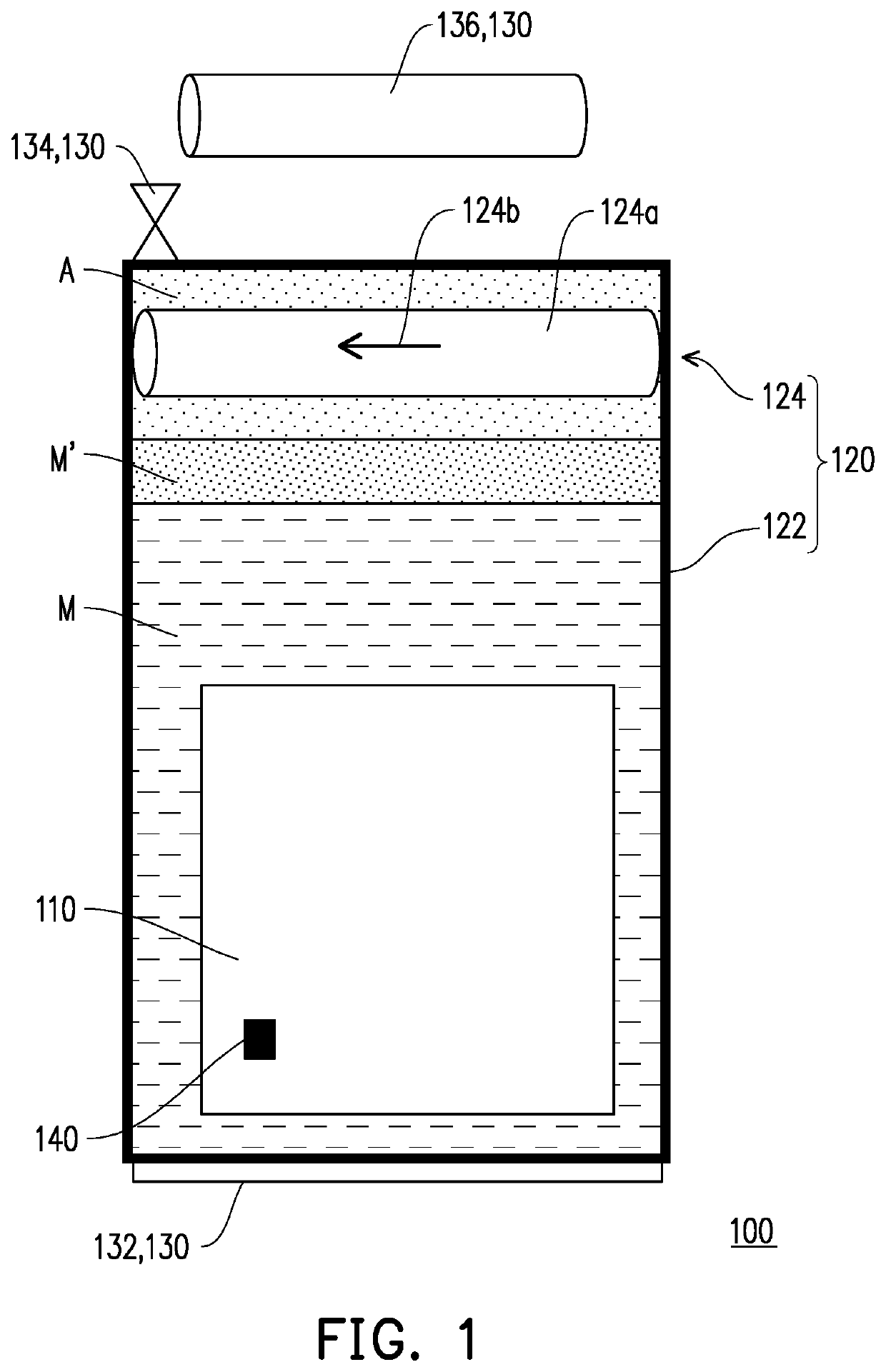

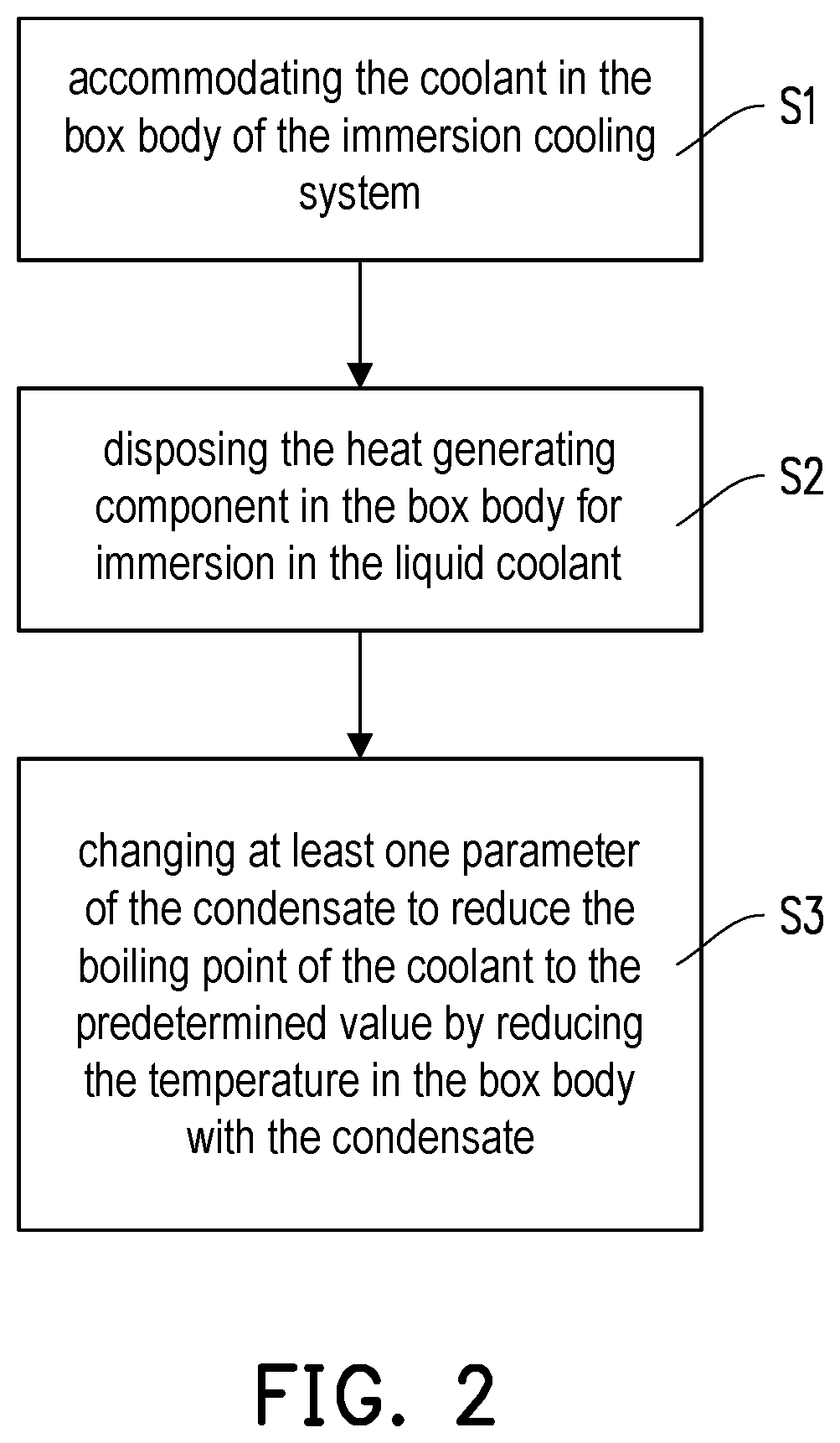

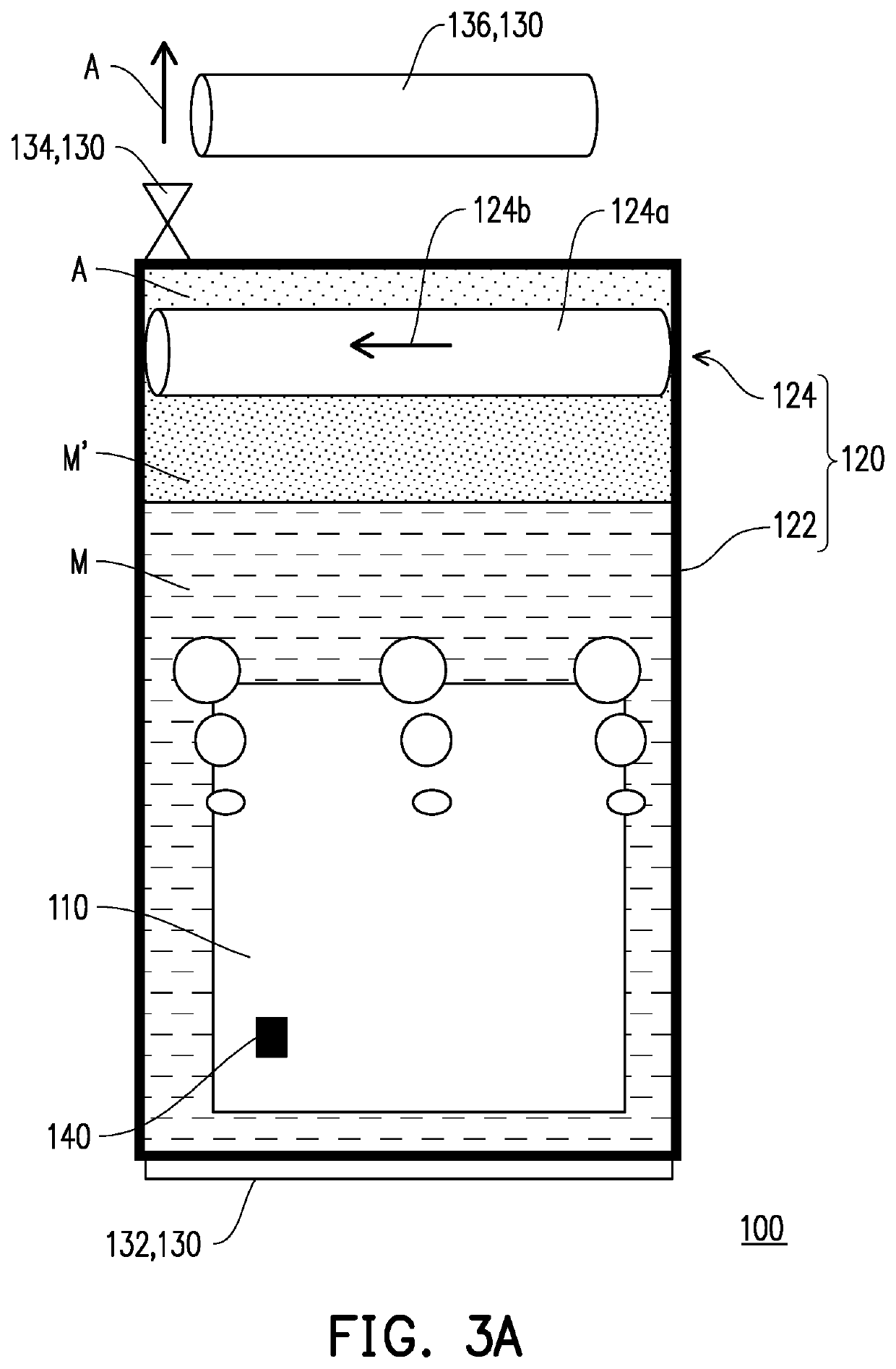

Electronic apparatus having immersion cooling system and operating method thereof

ActiveUS20220361357A1Improve abilitiesLower boiling pointDigital data processing detailsCooling/ventilation/heating modificationsLiquid stateProcess engineering

An electronic apparatus including at least one heat generating component and an immersion cooling system is provided. The immersion cooling system includes a box body and a condensation module. The box body is adapted to accommodate a coolant, and the heat generating component is disposed in the box body to be immersed in the coolant in a liquid state. The condensation module includes a pipeline and a condensate, and the pipeline passes through the box body and is adapted for the condensate to flow. At least one parameter of the condensate may be changed to lower a boiling point of the coolant to a predetermined value by lowering the temperature in the box body with the condensate. In addition, an operating method of the electronic apparatus is also provided.

Owner:WIWYNN CORP

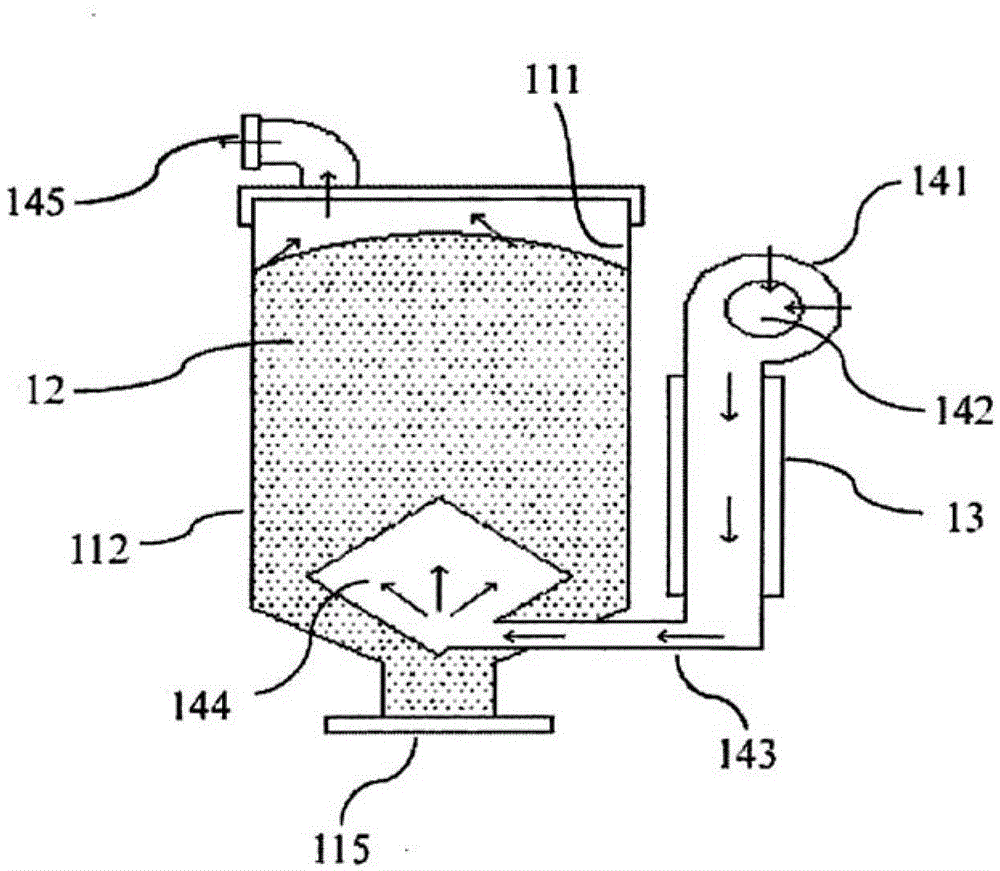

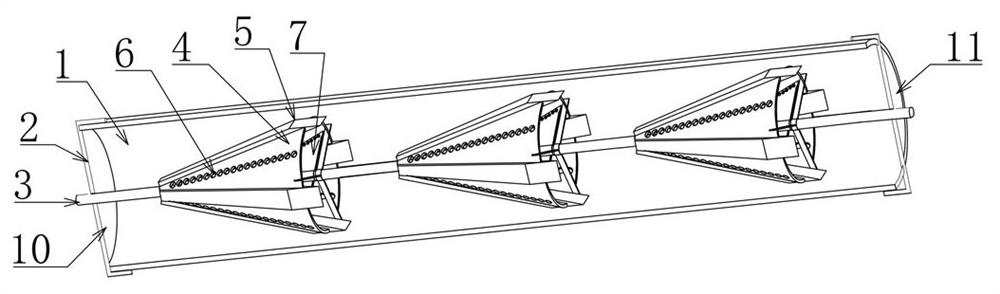

Device for extracting iris root oil by virtue of dynamic circulation type steam vacuum distillation

ActiveCN102260593BWill not gelatinizeAvoid gelatinizationEssential-oils/perfumesVacuum distillation separationThermodynamicsReboiler

Owner:YUNNAN EMERALD ESSENCE

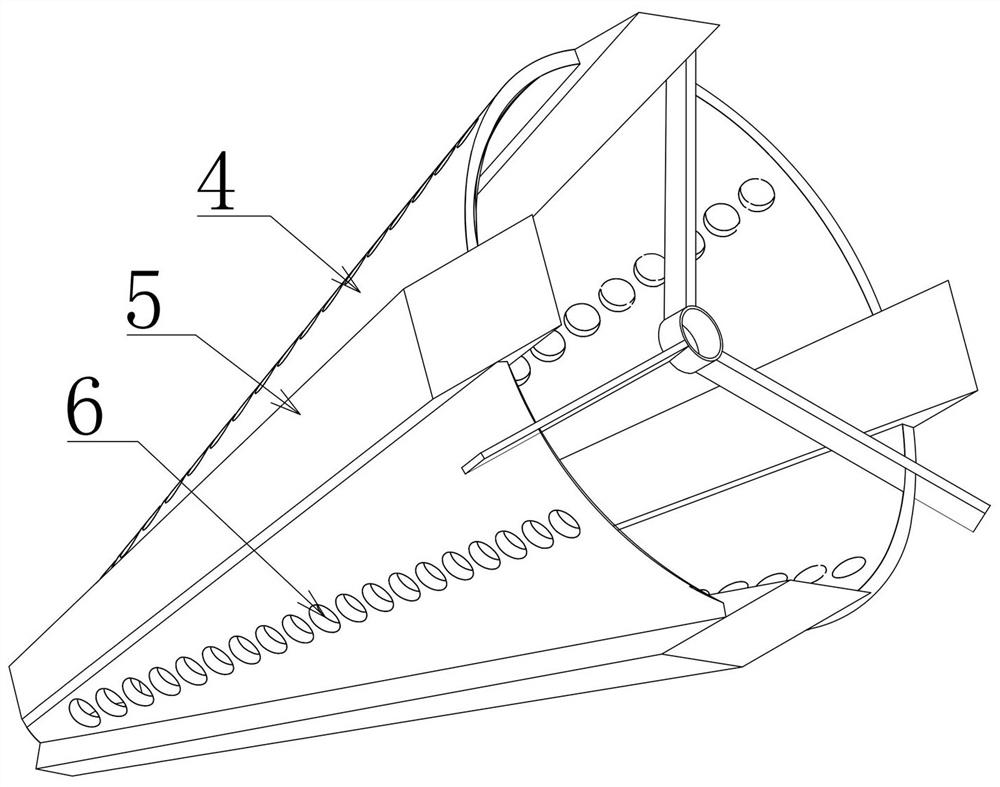

A self-generated potential-excited microbubble-enhanced evaporative heat transfer tube

ActiveCN113267079BHigh heat transferHigh densityWater/sewage treatment by heatingMechanical energy handlingStagnation pointEngineering

The invention belongs to the technical field of micro-heaters, in particular to a self-generated potential excited micro-bubble-enhanced evaporation heat exchange tube. The conical ring is provided with micro-holes in the axial direction, and permanent magnets are embedded in the conical ring to form a magnetic field. The fluid passes through the conical ring micro-holes to form a jet impinging blade to make it rotate, and a thin boundary layer will be formed near the stagnation point of the jet impingement, thereby enhancing the heat transfer efficiency. During the rotation of the blade, the coil cuts the magnetic field line in the magnetic field to form an electromotive force, and the thermal effect of the current prompts the micro-heater to work to excite the micro-bubbles, triggering the starting point of boiling and enhancing the boiling heat transfer. At the same time, the blade rotation increases the disturbance in the tube, increases the turbulence degree, reduces the angle between the fluid velocity field and the temperature gradient field in the tube, improves the degree of field synergy, and strengthens the heat transfer in the tube.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

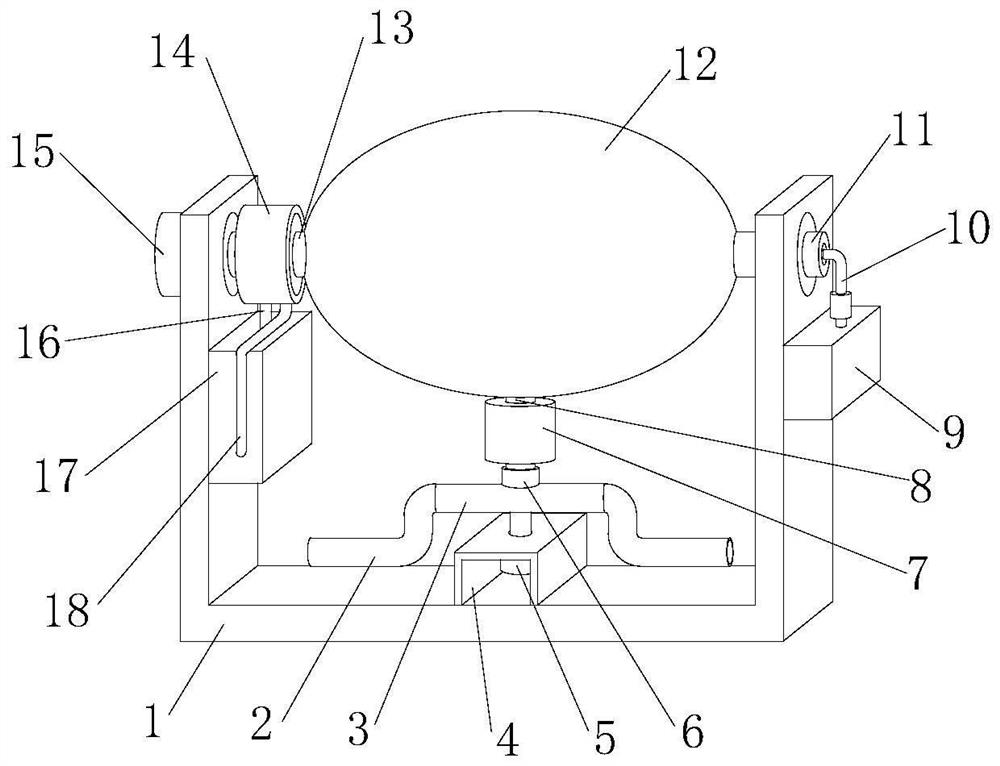

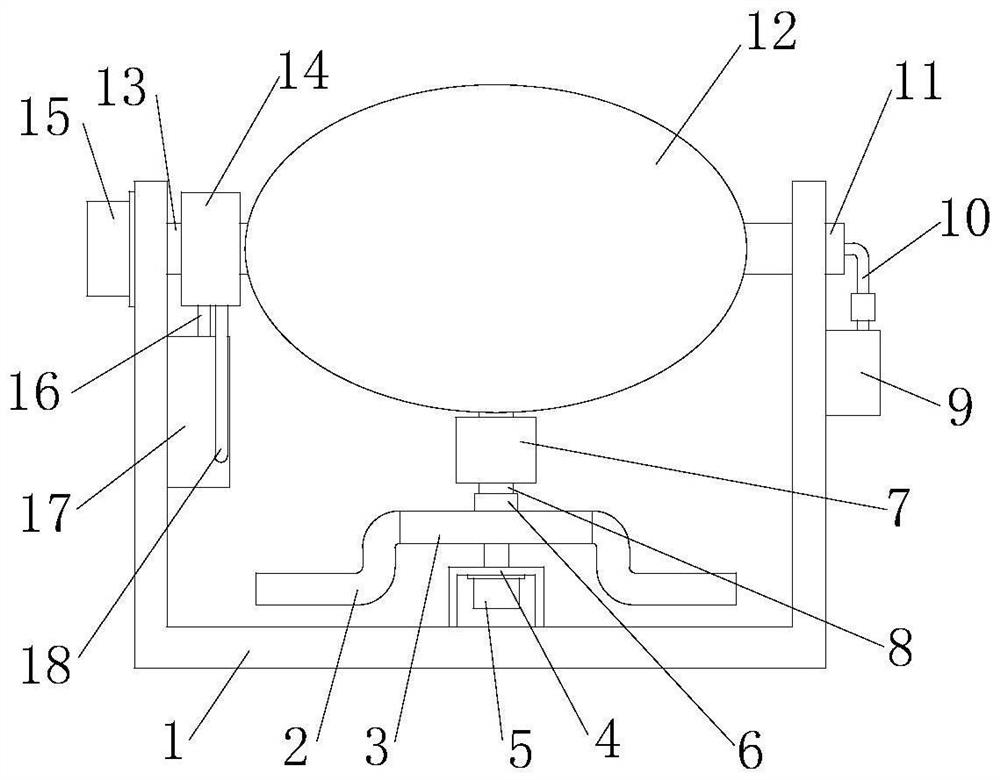

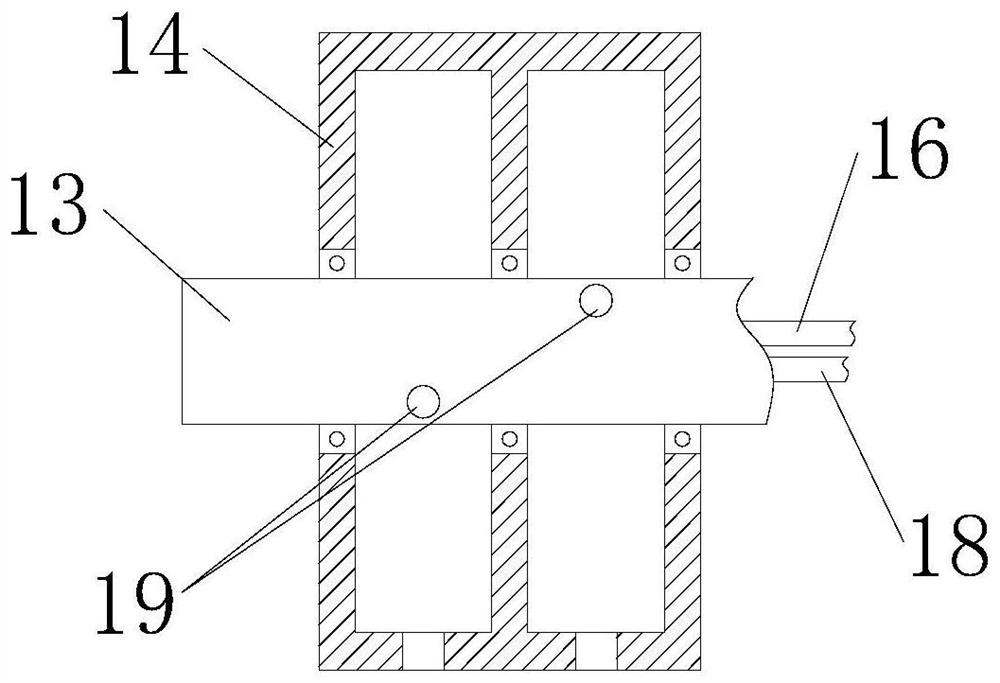

Vacuum drying equipment for synthesizing isooctyl salicylate and vacuum drying method thereof

PendingCN114353438APlay the role of rolling and stirringLower boiling pointDrying solid materials without heatDrying machines with non-progressive movementsPeristaltic pumpSynthetic substance

The invention discloses vacuum drying equipment for synthesizing isooctyl salicylate and a vacuum drying method of the vacuum drying equipment. The vacuum drying equipment comprises a U-shaped plate, a feeding pump, an oil cylinder, a vacuum pump, an elliptical box, a double-cavity round block, a spiral hole channel, an electric heating box and a peristaltic pump. The structure is reasonable, the vacuum pump continuously exhausts the interior of the oval box until the vacuum standard is achieved, the heated boiling point can be reduced, water vaporization can be accelerated, and liquid in the spiral hole channel, the inlet guide pipe and the outlet guide pipe can be circularly heated to be in a high-temperature state; a motor is operated to drive the elliptical box connected through a rotating rod to rotate, so that the effect of rolling and stirring the synthetic substances is achieved, the drying progress can be accelerated, the dried substances can enter a material pipe, and the drying efficiency is improved. And the other feeding pump used for discharging is operated to discharge the dried substances to a centralized treatment position.

Owner:ZHENJIANG GAOPENG PHARMA

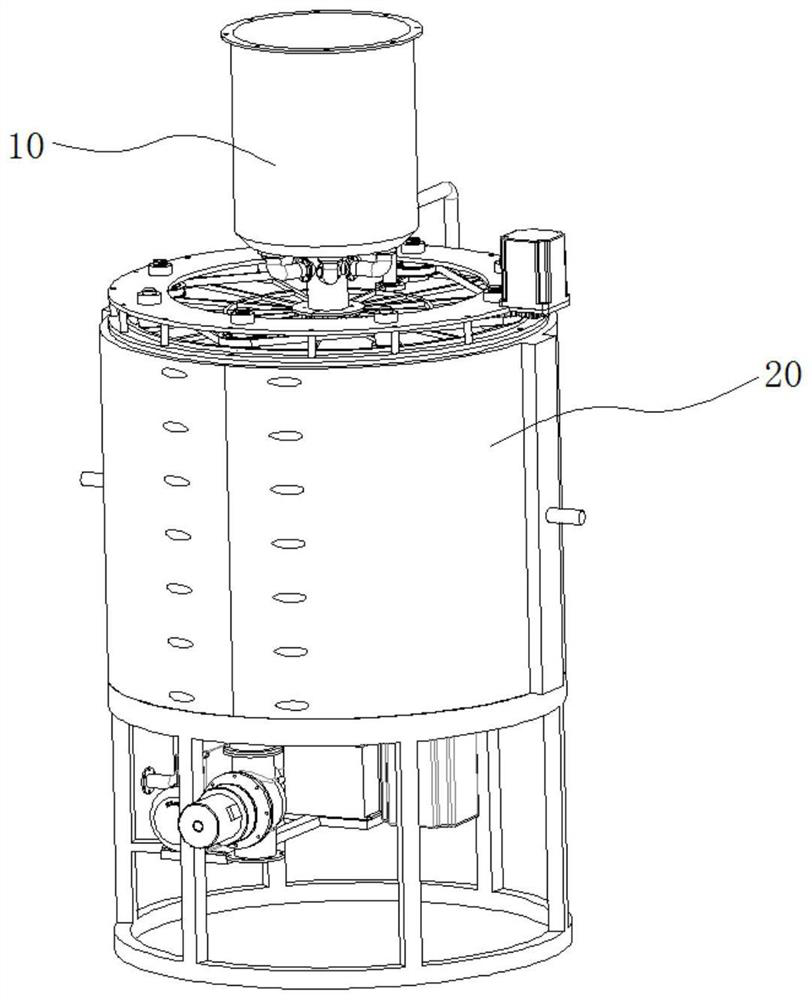

Method for primary concentration of donkey-hide gelatin

InactiveCN113069776AFully concentratedAutomatic recyclingEvaporator accessoriesMedicinal herbsColla corii asini

The invention discloses a method for primary concentration of donkey-hide gelatin. The method comprises the steps of S1 enabling a user to put donkey-hide gelatin liquid into a conveying device, and enabling the conveying device to guide the donkey-hide gelatin liquid into a concentration device; S2 carrying out heating concentration treatment on the donkey-hide gelatin liquid by a concentration mechanism of the concentration device; S3 pushing the concentrated donkey-hide gelatin liquid to a guide mechanism of the concentration device by a pushing device; S4 outputting the concentrated donkey-hide gelatin liquid outwards by the guide mechanism of the concentration device. After traditional donkey-hide gelatin concentration equipment is used for concentrating the donkey-hide gelatin liquid, the concentrated donkey-hide gelatin liquid needs to be recycled manually, so that the manpower and material resources of operation are greatly increased, and the traditional donkey-hide gelatin concentration equipment is difficult to fully concentrate the donkey-hide gelatin liquid; the donkey-hide gelatin liquid can be fully concentrated by adopting the unique design, and therefore, high-quality raw materials are provided for subsequent processing of medicinal materials; and in addition, the concentrated donkey-hide gelatin liquid can be automatically recycled, so that the working efficiency is improved while manpower and material resources are saved.

Owner:合肥方洛信息科技有限公司

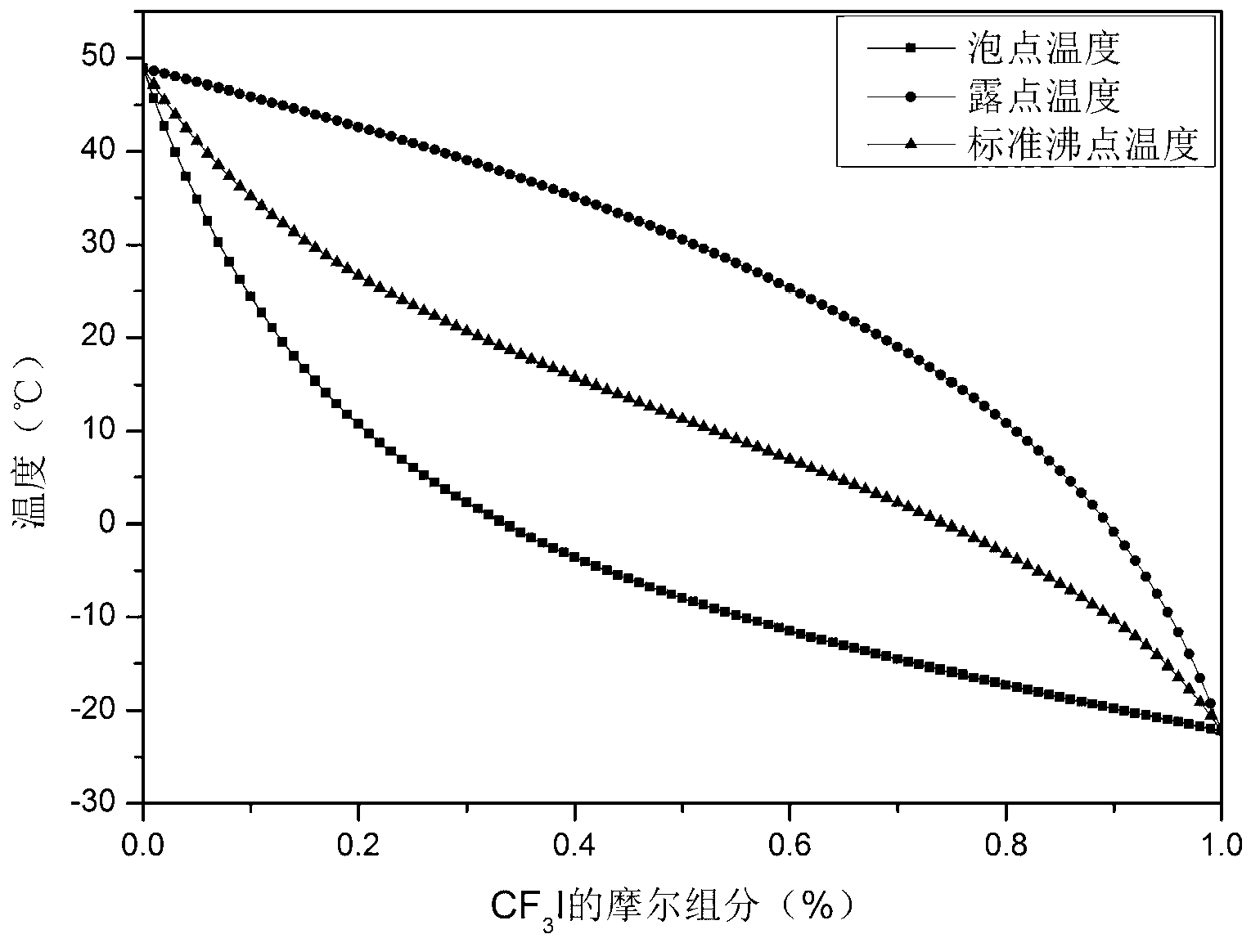

Polyurethane foaming agent

The invention discloses a polyurethane foaming agent, comprising the following components in mole percentage: 0.1-90% of trifluoroiodomethane CF3I and 10-99.9% of cyclopentane c-C5, preferably, 10-33% of trifluoroiodomethane and 67-90% of cyclopentane. The polyurethane foaming agent of the invention has advantages of good thermal insulation performance, boiling point temperature approaching room temperature and low combustibility, particularly, is suitable for hardened foaming or softened foaming for polyurethane foams, and is used for integrally foaming.

Owner:XI AN JIAOTONG UNIV

Closed brayton cycle excess heat generating system and method for using same for excess heat power generation

ActiveCN101787908BRealize comprehensive utilizationReduce wasteSteam engine plantsGas compressorEngineering

The invention relates to a closed brayton cycle excess heat generating system. A start pressurization system is connected with a helium gas inlet of a countercurrent flue gas heat exchanger through a helium gas circulation line, the helium gas inlet of the countercurrent flue gas heat exchanger is connected with a turbo-power device through the gas circulation line, a helium gas excess heat recovery outlet of a turbine return circuit heat regenerator is connected with a turbine return circuit radiator and a gas compressor in sequence through the helium gas circulation line, a helium gas heating gate of the turbine return circuit heat regenerator is connected with the gas compressor through the helium gas circulation line, the helium gas heating gate of the turbine return circuit heat regenerator is connected with the start pressurization system through the helium gas circulation line, the turbo-power device is coaxially connected with an electric generator device and the gas compressor. The closed brayton cycle excess heat generating system features wide temperature adaptation range to heat source exhaust gas, simple structure, high excess heat utilization factor and stability andreliability.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Wiped film type flash evaporator

InactiveCN113069779AShorten the timeImprove concentration efficiencyEvaporator accessoriesFlash distillationVacuum pumpFlash evaporation

The invention relates to a wiped film type flash evaporator. The flash evaporator comprises a rack, an evaporation pipe is vertically arranged in the rack, the upper side of the evaporation pipe is communicated with a feeding pipe, and the lower side of the evaporation pipe is communicated with a discharging pipe. A heating device used for heating the outer side wall of the evaporation pipe is further arranged in the rack. A rotating shaft is arranged in the evaporation pipe, the rotating shaft is vertically arranged, and the rotating shaft and the evaporation pipe are coaxially arranged. A wiped film plate is arranged on one side of the rotating shaft in the radial direction, the wiped film plate is vertically arranged, the side, away from the rotating shaft, of the wiped film plate in the width direction of the wiped film plate is fixedly connected with the rotating shaft, and the side, away from the rotating shaft, of the wiped film plate in the width direction of the wiped film plate and the inner side wall of the evaporation pipe are arranged at an interval. A driving assembly used for driving the rotating shaft to rotate around the axis of the rotating shaft is arranged at the upper end of the rotating shaft, a vacuum pump is arranged on the upper side of the evaporation pipe in a communicated mode, and the inlet of the vacuum pump is communicated with the evaporation pipe. The flash evaporator has the effect of improving the production efficiency.

Owner:SHANGHAI PILOTECH INSTR & EQUIP

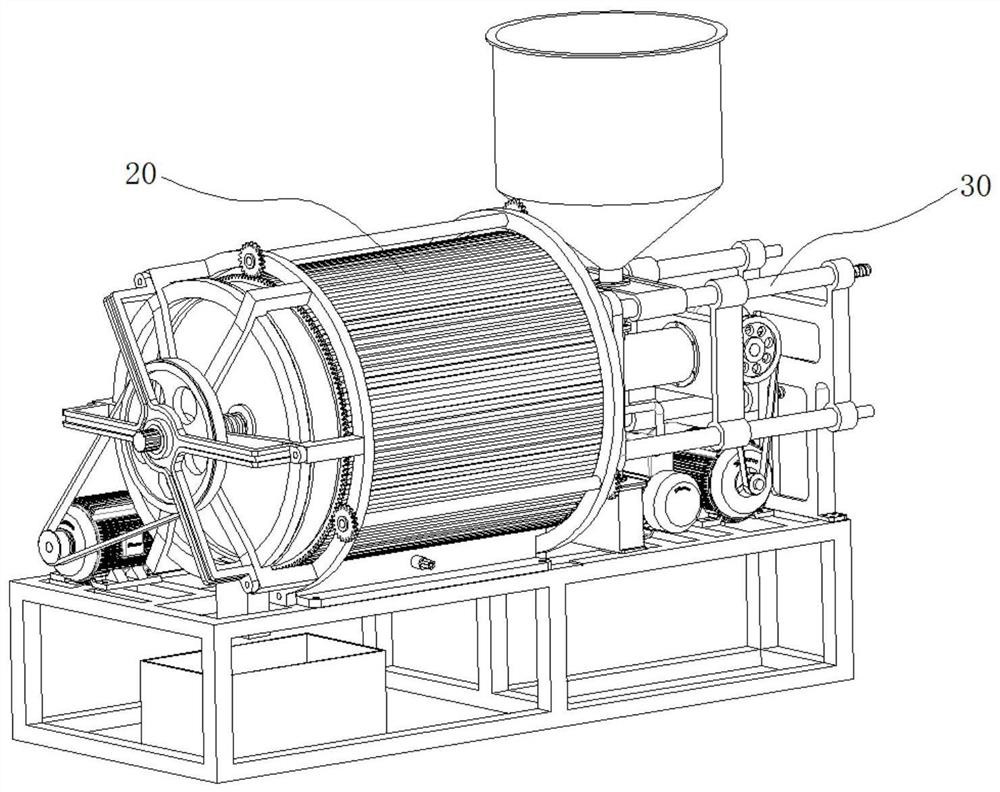

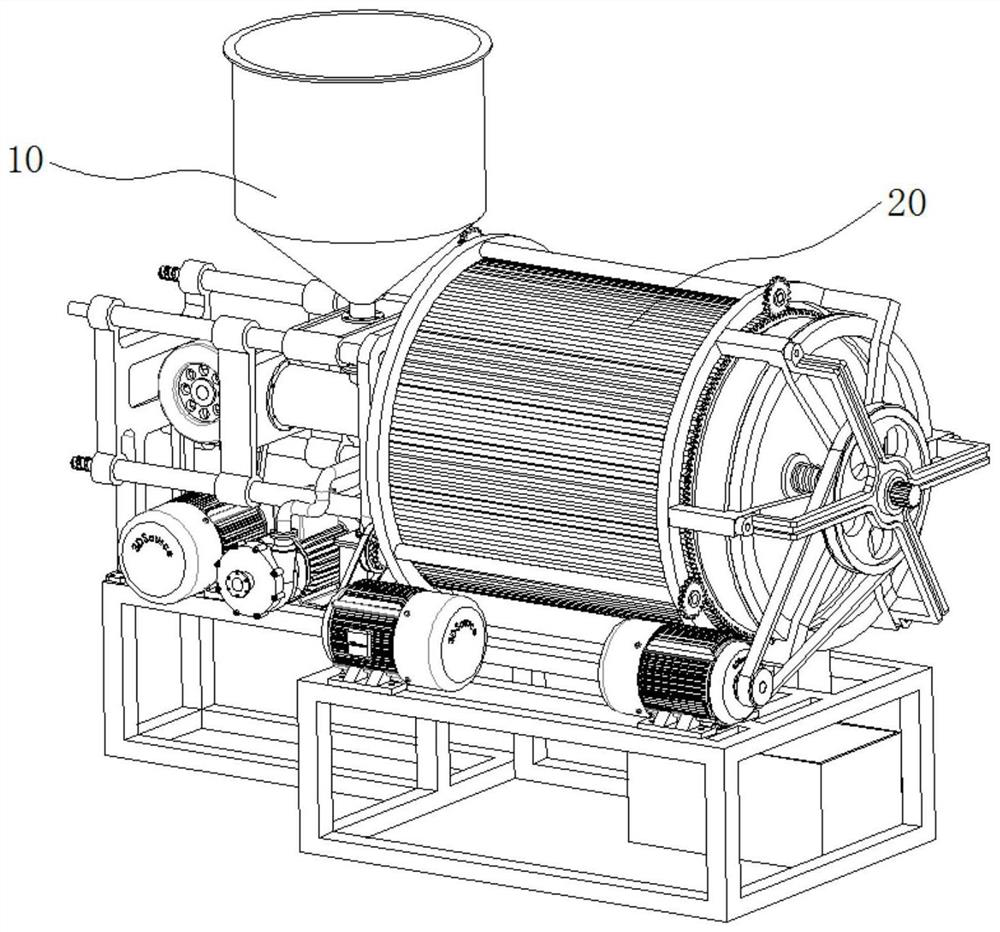

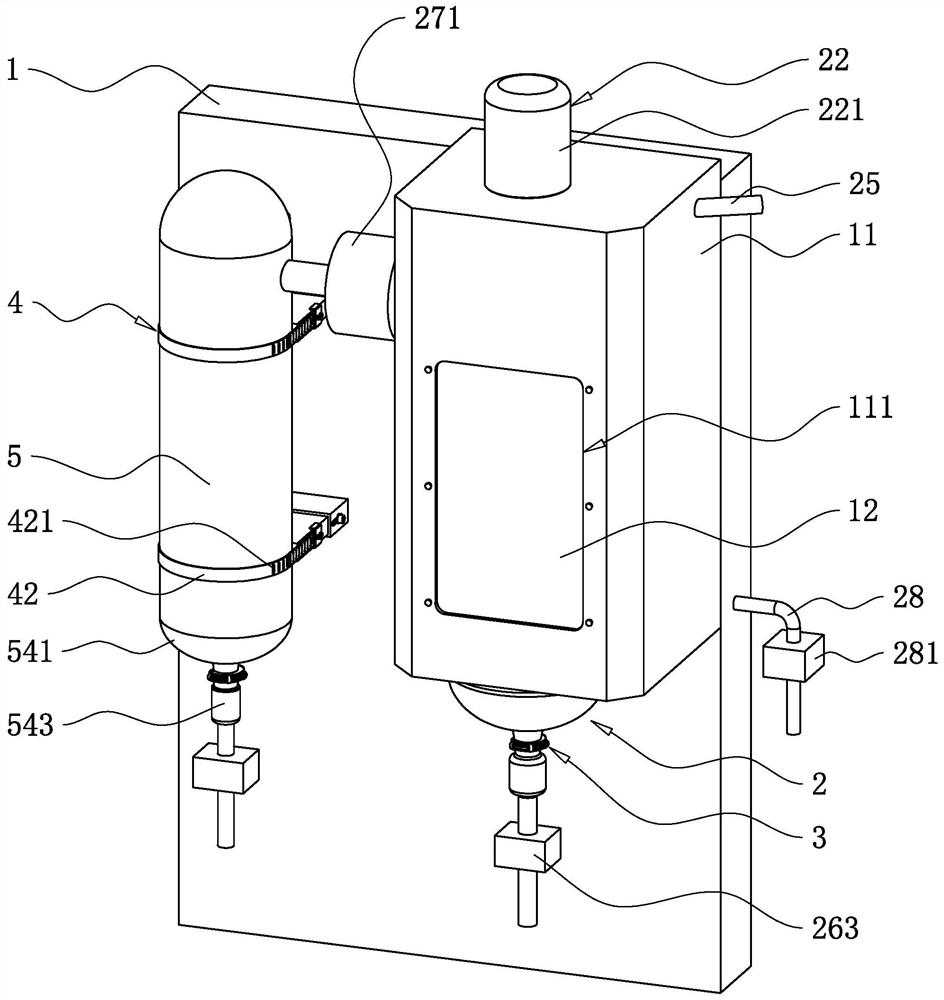

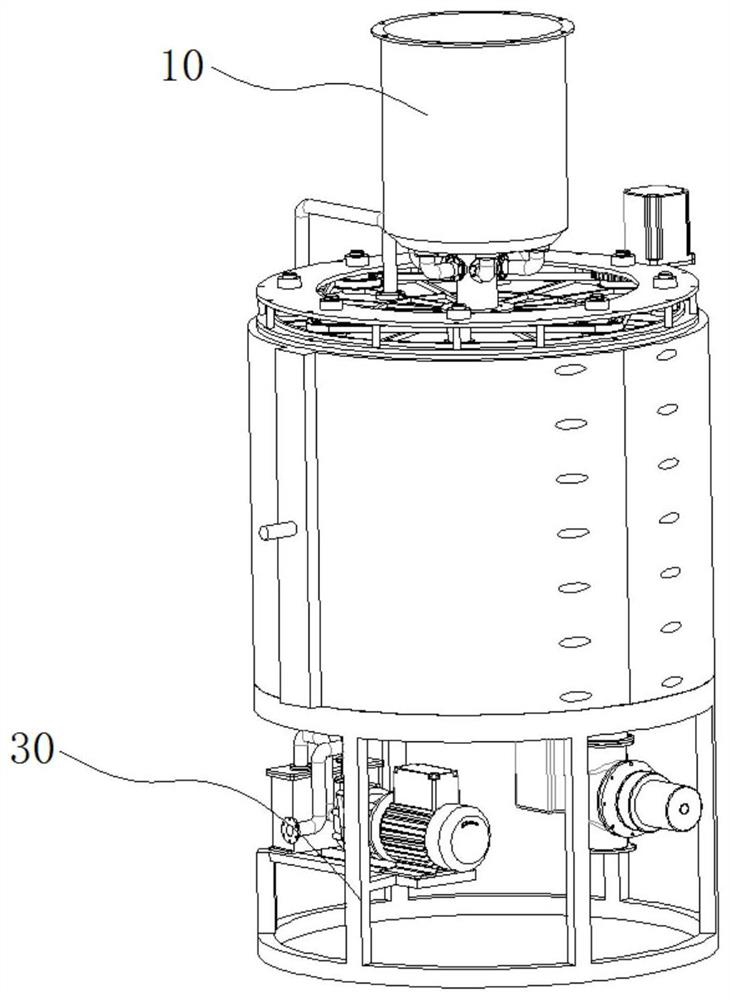

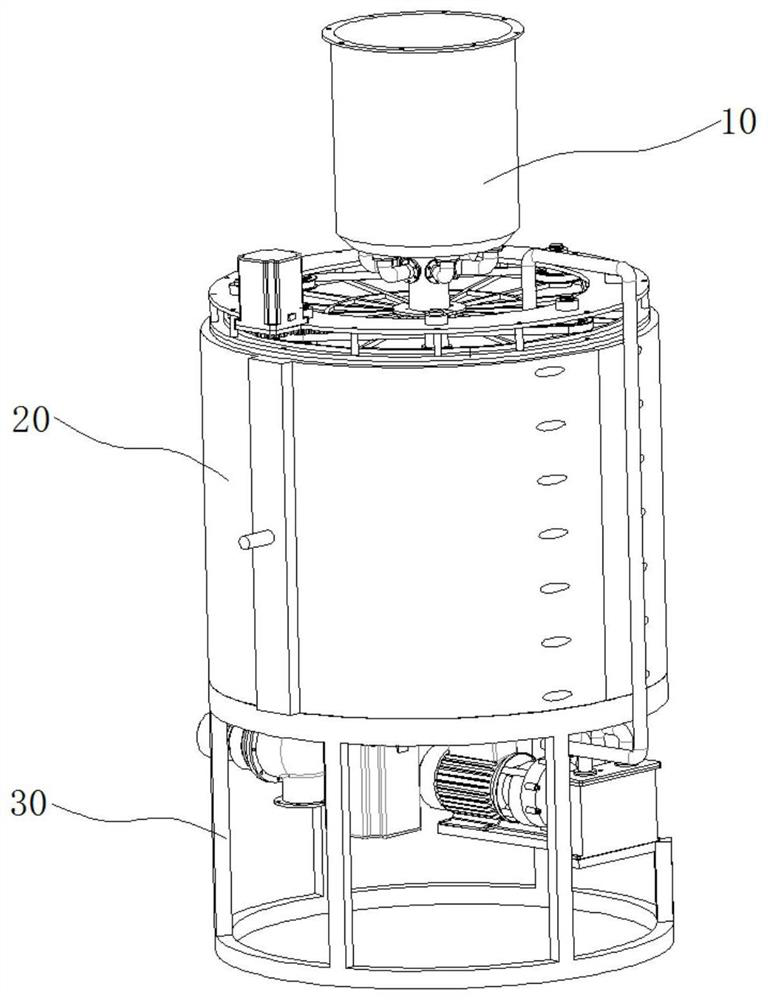

Primary donkey-hide gelatin concentration equipment

InactiveCN113082748AFully concentratedAutomatic recyclingEvaporator accessoriesColla corii asiniElectric machinery

The invention discloses primary donkey-hide gelatin concentration equipment, which comprises a base, a liquid spraying device and a concentration device are mounted on the base, the liquid spraying device is used for spraying donkey-hide gelatin liquid to the concentration device, and the concentration device is used for heating and concentrating the donkey-hide gelatin liquid and outputting the concentrated donkey-hide gelatin liquid outwards; the liquid spraying device comprises a liquid inlet mechanism and a liquid spraying mechanism, the liquid inlet mechanism is used for inputting donkey-hide gelatin liquid into the liquid spraying mechanism, and the liquid spraying mechanism is used for spraying the donkey-hide gelatin liquid to the concentration device; the liquid inlet mechanism comprises a liquid inlet cylinder, an upper fixing cylinder, a mounting cylinder and a liquid inlet motor; the upper fixing cylinder is of a circular cylinder structure with the top end closed and the bottom end open, the axis of the upper fixing cylinder is vertically arranged, a liquid inlet piston is coaxially arranged in the upper fixing cylinder, and an avoiding opening is further coaxially formed in the top end of the upper fixing cylinder; and the liquid inlet motor is installed on the upper end face of the upper fixing cylinder, and an output shaft of the liquid inlet motor and the upper fixing cylinder are coaxially arranged.

Owner:合肥方洛信息科技有限公司

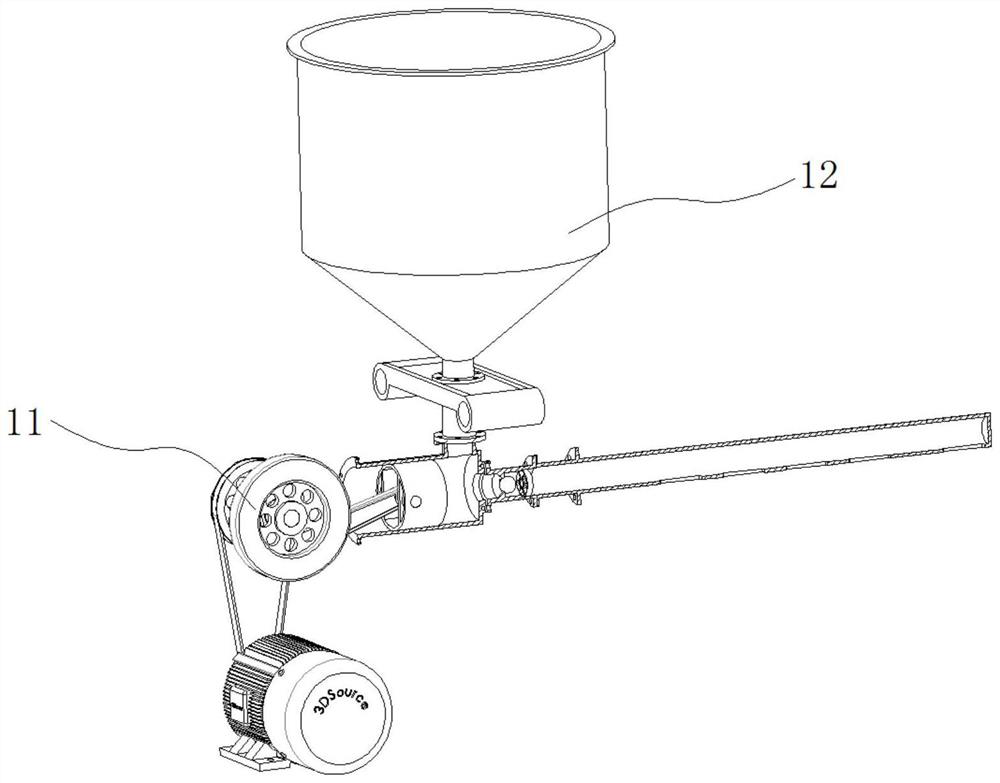

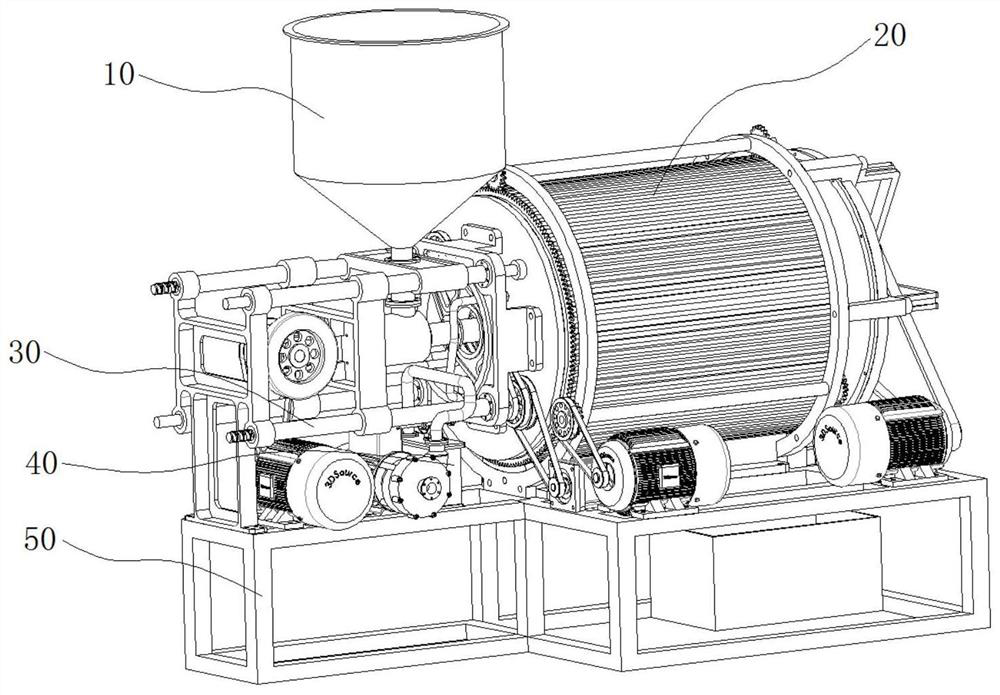

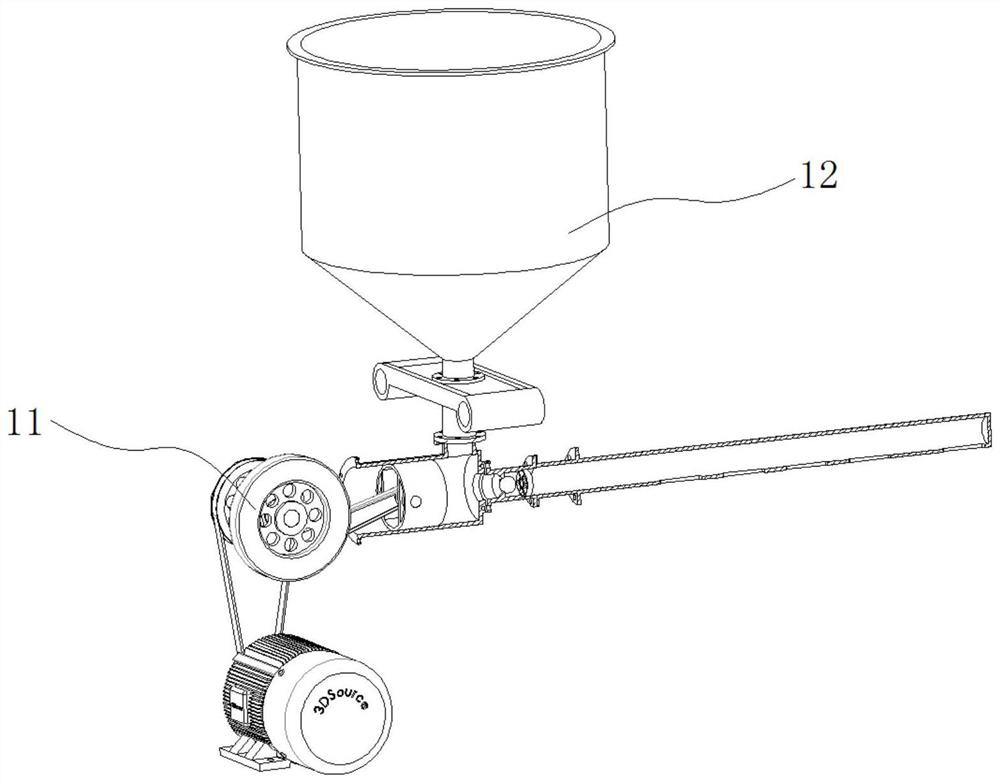

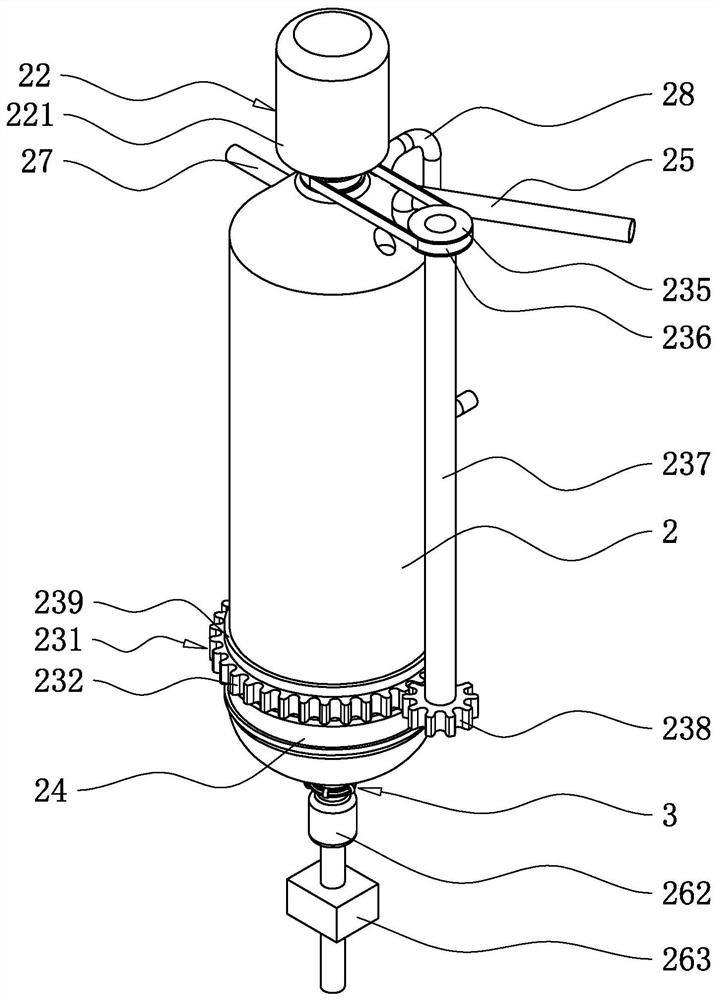

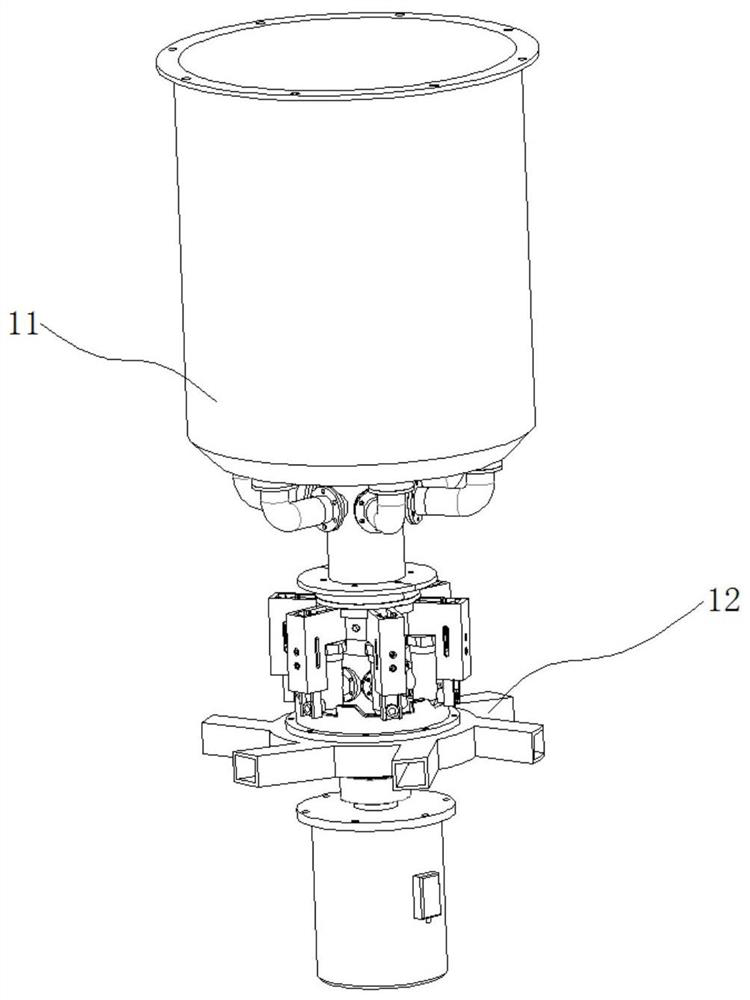

Centrifugal spraying feeding component for donkey-hide gelatin concentration

InactiveCN113082745AFully concentratedAutomatic recyclingEvaporator accessoriesUnknown materialsColla corii asiniElectric machinery

The invention discloses a centrifugal spraying feeding component for donkey-hide gelatin concentration, which comprises a liquid spraying device (10), the liquid spraying device (10) comprises a liquid inlet mechanism (11) and a liquid spraying mechanism (12), the liquid inlet mechanism (11) is used for inputting donkey-hide gelatin liquid into the liquid spraying mechanism (12), and the liquid spraying mechanism (12) is used for spraying the donkey-hide gelatin liquid into subsequent donkey-hide gelatin concentration equipment; the liquid inlet mechanism (11) comprises a liquid inlet cylinder (111), an upper fixing cylinder (112), a mounting cylinder (113) and a liquid inlet motor (119); the upper fixing cylinder (112) is of a circular cylinder structure with the top end closed and the bottom end open, the axis of the upper fixing cylinder (112) is vertically arranged, a liquid inlet piston (116) is coaxially arranged in the upper fixing cylinder (112), and an avoiding opening is further coaxially formed in the top end of the upper fixing cylinder (112); the liquid inlet motor (119) is installed on the upper end face of the upper fixing cylinder (112), and an output shaft of the liquid inlet motor (119) and the upper fixing cylinder (112) are coaxially arranged.

Owner:合肥方洛信息科技有限公司

Method for concentrating donkey-hide gelatin stock solution

InactiveCN113082744AFully concentratedAutomatic recyclingEvaporator accessoriesUnknown materialsMedicinal herbsColla corii asini

The invention discloses a method for concentrating a donkey-hide gelatin stock solution. The method comprises the following steps: S1, operating an air exhaust mechanism of a concentration device mounted on a base, and sucking and exhausting air in a heating cylinder; S2, putting donkey-hide gelatin liquid into a liquid spraying device; S3, communicating a liquid inlet mechanism of the liquid spraying device with a liquid spraying mechanism of the liquid spraying device; S4, spraying the donkey-hide gelatin liquid to the concentration device through the liquid spraying device; S5,outputting the concentrated donkey-hide gelatin liquid outwards by aconcentration device 20; and S6, outputting the concentrated donkey-hide gelatin liquid outwards by the concentration device. Traditional donkey-hide gelatin concentration equipment is difficult to fully concentrate donkey-hide gelatin liquid, the unique design adopted by the donkey-hide gelatin concentration equipment can fully concentrate the donkey-hide gelatin liquid, so that high-quality raw materials are provided for subsequent medicinal material processing, the concentrated donkey-hide gelatin liquid can be automatically recycled, manpower and material resources are saved, and meanwhile, the working efficiency is improved.

Owner:合肥方洛信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com