Wiped film type flash evaporator

A technology of scraping film and flash evaporation, which is applied in the direction of flash evaporation, evaporation, evaporator accessories, etc., and can solve the problems of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

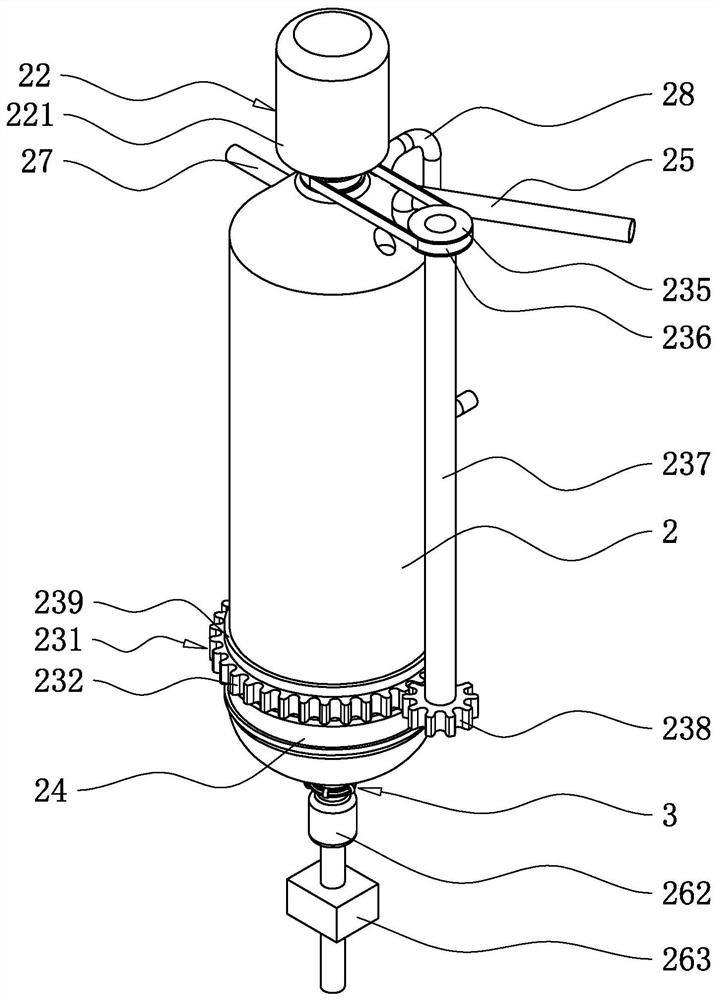

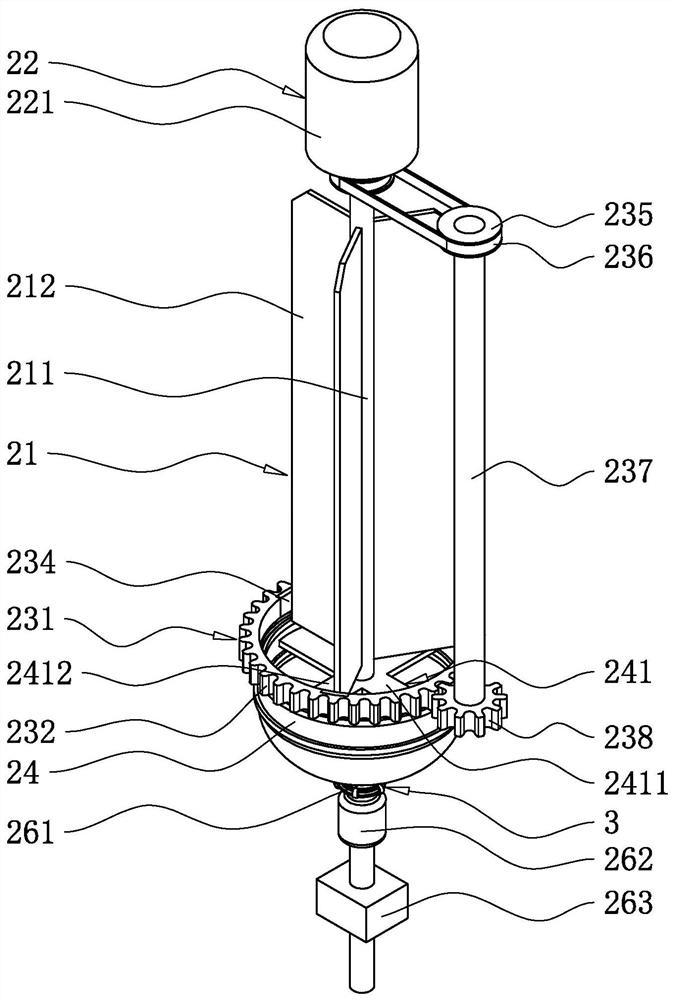

[0039] The following is attached Figure 1-7 The application is described in further detail.

[0040] The embodiment of the present application discloses a wiped film flash evaporator.

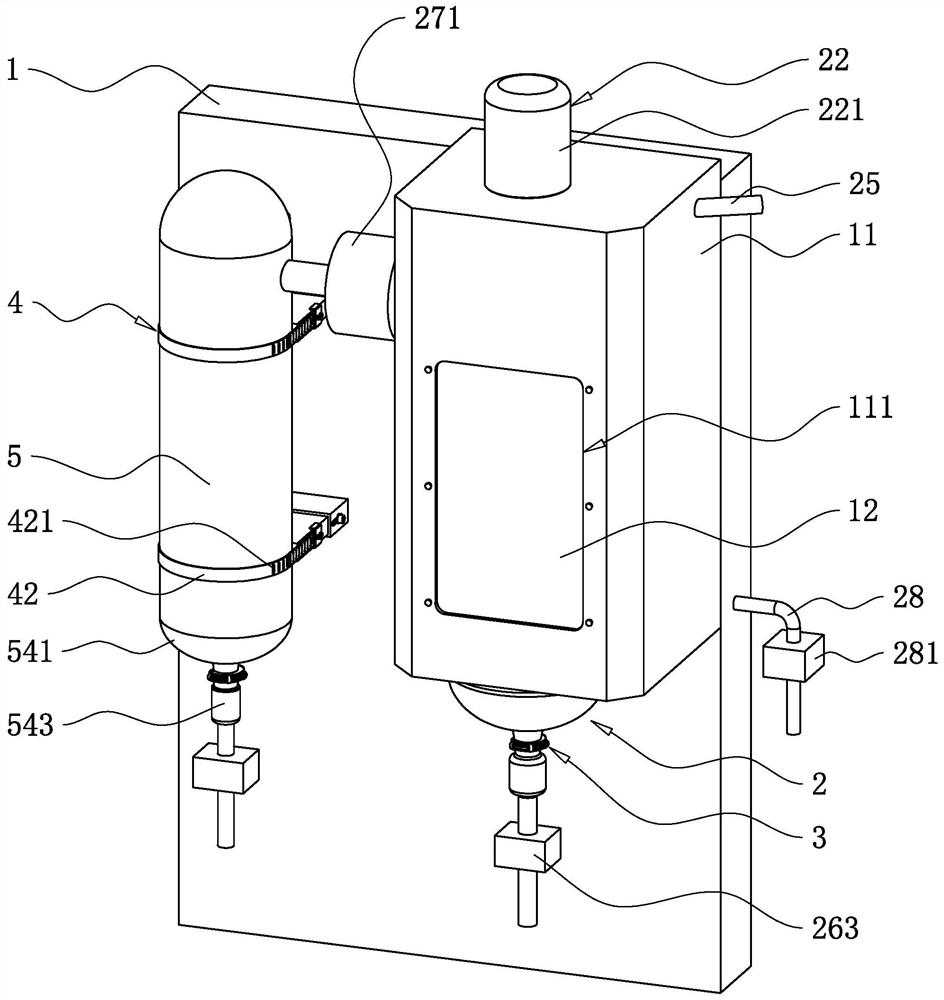

[0041] see figure 1 , figure 2 , the wiped film flash evaporator includes a frame 1, the frame 1 is vertically arranged, and one side of the width direction of the frame 1 is provided with a mounting frame 11, and the mounting frame 11 is located on one side of the frame 1 lengthwise direction. An evaporation tube 2 is arranged in the installation frame 11 , and the evaporation tube 2 is vertically arranged, and a film scraping device 21 is arranged in the evaporation tube 2 . A heating device 23 is also arranged in the installation frame 11 . The frame 1 is provided with a condensation pipe 5 along its own length direction away from the side of the mounting frame 11. The condensation pipe 5 is vertically arranged, and the upper side of the evaporation pipe 2 is connected with an air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com