Gas-fired internal combustion engine type mechanical steam recompression system and control method thereof

A gas-fired internal combustion engine and mechanical steam technology, which is applied to fuel systems, mechanical equipment, combustion engines, etc., can solve the problems of chemical methods polluting the environment, polluting the environment, and high power consumption of mechanical recompression systems, and achieves the goal of improving evaporation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

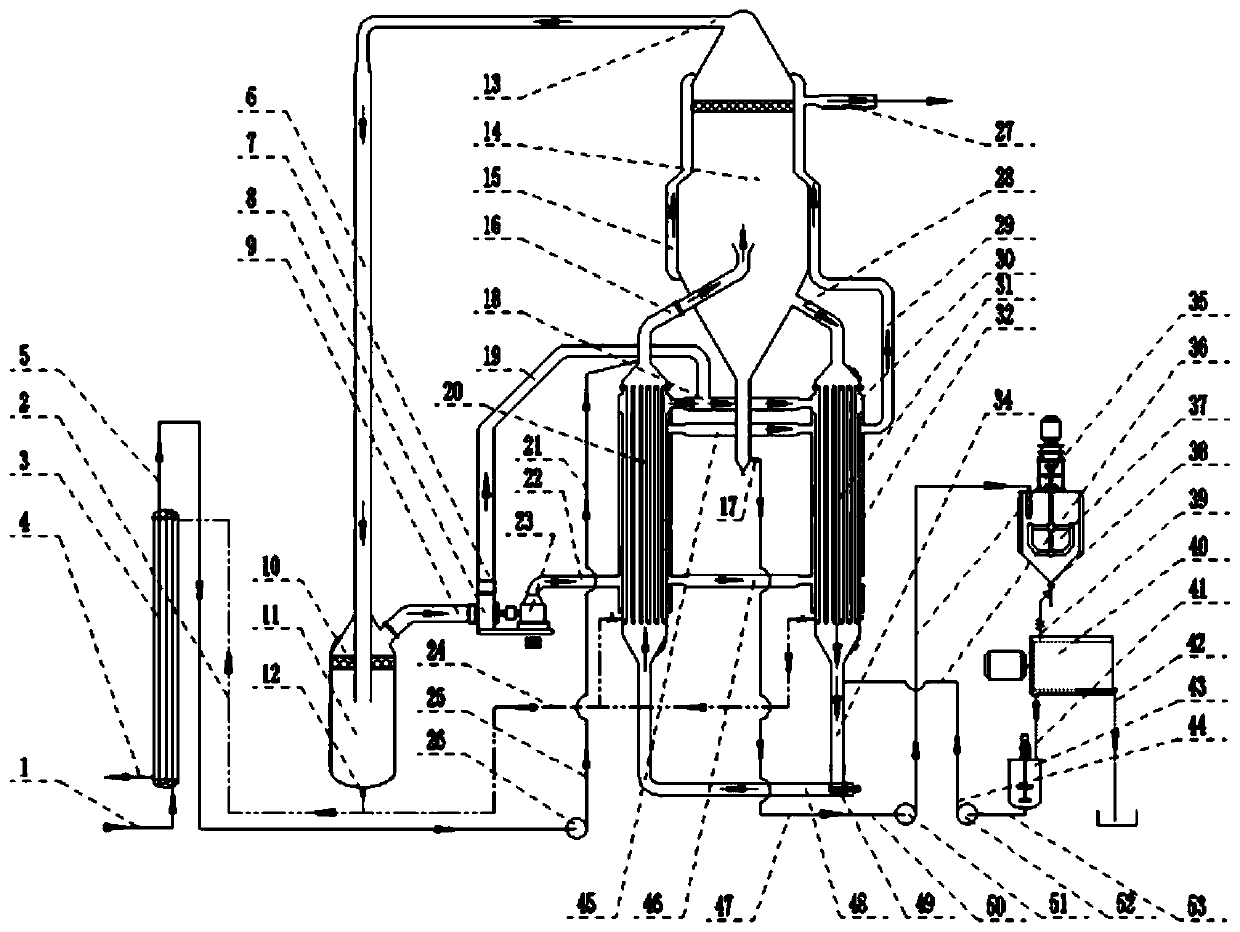

[0029] see figure 1 .

[0030] The gas internal combustion engine 23 uses natural gas as fuel, and the gas internal combustion engine directly drives the steam compressor 8 .

[0031] Sewage booster pump 26 extracts sewage to be treated from sewage pipeline 1, preheater 3, preheated sewage pipeline 5, sewage booster pump 26, high-pressure sewage delivery pipeline 25, high-pressure sewage delivery pipeline 21, evaporator sewage The inlet pipe 16 enters the evaporator 14 .

[0032] The sewage entering the evaporator 14, under the action of the sewage circulating pump 49, evaporates the residual liquid pipeline 28, the 2# heater 31, the sewage circulation pump inlet pipeline 34, the sewage circulation pump outlet pipeline 48, the 1# heater 20, the evaporator The sewage inlet pipe 16 enters the evaporator 14. The 2# heater 31 and the 1# heater 20 adopt a composite structure in which three flow paths are isolated: sewage circulation flow path, high temperature and high pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com