Low-vacuum sludge drying system

A drying system and low vacuum technology, applied in dewatering/drying/concentrating sludge treatment, combustion methods, combined devices, etc., can solve problems such as outstanding sludge treatment and disposal problems, reduce energy consumption, and improve water evaporation speed. , the effect of lowering the boiling point temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

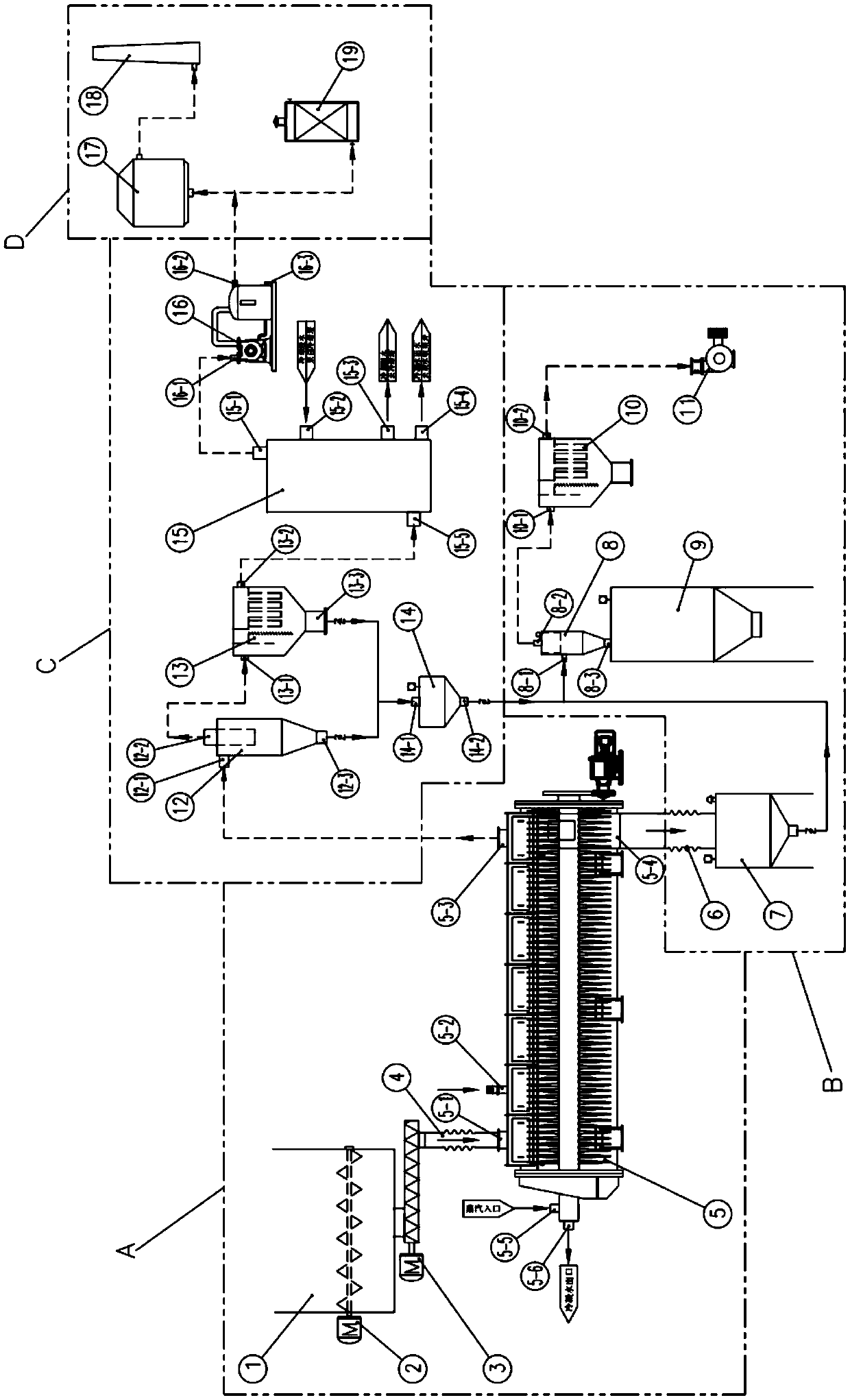

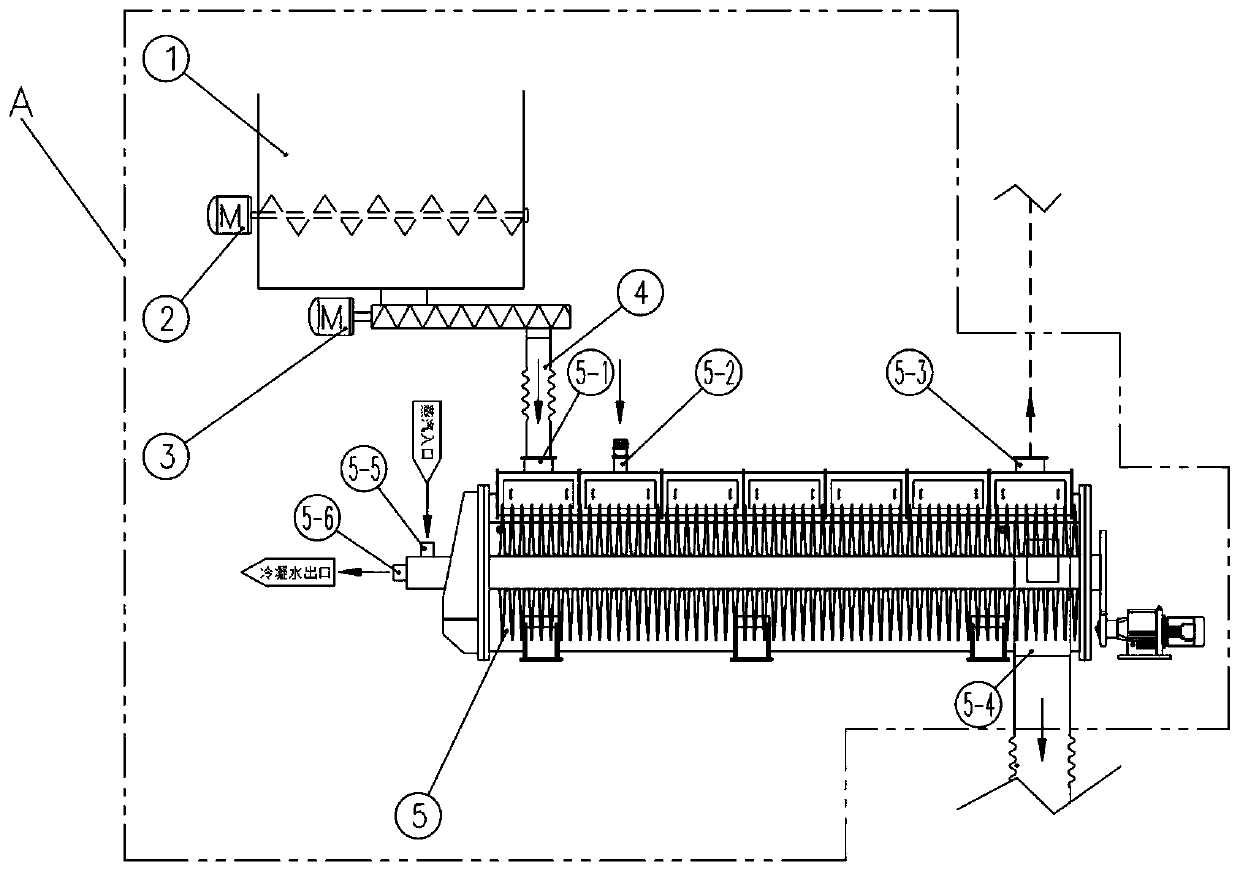

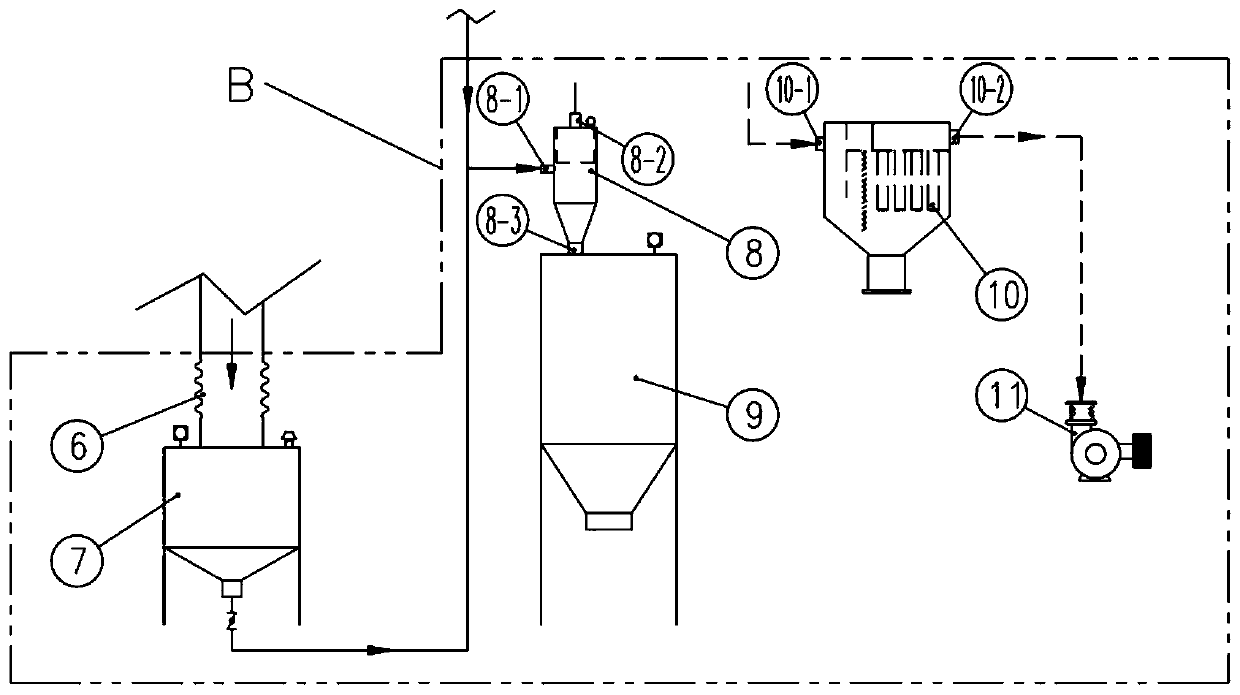

[0026] refer to Figure 1-2 , a low vacuum sludge drying system, comprising a wet sludge silo 1, an arch breaking device 2, a conveying device 3, a flexible feeding connection section 4, a low vacuum sludge drying device 5, and a flexible discharging connection section 6 , Buffer bin 7, Vacuum conveying device 8, Dry sludge bin 9, High-efficiency bag dust removal device 10, Roots blower 11, Cyclone dust removal device 12, High-efficiency bag dust collector 13, Storage bin 14, Condenser 15 , vacuum system 16, incineration device 17, chimney 18, deodorization device 19, wherein,

[0027] figure 1 Among them, Area A is the sludge drying system; Area B is the sludge conveying and storage system; Area C is the dust removal and condensation system; Area D is the waste gas treatment system;

[0028] The arch breaking device 2 is installed on the wet sludge silo 1, the bottom of the wet sludge silo 1 is connected to the inlet end of the conveying device 3, the output end of the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com