Closed brayton cycle excess heat generating system and method for using same for excess heat power generation

A technology of Brayton cycle and waste heat power generation, which is applied in the field of power station systems, can solve the problems of poor stability and reliability of waste heat power generation systems, small adaptability range of waste heat fluctuations, and low comprehensive utilization rate of waste heat, so as to realize utilization and reduce energy Effects of waste, high mechanical and power generation efficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

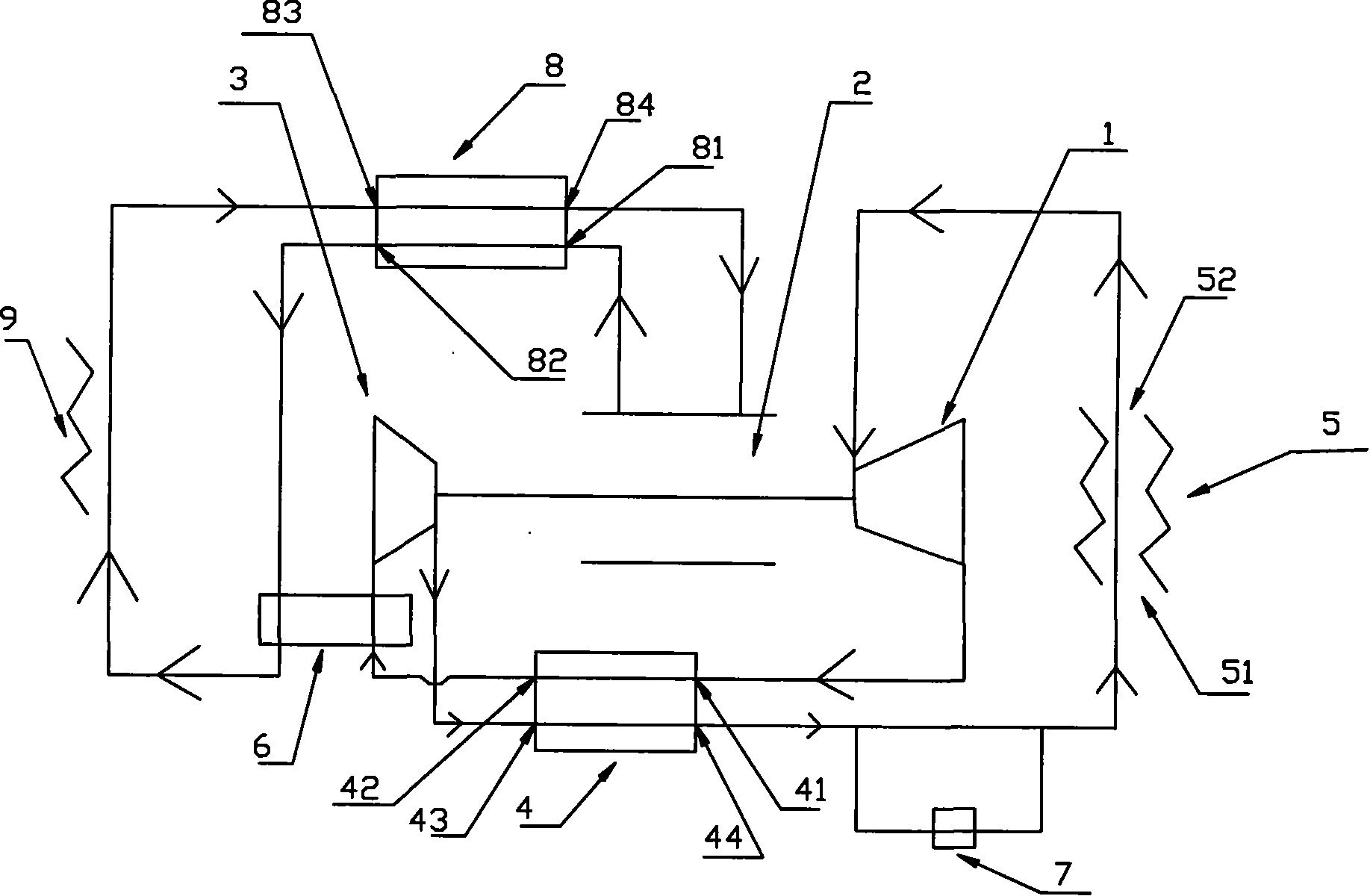

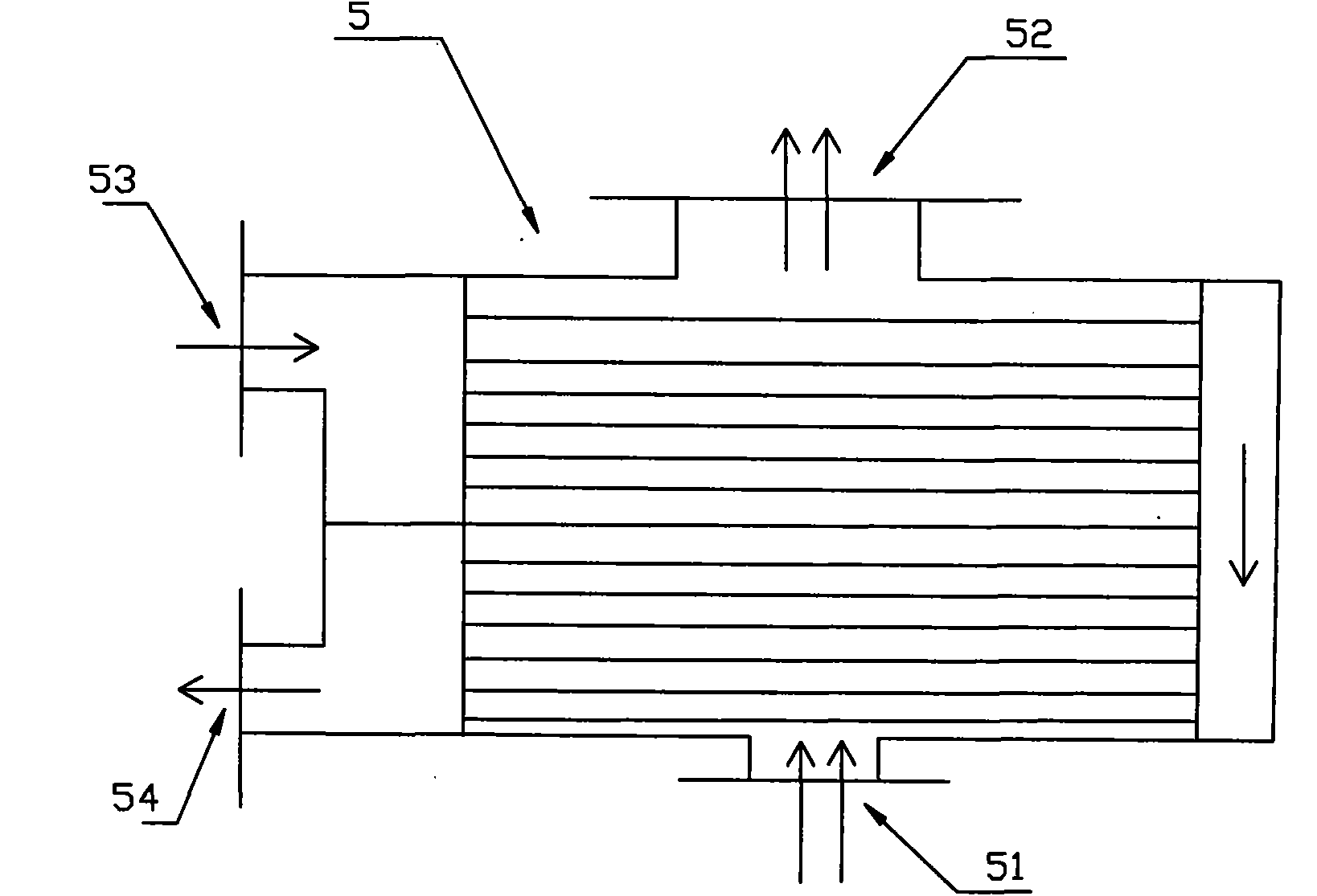

[0018] Such as figure 1 As shown, in the closed Brayton cycle waste heat power generation system of this embodiment, the start-up booster system 7 is connected to the helium inlet 51 of the counterflow flue gas heat exchanger 5 through the helium circulation pipeline, and the counterflow flue gas heat exchanger The helium outlet 52 of 5 is connected to the turbine power unit 1 through the helium circulation pipeline, and the helium waste heat recovery inlet 41 of the turbine circuit regenerator 4 is connected to the turbine power unit 1 through the helium circulation pipeline, The helium waste heat recovery outlet 42 of the turbine circuit regenerator 4 is sequentially connected to the turbine circuit radiator 6 and the gas compressor 3 through the helium circulation pipeline, and the helium gas in the turbine circuit regenerator 4 is heated The inlet 43 is connected to the gas compressor 3 through a helium circulation pipeline, and the helium heating outlet 44 of the turbine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com