Negative-pressure phase-change heat dissipation device and high-heat-flux electronic chip simulation heat dissipation system

A heat dissipation device and phase change technology, applied in electrical components, structural parts of electrical equipment, modification by conduction and heat transfer, etc., can solve the problems affecting the working performance of high-power chips, limited heat dissipation capacity, and prominent local hot spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in further detail below:

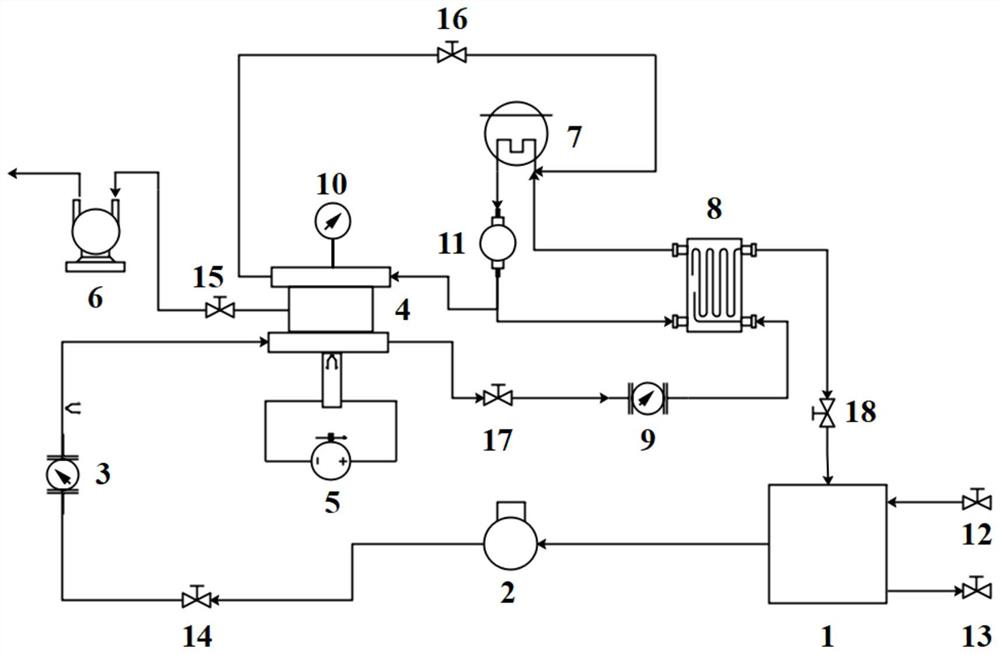

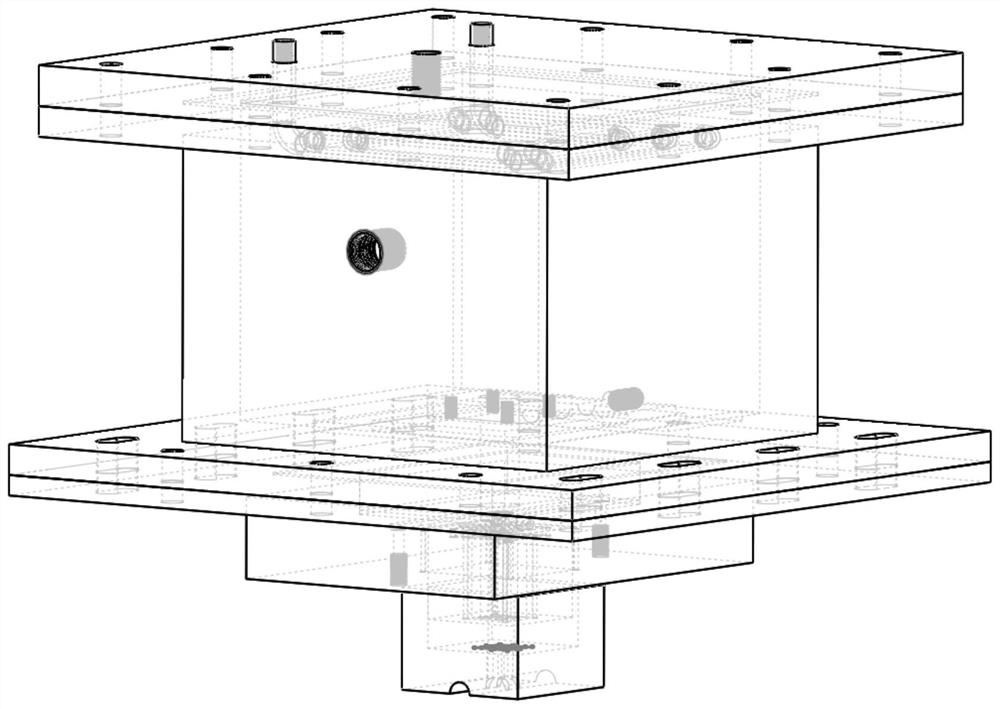

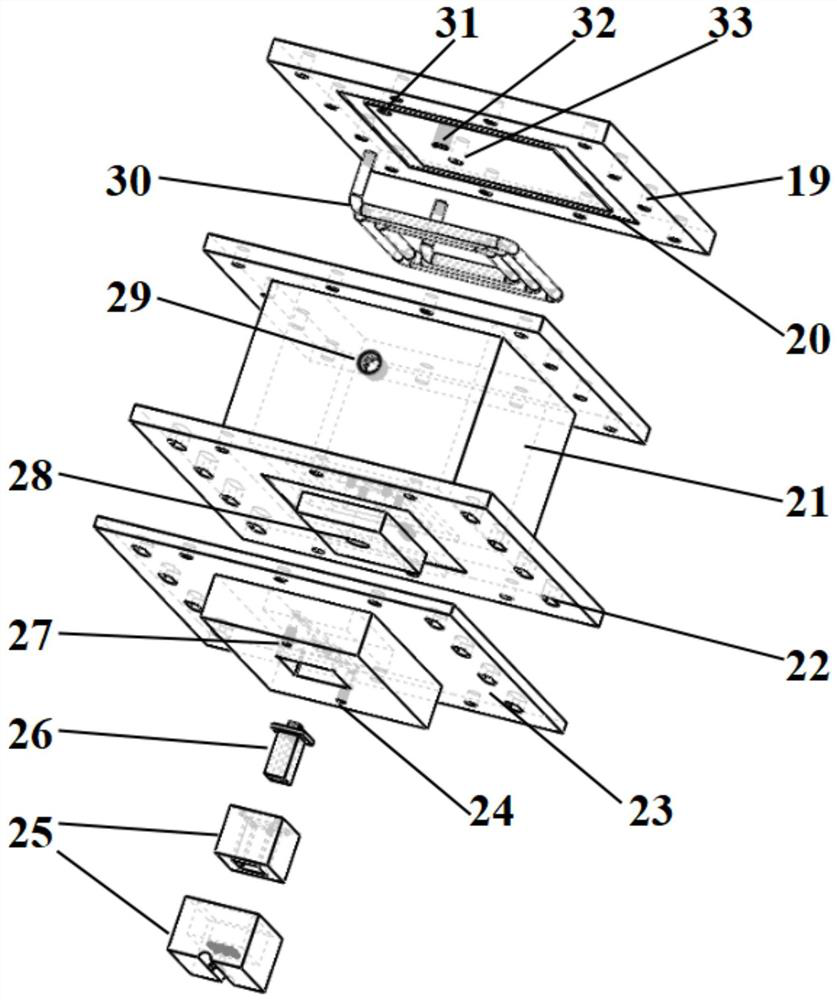

[0039] The present invention is a cold plate structure that utilizes boiling-coupled thin-film evaporation and uses hydraulic fluid to generate phase transition in a negative pressure environment, thereby realizing efficient heat dissipation of chips. The present invention generates a negative-pressure environment on one side of the evaporation film, increasing the On the one hand, it avoids the mutual influence of the traditional boiling heat exchange gas separation and liquid supply, on the other hand, it accelerates the evaporation power and rate of the liquid, significantly improves the working efficiency of the cold plate, and can achieve a heat flux density exceeding 1kW / cm 2 In consideration of operability, the present invention replaces the chips that actually work normally with simulated heat sources for heat generation.

[0040] Specifically, a negative-pressure phase-change cooling device for chip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com