Patents

Literature

42 results about "Pressure phases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

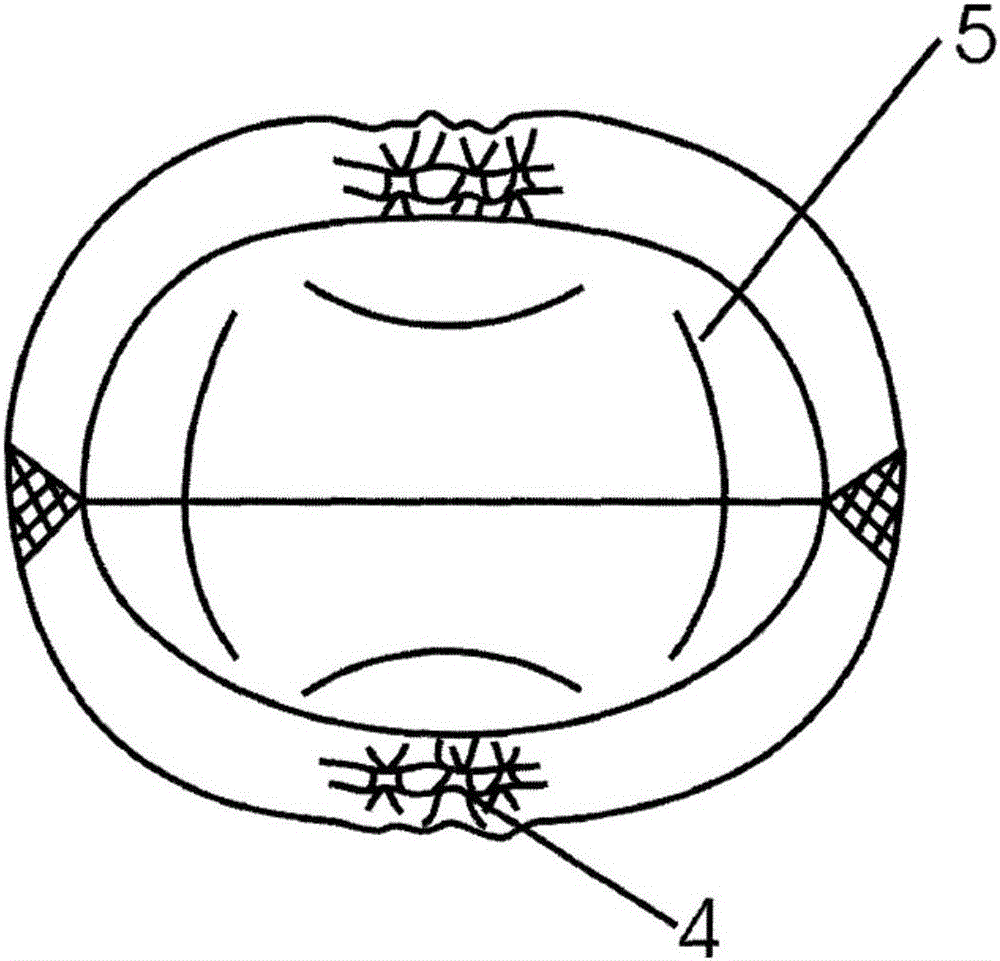

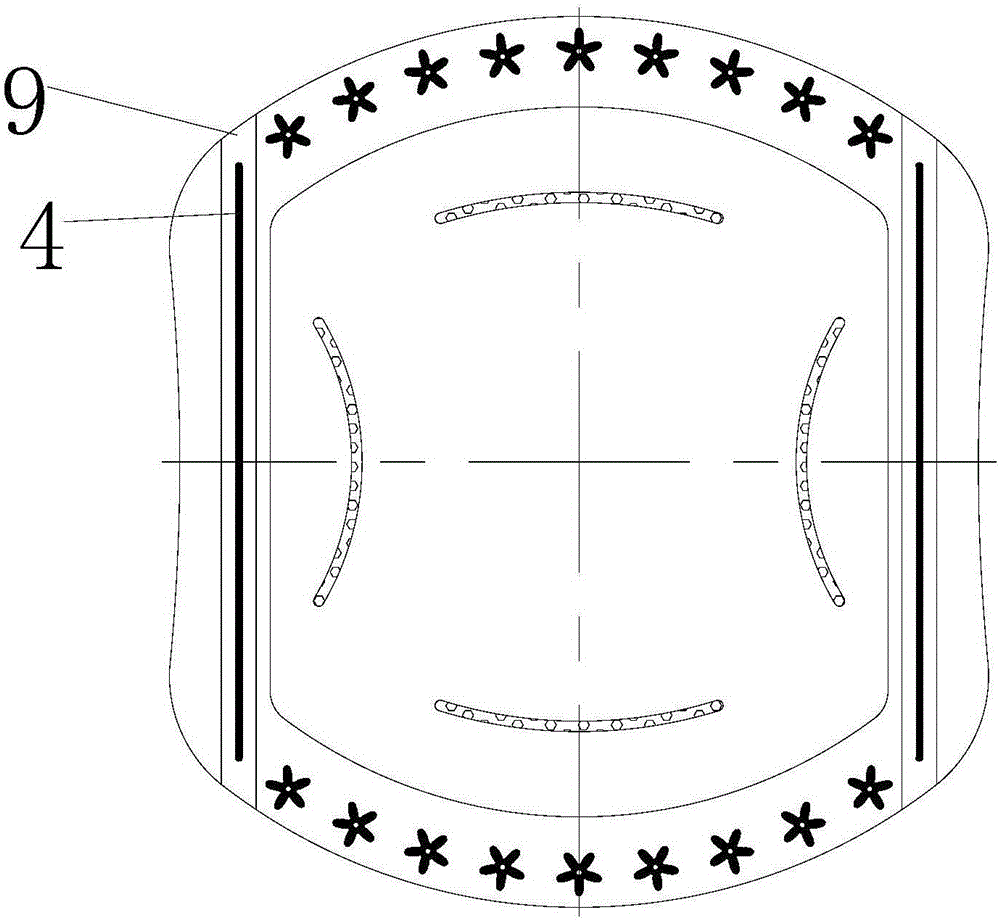

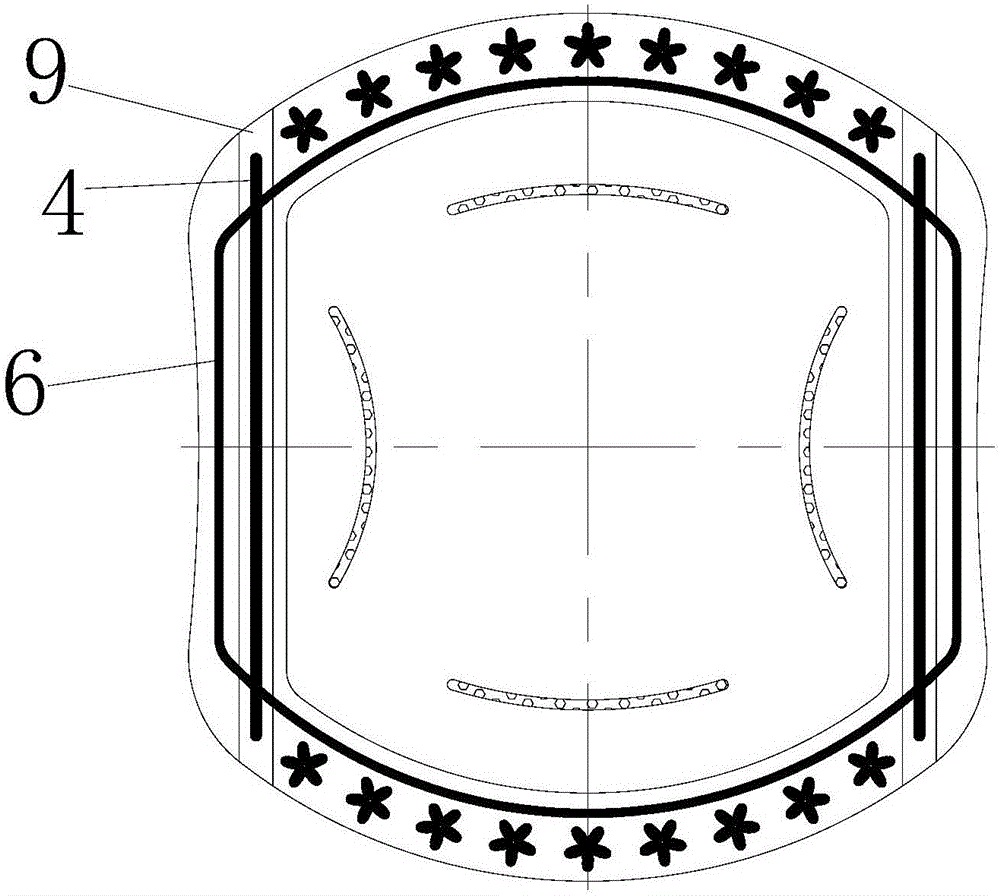

Method and device for soft tissue treatment

InactiveUS20060211958A1Good effectReduce unwanted damageUltrasound therapyChiropractic devicesMuscle tissueConnective tissue fiber

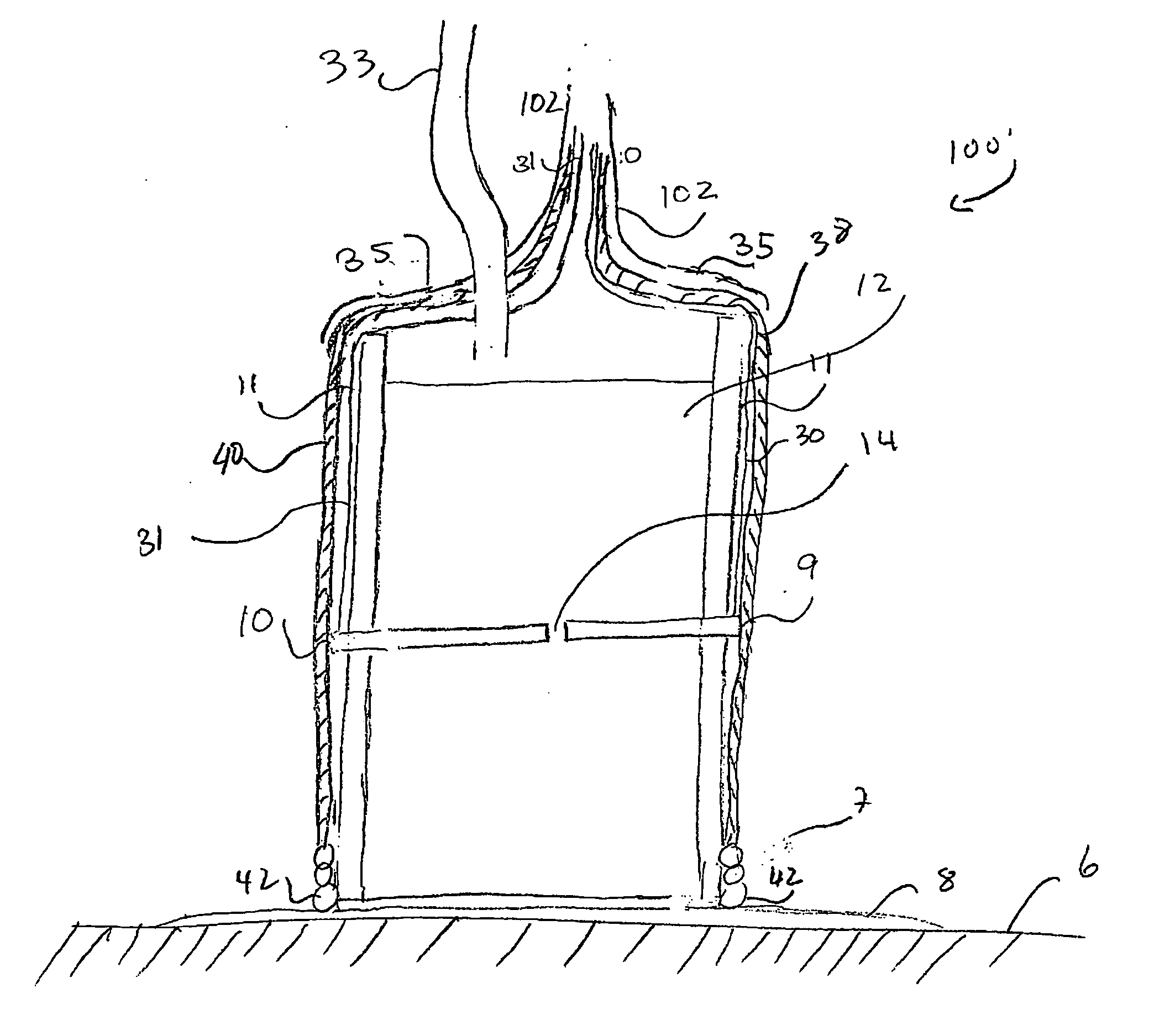

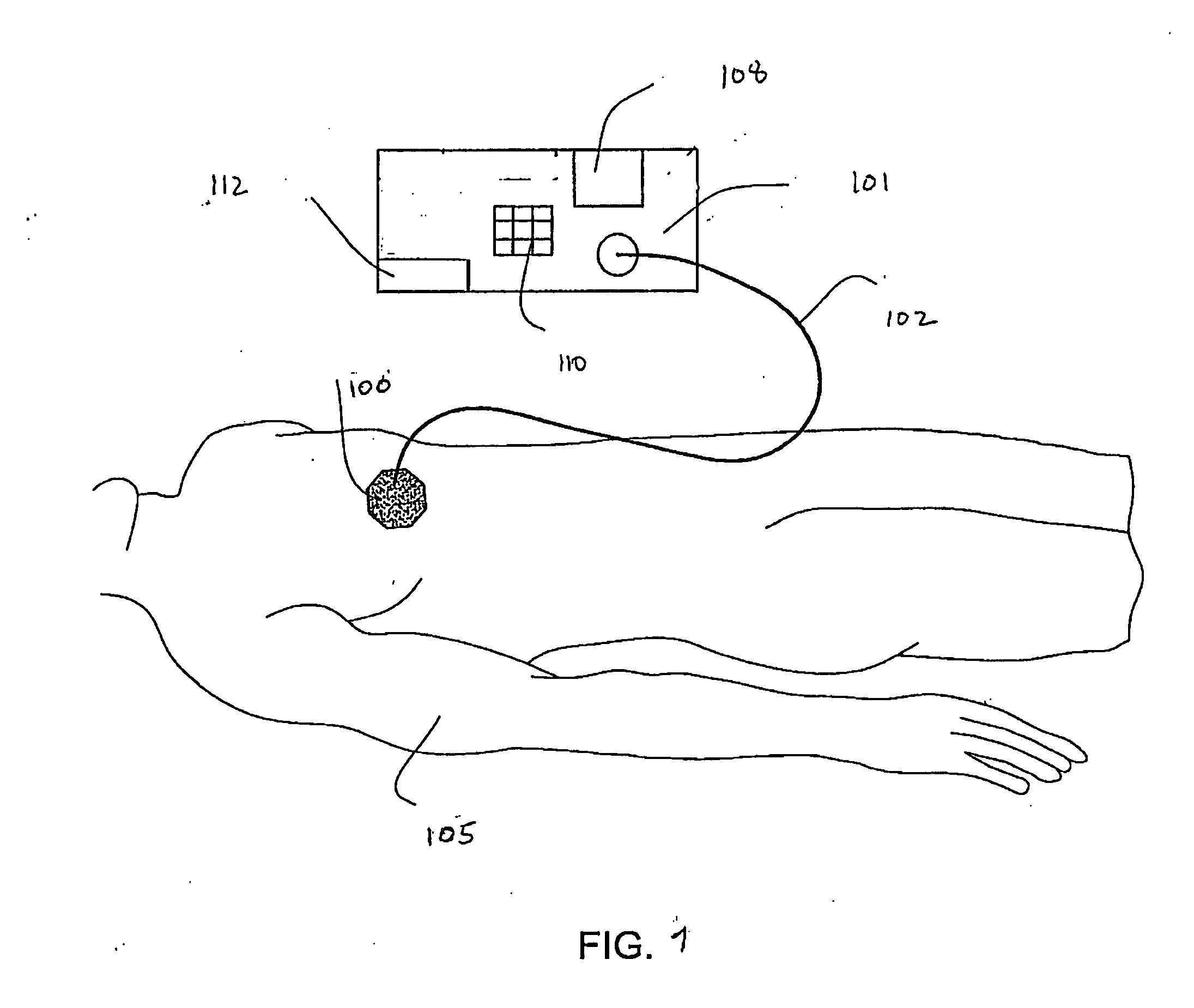

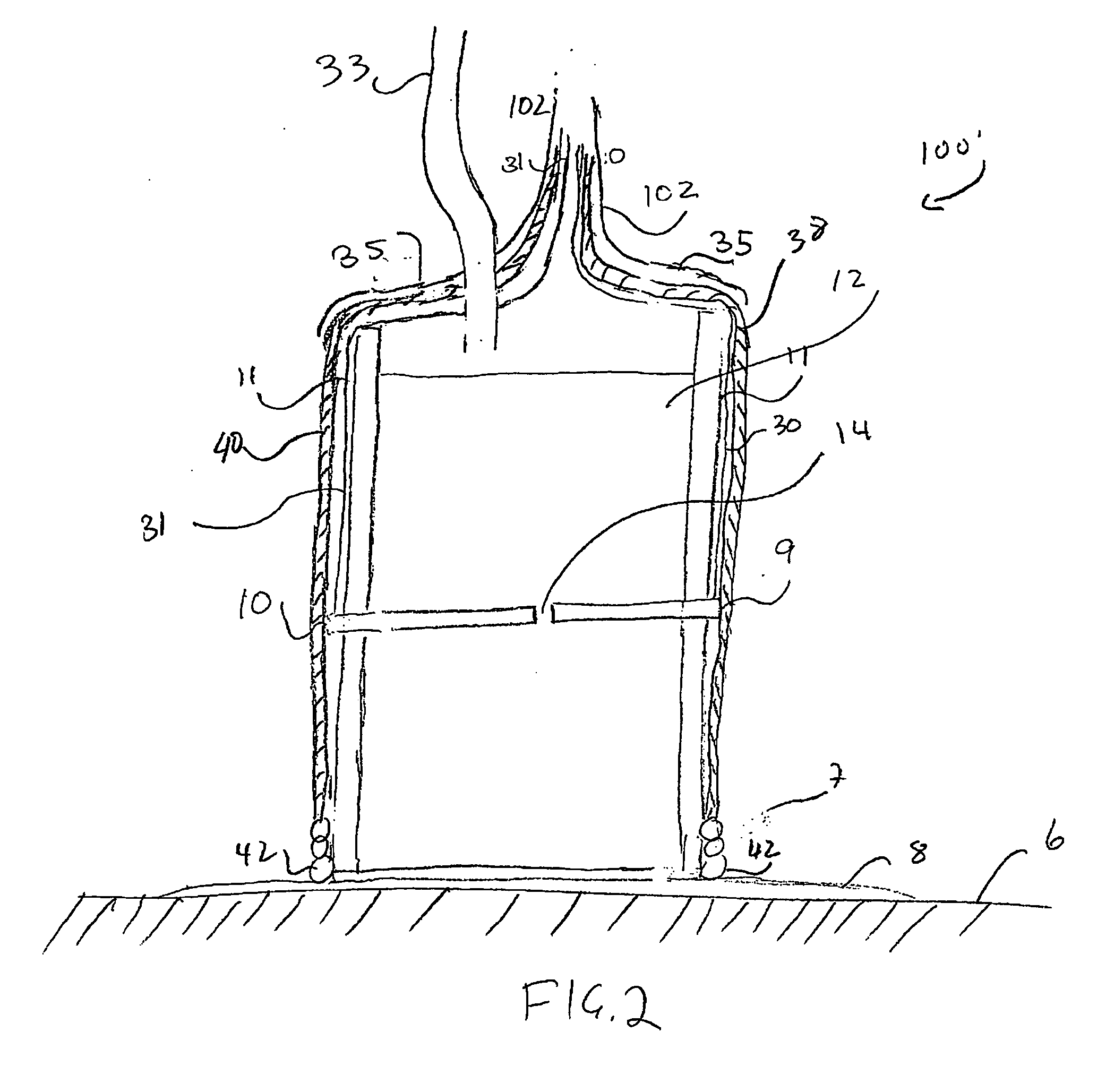

A method and system for non-invasive treatment of a soft tissue, such as adipose tissue, muscle tissue or connective tissue. The apparatus comprises an applicator configured to apply a pressure pulse to the skin surface having a negative pressure phase with respect to ambient pressure. The method comprises applying at least one pressure pulse to the skin surface overlying the soft tissue, where the pressure pulse has at least one negative pressure phase.

Owner:SYNERON MEDICAL LTD

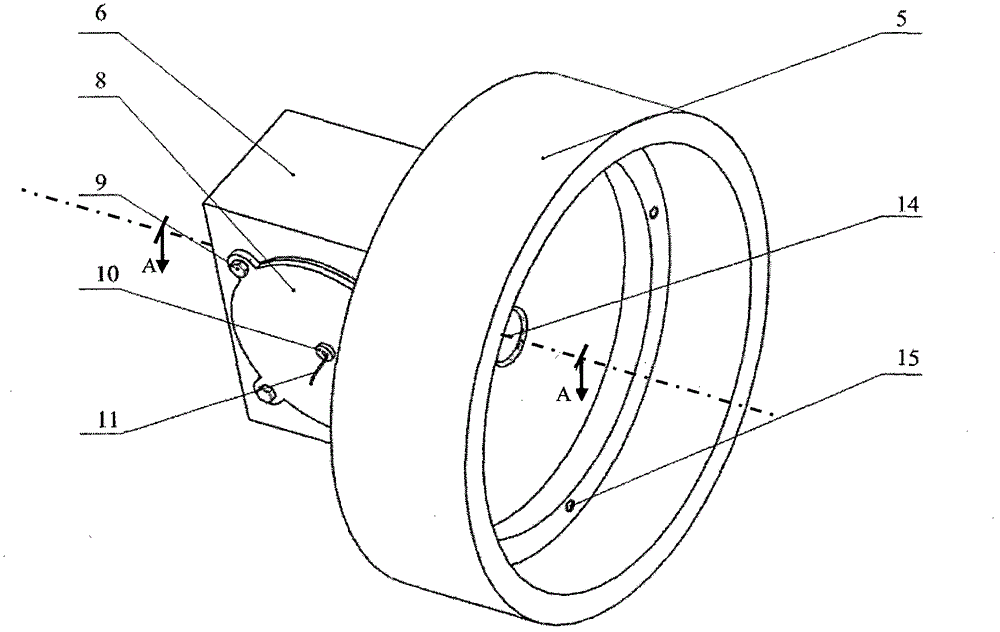

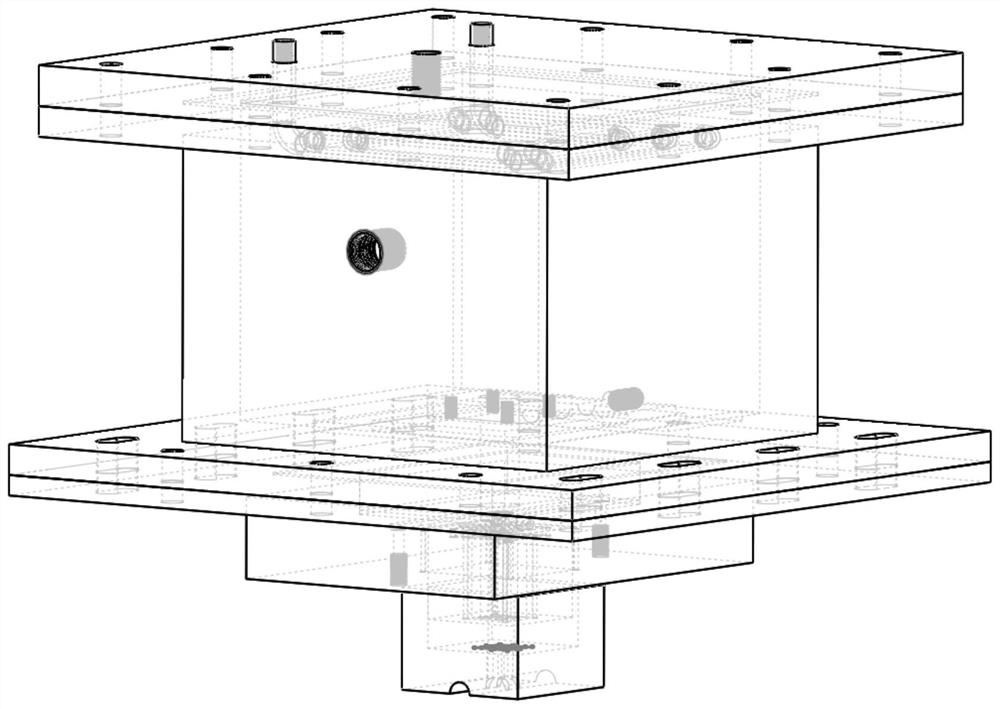

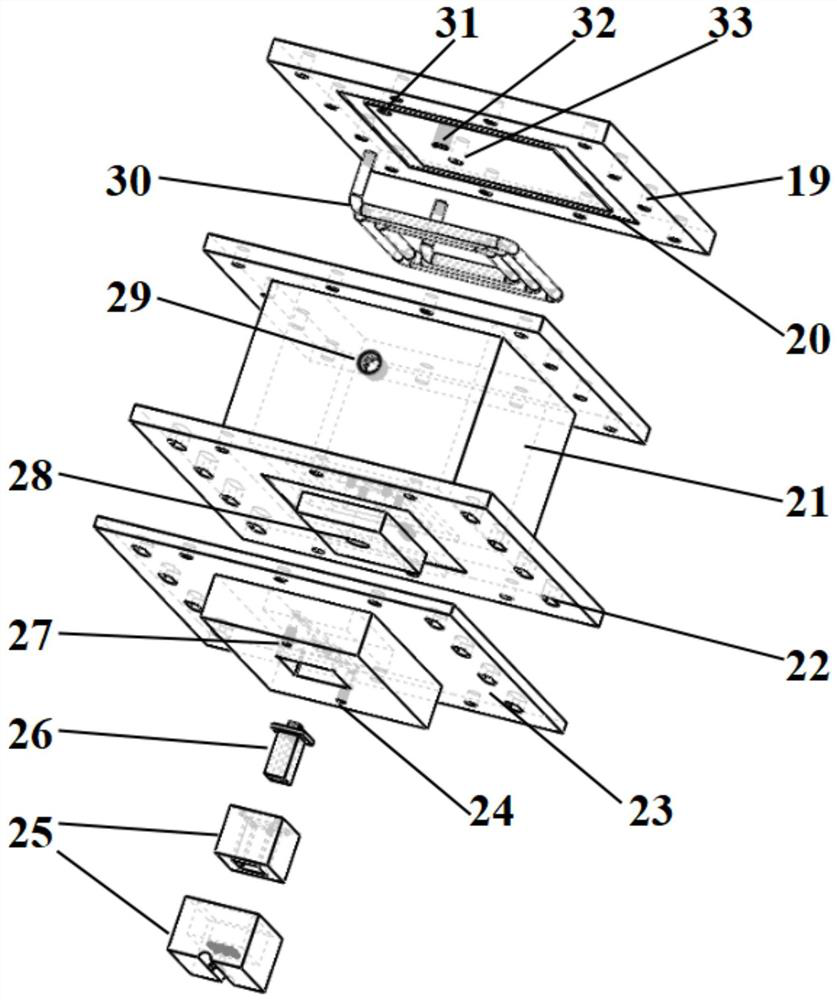

Dual-purpose cabin for dynamic pressure calibration of optical pressure sensitive coatings

InactiveCN104316262AEasy to switchTo achieve the effect of dual-use in one cabinFluid pressure measurementInterference resistanceSolenoid valve

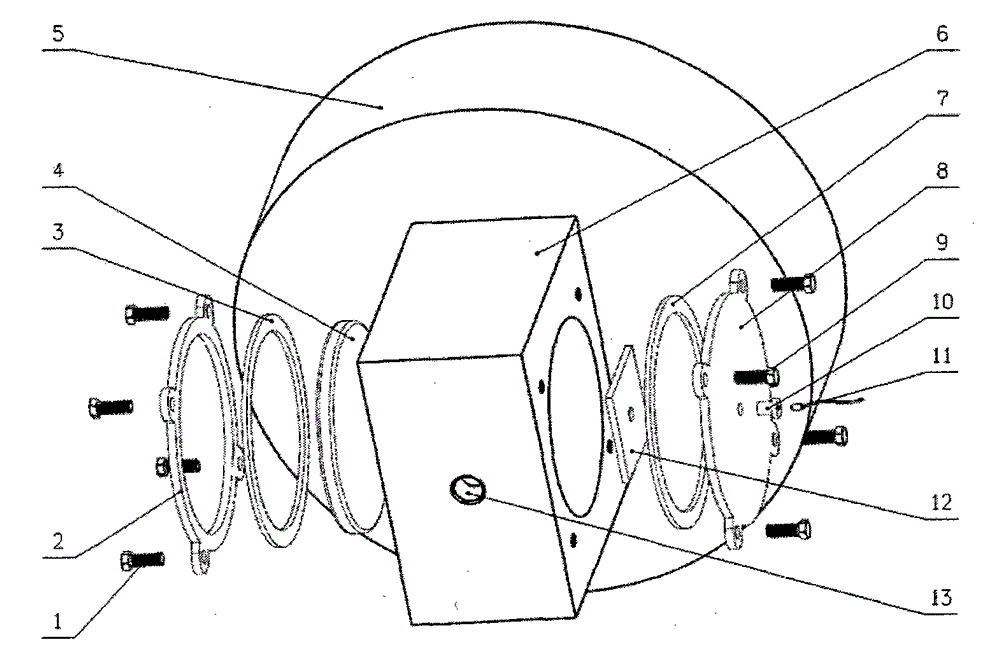

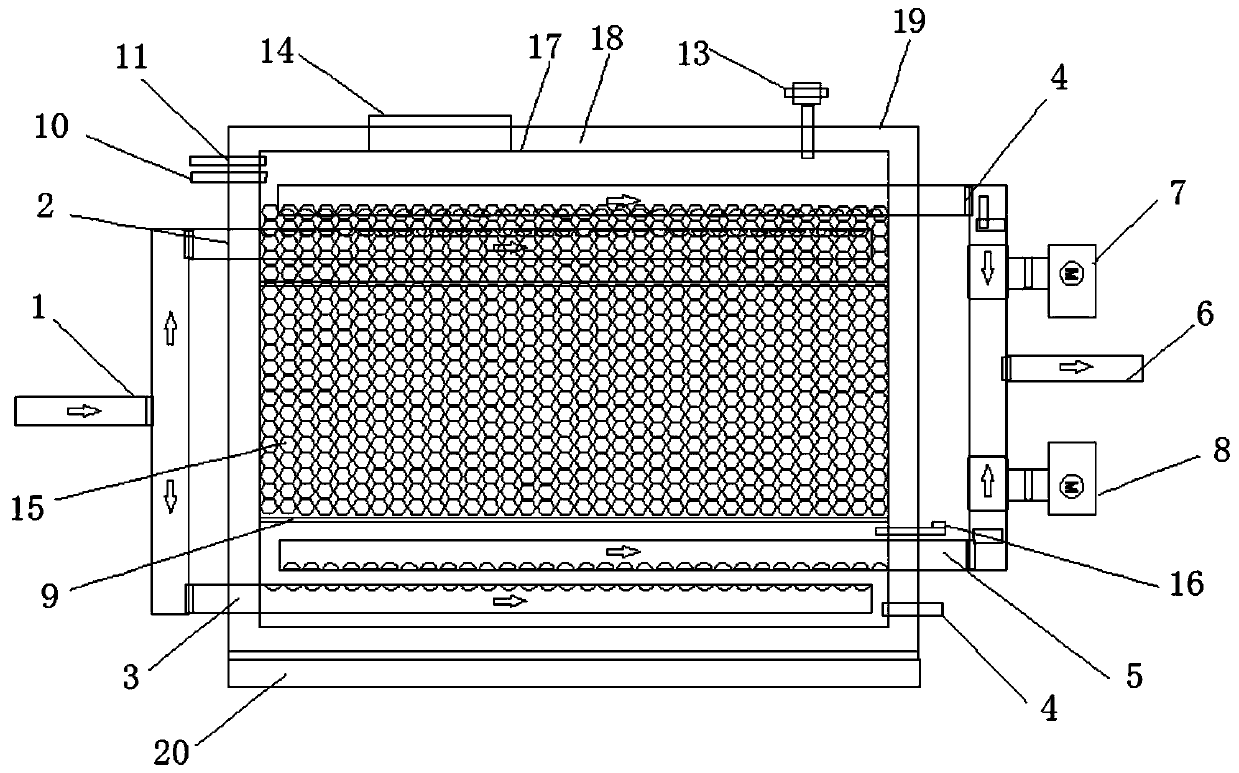

The invention relates to a dual-purpose cabin for dynamic pressure calibration of optical pressure sensitive coatings. The dual-purpose dynamic pressure calibration cabin is mainly used for dynamic pressure calibration of pressure sensitive coatings, meets special requirements of the pressure sensitive coatings for a dynamic calibration device, and fills the blank of domestic research in the field. Meanwhile, the calibration cabin is matched with a solenoid valve and a loudspeaker in use, and the effect of dual purposes can be achieved as aperiodic calibration and periodic calibration can be completed. To ensure convenient switching between a pressure phase step mode and a sine mode, a cabin body of the calibration cabin is specially provided with a structure for fixing pressure signal generation sources, namely the solenoid valve and the loudspeaker. A light path is designed on the calibration cabin to meet requirements of pressure testing of the pressure sensitive coatings for ultraviolet light. In addition, damping materials are pasted on the inner wall surface of an experiment section of the calibration cabin to reduce the size of the calibration cabin and avoid the interference of pressure reflected waves on calibration. The dual-purpose cabin is simple in structure, convenient to process and strong in the interference resistance, and can effectively reduce test cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

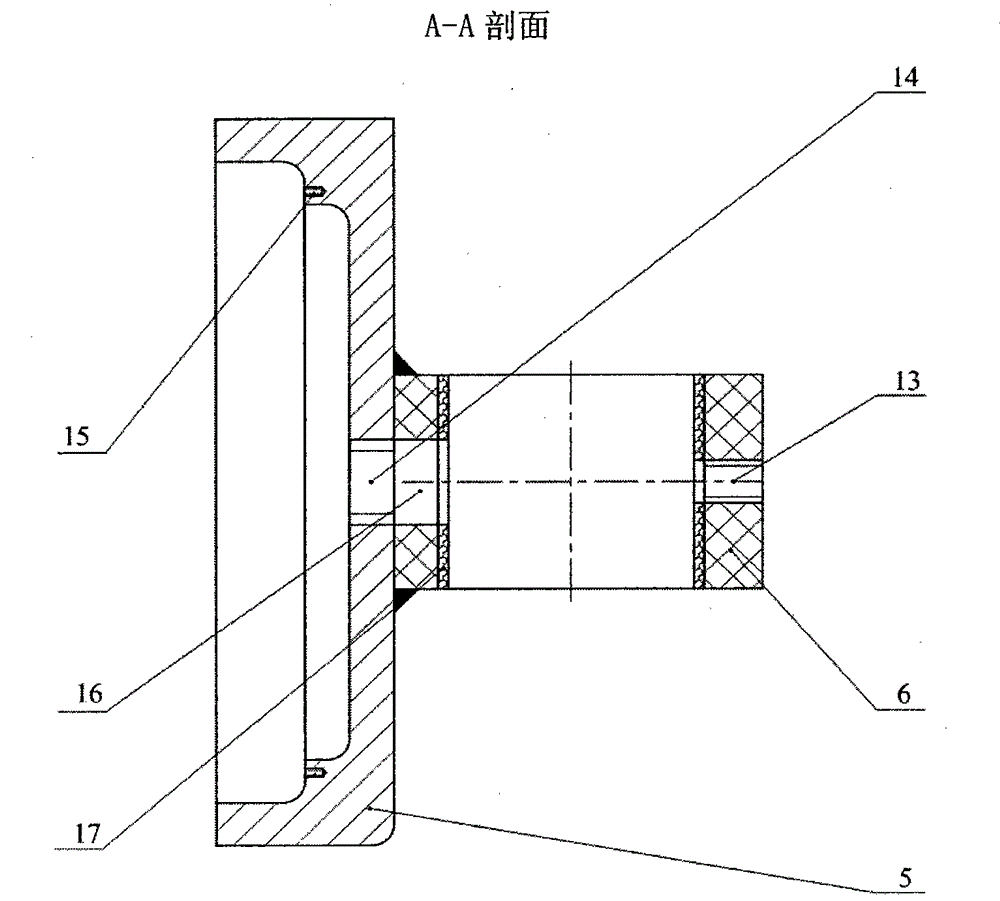

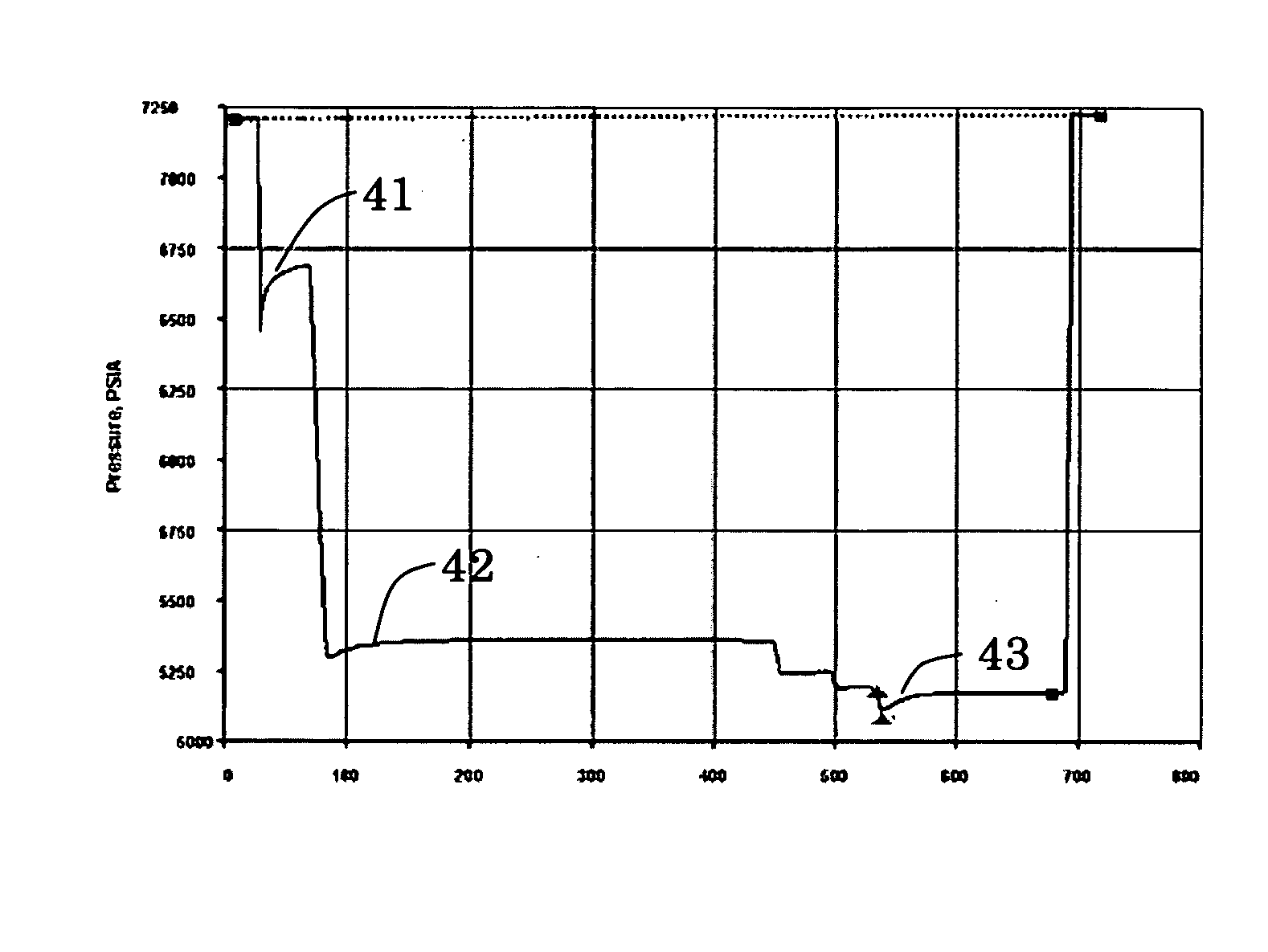

Method for measuring formation properties with a formation tester

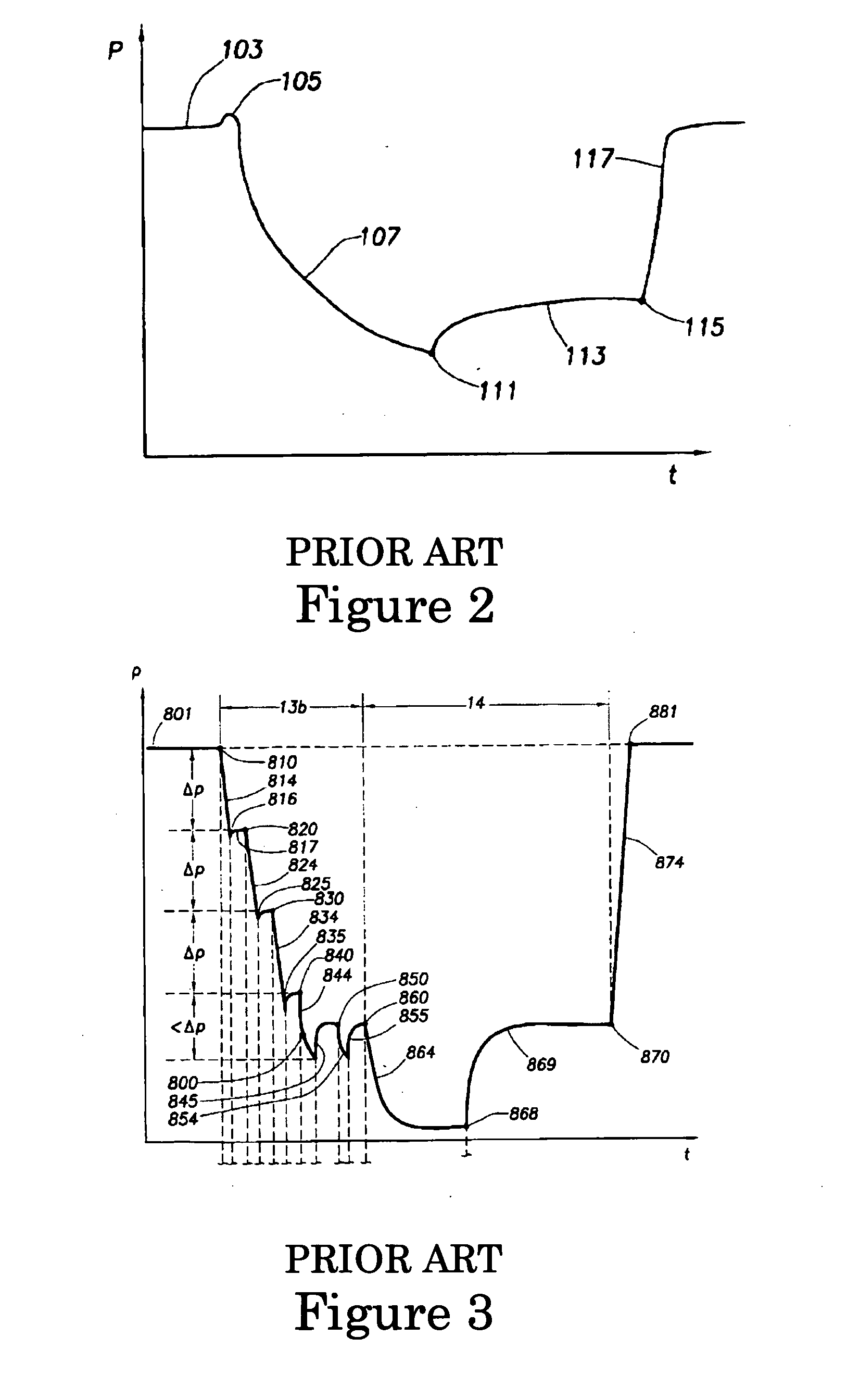

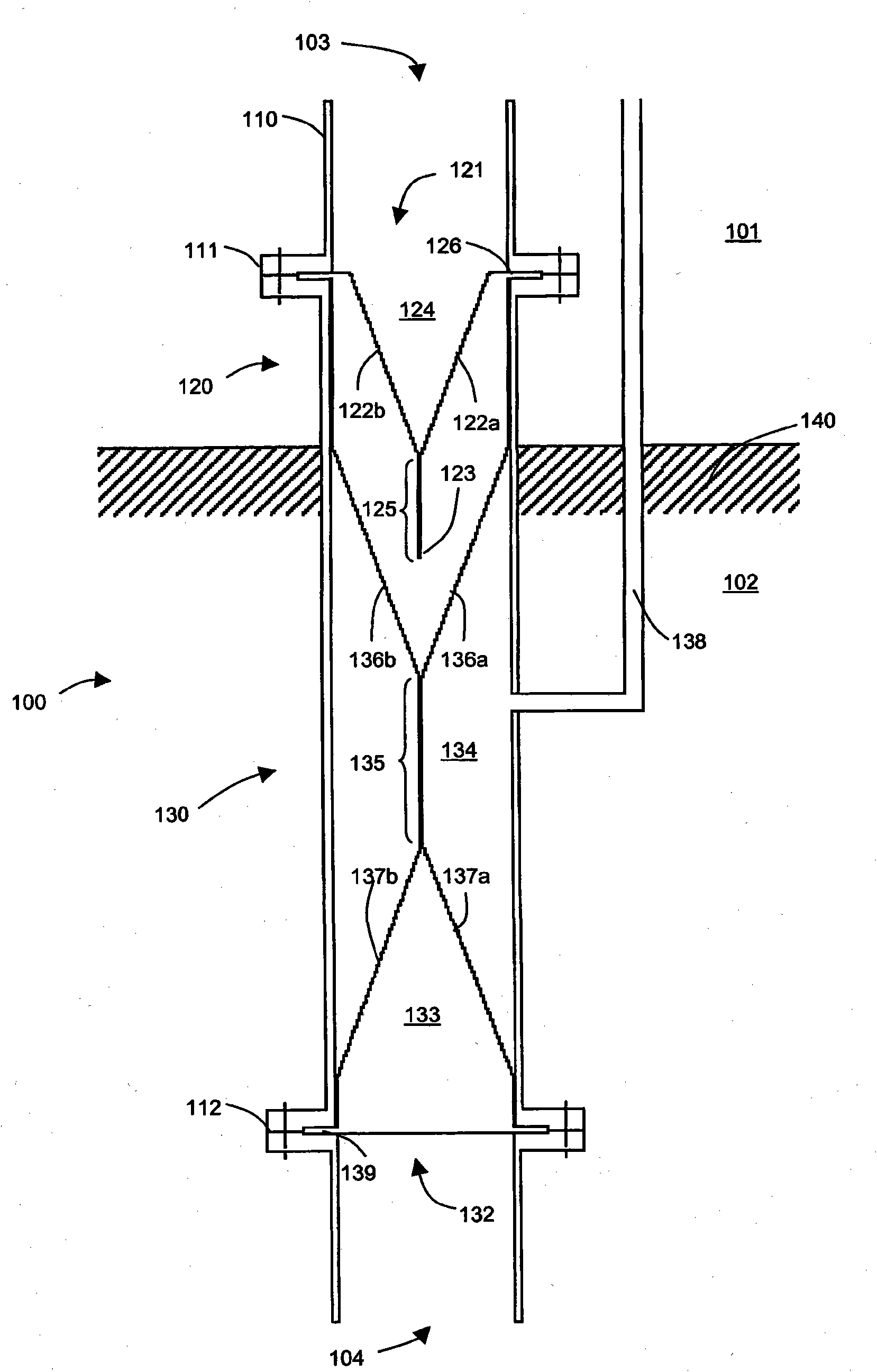

A method is disclosed for estimating a formation pressure using a formation tester disposed in a wellbore penetrating a formation, said method comprising: (a) establishing fluid communication between a pretest chamber in the downhole tool and the formation via a flowline, the flowline having an initial pressure therein; (b) moving a pretest piston in a controlled manner in the pretest chamber to reduce the initial pressure to a drawdown pressure during a drawdown phase; (c) terminating movement of the piston to permit the drawdown pressure to adjust to a stabilized pressure during a build-up phase and measuring simultaneously in relation to time, pressure P(t) and temperature T(t) in the pretest chamber; (d) extracting an index i(t) dependent of the pressure P(t) and the temperature T(t) informing on the build-up phase; (e) analyzing index i(t) and repeating steps (b)-(d) or going to step (f); (f) determining the formation pressure based on a final stabilized pressure in the flowline. And more generally a method could be used for estimating type of a build up pressure phase, the build up pressure phase being done after a drawdown pressure phase, said both drawdown and build up phases being done to determine formation pressure using a formation tester disposed in a wellbore penetrating a permeable formation, said permeable formation being able to create a formation flow, said method being characterized by using an index to determine the contribution of formation flow on the pressure build up phase.

Owner:SCHLUMBERGER TECH CORP

Ventilator arrangement for gravitational fluid discharge via high and low pressure phase

InactiveCN101980910APrevent backflowBlock flowCheck valvesDomestic plumbingAmbient pressureEngineering

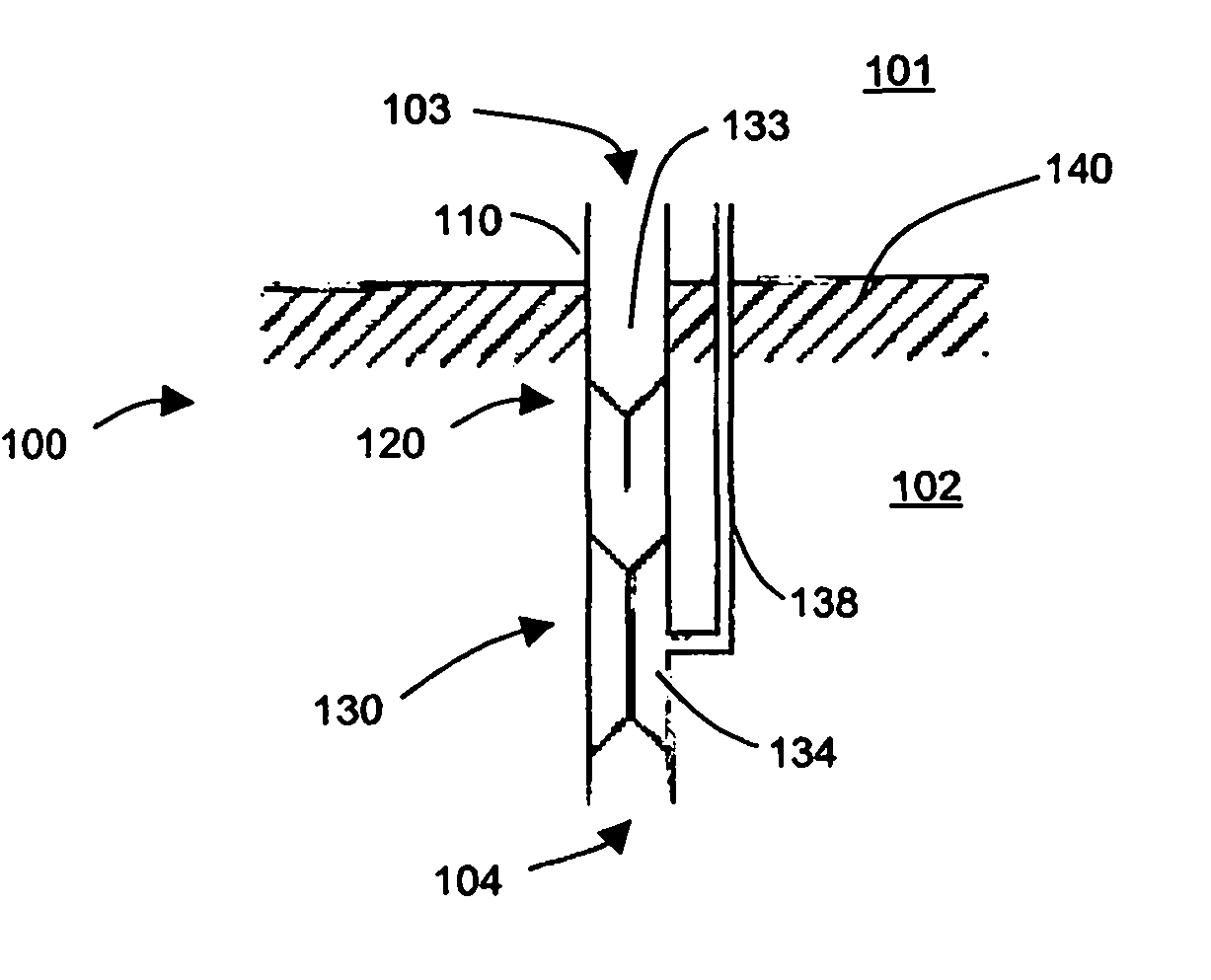

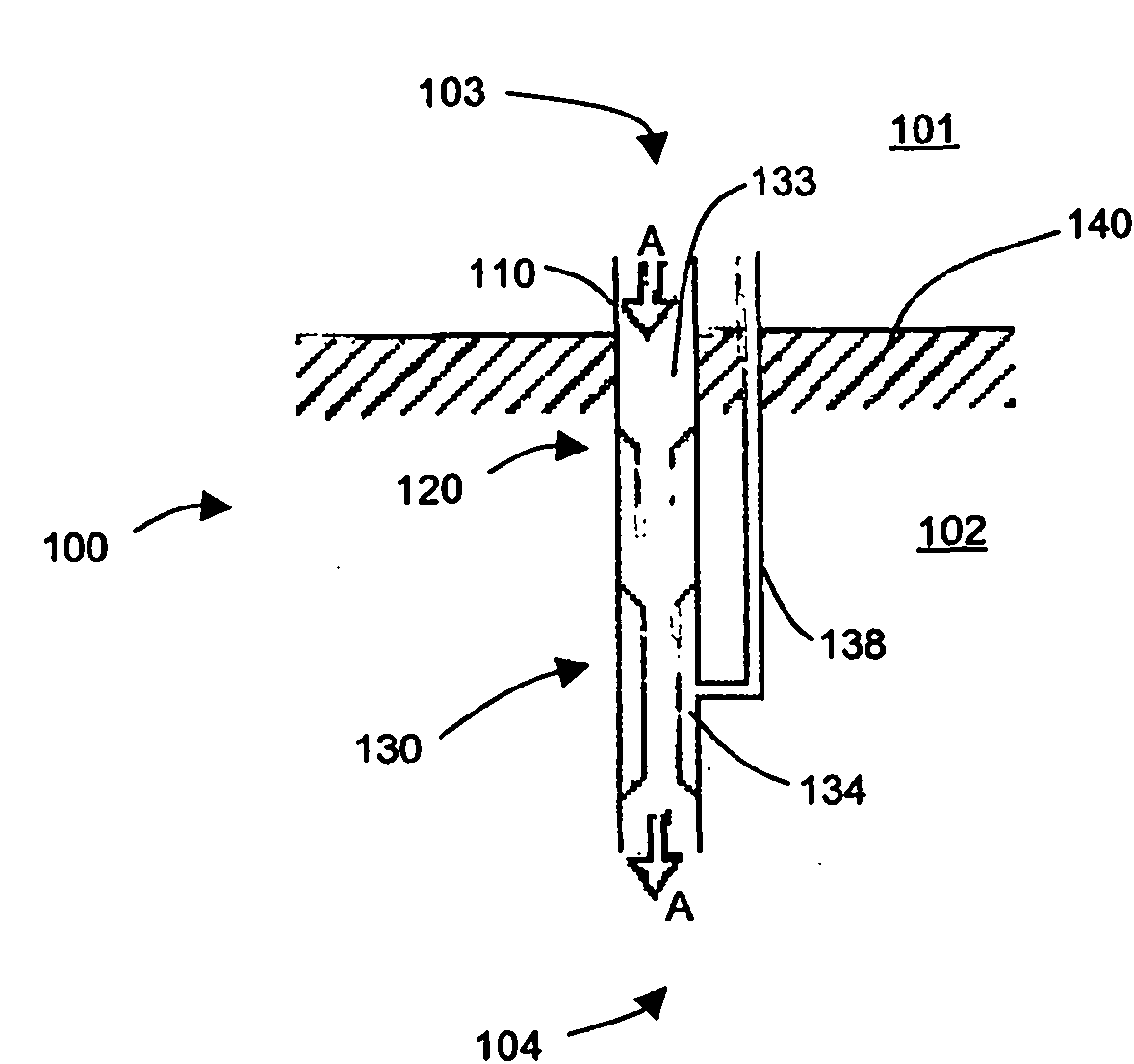

The invention relates to a device for discharging a fluid medium from a space (101), which is pressure-damped as opposed to an environment, into the environment (102). The invention further relates to a valve arrangement for discharging a fluid medium from a space, which is pressure-damped as opposed to an environment, into the environment, comprising an inlet opening (103), which is in gas pressure contact with the pressure-damped space in the installed position, an outlet opening (104) positioned below the inlet opening in the installed position in the direction of gravity, said outlet opening being in gas pressure contact with the environment in the installed position, a connecting channel (110) connecting the inlet opening to the outlet opening, a return flow stop valve (120), which is configured in order to allow the fluid medium to pass from the inlet opening to the outlet opening under the influence of gravity, and in order to close it off if a predetermined gas overpressure present in the environment as opposed to the pressure-damped space is exceeded, a through-flow stop valve (130), which is configured to allow the fluid medium to pass from the inlet opening to the outlet opening under the influence of gravity, and to close it off if a predetermined gas overpressure present in the pressure-damped space as opposed to the environment is exceeded.

Owner:EVAC GMBH

Antineoplastic medicine prepared through gelsmium elegans medicinal materials

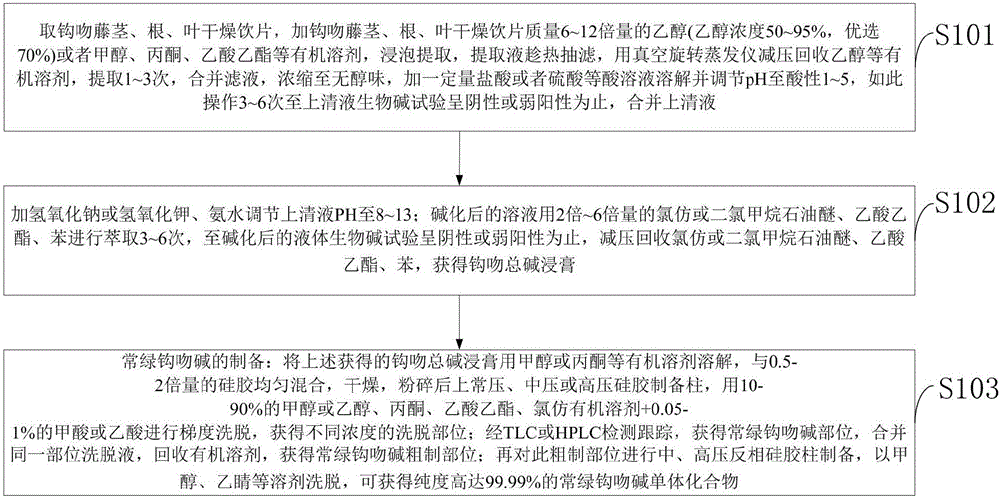

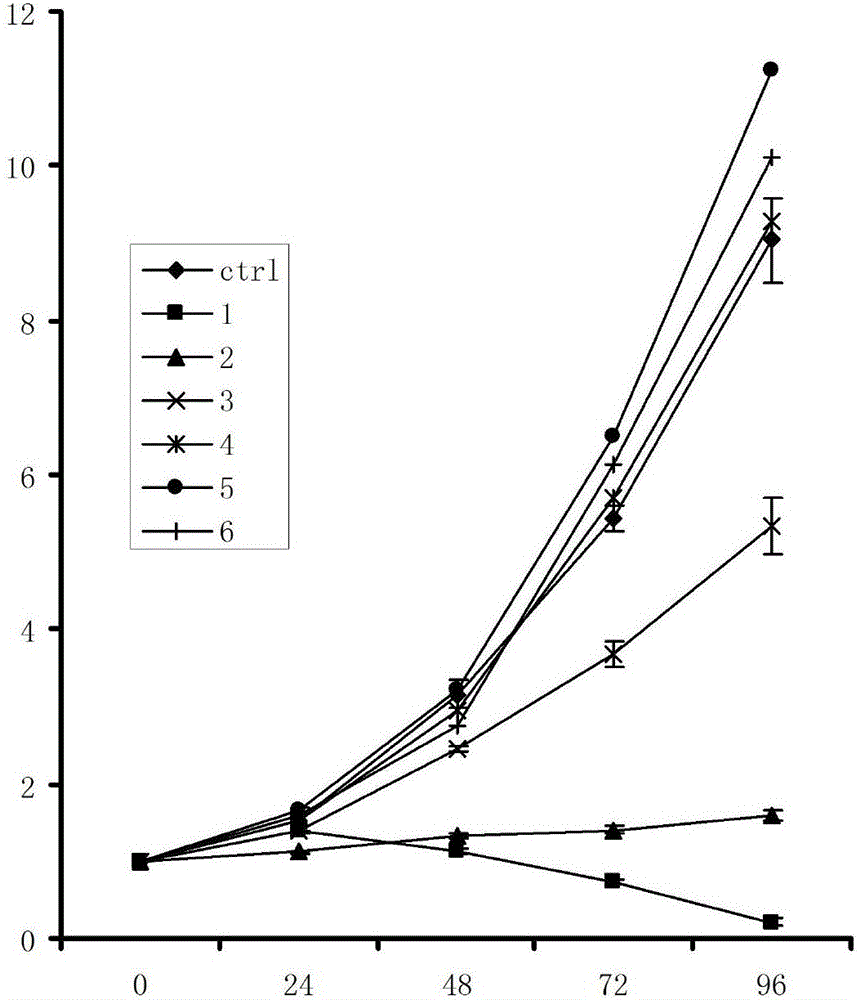

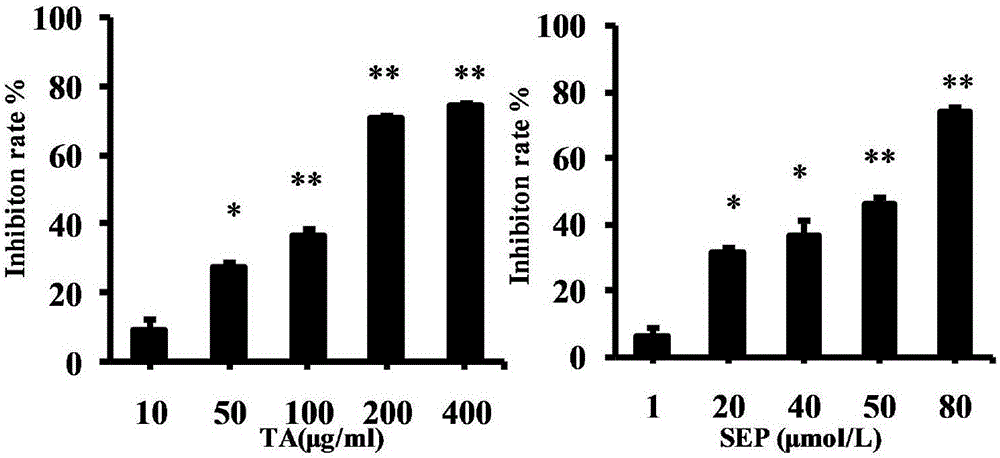

InactiveCN106539795AReduced activitySlow down proliferationOrganic active ingredientsAntineoplastic agentsMedicinal herbsSilica gel

The invention discloses an antineoplastic medicine prepared through gelsmium elegans medicinal materials. The antineoplastic medicine comprises the following steps that fresh gelsmium elegans rattan stems and / or roots and / or leave and / or dry medicinal slices are taken, steeping and extracting are conducted, ethyl alcohol is recycled by reducing pressure, concentration is conducted until the alcohol taste is eliminated, acid is added for dissolving, PH is adjusted, and upper clear liquid is taken; alkali is added, PH is adjusted to be 9-10, solution extraction is conducted, organic solvent is recycled, and gelsmium elegans total alkaloid extractum is obtained; the extractum is dissolved through methyl alcohol and the like and blended with silica gel, drying and crushing are conducted, the upper silica gel is prepared to a column, gradient elute is conducted by organic solvent, and rough-wrought portions of sempervirine are obtained; and high-middle-pressure phase reversal silica gel column preparation is conducted. The gelsmium elegans total alkaloid begins to exert influences on activity of tumour cells after being added for four hours, and the multiplication speed of the tumour cells is lowered a little compared with a blank group; and the sempervirine begins to exert influences on activity of the tumour cells after being added for five hours, the sempervirine with a low dosage can lower the multiplication speed of the tumour cells, and the sempervirine with a high dosage can kill the tumour cells.

Owner:FUJIAN UNIV OF TRADITIONAL CHINESE MEDICINE

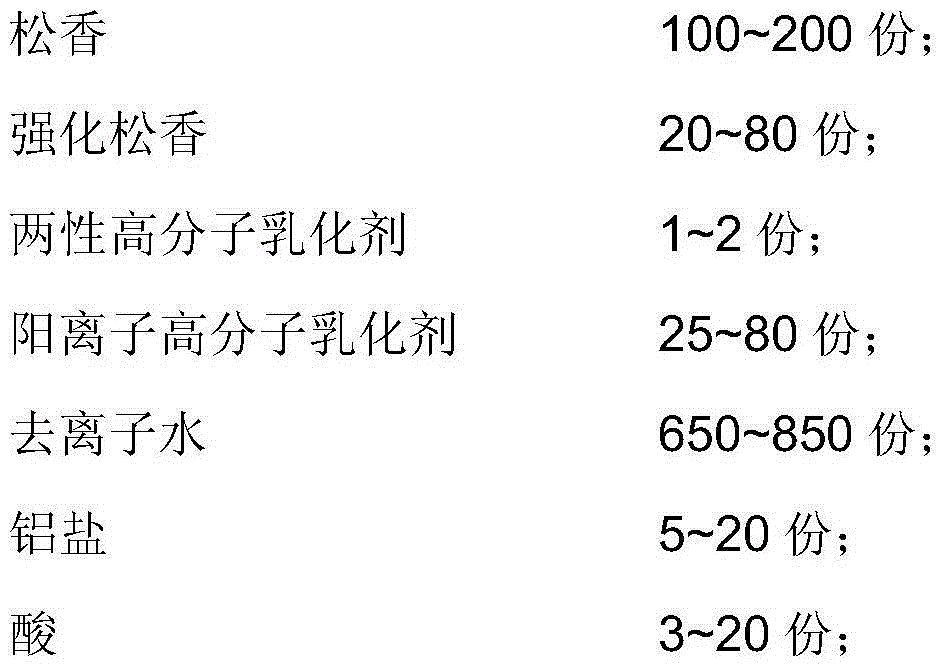

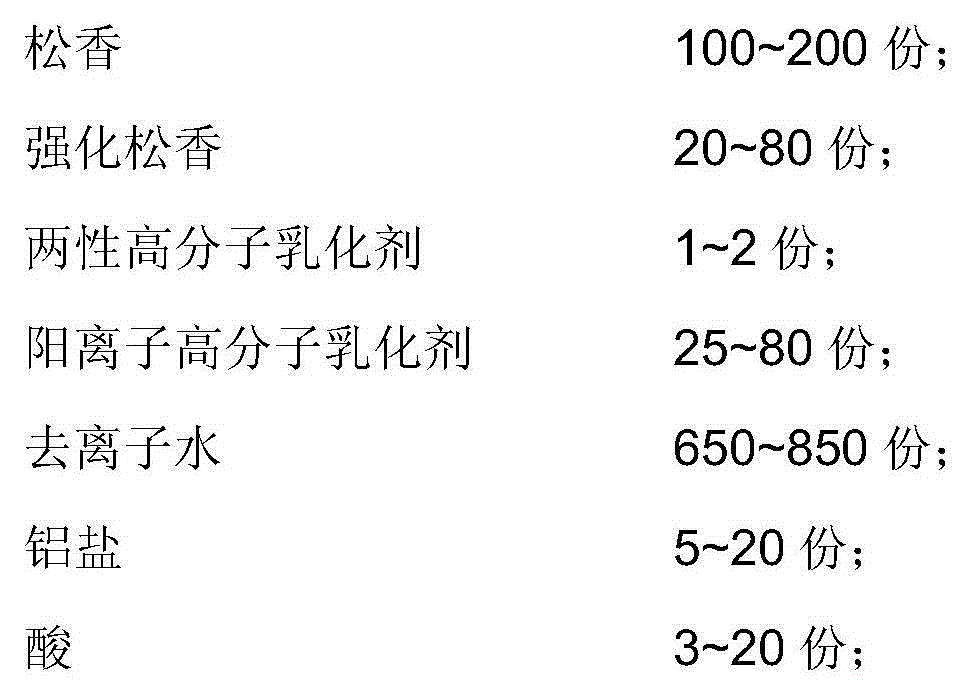

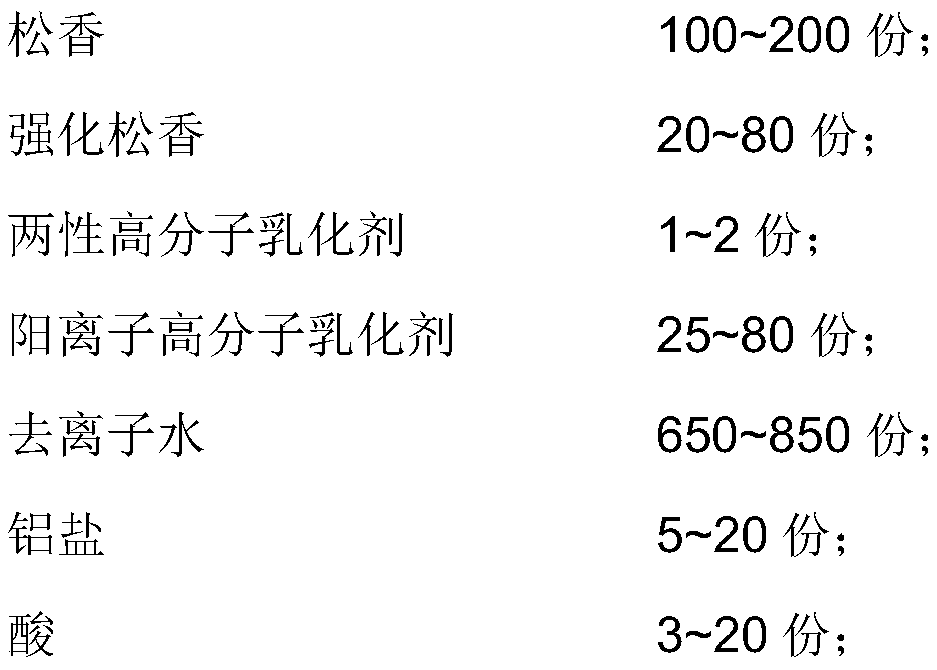

High-performance cationic rosin size and preparation method thereof

ActiveCN106317421AImprove stabilitySolve the problems of interworkingWater-repelling agents additionRosin additionPolymer scienceRosin

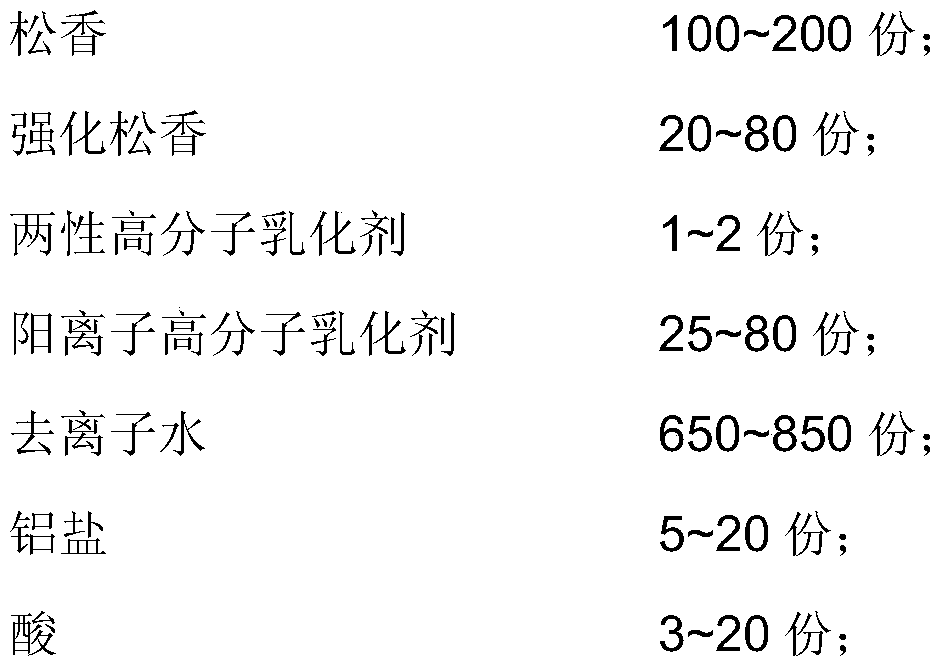

The invention discloses a high-performance cationic rosin size and a preparation method thereof. The high-performance cationic rosin size is prepared by adopting an interworking emulsification system of an amphoteric polymeric emulsifier and a high-cationic-degree polymeric emulsifier and by using a normal-temperature normal-pressure phase inversion method. The preparation method is simple in preparation process and relatively small in investment, and compared with a cationic rosin size prepared by using a conventional normal-temperature normal-pressure phase inversion method, the high-performance cationic rosin size prepared by the method disclosed by the invention is not liable to bubble, relatively small in particle size and relatively good in stability.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

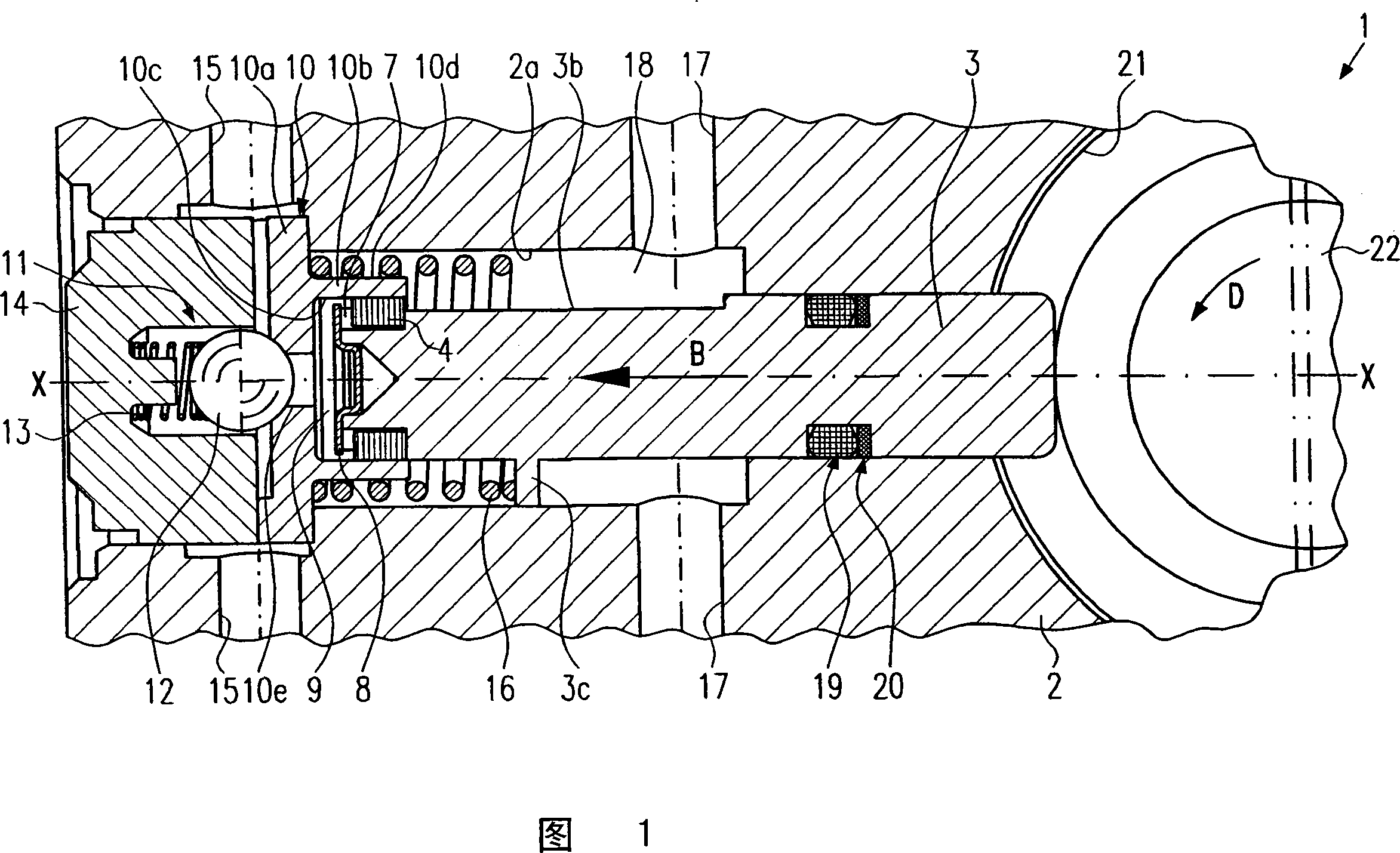

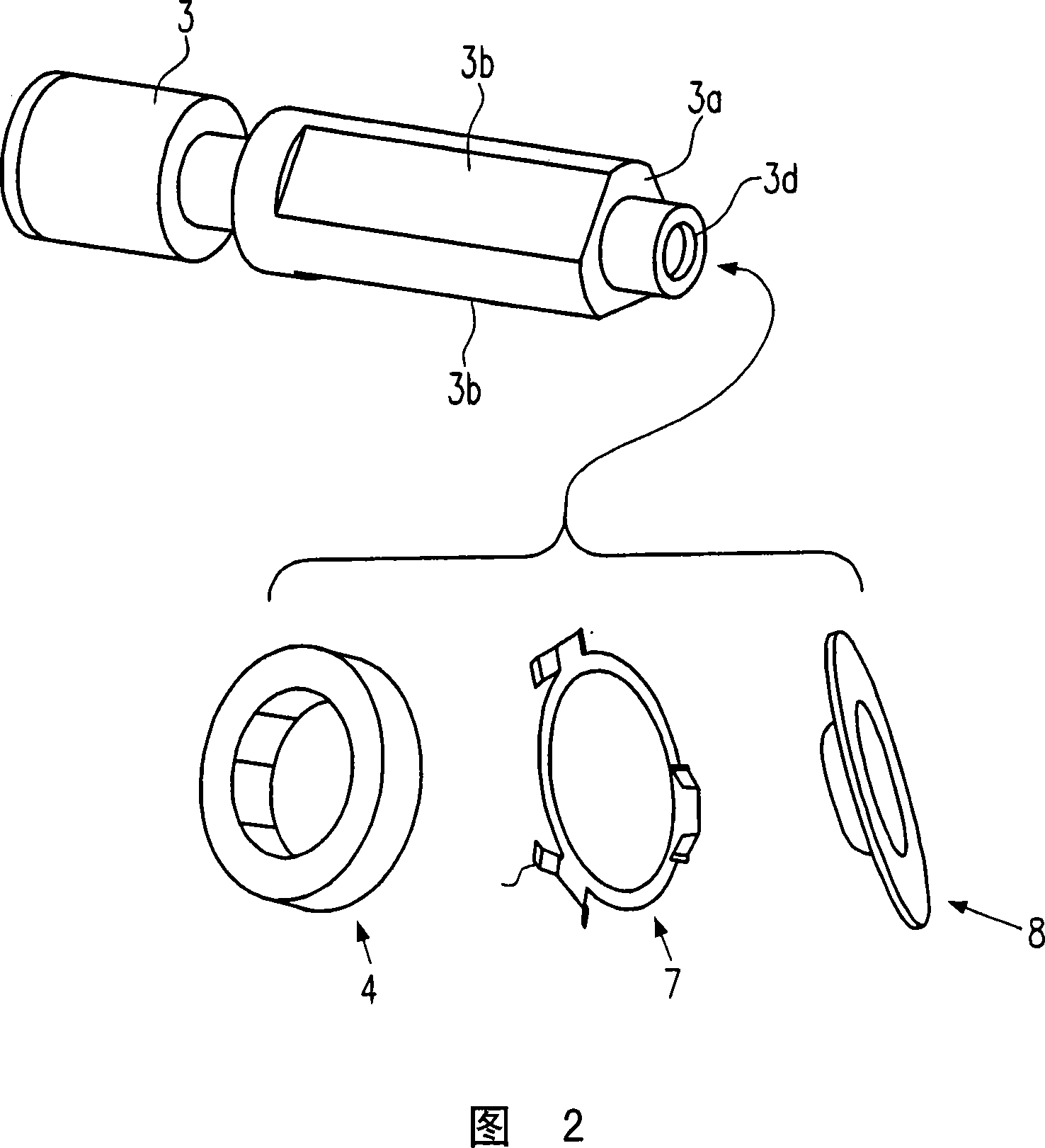

Piston pump with improved efficiency

InactiveCN1993550ASimple structureEasy to openPositive displacement pump componentsWorking fluid for enginesEngineeringHydraulic fluid

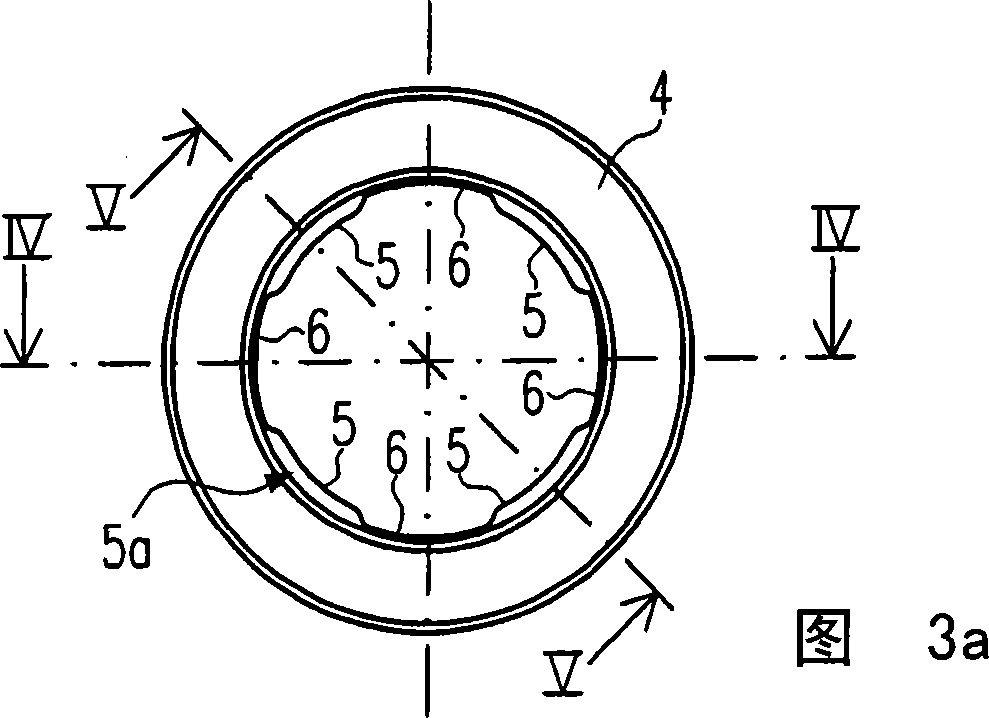

The invention relates to a piston pump for the supply of hydraulic fluid, comprising a reciprocating piston (3), for generation of pressure in a pressure chamber (9), with a seal element (4) arranged on the piston (3), which seals the pressure chamber (9) against a low-pressure region (18) of the piton pump in the pressure phase and which opens a connection between the pressure chamber (9) and the low pressure region (18) in an inlet phase, in order to introduce hydraulic fluid into the pressure chamber.

Owner:ROBERT BOSCH GMBH

Normal-pressure phase change heat storage device

The invention belongs to the technical field of phase change material energy storage, and in particular, relates to a normal-pressure phase change heat storage device. The device comprises main waterinlet and water outlet pipes connected with a circulating system, and heat supply water inlet and water outlet pipes and heat storage water inlet and water outlet pipes placed in a liner and connectedwith the main water inlet and water outlet pipes; and water distribution holes are mechanically formed in the water inlet and water outlet pipes in the device in proportion. A heat supply electric two-way valve communicating with the heat supply water outlet pipe and a heat storage electric two-way valve communicating with the heat storage water outlet pipe are additionally mounted out of an outer shell; multiple layers of separation plates are arranged in the liner; energy storage balls are placed in the separation plates; and the liner is provided with a water feeding port, a water overflowing port, a dirt discharge port, a liquid level sensor and a maintenance port communicating with the outer shell and an insulation material. The device has the advantages of reliable structure, stableheat outputting, high heat efficiency, simple installation, high heat exchange efficiency and high unit volume heat storage quantity.

Owner:山西焕星科技股份有限公司

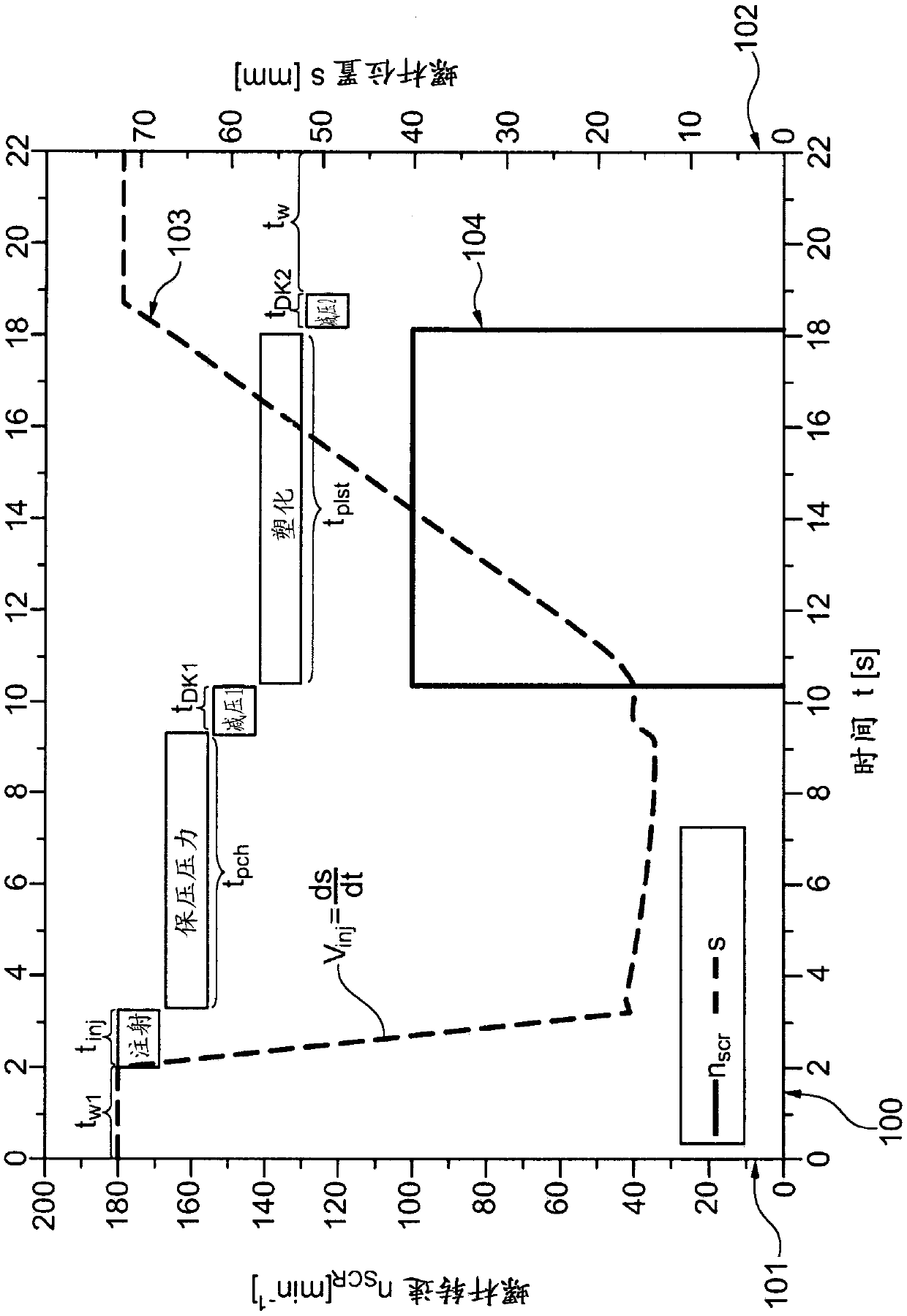

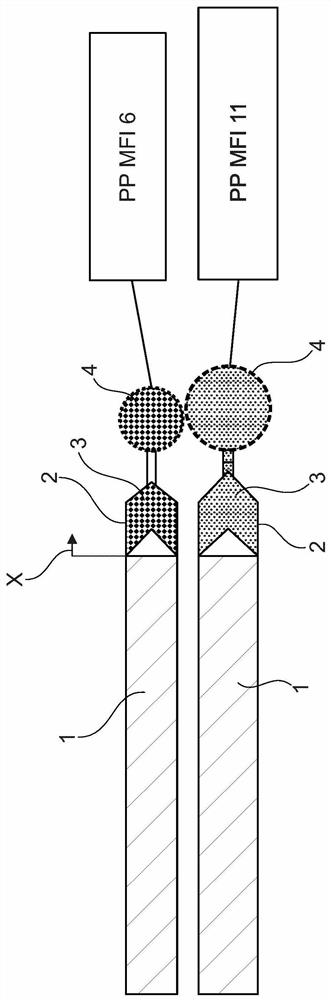

Method for operating an injection-moulding machine

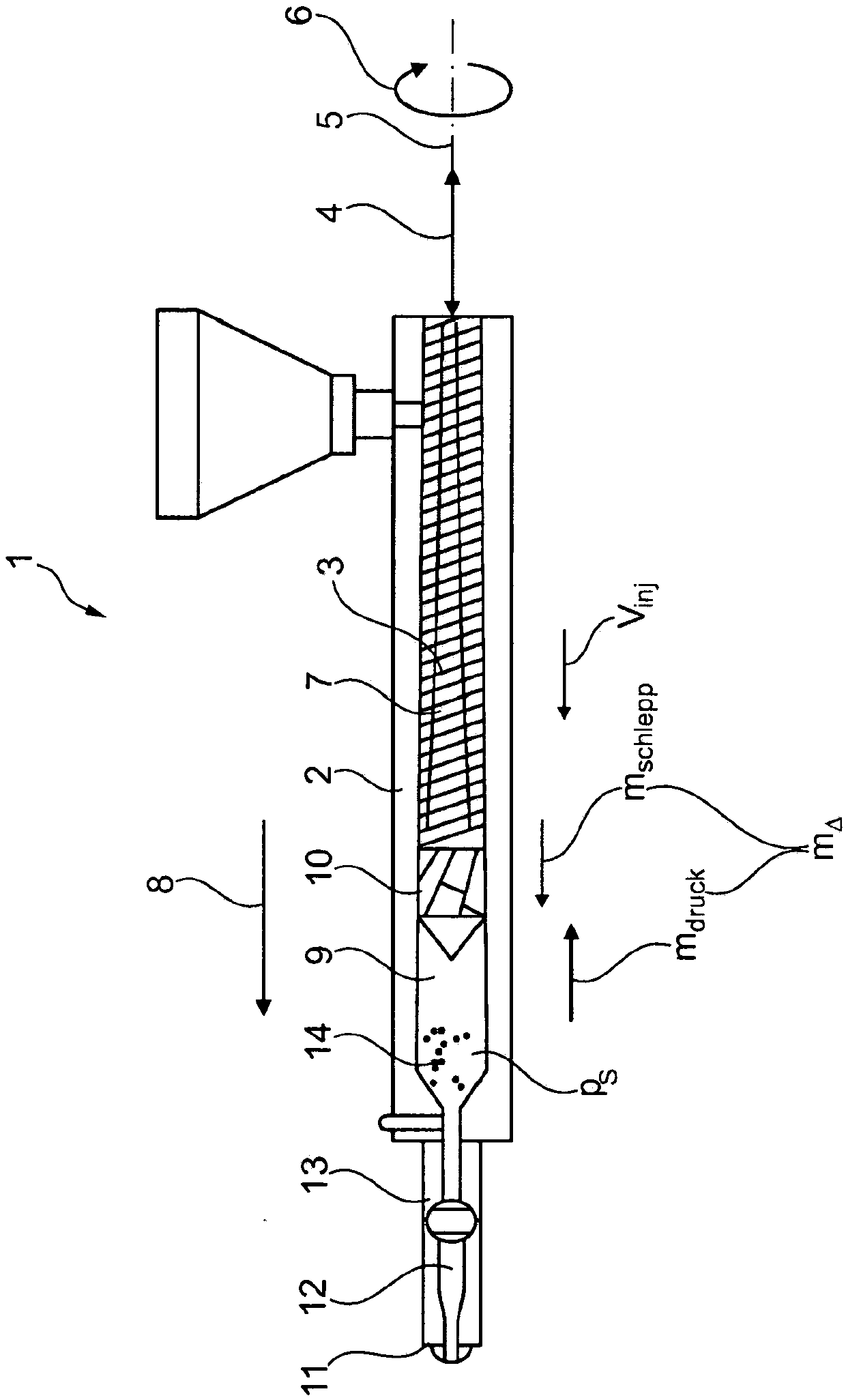

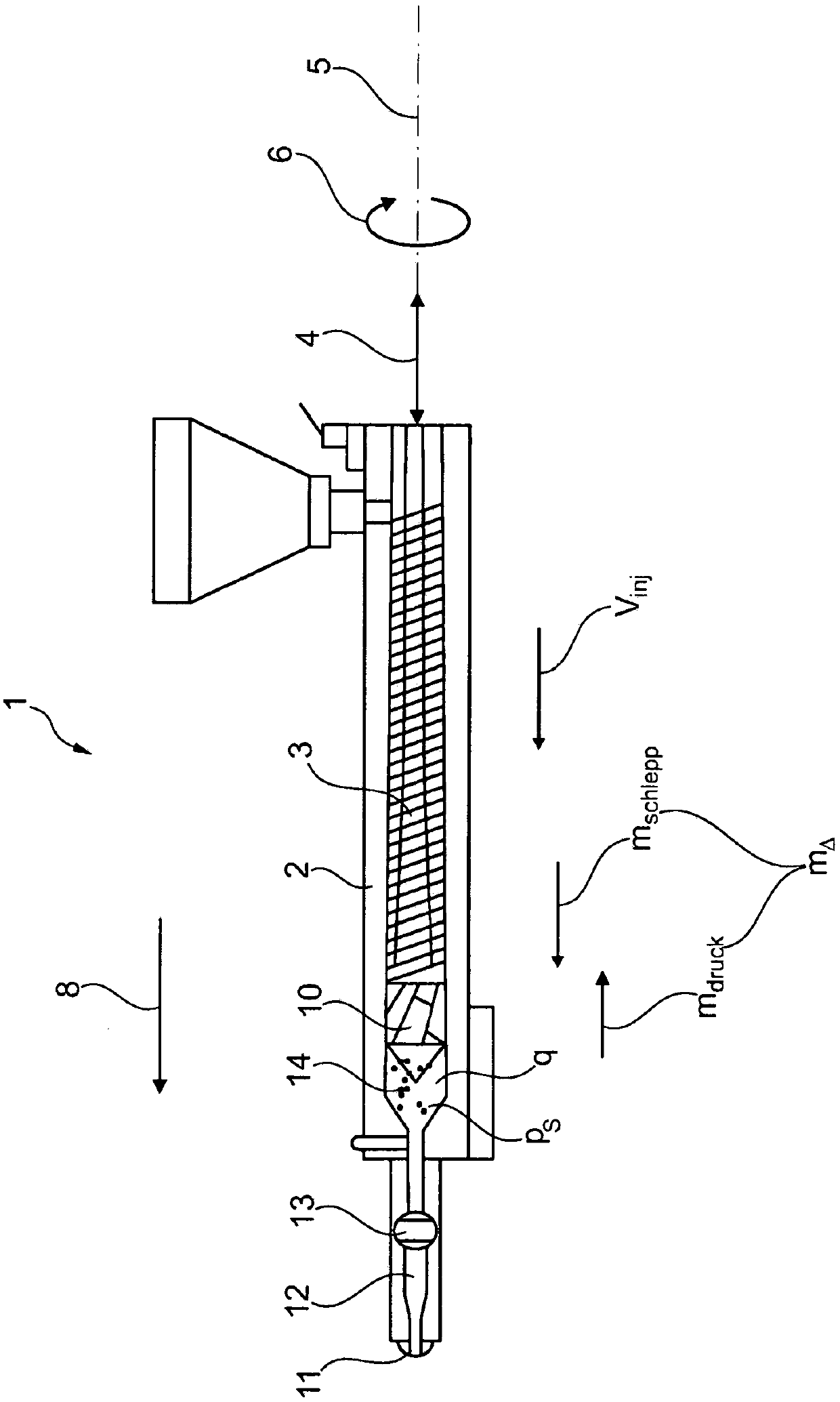

The invention relates to a method for operating an injection-moulding machine, having at least one plasticization device (2, 3) with at least one plasticization screw (3) which can be driven in rotation about a screw longitudinal axis (5) and so as to be movable in translation along the screw longitudinal axis (5), wherein, by way of the plasticization device (2, 3), a plastics melt (14) for injection into a mould cavity is provided in a screw antechamber (9), wherein, for the injection of the plastics melt (14) into the mould cavity, that is to say at least during an injection phase and during a follow-up pressure phase, the plasticization screw (3) is driven both in translation and in rotation by way of at least one drive device, wherein the driving of the plasticization screw (3) in rotation is performed with a rotational speed (nscr) such that a backflow (mdruck) of the melt from the screw antechamber (9) back into screw flights (71) of the plasticization screw (3) owing to a translational injection movement of the plasticization screw (3) has superposed on it an opposing delivery flow (mschlepp) effected by way of the rotation of the plasticization screw (3), wherein a flow difference (m[delta]) between backflow (mdruck) and opposing delivery flow (mschlepp) arises, and the flow difference (m[delta]) is, at least during the injection phase, influenced by influencing of therotational speed (nscr) of the plasticization screw (3), and the method is performed without using a backflow preventer.

Owner:KRAUSSMAFFEI TECH GMBH

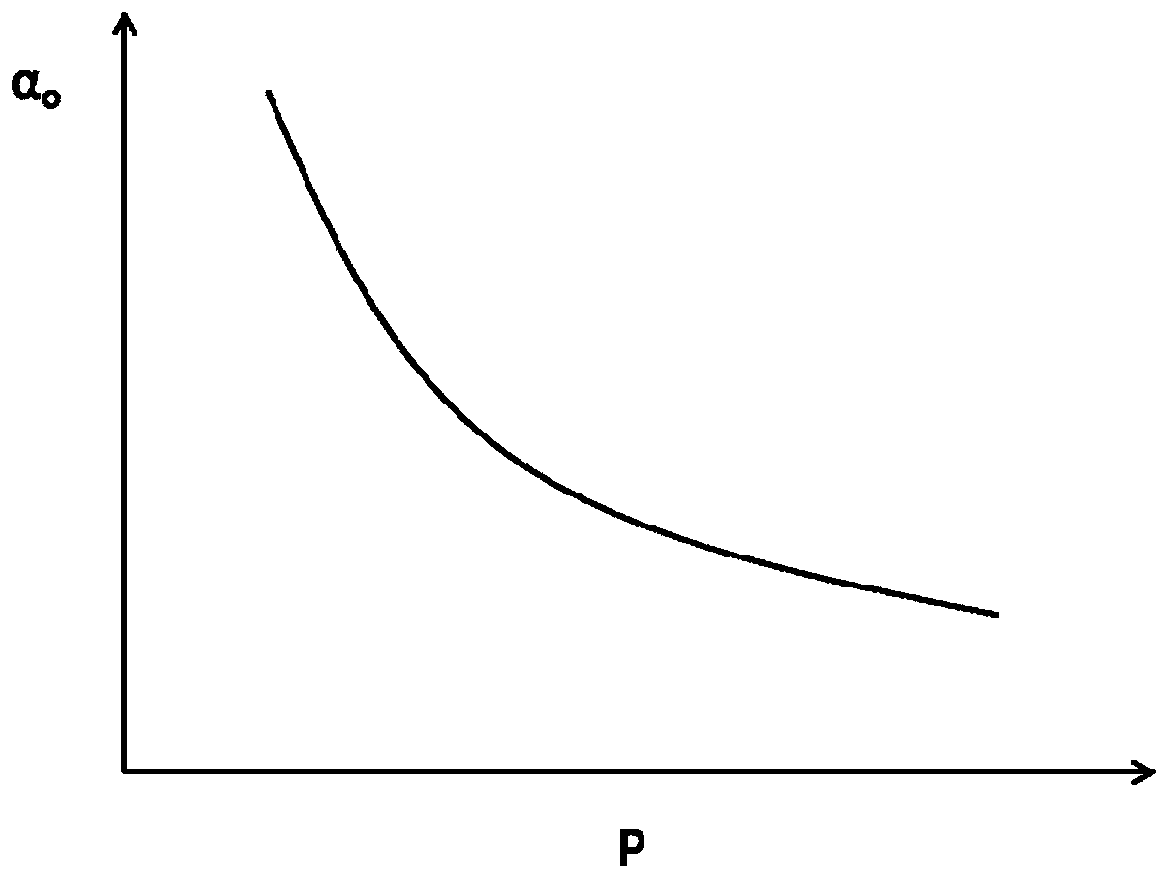

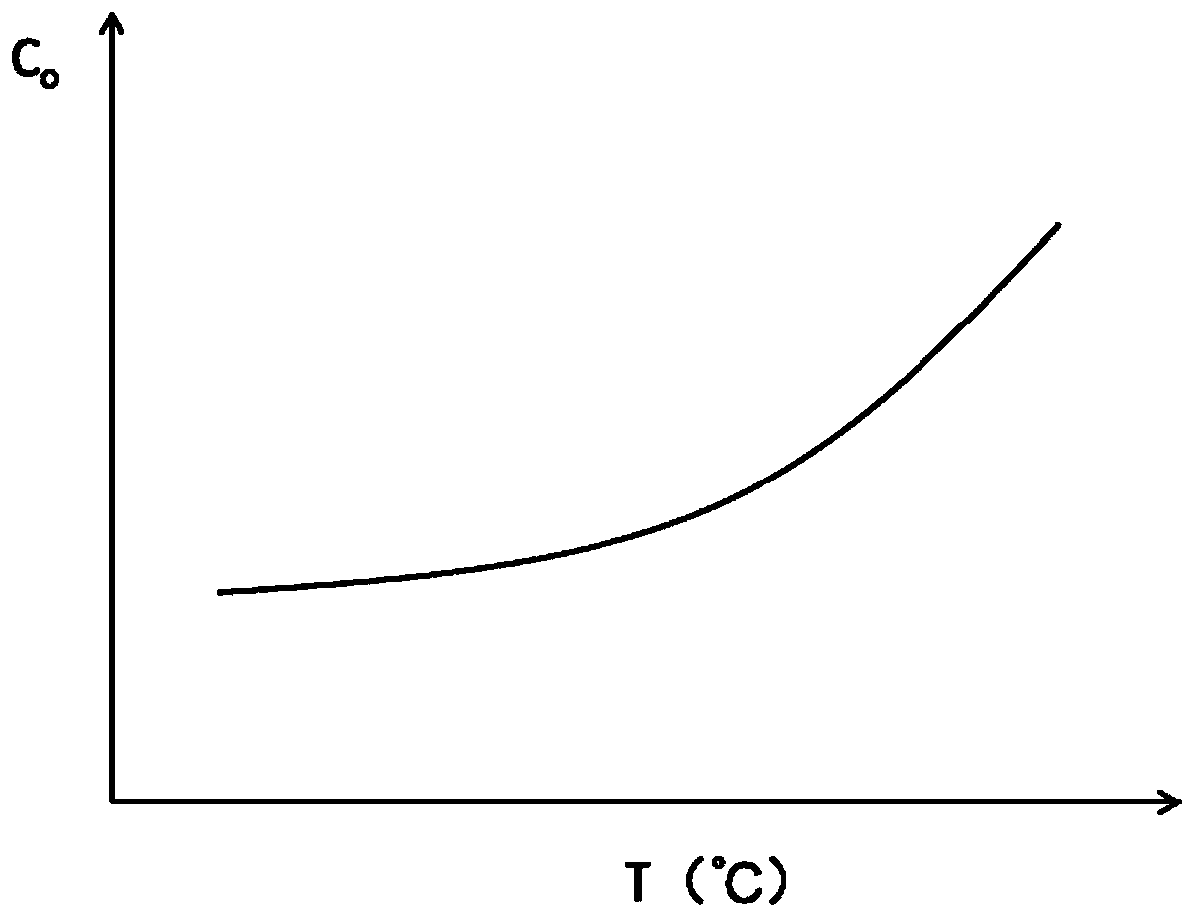

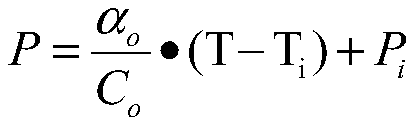

Tight oil steam flooding steam temperature design method

InactiveCN111022012AIncrease formation energyImprove the development effectFluid removalThermodynamicsTight oil

The invention discloses a tight oil steam flooding steam temperature design method, and aims at defining the optimal steam temperature range in a tight oil reservoir and calculating the change degreeof formation pressure when the temperature of the oil reservoir is heated to different degrees by taking a crude oil thermal expansion coefficient and a compression coefficient tested by a high-temperature and high-pressure phase analyzer as the basis. Meanwhile, a calculation method of the optimal steam temperature is provided under the condition of considering the starting pressure gradient andthe rupture pressure. According to the method, the limitation that steam flooding is only suitable for thick oil development in the past is broken through, a theoretical basis is provided for tight oil supplementing stratum energy parameter optimization and a new method is provided for improving the tight oil development effect.

Owner:PETROCHINA CO LTD

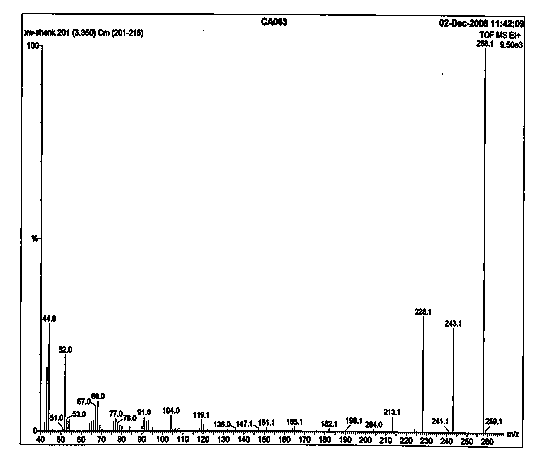

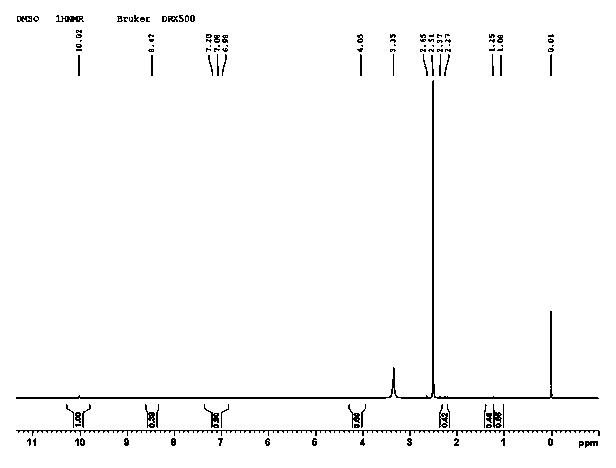

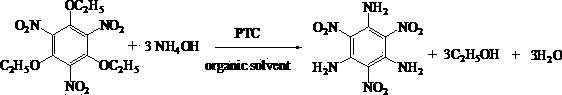

Method for synthesizing TATB (triamino trinitrobenzene) by normal pressure phase-transfer catalysis and amination

ActiveCN103408435ASolving Chlorine ProblemsReduce usageOrganic compound preparationAmino compound preparationSynthesis methodsEthyl Chloride

The invention discloses a method for synthesizing TATB (triamino trinitrobenzene) by normal pressure phase-transfer catalysis and amination. The method comprises the following steps: 1, adding 1,3,5-triethoxy-2,4,6-triaminobenzene, an organic solvent and a phase-transfer catalyst into a reactor, raising temperature and stirring, and dropwise adding ammonium hydroxide to carry out a reflux reaction; 2, after the reaction is ended, and separating a product and mother liquor, wherein the product is washed and dried to obtain TATB; and 3, analyzing and calibrating the mother liquor so as to be recycled and reused. Compared with the prior art, the method disclosed by the invention has the remarkable advantages that (1) the product TATB does not contain chlorine element, so that the chlorine-containing problem in a traditional synthesis method is solved; (2) the purity of the prepared TATB product which is not subjected to purification treatment can reach more than 98.0 percent; (3) reaction conditions are mild, the reaction operation is simple, and as the TATB is synthesized in a normal temperature phase-transfer catalysis and amination system, an airtight high pressure reaction kettle is not required, and industrial large-scale production is facilitated.

Owner:NANJING UNIV OF SCI & TECH

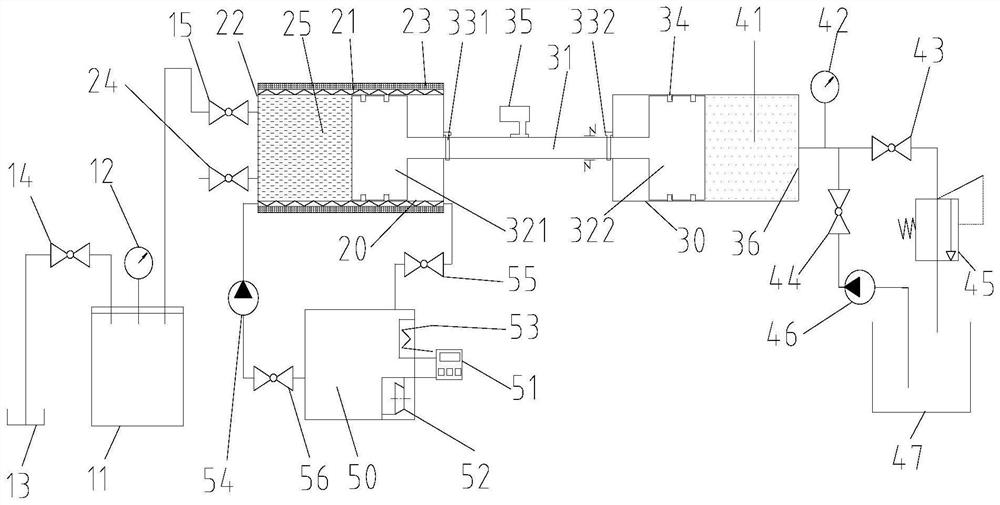

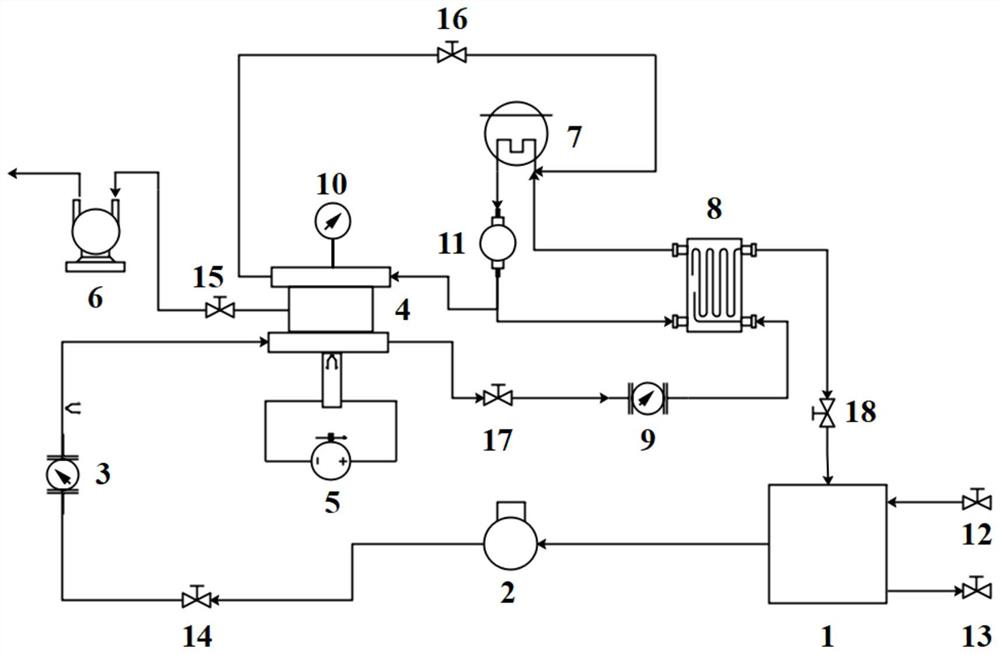

Experimental device capable of accurately measuring high-pressure volume change rate of phase change material

PendingCN114441586AEliminate measurement errorsAccurate measurementInvestigating phase/state changeTemperature controlControl system

The invention discloses an experimental device capable of accurately measuring the high-pressure volume change rate of a phase-change material. The experimental device comprises a phase-change material exhaust system, a phase-change heat exchange system, a displacement monitoring system, a pressure regulation and control system and a temperature control system. The phase-change material exhaust system comprises a vacuum pump and a vacuum tank; the phase-change heat exchange system is a part for containing a phase-change material to be tested; the displacement measuring system mainly comprises a piston rod and a laser displacement sensor; the pressure regulation and control system mainly comprises a pressure gauge, an overflow valve, a high-pressure oil cavity, a high-pressure oil pump and a high-pressure oil storage tank; the temperature control system mainly comprises a constant-temperature water tank, an electric heater, a compression refrigerator and a PID temperature controller. The high-pressure oil cavity and the overflow valve are used in cooperation to achieve stable pressure control, then the constant-pressure phase change process of the phase change material is achieved, meanwhile, measurement errors caused by the fact that the volume of high-pressure oil changes along with pressure are completely eliminated through measurement of the volume change rate, and finally accurate measurement of the volume change rate of the phase change material under different pressures is completed.

Owner:TIANJIN UNIV

Processing method of melon seeds

The invention relates to the technical field of food processing and particularly relates to a processing method of melon seeds. The processing method comprises the following steps: screening, preparing materials, boiling, drying, frying, cleaning and selecting and packaging. According to the processing method of the melon seeds, the melon seeds are added into a boiling pot and then are vacuumized, so that air in inner pores of the melon seeds can be removed very well and pre-boiling materials can penetrate into the melon seeds very well; two different negative-pressure phases are set so that the tasty effect is relatively good and inner parts and outer parts of the melon seeds are tasty; the processing time is short and seed kernels of the processed melon seeds are crispy; the loss of nutrients is relatively less and shells and membranes have good color and luster; and the taste of the product and the comprehensive level of the melon seeds are remarkably improved and the popularization and application values are very good.

Owner:山丹县精海农副产品加工有限责任公司

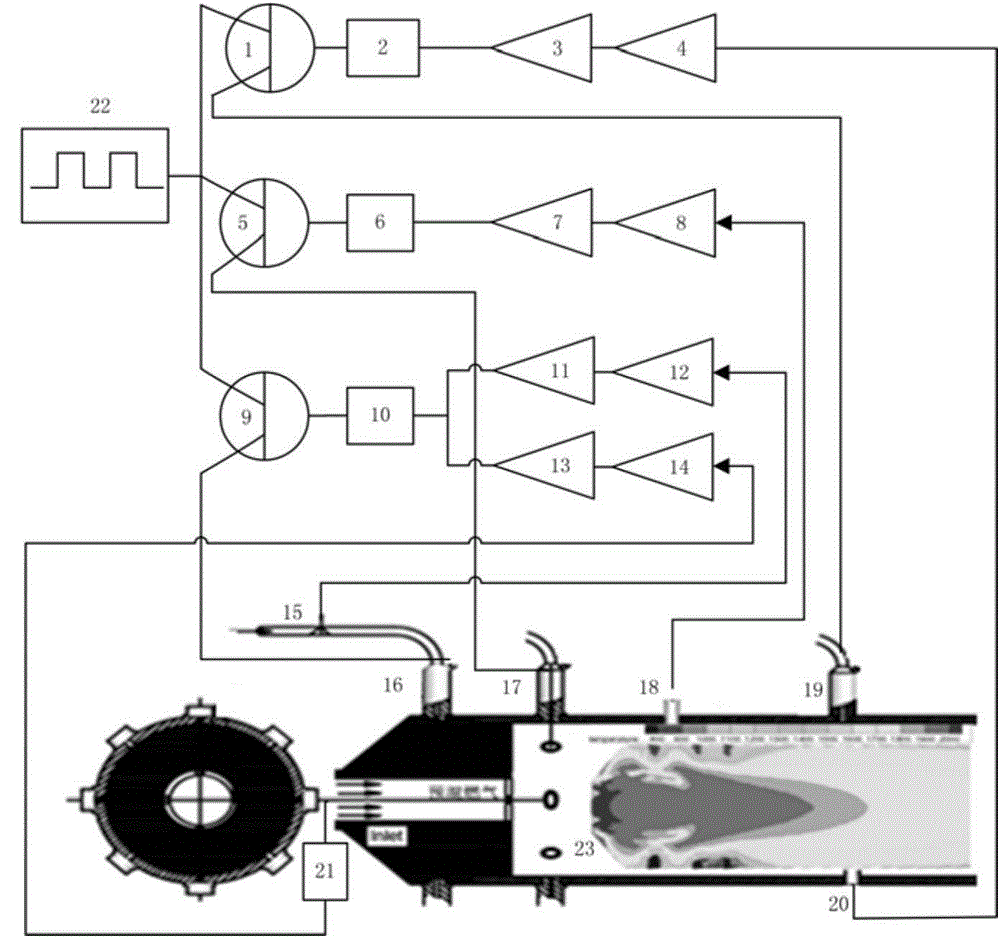

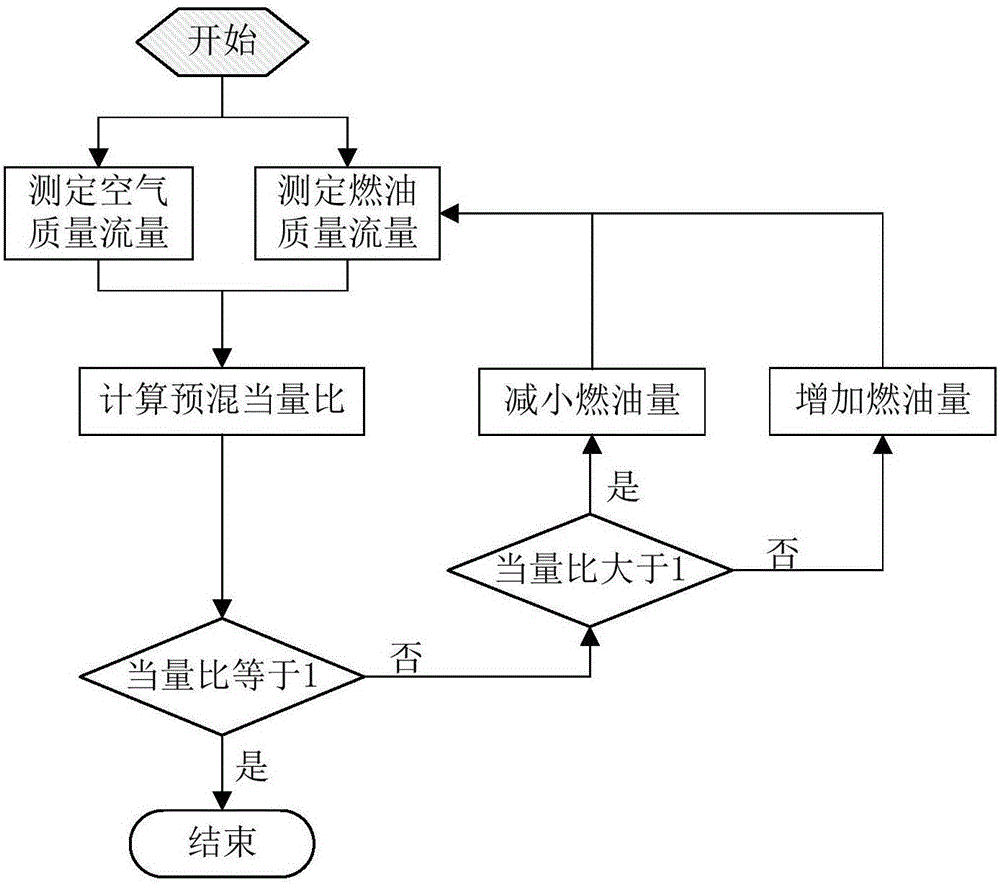

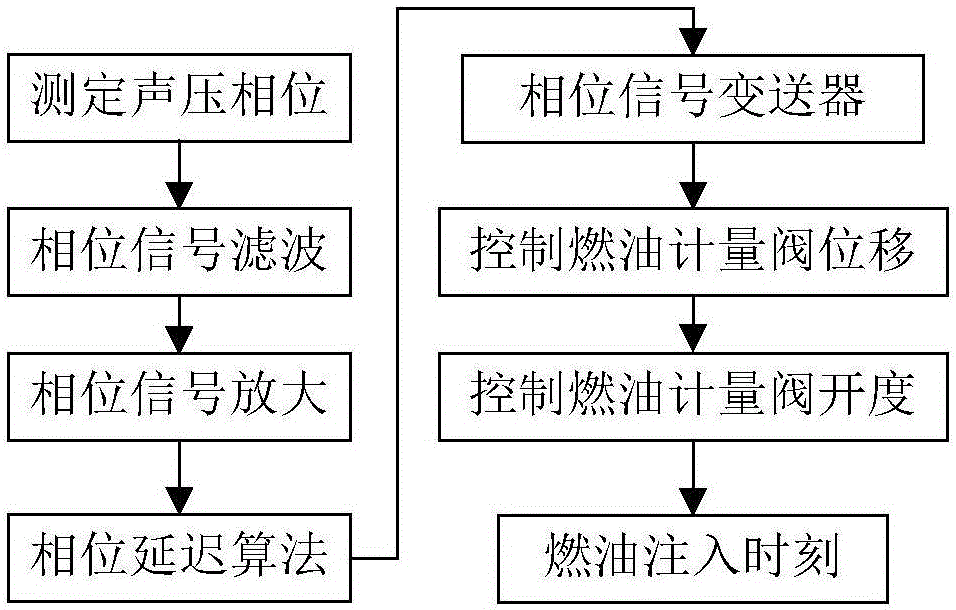

Low-emission three-loop lean oil pre-mixing and active combustion control device and method

ActiveCN106523164AEmission reductionAvoid instabilityTurbine/propulsion fuel controlCombustion instabilityEquivalence ratio

The invention discloses a low-emission three-loop lean oil pre-mixing and active combustion control device and method, and aims at solving the problem that the pre-mixing of the lean oil in the working process of an existing gas turbine or aircraft engine leads to unstable combustion, resulting in high combustion pollutant emission. The method is characterized in that a pre-mixing equivalence ratio based fuel oil control mode is that the lean oil is pre-mixed and the equivalence ratio of the fuel oil and the air is controlled to achieve the full combustion of the fuel oil and the reduction of the temperature of combustion flame, so as to realize the reduction of NOx emission; an acoustic pressure phase delay based fuel oil control mode is that the fuel oil filling time is controlled to inhibit the unstable thermal noise in combustion according to the measured noise pressure vibration condition and through the phase delay algorithm; an LMS (Least Mean Square) based fuel oil control mode is that the temperature of a combustion low-cycle heat release circulation area is measured, and then the LMS algorithm is carried out to control the fuel oil filling quantity so as to solve the problem of thermal shock of the low-cycle heat release circulation area, and as a result, the combustion instability can be reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Negative-pressure phase-change heat dissipation device and high-heat-flux electronic chip simulation heat dissipation system

ActiveCN112702889AAvoid separationBreak away quicklyModifications by conduction heat transferEvaporation heat transferHeat flow

The invention discloses a negative-pressure phase-change heat dissipation device and a high-heat-flux electronic chip simulation heat dissipation system, which utilize boiling coupling film evaporation to use a water working medium to generate phase change in a negative pressure environment, so as to realize efficient heat dissipation of a chip, and solve the problems that a liquid supply channel and a gas separation channel of an existing chip cold plate are mixed and the heat transfer capacity is low. A negative pressure environment is generated on one side of an evaporation waterproof breathable film, the pressure difference between the two sides of the film is increased, on one hand, mutual interference of traditional boiling heat exchange gas separation and liquid supply is avoided, on the other hand, the evaporation power and speed of the liquid are enhanced, the working efficiency of the cold plate is remarkably improved by utilizing a film evaporation mechanism, and the heat dissipation requirement that the heat flux density exceeds 1 kW / cm<2> can be met.

Owner:XI AN JIAOTONG UNIV

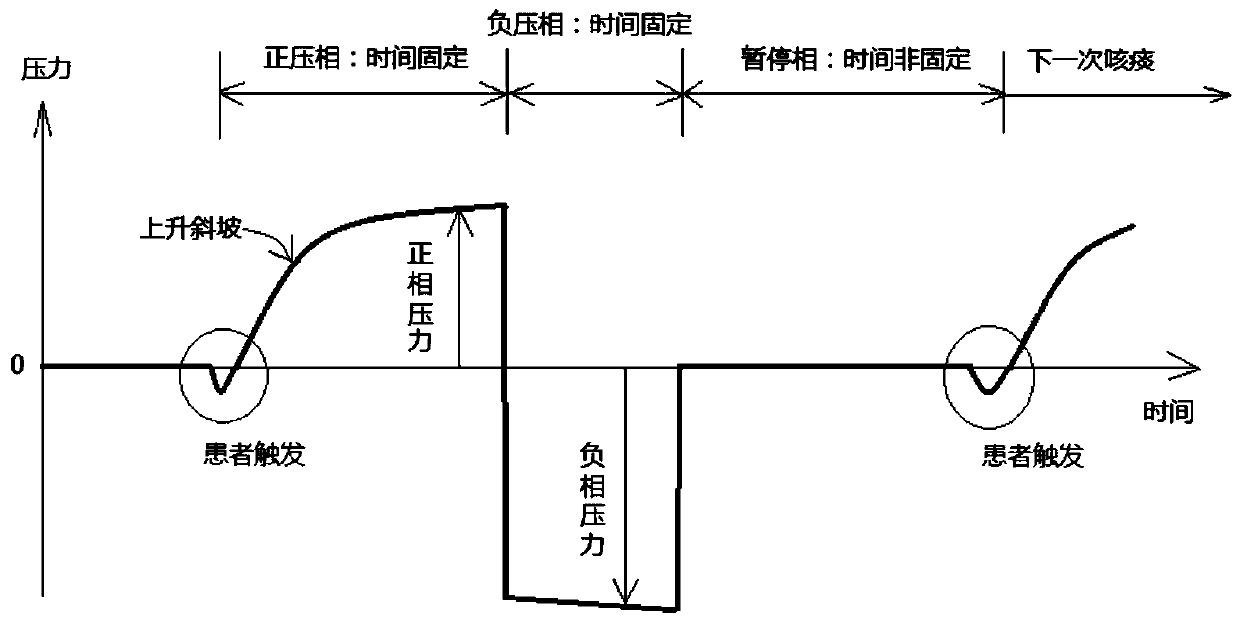

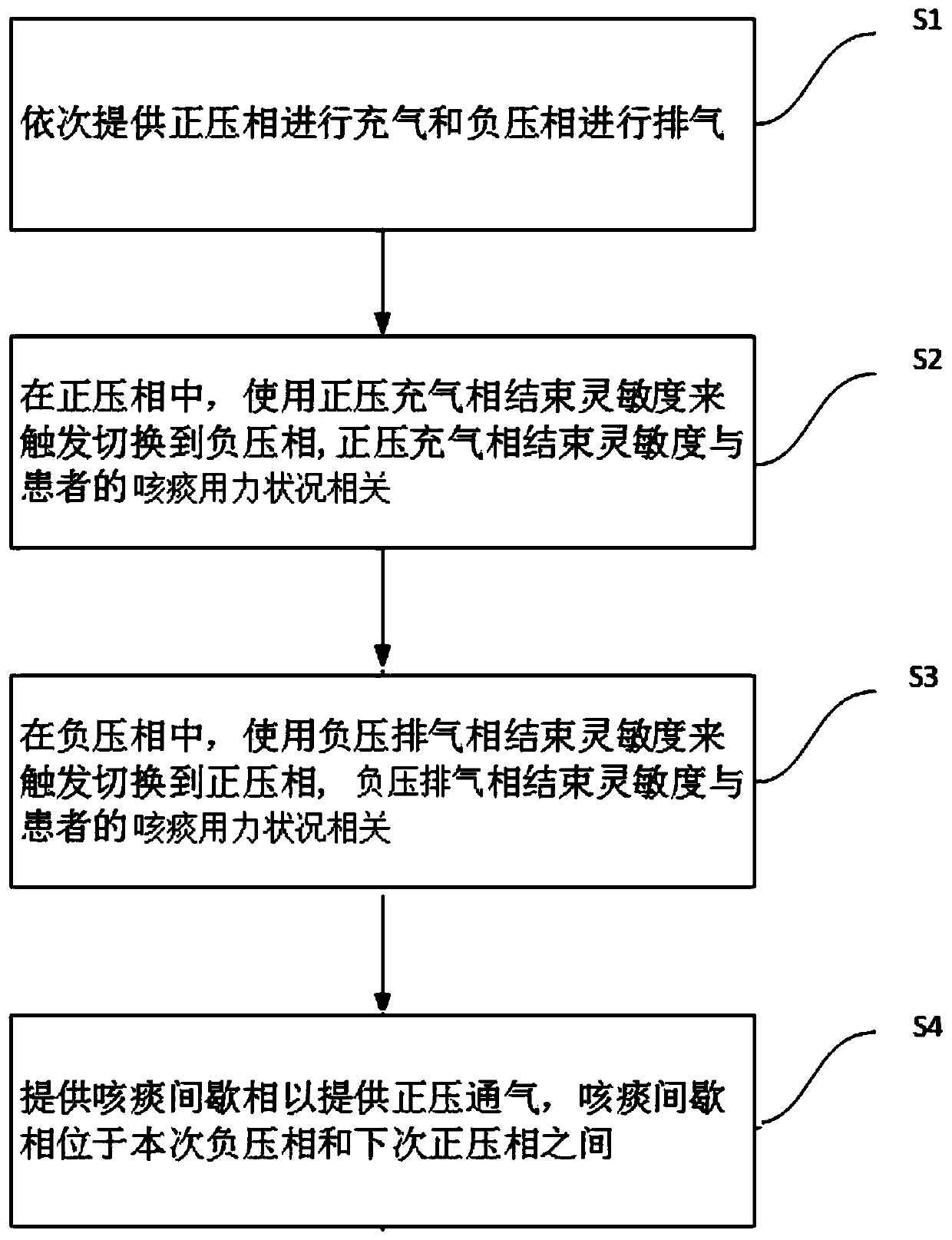

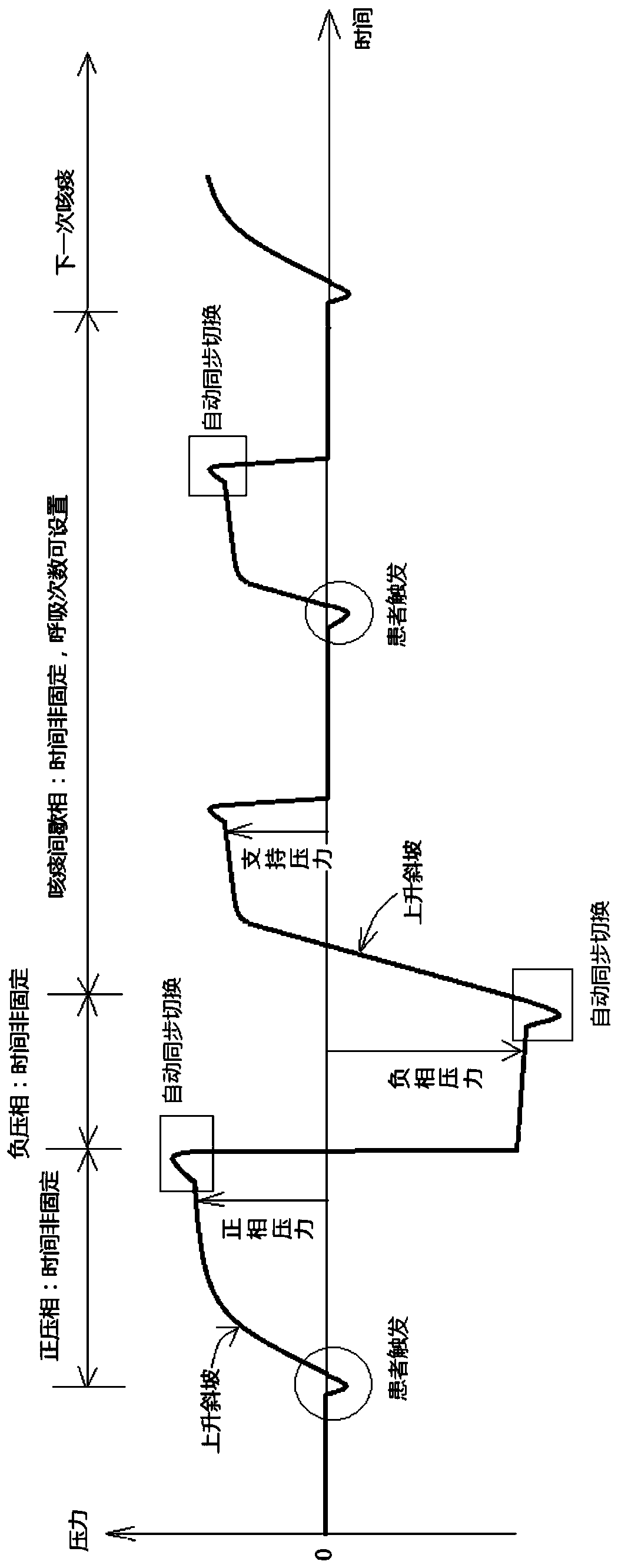

Synchronous automatic expectoration method and system

ActiveCN110101945ASynchronization of cough forceSynchronized cough force releaseRespiratorsMedical devicesPositive airway pressureTreatment effect

The invention relates to a synchronous automatic expectoration method. The method comprises the steps that S1, in sequence, a positive pressure phase is provided for air inflation, and a negative pressure phase is provided for air discharging; S2, in the positive pressure phase, a positive pressure air inflation phase ending sensitivity is used for triggering a switch to the negative pressure phase, and the positive pressure air inflation phase ending sensitivity is related to a cough force condition of a patient; S3, in the negative pressure phase, a negative pressure air discharging phase ending sensitivity is used for triggering a switch to the negative pressure phase or a cough intermittence phase, and the negative pressure air discharging phase ending sensitivity is related to the cough force condition of the patient; S4, the cough intermittence phase is provided and located between the negative pressure air discharging phase this time and the positive pressure air inflation phasenext time, and positive pressure supporting ventilation is provided at the cough intermittence phase multiple times. The invention further provides a synchronous automatic expectoration system. By applying the method and system, the treatment effect of sputum clear-away on the trachea when a patient wears the expectoration system can be improved.

Owner:RUXIN BEIJING MEDICAL SYST CO LTD

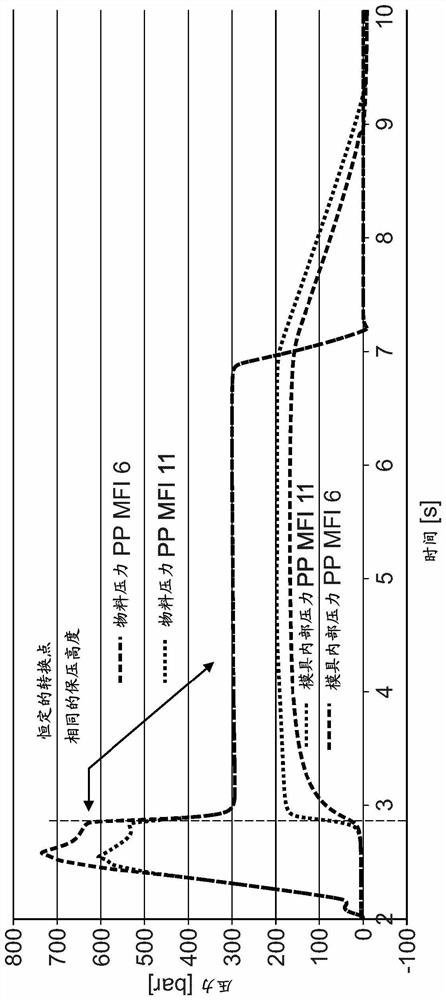

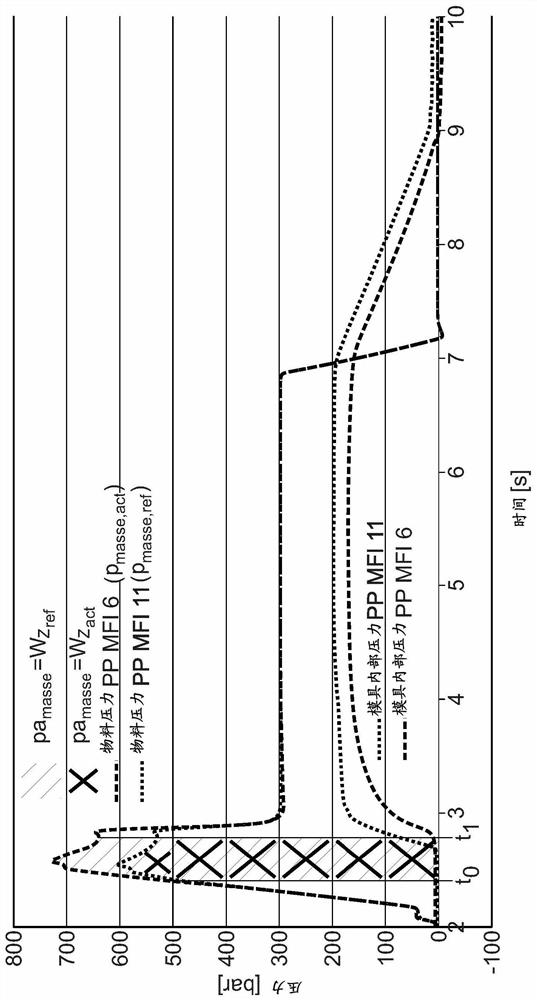

Method for operating an injection-molding machine, in particular with respect to improved constant mold filling, and injection-molding machine for carrying out the method

The invention relates to a method for operating an injection-molding machine, the method comprising the steps: a) in a current injection-molding cycle, after an accepted-part reference injection-molding cycle learned in a learning phase: detecting a compound pressure change k1 relative to an accepted-part reference compound pressure pmasse,ref during at least part of an injection phase of the current injection-molding cycle by measuring a current compound pressure pmasse,act and comparing the current compound pressure pmasse,act with the accepted-part reference compound pressure pmasse,ref; b) determining a target mold internal pressure curve pwkz,soll(t) for a holding-pressure phase of the current injection-molding cycle, wherein for this purpose a mold internal pressure curve pwkz,ref (t) of the accepted-part reference injection-molding cycle is adjusted at least in dependence on the compound pressure change k1 detected in step a); and c) traveling the holding-pressure curve pmasse,Hld,act(t) of the current injection-molding cycle in such a way that an actual mold internal pressure curve pwkz,act(t) of the current injection-molding cycle runs at least more closely along the target mold internal pressure curve pwkz,soll(t) than a mold internal pressure curve pwkz,ref(t) that is unchanged in comparison with the accepted-part reference cycle.

Owner:KRAUSSMAFFEI TECH GMBH

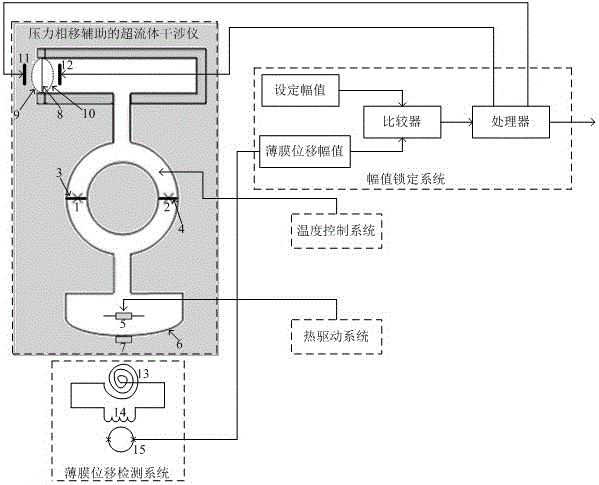

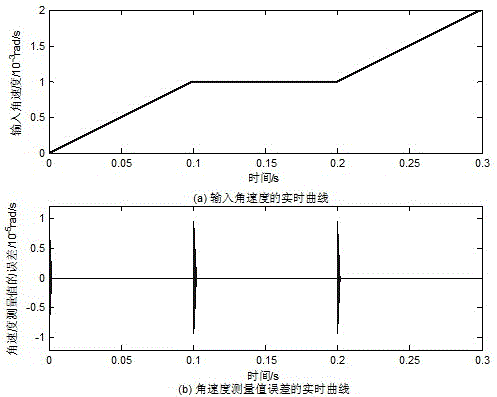

A Superfluid Gyro Device Based on Pressure Phase Shift Assist

InactiveCN103954273BHigh sensitivityQuick responseSagnac effect gyrometersTemperature controlGyroscope

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

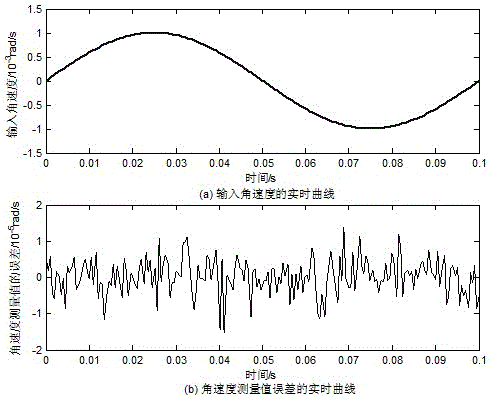

A closed-loop expectoration method and system for automatic titration of expectoration pressure

ActiveCN110038198BLess reliance on experienceReduce titration workloadRespiratorsMedical devicesMedicineEngineering

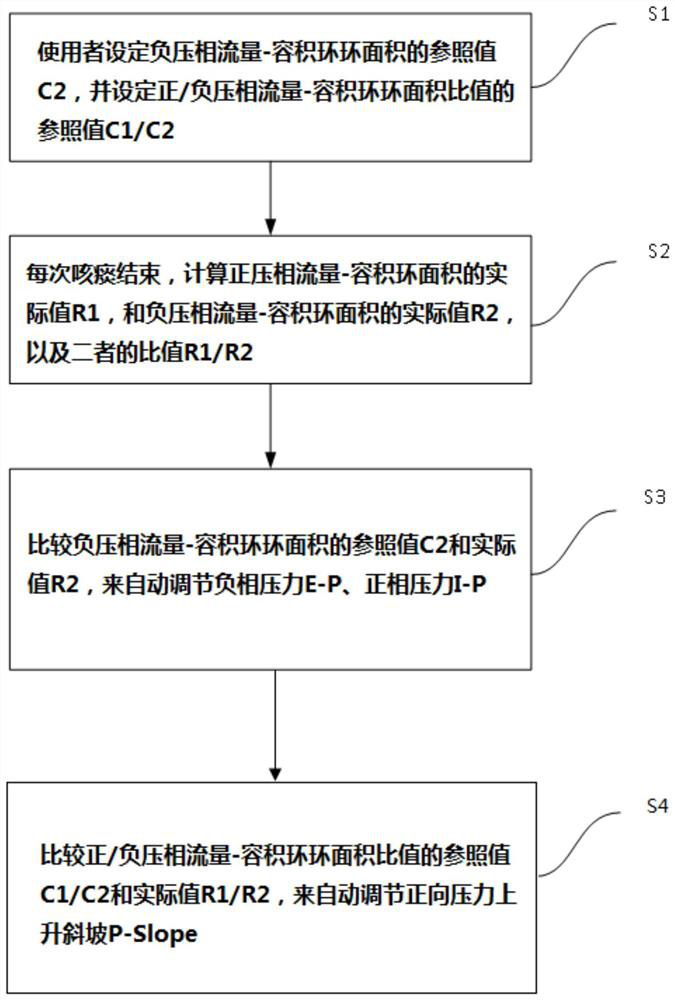

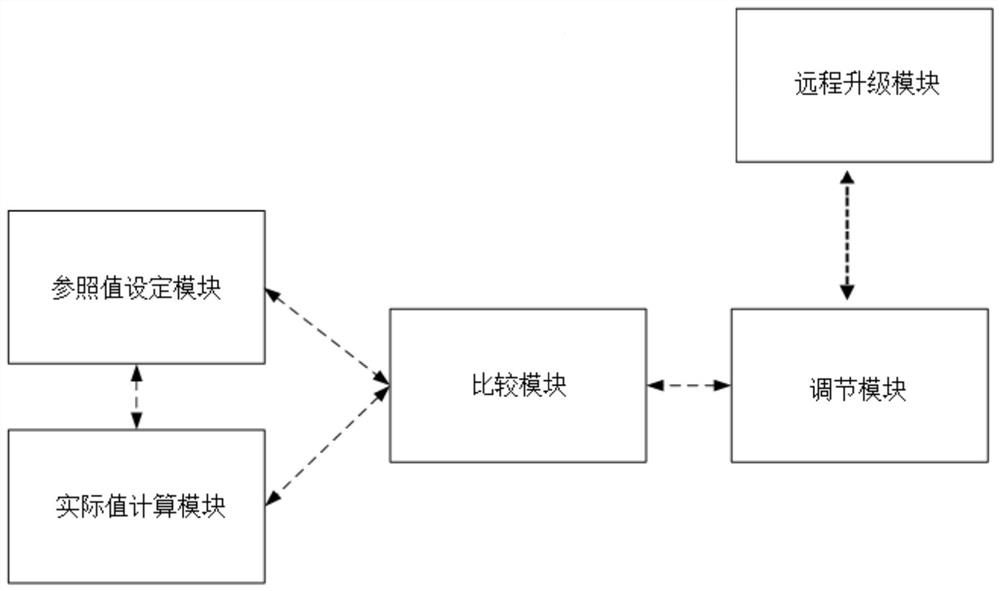

The invention relates to a closed-loop expectoration method for automatically titrating the pressure of expectoration, comprising S1, setting the reference value C2 of the user's negative pressure phase flow-volume ring area F-V ring area; S2, calculating the user's The actual value R2 of the negative pressure phase F-V ring area; S3, compare the reference value C2 of the negative pressure phase F-V ring area, and the actual value R2 of the negative pressure phase flow-volume ring area to adjust the negative phase pressure E-P and / or normal phase pressure I‑P. The present invention also proposes a closed-loop expectoration system for automatically titrating the pressure of expectoration, including: a reference value setting module, which sets the reference value C2 of the negative pressure phase flow-volume ring area F-V ring area; the actual value calculation module , monitor and calculate the actual value R2 of the negative pressure phase F-V ring area; the comparison module compares the reference value C2 and the actual value R2; the adjustment module adjusts the negative phase pressure E-P and the positive phase based on the results of the comparison module Pressure I‑P. The expectoration method and system of the present invention ensure safer and more effective expectoration.

Owner:RUXIN BEIJING MEDICAL SYST CO LTD

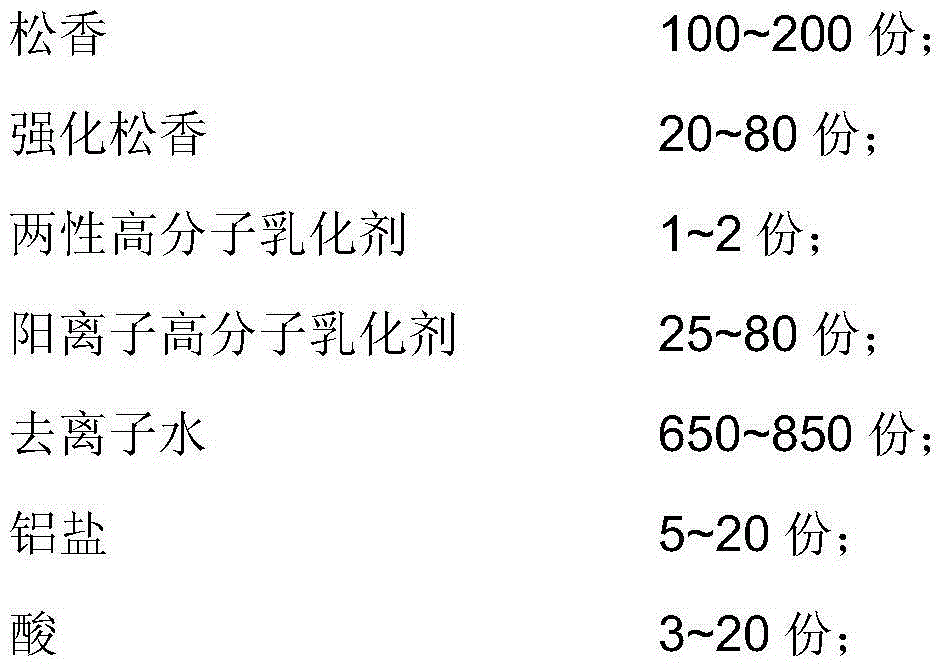

A kind of high-performance cationic rosin glue and preparation method thereof

ActiveCN106317421BImprove stabilitySolve the problems of interworkingWater-repelling agents additionRosin additionPolymer scienceRosin

The invention discloses a high-performance cationic rosin size and a preparation method thereof. The high-performance cationic rosin size is prepared by adopting an interworking emulsification system of an amphoteric polymeric emulsifier and a high-cationic-degree polymeric emulsifier and by using a normal-temperature normal-pressure phase inversion method. The preparation method is simple in preparation process and relatively small in investment, and compared with a cationic rosin size prepared by using a conventional normal-temperature normal-pressure phase inversion method, the high-performance cationic rosin size prepared by the method disclosed by the invention is not liable to bubble, relatively small in particle size and relatively good in stability.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

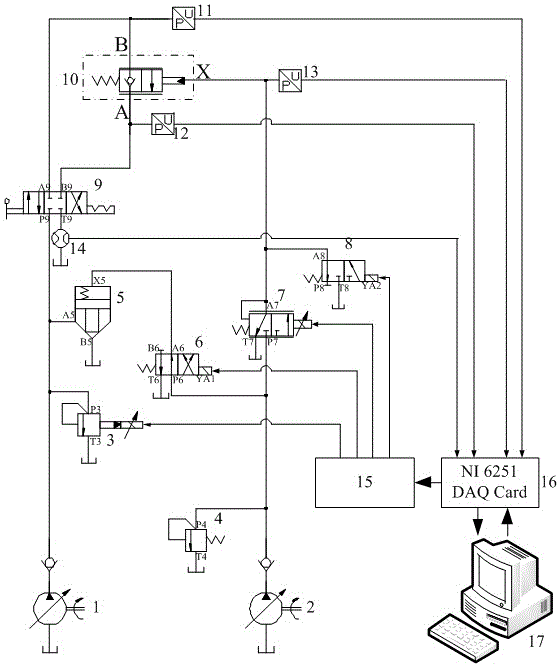

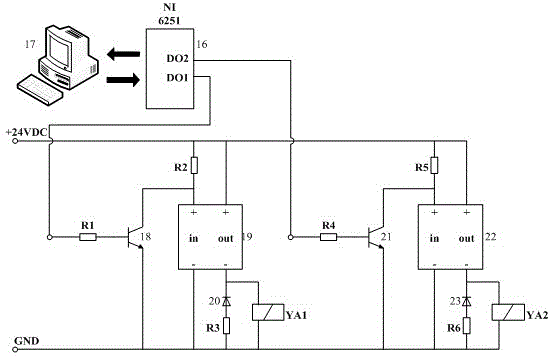

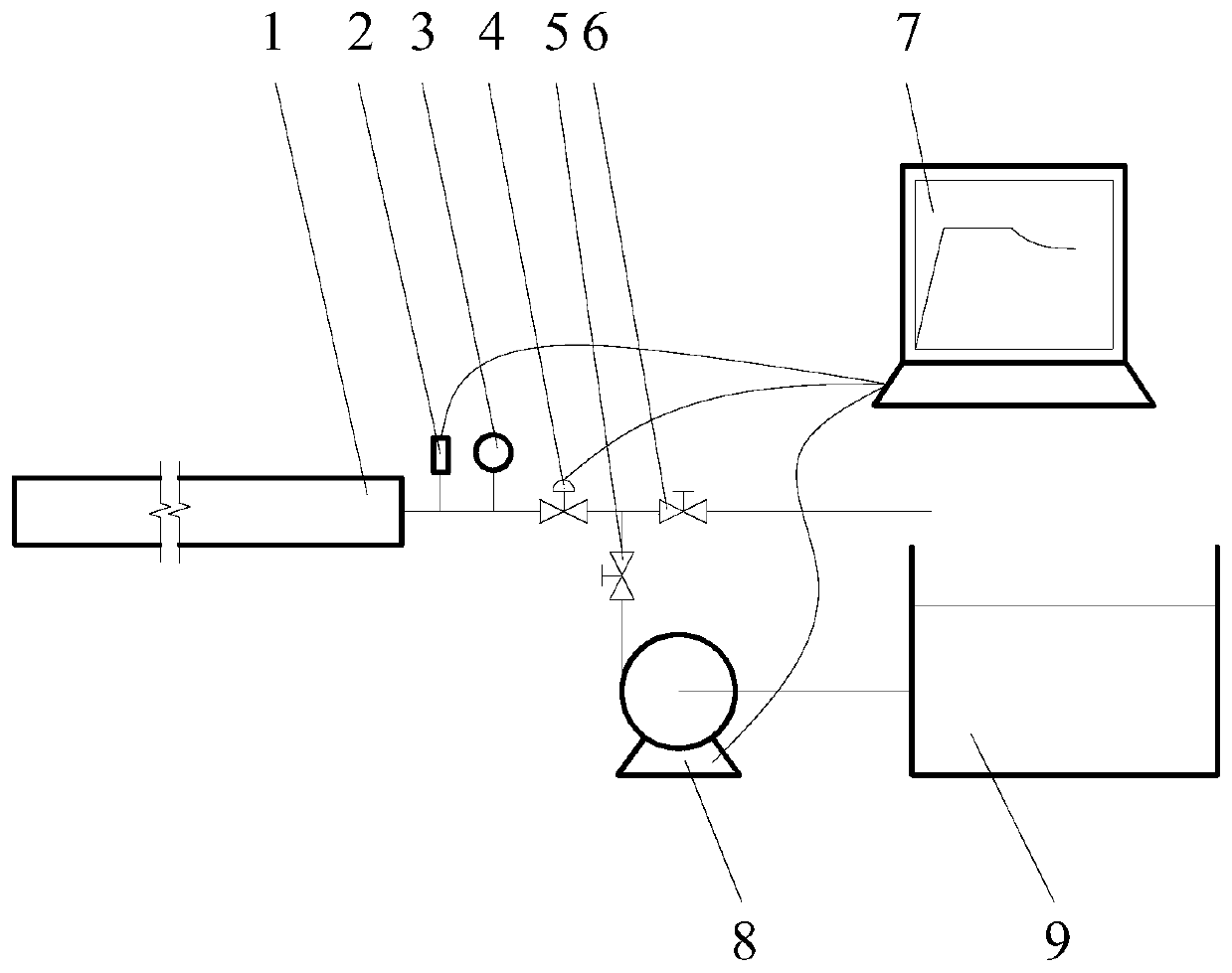

Test System for Pilot Load Control Valve

The invention discloses a testing system of a pilot-operated type load control valve. The testing system of the pilot-operated type load control valve comprises a main oil line hydraulic pump, a pilot-operated oil line hydraulic pump, a proportional overflow valve, a manual overflow valve, a pilot-operated two-way cartridge valve, a main oil line pilot-operated reversing valve, a proportional pressure reducing valve, a leading oil line pilot-operated reversing valve, a manual directional valve, a tested load control valve, a loading pressure transmitter, an oil return pressure transmitter, a control pressure transmitter, a flowmeter, a power amplification device, a data acquisition card, a computer, a main phase step module and a pilot-operated phase step module. The testing system of the pilot-operated type load control valve can conduct comprehensive testing on the one-way connecting characteristic, the load pressure - flow characteristic, the control pressure - flow characteristic, the load pressure phase step characteristic and the control pressure phase step characteristic of the pilot-operated type load control valve.

Owner:ZHEJIANG UNIV

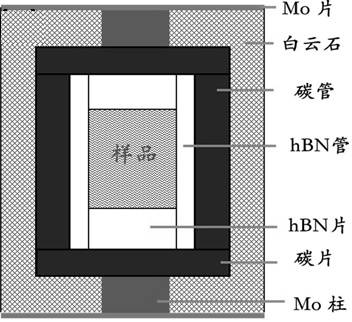

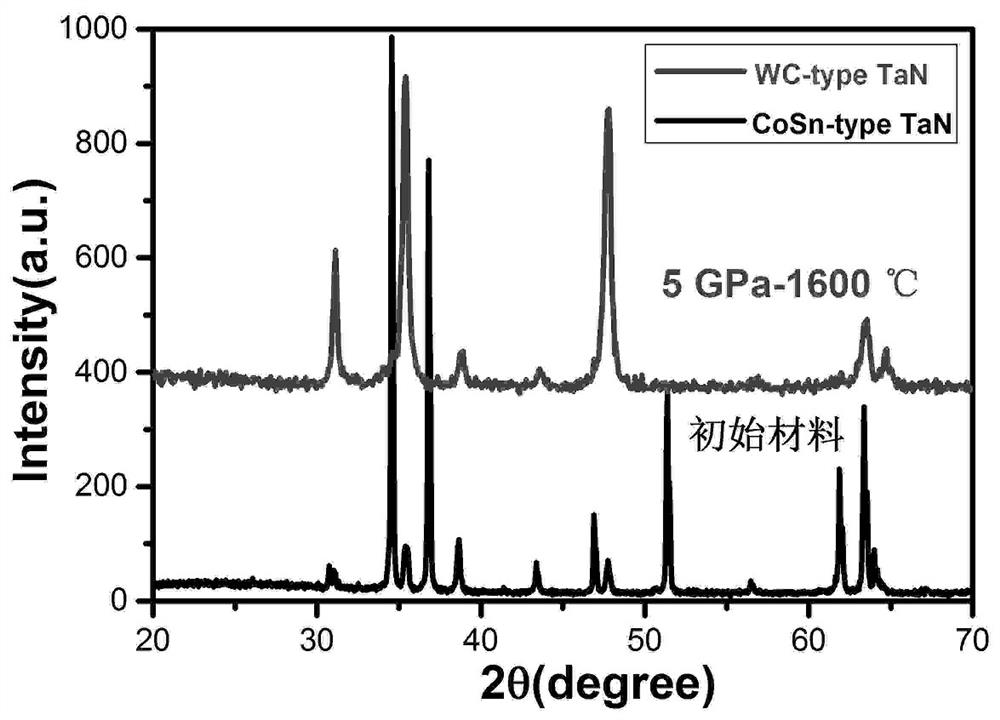

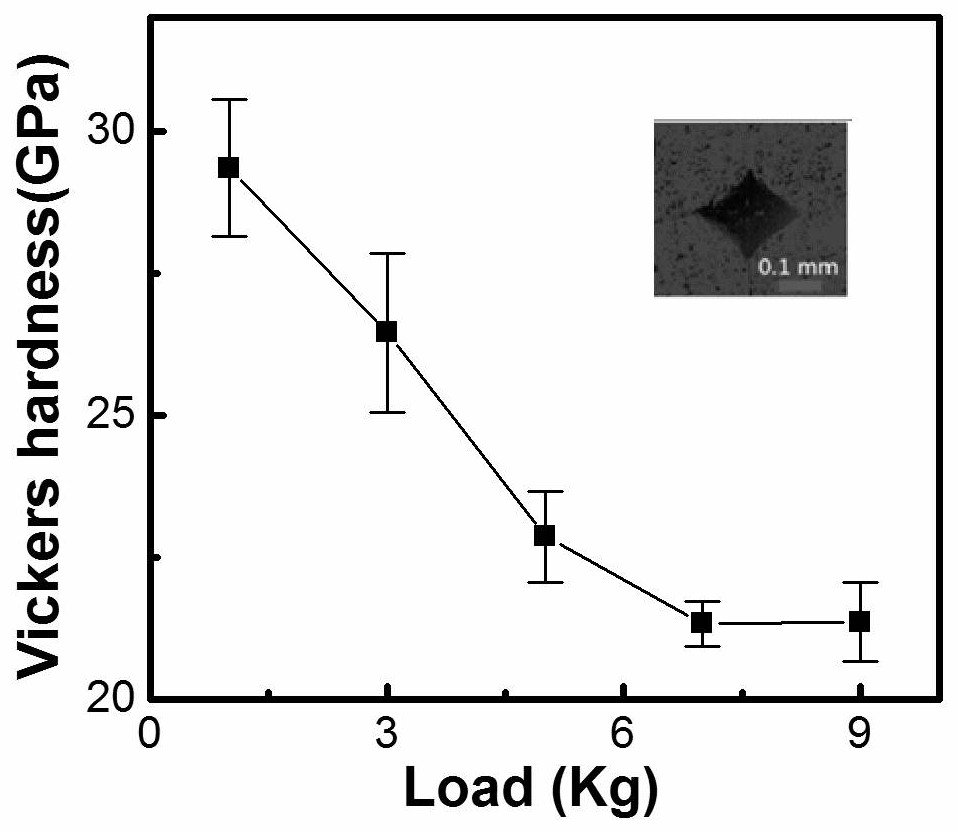

High-hardness and high-thermal-stability tantalum nitride block prepared based on domestic cubic press

The invention discloses a preparation method for preparing a large-size tantalum nitride block based on a domestic cubic press. The preparation process comprises the following steps: (1) grinding a tantalum nitride initial material; (2) carrying out vacuum treatment on the tantalum nitride powder obtained by grinding, and pre-pressing into a cylindrical block; (3) putting the pressed cylindrical block into a high-pressure synthesis block; (4) placing the high-pressure synthesis block in a synthesis cavity of a domestic cubic press for high-temperature and high-pressure phase change sintering; the sintering pressure is 2-6 GPa; the temperature is 600 to 1800 DEG C; the heat preservation time is 5-60 minutes; and (5) after sintering is completed, cooling and pressure relief are performed, and a tantalum nitride sintered body with the block diameter reaching 10 mm is taken out. The tantalum nitride block prepared by the method has the characteristics of uniform microstructure, few pores and better hardness and thermal stability than the traditional pure-phase tungsten carbide, and can be widely applied to the fields of mechanical manufacturing, geological drilling, grinding tool industry and the like.

Owner:SICHUAN UNIV

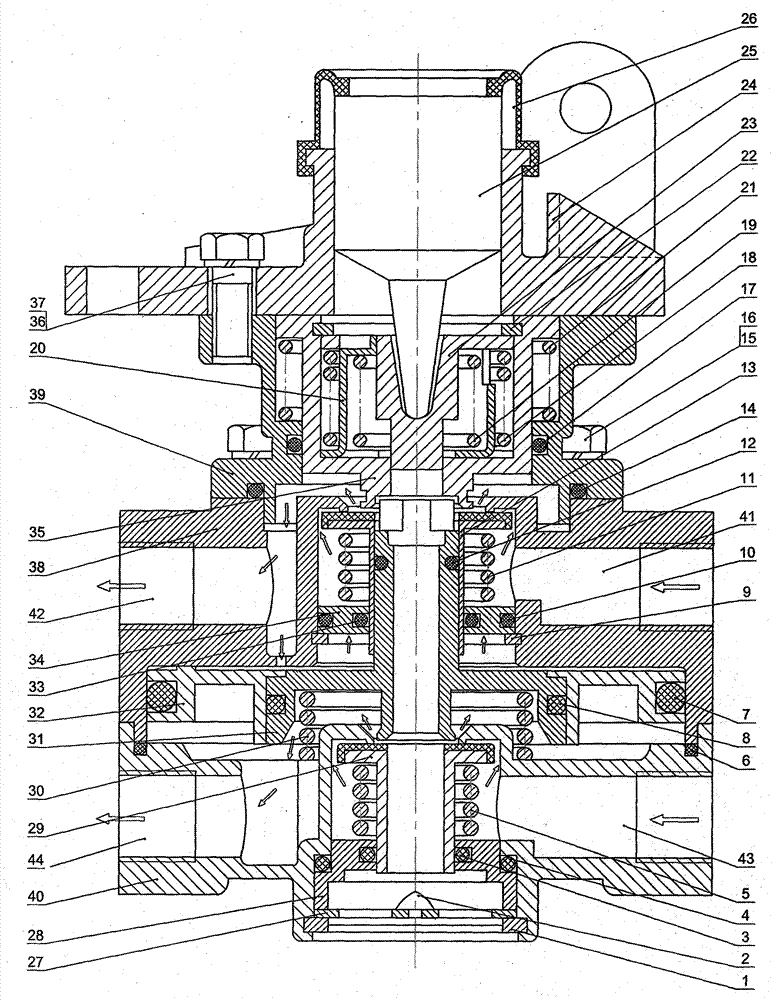

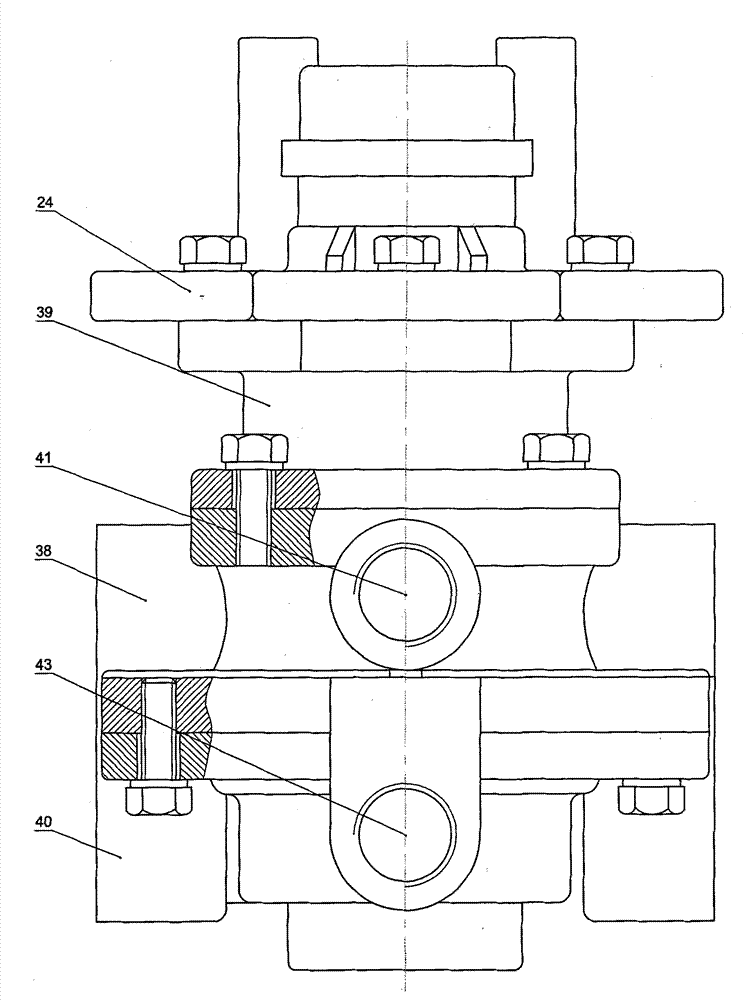

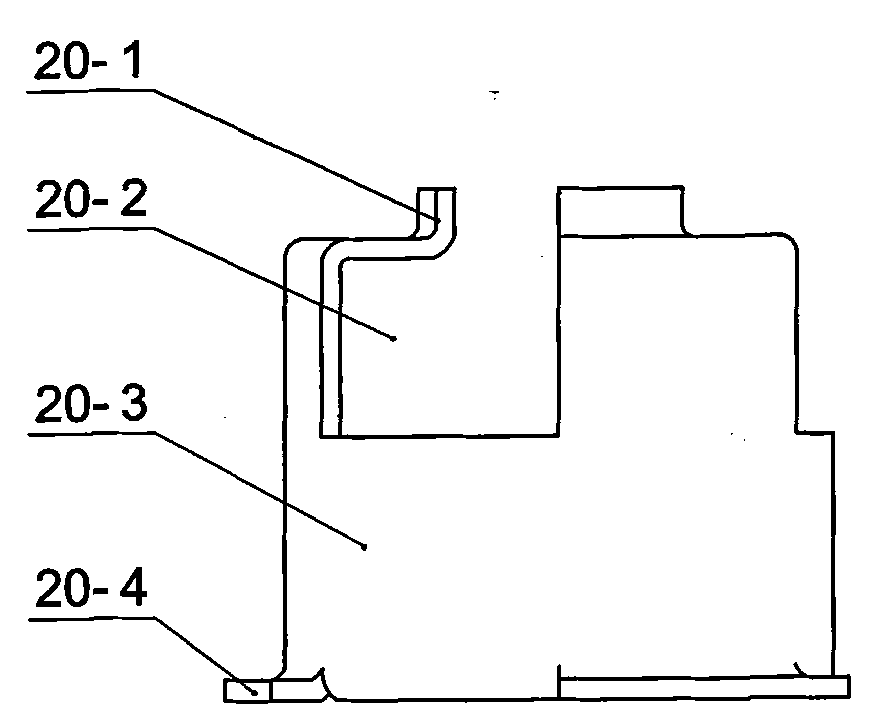

Two-stage cadence braking master valve (type V)

InactiveCN101837774BAvoid carbonizationFast and powerful combinationApplication and release valvesEngineeringPressure phases

The invention relates to a two-stage cadence braking master valve (type V), which comprises an upper valve body, a middle valve body and a lower valve body, wherein the upper valve body and the middle valve body are connected, sealed and fixed by a piston cylinder body; the upper edge of the lower valve body and the lower edge of the middle valve body are matched, nested, sealed and fixed; an upper piston assembly and a lower piston assembly are respectively arranged in the piston cylinder body and the middle valve body; an upper valve assembly and a lower valve assembly are respectively arranged in the middle valve body and the lower valve body; an inlet hole and an outlet hole are respectively arranged on the side surfaces of the middle valve body and the lower valve body; and the upperpiston assembly comprises an upper piston, a spring kit clamp and a mandril base. The braking master valve can generate sudden energy in the weak pressure phase at the beginning of braking, can promote rapid and powerful combination between a brake pad and a friction sheave to always maintain in a good combination condition and ensure a favorable braking effect. Meanwhile, the friction between the brake pad and the friction sheave can be reduced to the minimum extent, the brake pad is prevented from carbonizing and the service life of a braking system is prolonged.

Owner:CHANGTONG TECH

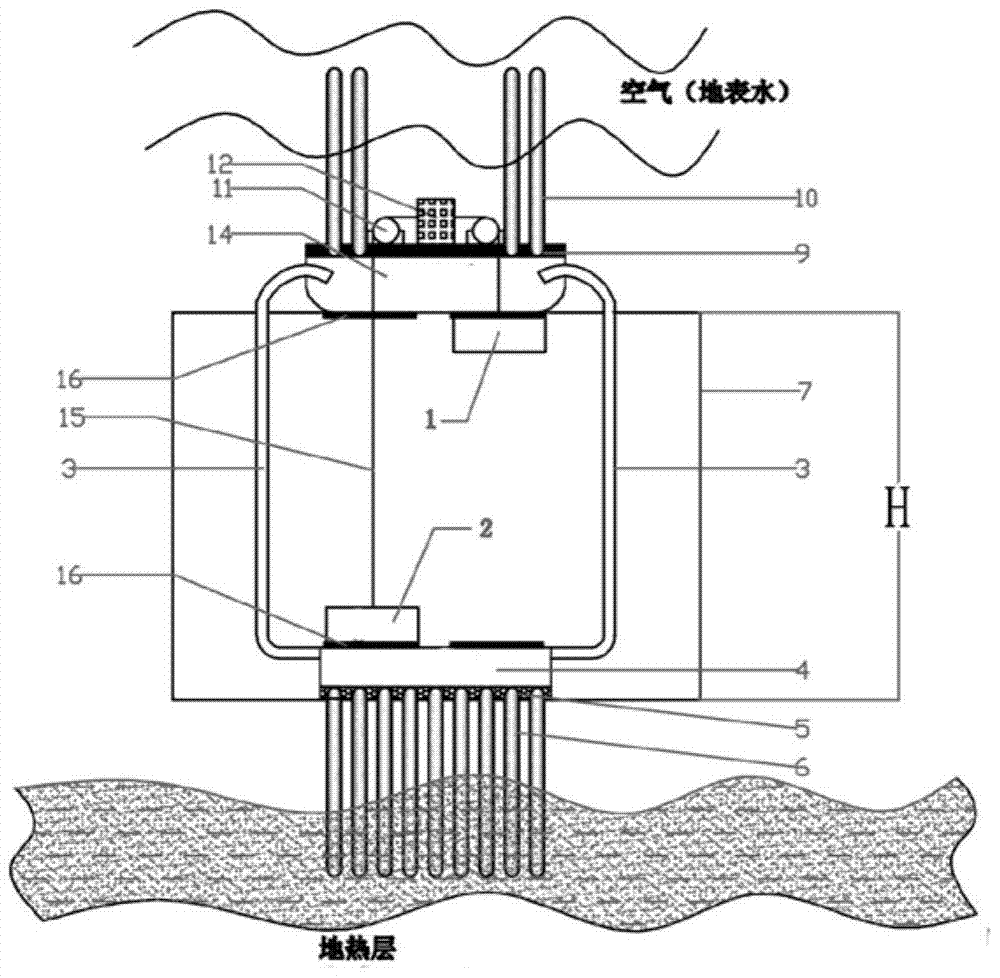

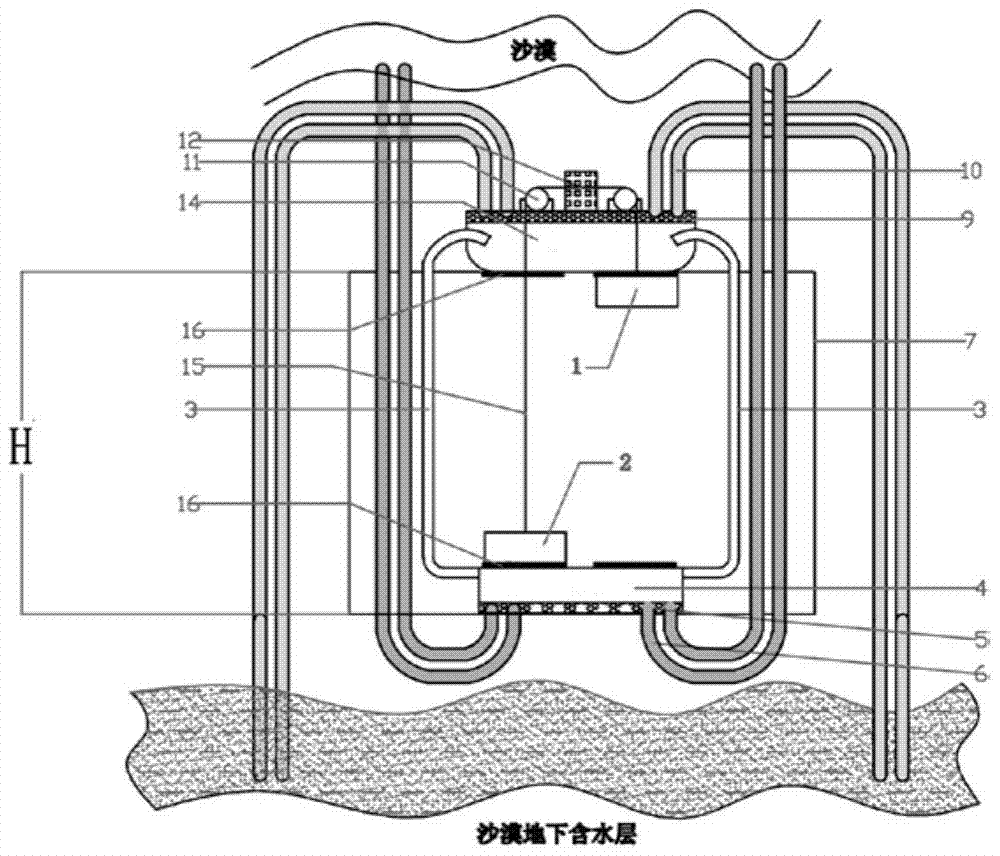

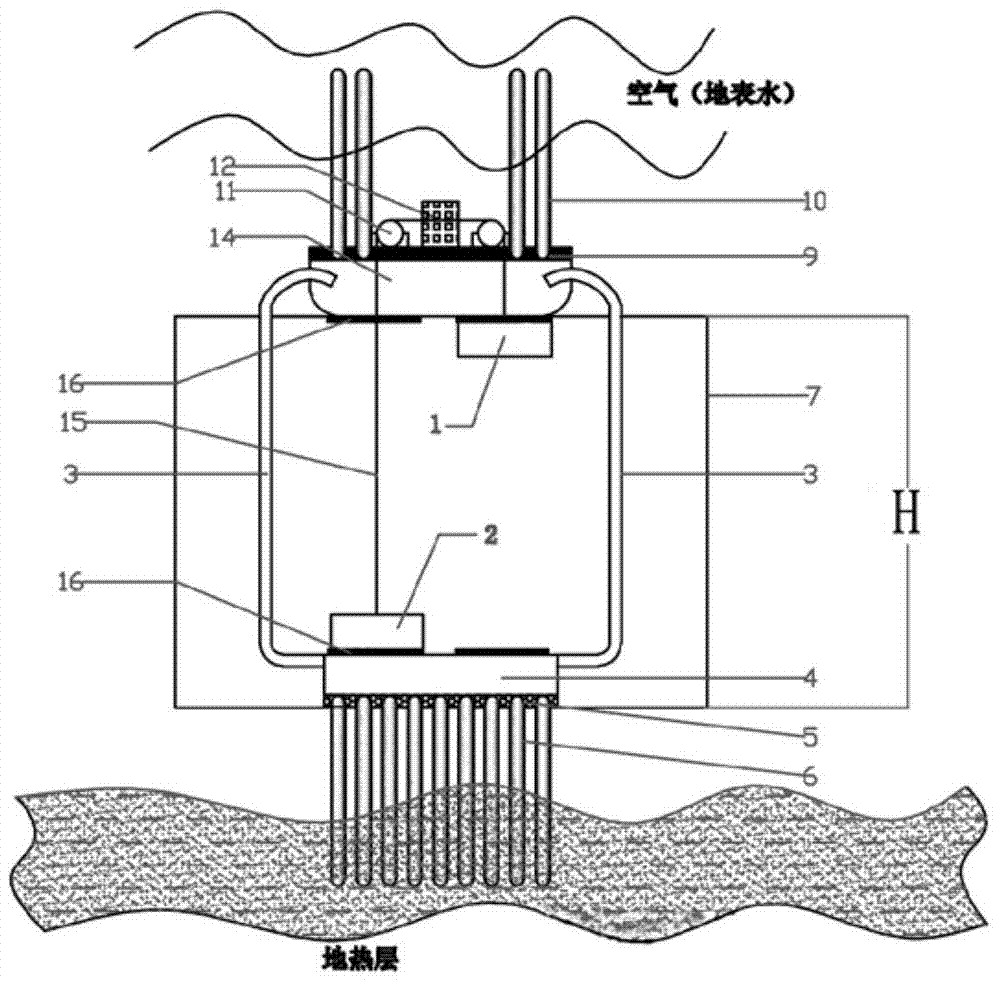

Negative pressure phase change power generation system and steam turbine power generation device

ActiveCN105283668BNo pollution in the processIncrease profitMachines/enginesGeothermal systemsLiquid mediumHeat conducting

The invention relates to the technical field of power generation equipment, in particular to a negative pressure phase change power generation system and a steam turbine power generation device. The system includes a heating superconducting heat pipe, a heat dissipation superconducting heat pipe, a heating room, a condensation room and a gas delivery pipeline; there is a height difference between the heating room and the condensation room and is connected through a gas delivery pipeline; the heat absorption end of the heating superconducting heat pipe and the The heat source is connected, the heat dissipation end of the heating superconducting heat pipe is connected with the heating plate, and the heating room is equipped with a thermal liquid medium. The heat dissipation end of the heat pipe is connected with a low-temperature heat source. The invention introduces the earth's natural energy into recombined phase-change power generation through heat pipes or superconductors, effectively replaces conventional energy sources such as coal and nuclear energy, maximizes the use of infinite natural resources, and improves the utilization rate of natural resources. The power generation system has simple equipment, low cost input, easy manufacture and no pollution.

Owner:LANZHOU JINFULE BIOTECH CO LTD +3

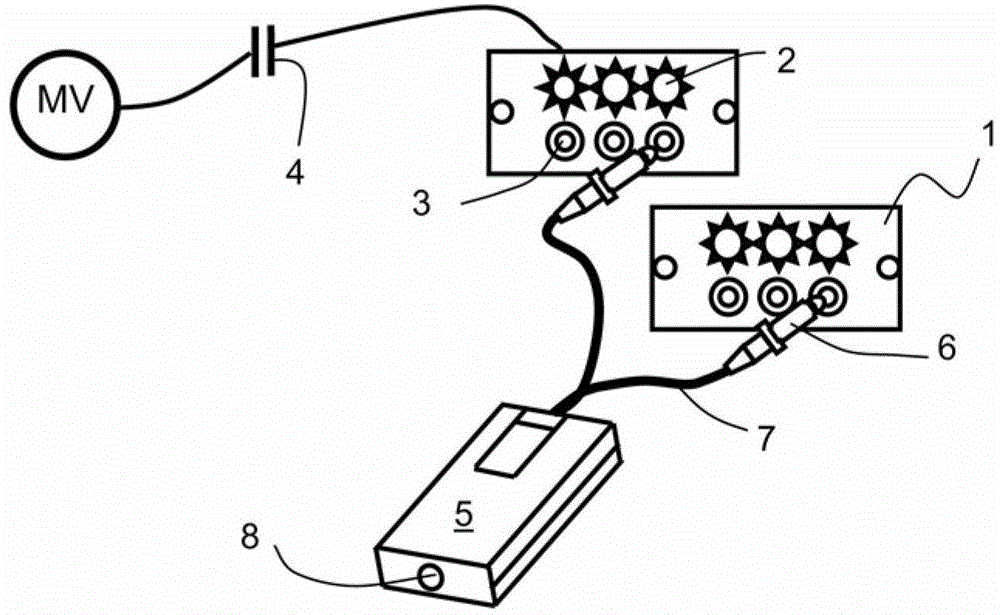

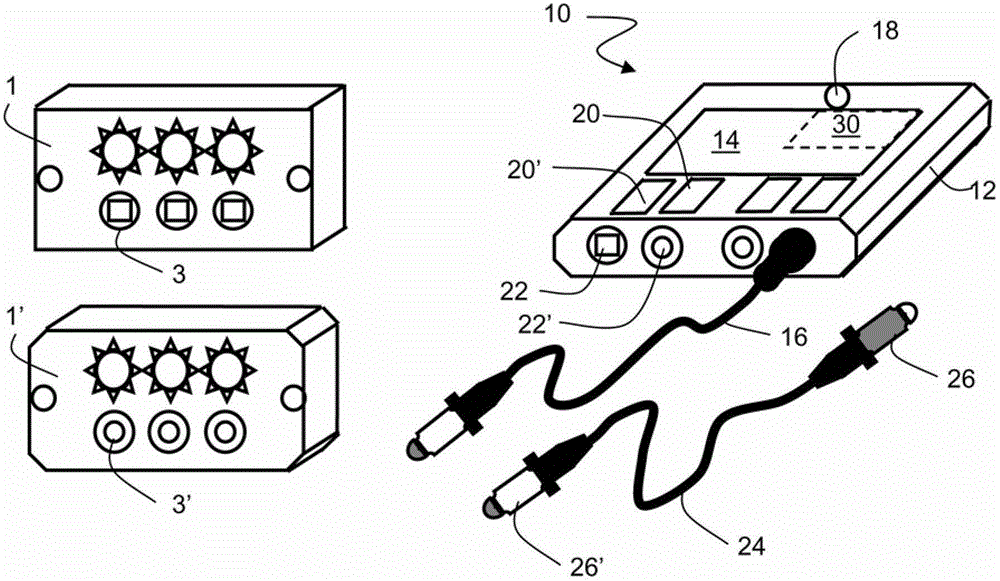

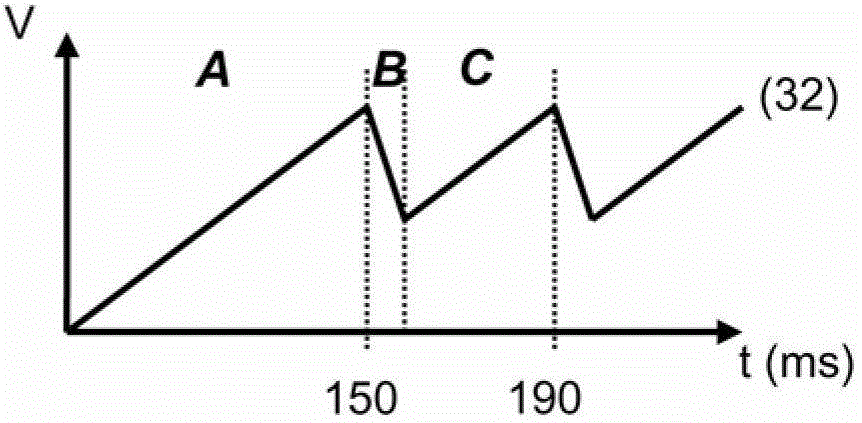

System powered phase comparison device

In order to check the phase match between two medium voltage equipped units equipped with VPIS (1, 1'), a phase comparator (10) can be used. The connector (16) of the comparator (10) is plugged into the terminals (3, 3') of the two VPIS (1, 1') in order to obtain a signal representing the voltage flowing therein, and the part (14) compares the signal to The LED (18) is illuminated where a mismatch is observed. According to the invention, the connector (16) of the comparator (10) is suitable for comparators (10) that can be used for two VPIS (1, 1') of different generations, such as With different connection terminals (3, 3'). The comparator (10) is powered directly by means of the available voltage signal of the VPIS (1, 1'), and the power supply management part (30) of the diode (18) has been developed in order to meet the safety conditions when the diode (18) is illuminated, while Regardless of the small amount of energy available.

Owner:SCHNEIDER ELECTRIC IND SAS

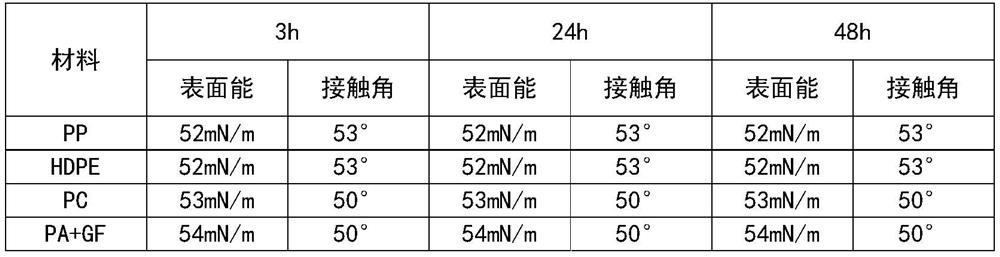

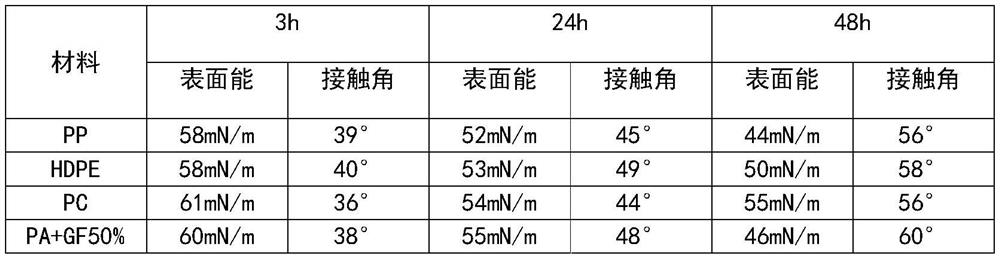

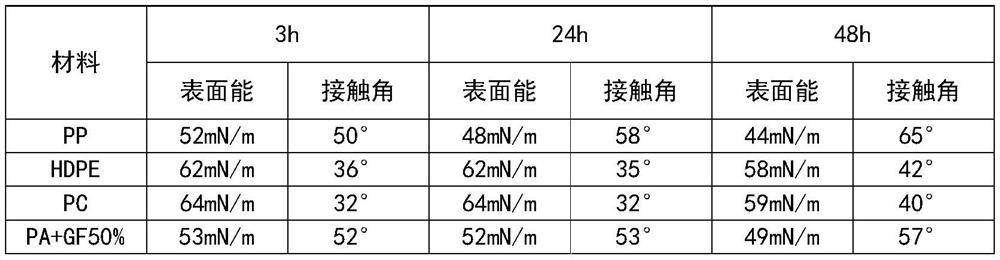

A multi-stage pressurized fluorination treatment method for the surface of plastic parts

ActiveCN108586789BNo drop in surface wetting tensionPersistent and stable surface wetting tension valuesAdhesive glueNitrogen gas

The invention discloses a multi-stage pressurized fluorination treatment method of the surface of a plastic part. According to the multi-stage pressurized fluorination treatment method, except for cleaning and drying the plastic part and replacing air inside a closed reaction chamber of fluorination equipment with nitrogen gas, a core technology is achieved by preheating the reaction chamber tillthe internal temperature is 35-45 DEG C and then inflating mixed gas of fluorine gas, nitrogen gas and oxygen gas, wherein the volume ratio of the fluorine gas to the nitrogen gas is 1:6 to 1:10 and the oxygen gas accounts for 1 / 200-1 / 400 of the volume of the fluorine gas; a reaction is divided into n pressure stages, n is a natural number of 2-5, the chamber pressure in a first pressure stage is5-10mbar, the pressure deltaP in an adjacent pressure stage increases to 5-100mbar, and the reaction time in each pressure stage is 3-10 minutes; finally, at the end of the reaction, the plastic partis taken out. By the multi-stage pressurized fluorination treatment method, the surface energy of the plastic part can be effectively improved and maintained stable, so that better bonding of the plastic part with ink, paint, glue, coating, a foil and other materials is guaranteed, and a better bonding effect is achieved.

Owner:JRB PACKING CO LTD

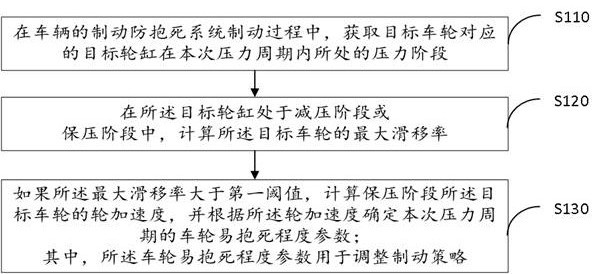

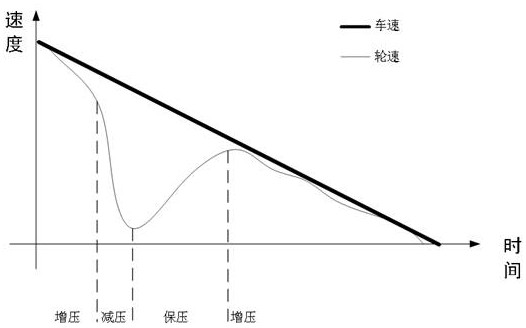

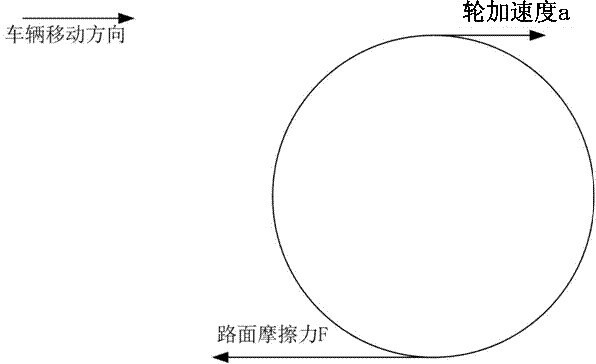

Calculation method, device and storage medium of wheel lock-easy degree parameter

The invention relates to the field of calculation of driving parameters, and discloses a calculation method, equipment and storage medium for parameters of the degree of easy locking of wheels. The method includes: during the braking process of the anti-lock braking system of the vehicle, acquiring the pressure stage of the target wheel cylinder corresponding to the target wheel in this pressure cycle; In the pressure stage, calculate the maximum slip ratio of the target wheel; if the maximum slip ratio is greater than the first threshold, calculate the wheel acceleration of the target wheel in the pressure holding stage, and determine this pressure cycle according to the wheel acceleration The parameters of the degree of easy locking of the wheel. This embodiment proposes a parameter characterizing the ease of wheel locking and a calculation method for the parameter.

Owner:TIANJIN SOTEREA AUTOMOTIVE TECH LMITED CO +1

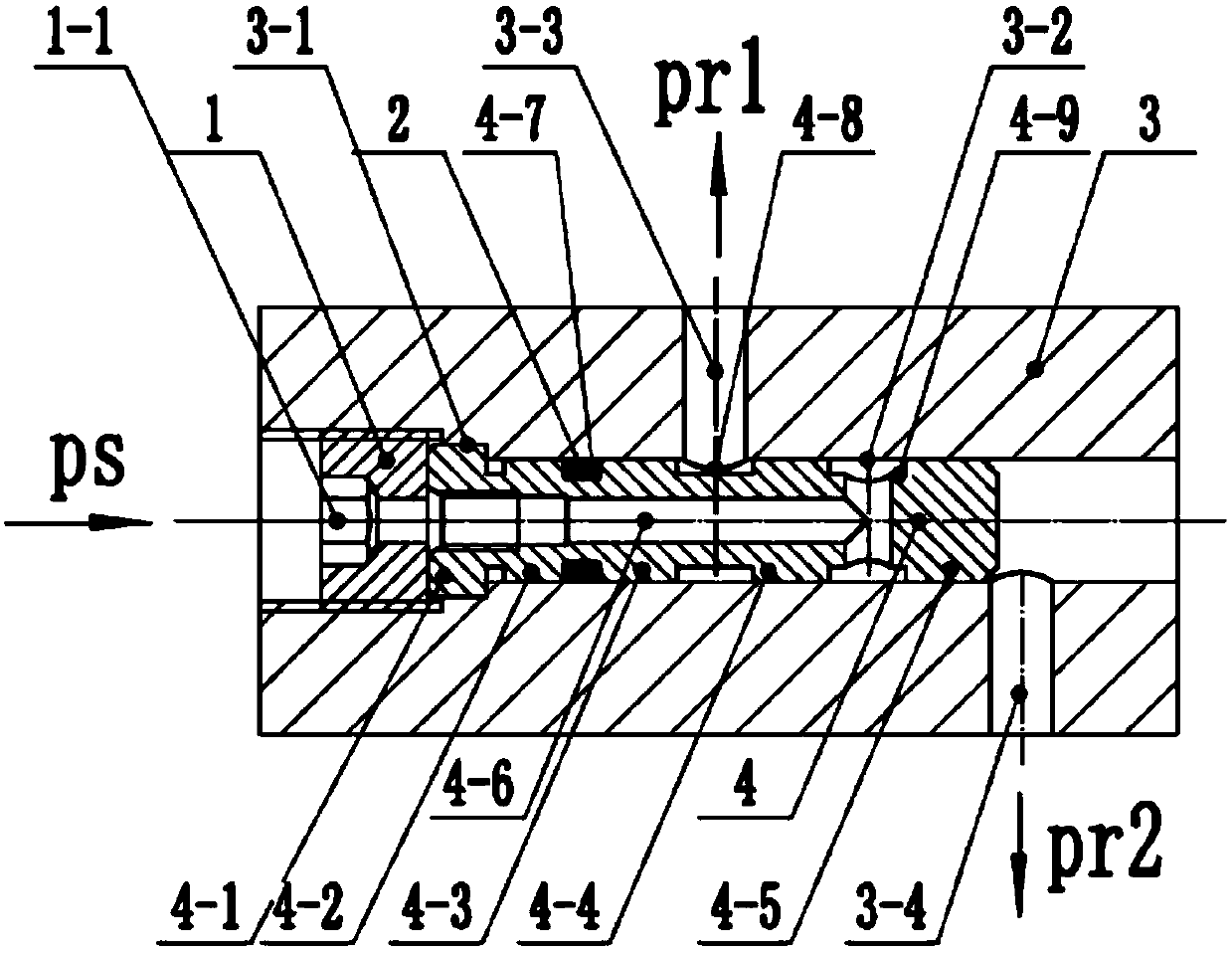

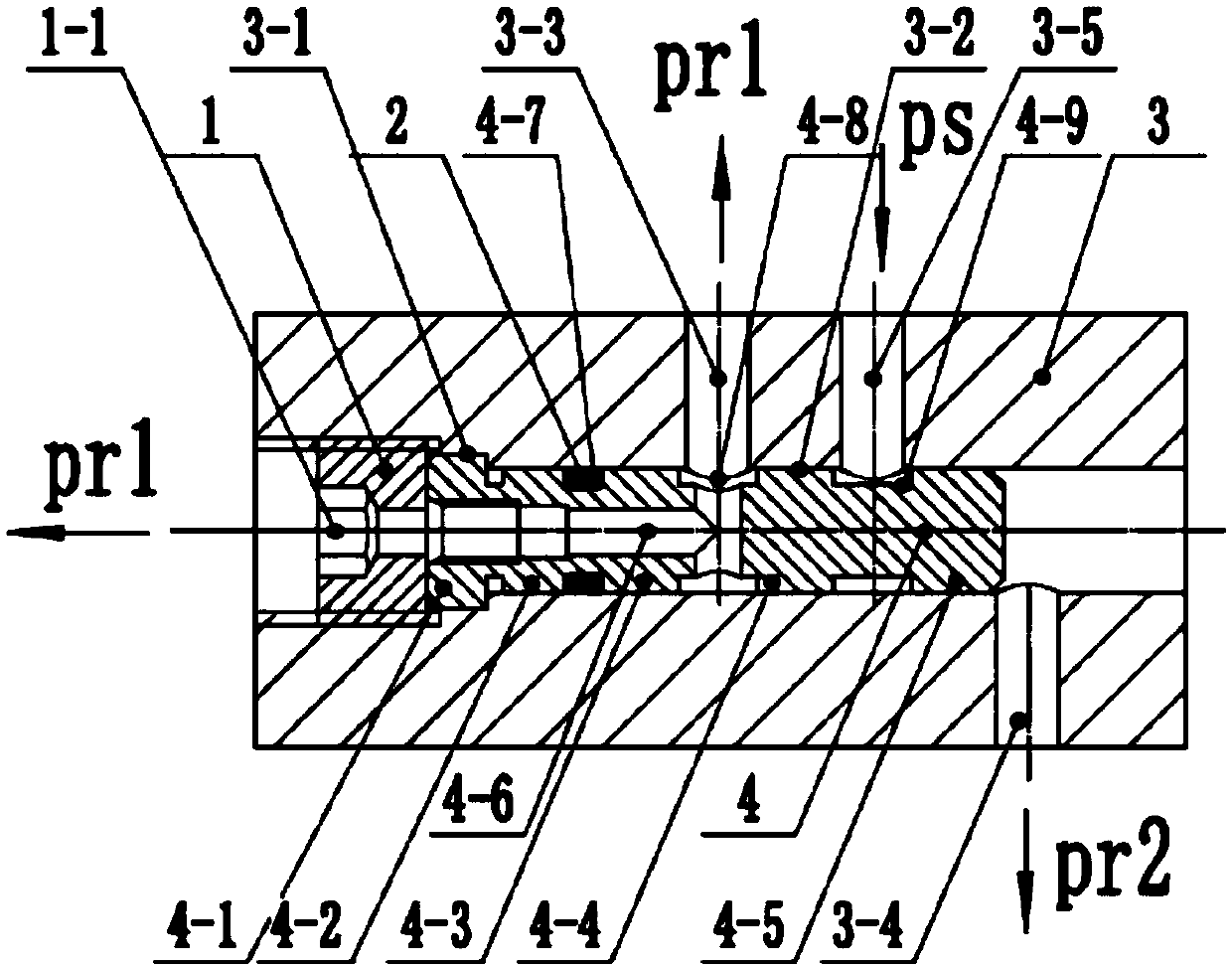

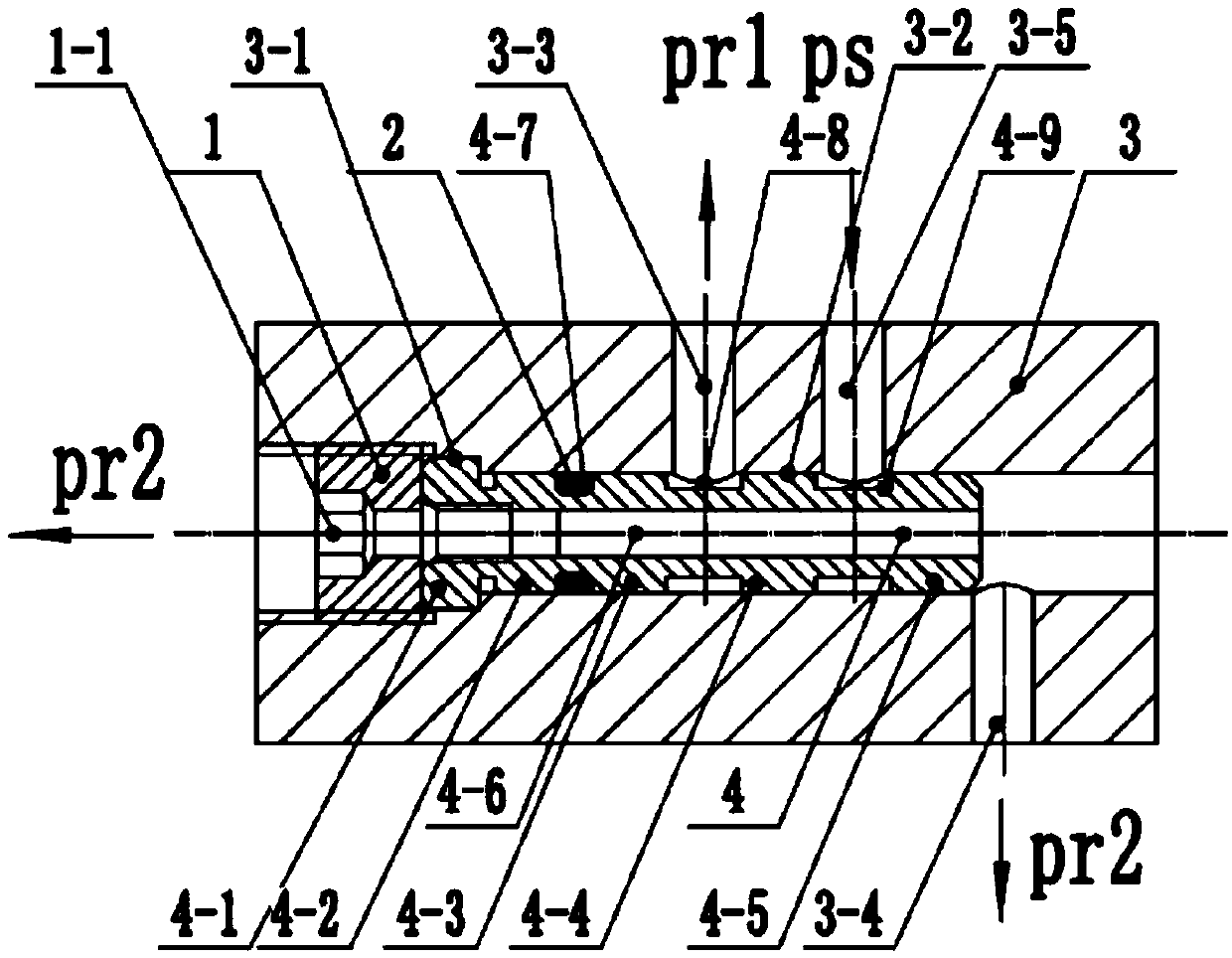

Two-stage annular gap throttling device

ActiveCN106151274BReduce difficultyReduce in quantityBearing assemblyShaftsEngineeringPressure phases

The invention relates to a two-section type annular gap throttling device which comprises a throttle device mounting body, a jack screw with a hole, an O-shaped sealing ring and a throttle device body. The throttle device body mounting body consists of a front cavity, a rear cavity and an oil leading hole; the throttle device body consists of a shoulder part, a mounting section, a first throttling section, a second throttling section, a sealed ring groove, a throttling ring groove, an oil inlet ring groove and a threaded oil hole; the throttle device body is used for pressing the shoulder part of the throttle device to the bottom of the front cavity of the throttle device mounting body through the jack screw with the hole, so that axial positioning is realized; the outer circle of the mounting section is matched with the rear cavity to realize radial positioning; outer diameter and length of the first throttling section are the same as those of the second throttling section; the first throttling section, the second throttling section and the rear cavity of the same size are matched to form a throttling gap which is greater than a positioning gap of the mounting section; during use, oil is introduced through the oil inlet ring groove, and flows into a group of oil storage cavities of the same structural size towards the left side and the right side separately after being throttled by the first throttling section and the second throttling section. The two-section type annular gap throttling device is compact in structure, and is easy to regulate pressure phase and the like of the oil storage cavities.

Owner:SUZHOU CHENNA AUTOMATION TECH CO LTD

Tightness test method for high density polyethylene pipes used in nuclear power plants

ActiveCN108195527BHigh customization requirementsHigh anti-leakage requirementsMeasurement of fluid loss/gain rateNuclear powerEngineering

The invention relates to polyethylene tube test techniques and is intended to provide a tightness test and evaluation method for high-density polyethylene tubes for nuclear power stations, comprising:injecting an HDPE (high-density polyethylene) tube fully with water through a water pump, and increasing the pressure continuously to a test pressure at the controlled pressure increase rate range of40-120 kPa / min; holding the pressure for 4 h, and supplementing water so that the pressure in the tube is maintained to the test pressure; stabilizing the pressure for 1 h, recording pressure data, and drawing a pressure change curve graph; acquiring an actual pressure drop of tightness test according to a ratio of a pressure difference of start and end moments of a stabilized pressure phase to the test pressure; when the actual pressure drop is less than an allowable pressure drop, considering that the tightness test for the HDPE tube is qualified. The method has the advantages that tightness test for the HDPE tube quits using test standards or methods for steel tubes or tubes of other fixed material and structure, and however, a specific acceptance standard for tightness test is made according to the specific tube material and structure and test environments.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com