Negative pressure phase change power generation system and steam turbine power generation device

A power generation system and phase change technology, applied in geothermal energy systems, machines/engines, mechanisms for generating mechanical power, etc., can solve the problems of high energy consumption of power generation devices, limited power generation, unfavorable environmental protection, etc., and achieve low cost input, Improve utilization rate and make easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

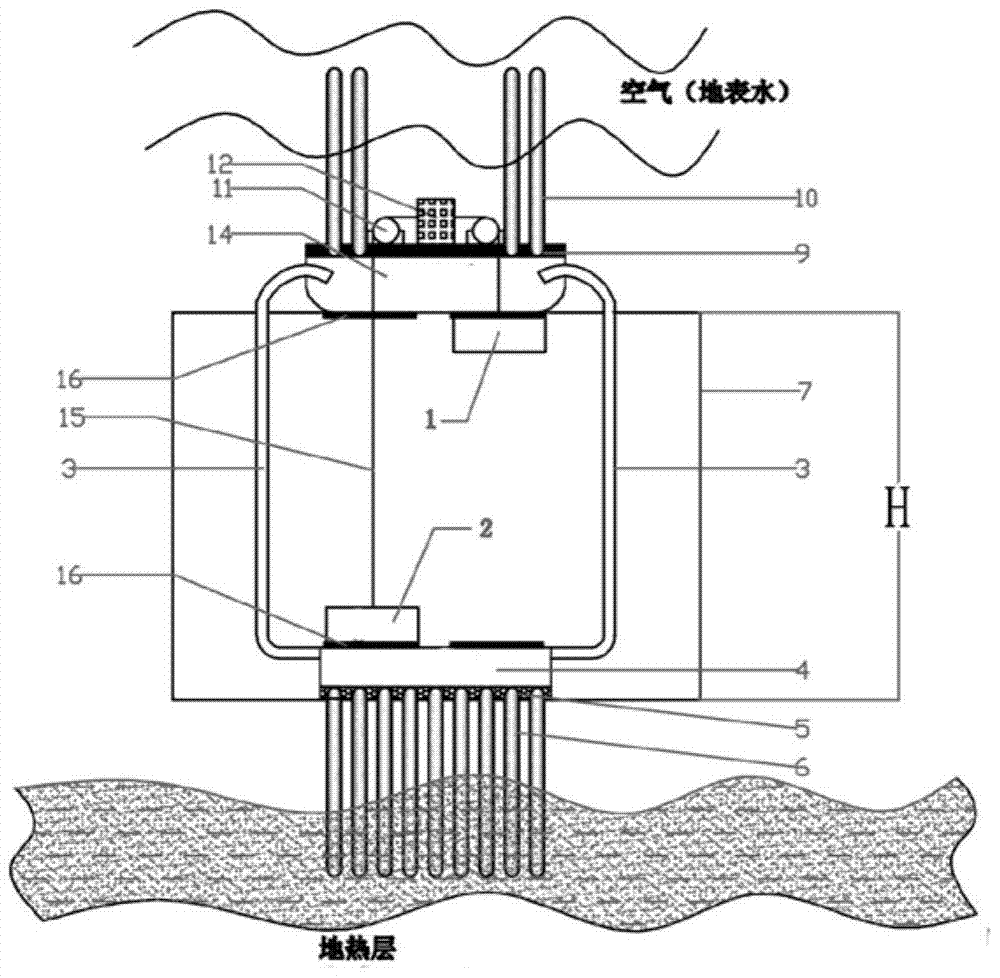

[0034] Such as figure 1 As shown, the low-temperature negative pressure phase-change power generation device of the embodiment of the present invention includes a first power generation box, a second power generation box, a gas delivery pipeline 3, and a heating room (the liquid in the power generation box is put into it, and then liquefied device) 4, heating plate 5, heating superconducting heat pipe 6, fixing and stabilizing device of the whole device 7, heat dissipation plate 9, heat dissipation superconducting heat pipe 10, power generation box guiding device 11, generator set 12, condensation room 14, power generation Box movement connecting device 15, liquid filling valve 16.

[0035] The heating plate 5 is connected with the heat dissipation end of the heating superconducting heat pipe 6, so that the heat conduction is more uniform and rapid. The heat dissipation plate 9 is made of high thermal conductivity material, and the heat dissipation plate 9 is connected with t...

Embodiment 2

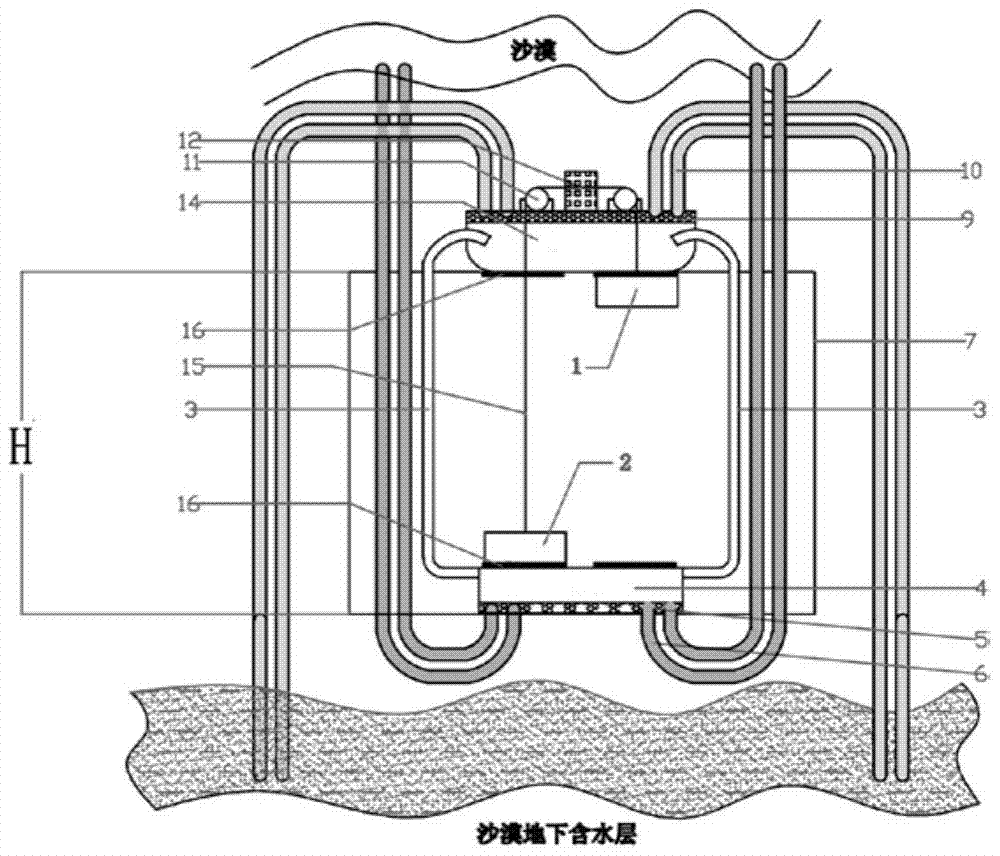

[0044] Such as figure 2 As shown, the difference between this embodiment and the above-mentioned embodiments is that the structure of the heating superconducting heat pipe 6 and the heat dissipation superconducting heat pipe 10 are somewhat different. figure 2 The heating superconducting heat pipe 6 draws heat energy from the top high-temperature heat source of the fixing and stabilizing device 7 of the whole device, and then transfers the heat energy to the heating room 4 by heating the superconducting heat pipe 6, and converts the gaseous medium in the condensation room into The heat energy released during the process of liquid medium is transferred to the bottom low-temperature heat source of the fixing and stabilizing device 7 of the whole device through the heat dissipation superconducting heat pipe 10, thereby completing the process of phase change power generation and generating electric energy.

[0045] figure 2 It is suitable for the condition that the bottom of t...

Embodiment 3

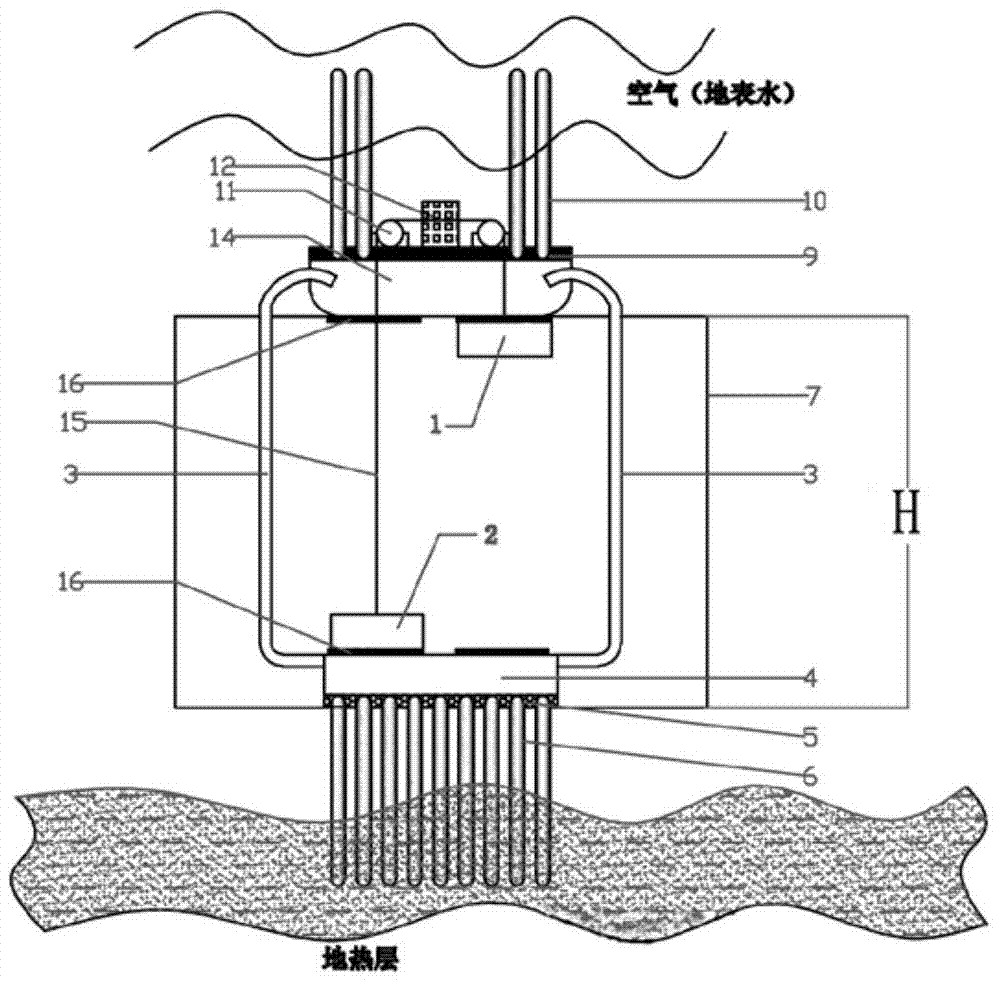

[0047] Such as image 3 as shown, image 3 structure with figure 1 The structures are the same, except that the heating room 4, the gas delivery pipeline 3, the condensation room 14, the first power generation box 1, the second power generation box 2 and the second power generation box 2 etc. will select materials that can withstand high temperature and high pressure. For example, the high-temperature underground geothermal energy is used as a high-temperature heat source, and the air and surface water on the ground are used as a low-temperature heat source.

[0048] image 3 The selected high-temperature heat source is higher than 100°C, and the pressure generated is greater than normal atmospheric pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com