Patents

Literature

41results about How to "Increase formation energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blocking remover used for hypotonic inhomogeneous sandstone reservoir and using method of blocking remover

ActiveCN104031625AImprove permeabilityHigh viscosityFluid removalDrilling compositionOrganic acidFoaming agent

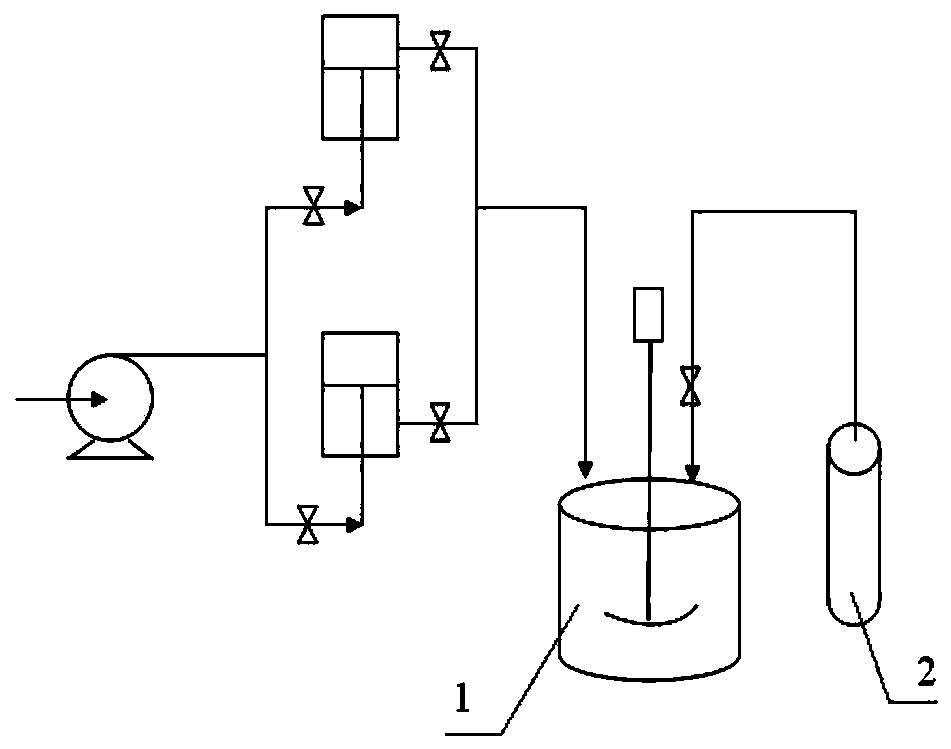

The invention discloses a blocking remover for hypotonic inhomogeneous sandstone reservoir and a using method of the blocking remover. The blocking remover comprises an agent A, an agent B and an agent C, wherein the agent A consists of the following components in percentage by weight: 10%-25% of oxidant, 8%-12% of activator and the balance of water; the agent B consists of 10%-15% of a reducing agent, 0.3%-1.2% of a foaming agent, 0.3%-0.6% of a foam stabilizer, and the balance of water; the agent C consists of 8%-12% of HCL, 6%-10% of organic acid, 2%-5% of NH4HF2, 0.5%-1.5% of a corrosion inhibitor, 0.5%-1.5% of an iron ion stabilizer and the balance of water. The using method comprises the steps of step one, preparing the agent A, the agent B and the agent C; and step two, injecting the agent A into a ground layer by a pipeline, then injecting the agent B into the ground layer, and finally injecting the agent C into the ground layer. The blocking remover disclosed by the invention has beneficial effects that the blocking remover disclosed by the invention can be applied to decompression and augmented injection of a water injecting well and deep unblocking of an oil well; and the blocking remover has better effect while being applied to augmented injection of the water well in a reservoir non-homogeneous oil-field block.

Owner:CHINA PETROLEUM & CHEM CORP

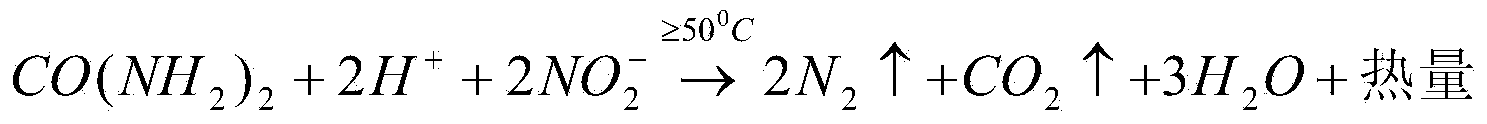

Air injection-assisted super heavy oil underground cracking improvement technology based on shaft heating modes

InactiveCN106499376AEmission reductionAchieve emissionsConstructionsFluid removalReaction rateHeater Rod

The invention provides a technology method for comprehensive oil production and in-situ improvement of super heavy oil, oil shale, kerogen and medium and low-maturity shale oil reservoirs. The technology method is characterized in that a novel shaft electric heating in-situ cracking improvement technology is adopted, and is assisted by an air injection technology; by drilling a production well group into an oil bearing reservoir or adjusting the existing well network, a heating well, an air injection well and a production well are reasonably arranged; air is injected into the reservoir, and a heating cable in a heating well shaft is connected with an electric heating bar to heat the oil bearing reservoir, so as to realize the improvement of underground cracking of crude oil. The technology method has the advantages that by combining the advantages of shaft electric heating and air injection technologies, the problems of single heat transfer type, insufficient driving energy and the like in a single shaft electric heating mode are solved; by utilizing the heat effect of crude oil and oil oxidizing reaction, the stratum temperature is increased, the cracking temperature of the crude oil is decreased, the reaction rate of in-situ cracking is accelerated, the recovery efficient of the crude oil is improved, and the consumption of water resources and carbon emission are decreased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

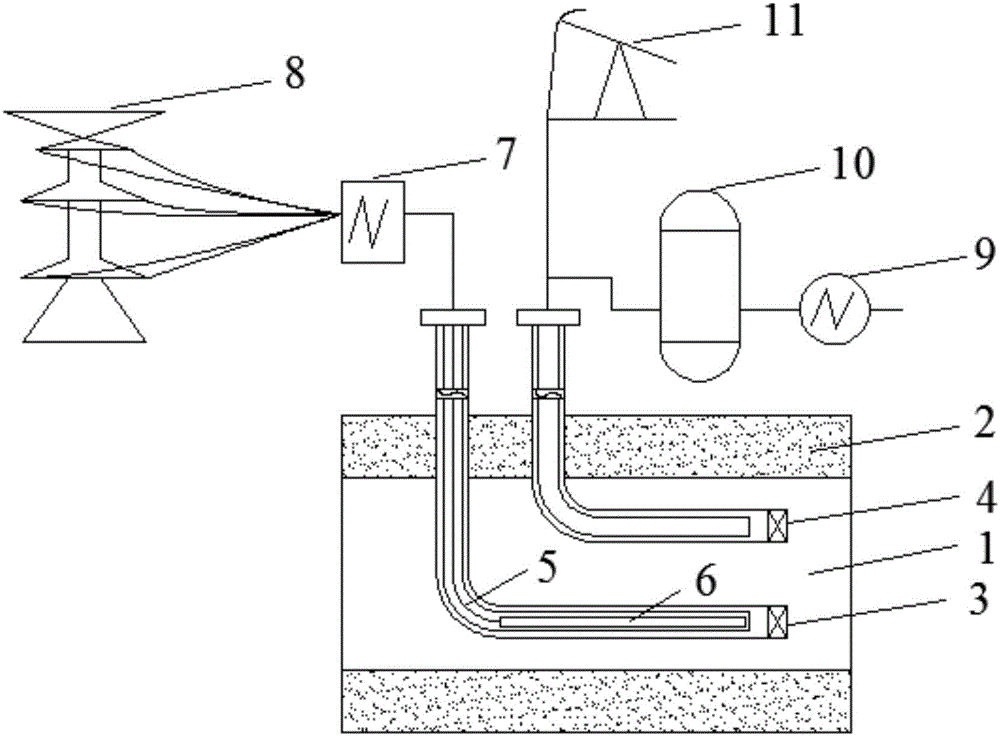

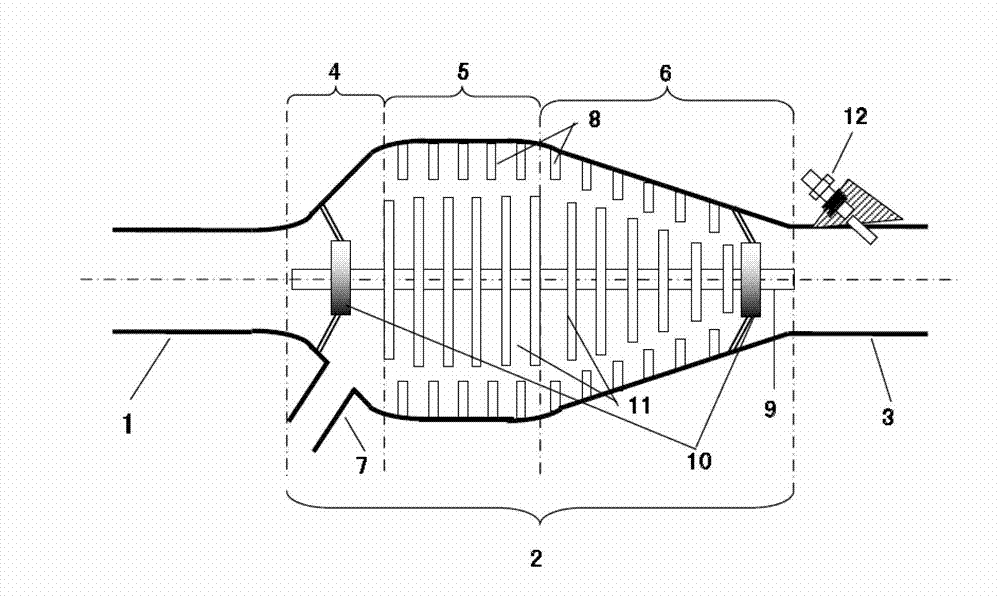

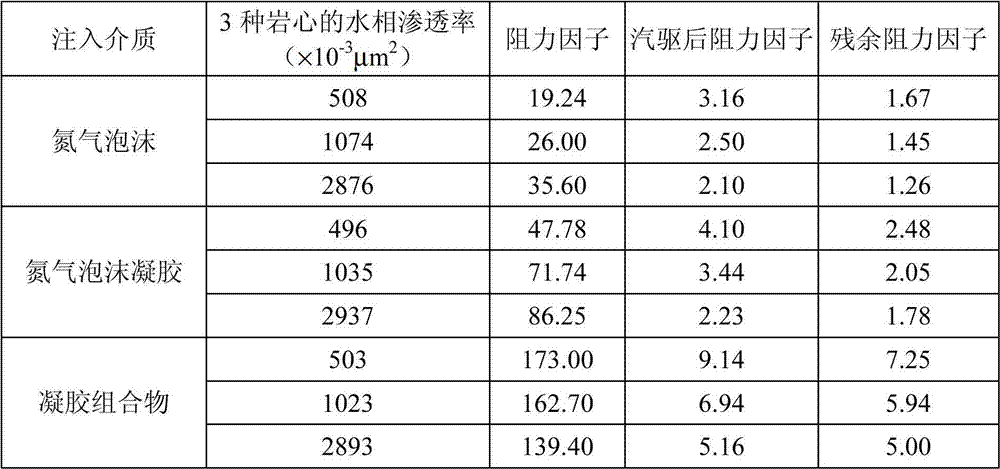

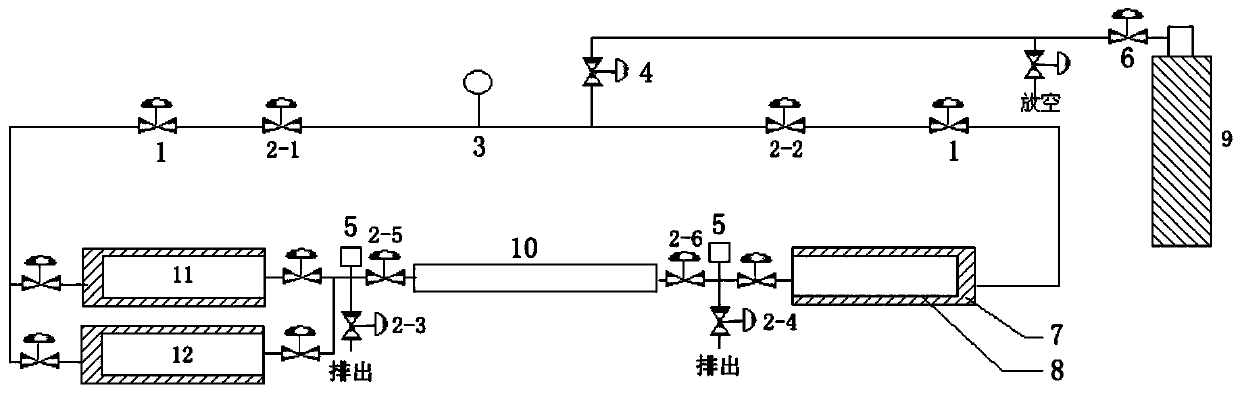

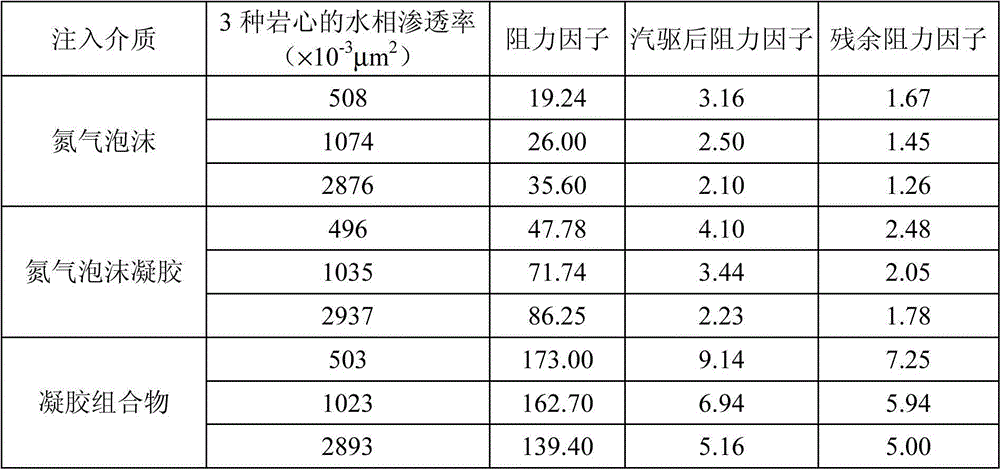

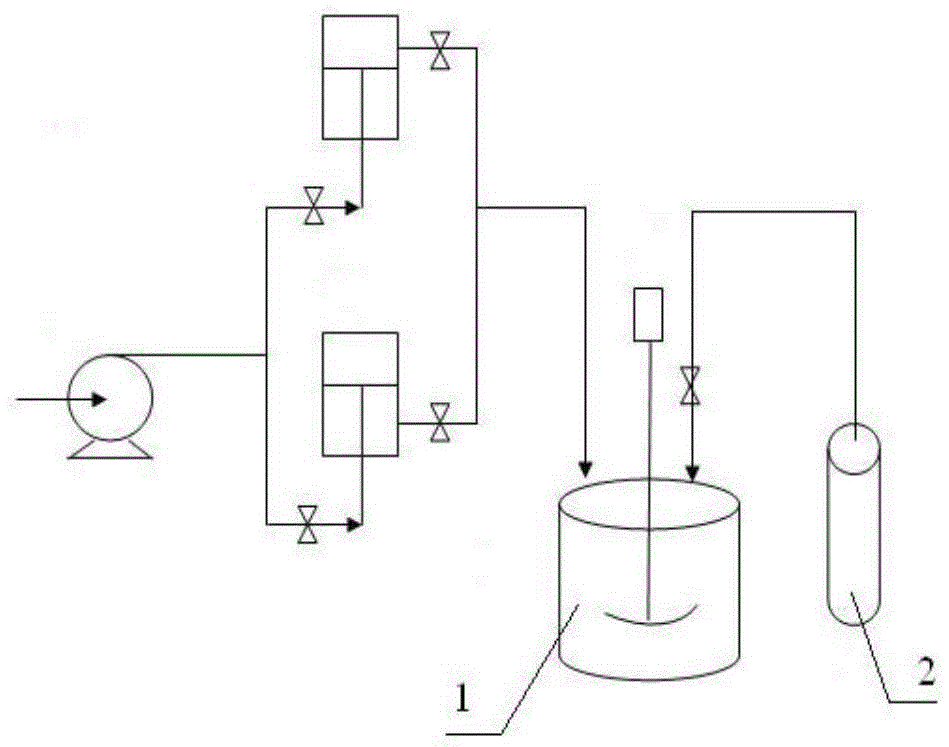

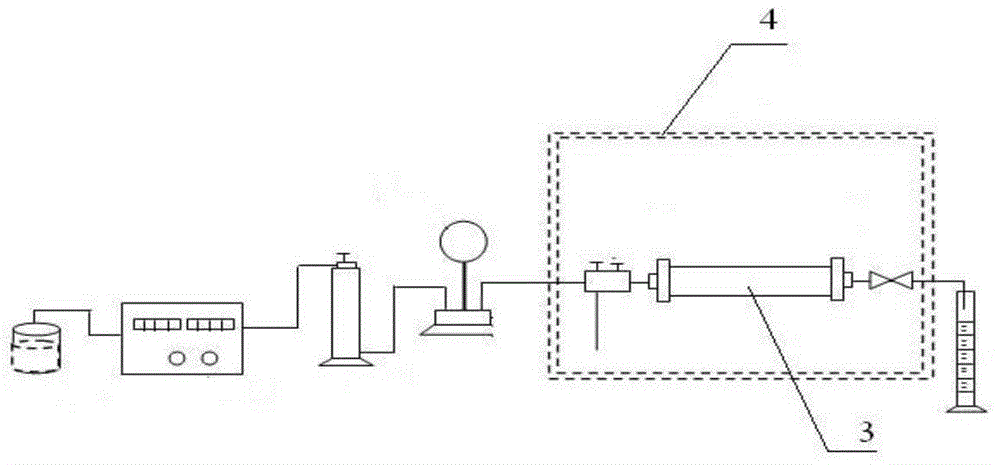

Gel composition and nitrogen-foamed gel composite temporary plugging agent containing same

ActiveCN103030916ASimple structureImprove stabilityFluid removalDrilling compositionFoaming agentChemical composition

The invention provides a gel composition and a nitrogen-foamed gel composite temporary plugging agent containing the same. The gel composition comprises the following components in percentage by mass: 1.0% of partially hydrolyzed polyacrylamide, 1.5% of formaldehyde, 0.5% of hydroquinone and the balance of water. The nitrogen-foamed gel composite temporary plugging agent comprises nitrogen and foamed gel, wherein the foamed gel is a mixture of the gel composition and a high-temperature-resistant foaming agent; and the volume ratio of the nitrogen to the foamed gel is (40-60):1. The invention also provides a coupled internal / external swirl foam generator which can be used as a facility for preparing the nitrogen-foamed gel composite temporary plugging agent. The invention also provides a method for inhibiting high-throughput-frequency well steam channeling interference of thick oil, which has the characteristics of small formation damage, strong selectivity for measures and the like and has the effect of gas energization.

Owner:PETROCHINA CO LTD

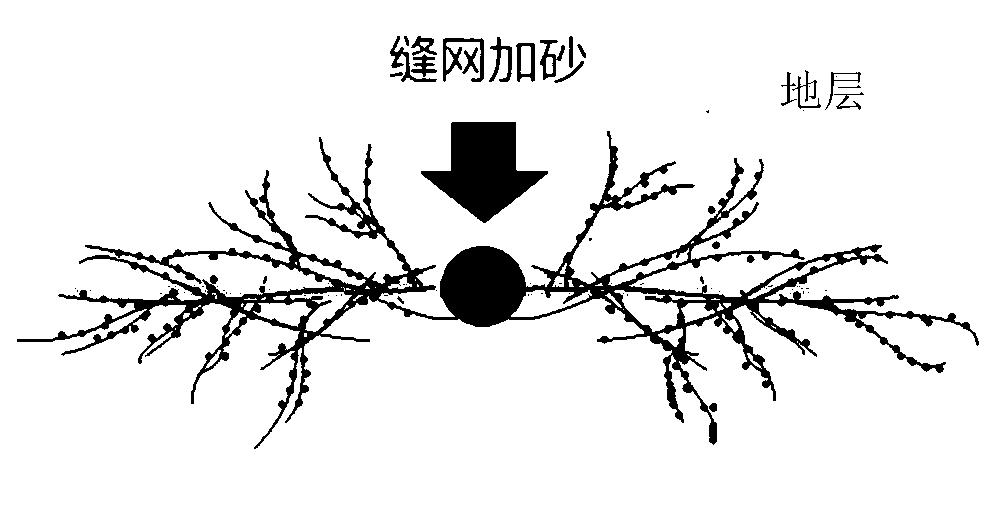

Carbon dioxide-anti-drag water compound fracturing method

InactiveCN105888641ALow flow resistanceInhibit swellingFluid removalDrilling compositionCompound fracturesFracturing fluid

The invention provides a carbon dioxide-anti-drag water compound fracturing method which comprises the following steps of: injecting liquid carbon dioxide fracturing fluid into a stratum; after a period of time, stopping injecting the liquid carbon dioxide fracturing fluid, and then injecting anti-drag water fracturing fluid not added with a propping agent; and after a period of time, stopping injecting the anti-drag water fracturing fluid not added with the propping agent, then injecting anti-drag water compound fracturing fluid carrying the propping agent, and stopping after a period of time. According to the method, different system fracturing fluids are adopted in different injection phases, and special properties of different fracturing fluids are reasonably utilized, so that the effect of enlarging crack network scale, communicating stratum primary fractures, enhancing fracture efficiency, improving the seepage environment of the stratum and improving the reservoir yield; a carbon dioxide-anti-drag water compound fracturing process is applied to a low percolation oil and gas reservoir, so that the per-well yield can be improved, and the problem that traditional fracturing process for low percolation oil and gas reservoirs is poor in productivity improvement effect.

Owner:BEIJING NIUHE RUICHEN ENERGY TECH CO LTD

Method for acidification to dispel block

The present invention discloses an acidizing plugging removal method which comprises steps of: injecting liquid gas as energy increased slug into target layer before traditional acidification process, the liquid gas is liquid nitrogen or liquid carbon dioxide, the injection rate is 1-1.5 stere each meter oil layer, optimal selection is 1.2 stere, the injection speed is 100-250L / min, optimal selection is 200L / min. The method of present invention can relieve zone blocking, improve yield of oil well, successful rate of plugging removal is above 98%, the average base increase production of single well is above 1.5ton / day.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Carbon dioxide anhydrous sand fracturing method

ActiveCN108825194AHigh viscosityImprove sand carrying capacityFluid removalFracturing fluidPressure balance

The invention provides a carbon dioxide anhydrous sand fracturing method. The method comprises the following steps that (1) a gas well and a reservoir which are subjected to carbon dioxide anhydrous sand fracturing are selected; (2) fracturing for fracture forming is carried out, specifically, carbon dioxide is injected into an oil pipe and oil sleeve annulus at the same time, wherein the injection displacement of carbon dioxide prepad is greater than the injection displacement of carbon dioxide in the oil pipe; (3) a gap of a fracturing crack is filled, specifically, a carbon dioxide sand-carrying solution and a viscosity increasing agent are injected into the oil sleeve annulus; and (4) sand stopping and displacing are carried out. Carbon dioxide is simultaneously injected into the oil pipe and the oil sleeve annulus, and pressure balance is achieved; the viscosity increasing agent is added, so that the viscosity and the sand carrying performance of the carbon dioxide are improved, carbon dioxide anhydrous sand fracturing is realized, and the method has the characteristics of small damage to the reservoir, crack filling with a propping agent, and good crack morphology and stability. According to the method, few additives are used, so that the damage and pollution to the environment and the stratum are reduced, and the cost of fracturing fluid is greatly reduced; and carbon dioxide can adsorb and replace natural gas on rock walls, so that the yield of natural gas is improved.

Owner:PETROCHINA CO LTD

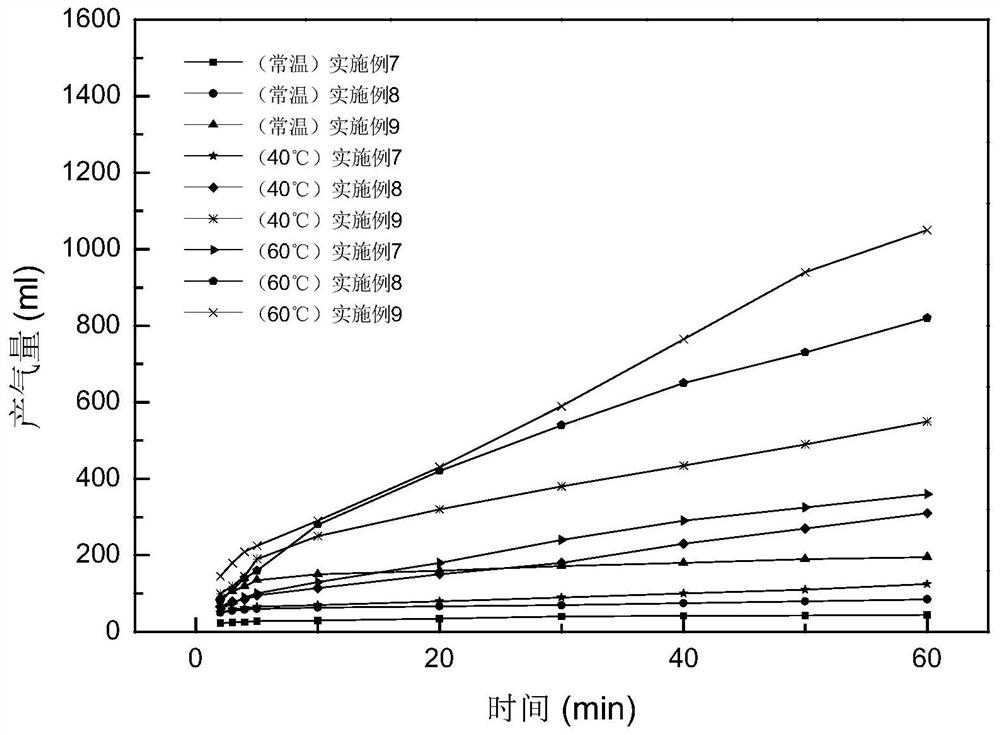

Efficient self-produced gas foam fracturing fluid and construction method thereof

ActiveCN109762549AReduce construction riskIncrease net pressureFluid removalDrilling compositionTruckCorrosion

The invention provides efficient self-produced gas foam fracturing fluid and a construction method thereof. The foam fracturing fluid is composed of base fluid, gas-producing fluid and a heat-producing agent, wherein the mass ratio of the base liquid, the gas-producing liquid and the heat-producing agent is 100:(30 to 42):(5 to 9). During construction, the base liquid and the gas-producing liquidare sucked and pumped into the underground together through a sand mixing truck at the mass ratio, and the heat-producing agent is pumped into the underground along with a propping agent. According tothe efficient self-produced gas foam fracturing fluid and the construction method thereof, liquid nitrogen accompanying injection is not required, the field process is simplified, the construction cost is reduced, and the purpose of increasing formation energy, improving the reservoir fluid flow capacity and increasing production are achieved through a large amount of gas produced by a chemical reaction; a large amount of inert safety gas can be quickly produced, and toxic gas of nitrogen oxide cannot be produced, the construction risks are lowered, and meanwhile, the alkaline environment produced by reaction products is conducive to rubber forming of the fracturing fluid and corrosion protection of down-hole strings; and by producing foam, the net formation pressure is increased througha Jamin effect, fast flowback can be achieved, heat is produced by deep formation to promote rubber breaking, and damage of the fracturing fluid to reservoir is lowered.

Owner:PETROCHINA CO LTD

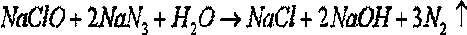

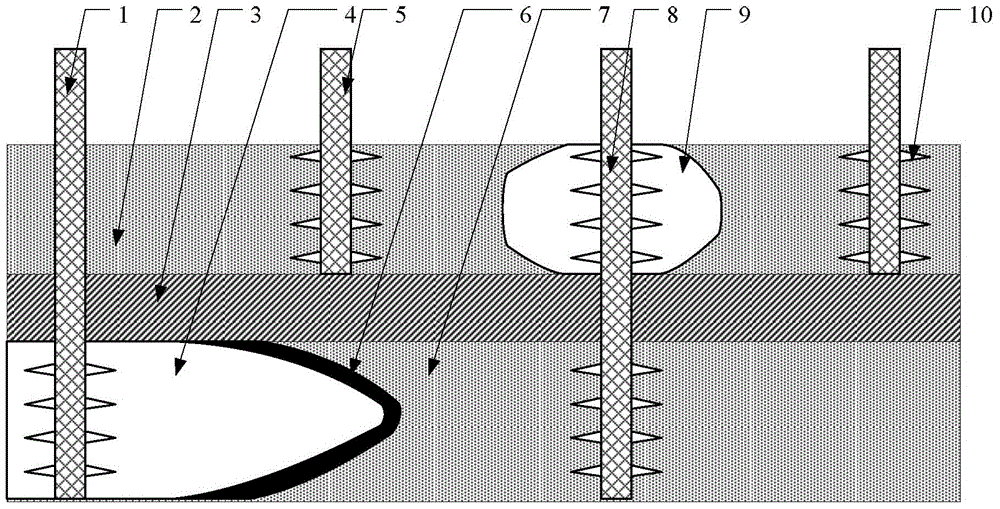

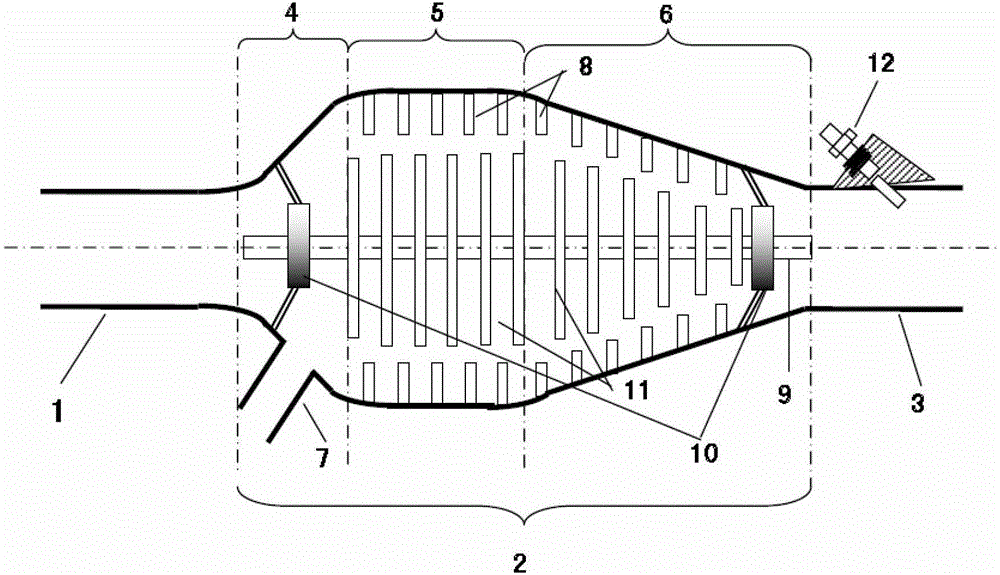

Application of in-situ combustion flue gas to oil deposit exploitation and system

ActiveCN104533368AIncrease oil productionIncrease production capacityFluid removalToxic gasVapor–liquid separator

The invention provides an application of in-situ combustion flue gas to oil deposit exploitation and a system. According to oil deposit exploitation, the flue gas generated by in-situ combustion is reinjected into an adjacent oil reservoir of the in-situ combustion to achieve gas driving of the oil reservoir. Equipment at least comprises a fireflooding oil reservoir and a steam injection oil reservoir. The flue gas down-hole reinjection system comprises a casing pipe (21), a gas injection perforating pipe (22) and an oil-extraction oil pipe (23), wherein the gas injection perforating pipe (22) and the oil-extraction oil pipe (23) are arranged in the casing pipe side by side. A one-way valve (29) is arranged at the position, opposite to the bottom of the in-situ combustion, of the gas injection perforating pipe, and a hole (210) is formed in the position, opposite to the steam injection oil reservoir, of the gas injection perforating pipe. A gas-liquid separator (28) is arranged at the position, opposite to the bottom of the in-situ combustion, of the oil-extraction oil pipe. According to the application and the system, effective utilization of the flue gas is ensured, and the ground treatment and reinjection process is simplified; a flue gas injection target oil reservoir is effectively controlled, and therefore the production safety in the air injection process is ensured; due to oil reservoir flue gas driving, the recovery ratio of a heavy oil reservoir is increased, and the emission of greenhouse gas and poisonous gas is reduced.

Owner:PETROCHINA CO LTD

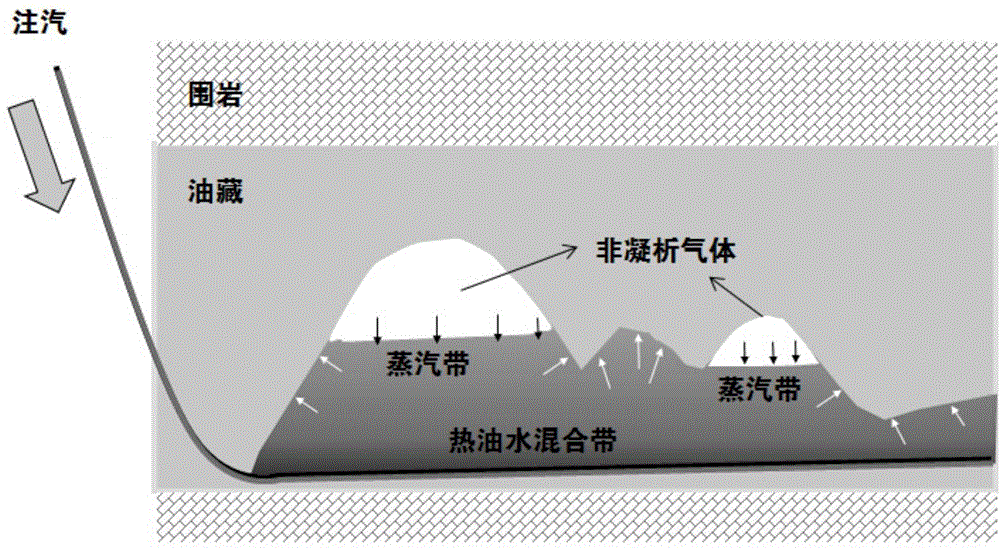

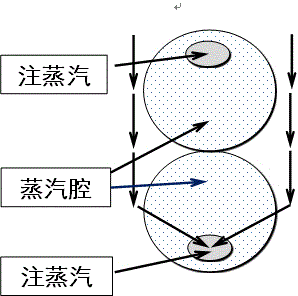

Steam huff and puff exploitation method

InactiveCN104389569AIncrease injection volumeImprove flowback capacityFluid removalProduct gasHydrocarbon

The invention provides a steam huff and puff exploitation method. The method comprises the following steps: selecting a well network of a closed horizontal well as an injection and exploitation well network; injecting non-condensed non-hydrocarbon gas into the injection and exploitation well network, wherein the injection amount is calculated according to the following formula: Q=AV / T, wherein Q is a ground injection amount of the non-condensed non-hydrocarbon gas, the unit of Q is m<3>, V is a ground layer voidage volume, the unit of V is m<3>, A is 9669, T is a ground layer temperature, and the unit of T is K; continuously injecting high-temperature steam into the injection and exploitation well network; carrying out a huff and puff production process, and carrying out sleeve gas monitoring in the production process; when the content of injected gas is raised to 70%-100%, closing a well for 6-12 hours; after a gas-liquid interface is recovered, opening the well to produce. The steam huff and puff exploitation method provided by the invention can be used for steam huff and puff exploitation of heavy oil reservoirs, and the steam huff and puff exploitation effect of the heavy oil reservoirs can be effectively improved.

Owner:PETROCHINA CO LTD

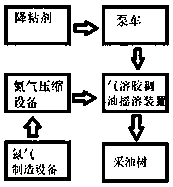

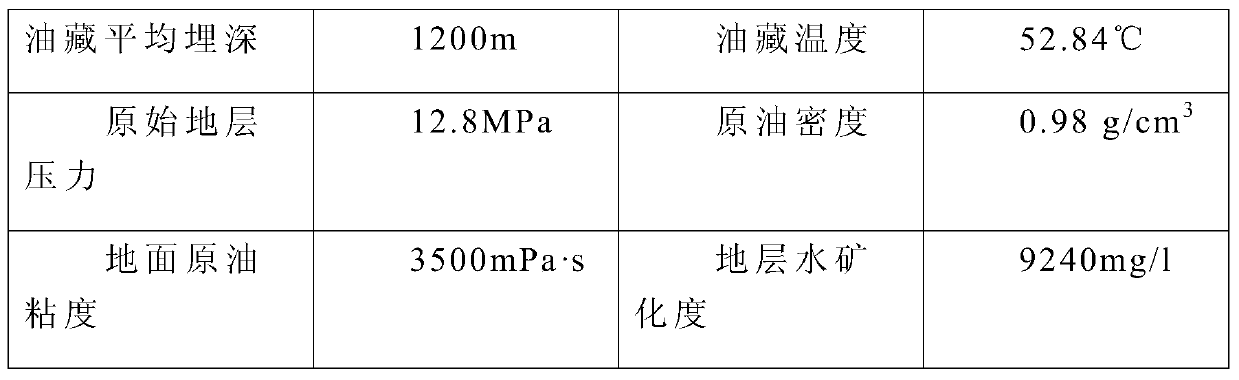

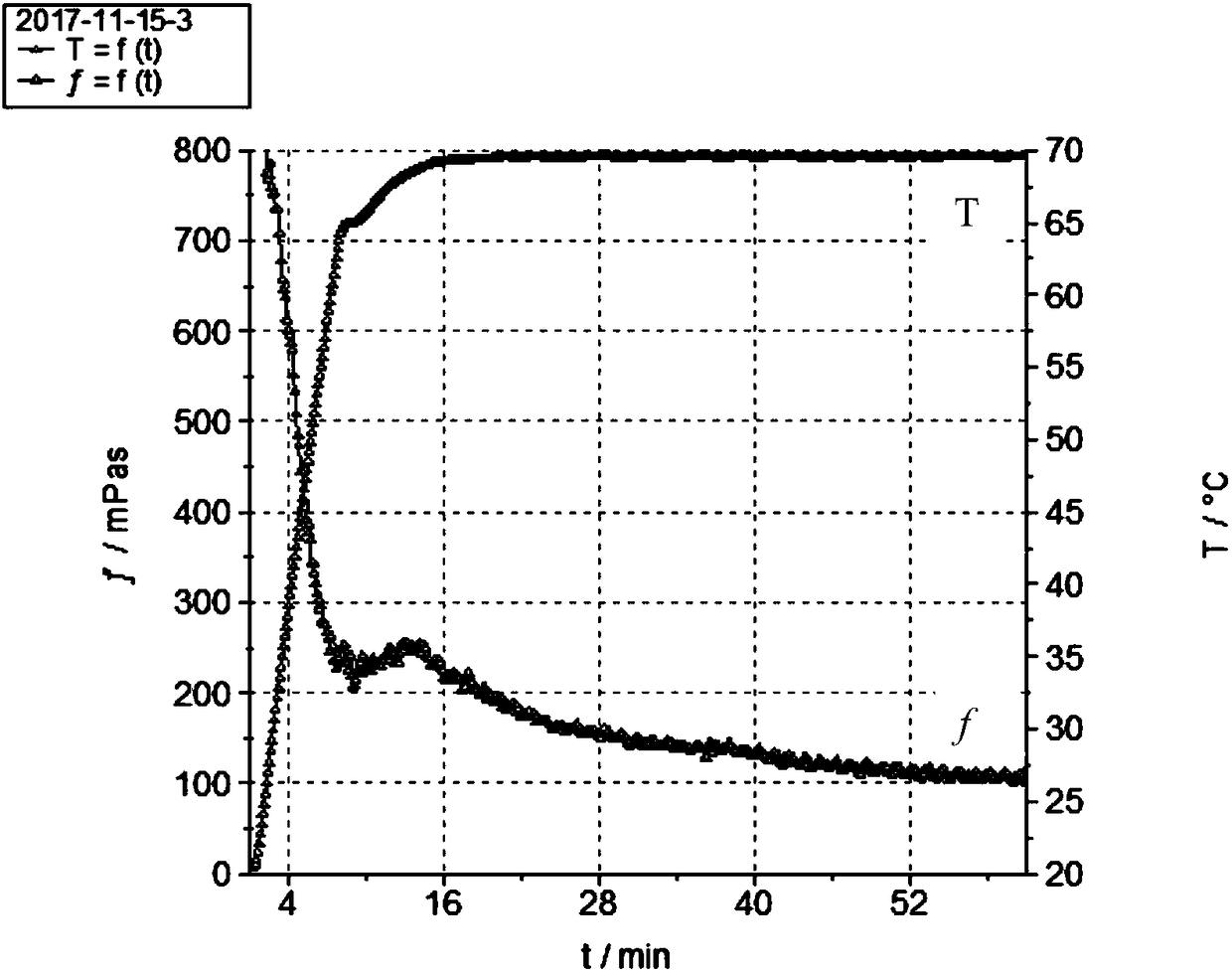

Aerosol heavy oil shaking and dissolving device and viscosity reducing method

The invention discloses an aerosol heavy oil shaking and dissolving device and a viscosity reducing method. Nitrogen is produced by ground equipment, and the nitrogen is pressurized by using nitrogencompression equipment and input into an air inlet pipe of the aerosol heavy oil shaking and dissolving device; meanwhile, a viscosity reducer is injected into a liquid inlet pipe of the aerosol heavyoil shaking and dissolving device by a pumper, the nitrogen and the viscosity reducer are mixed and atomized to form aerosol in the aerosol heavy oil shaking and dissolving device to be pumped into downhole; and after injection is completed, a well is shut in and soaked, and after the aerosol fully reacts with an oil reservoir, the well is opened for production. The aerosol heavy oil shaking and dissolving device is applied to the oil and gas field exploitation process, the nitrogen and chemical agents into the well are atomized to squeeze and inject into an oil layer of an oil well to ensurenormal production of the oil well through a ground aerosol generator.

Owner:CHINA PETROLEUM & CHEM CORP +1

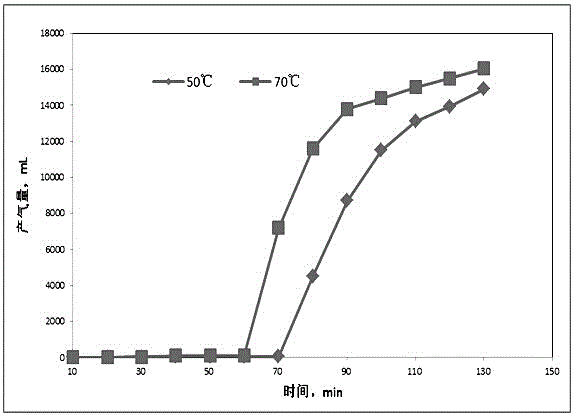

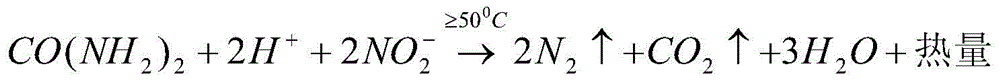

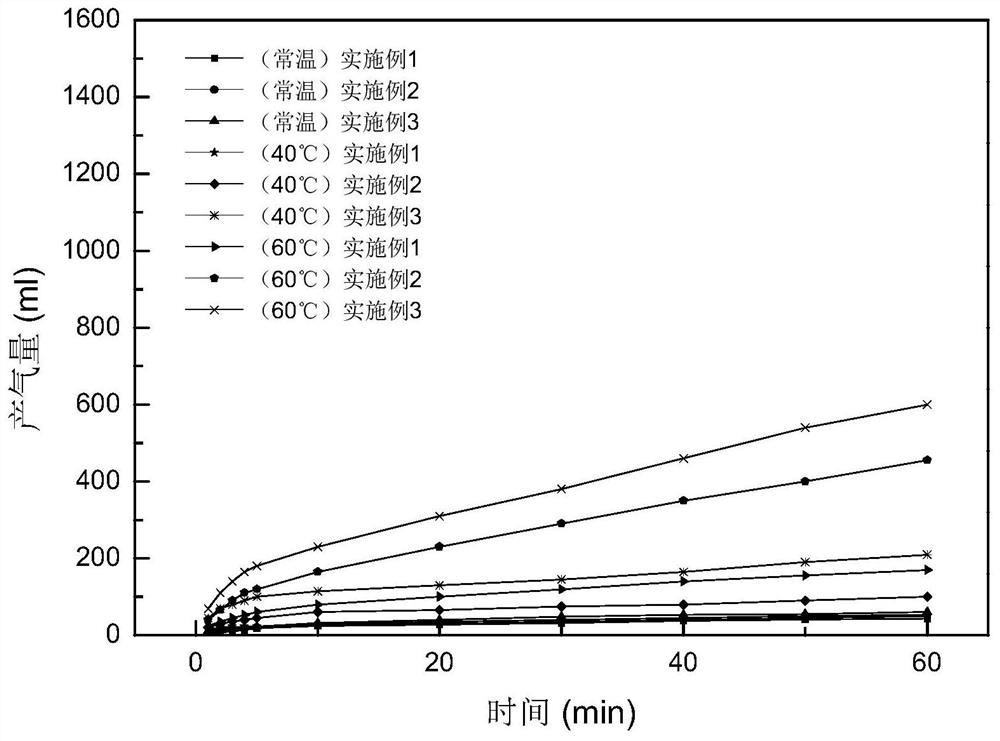

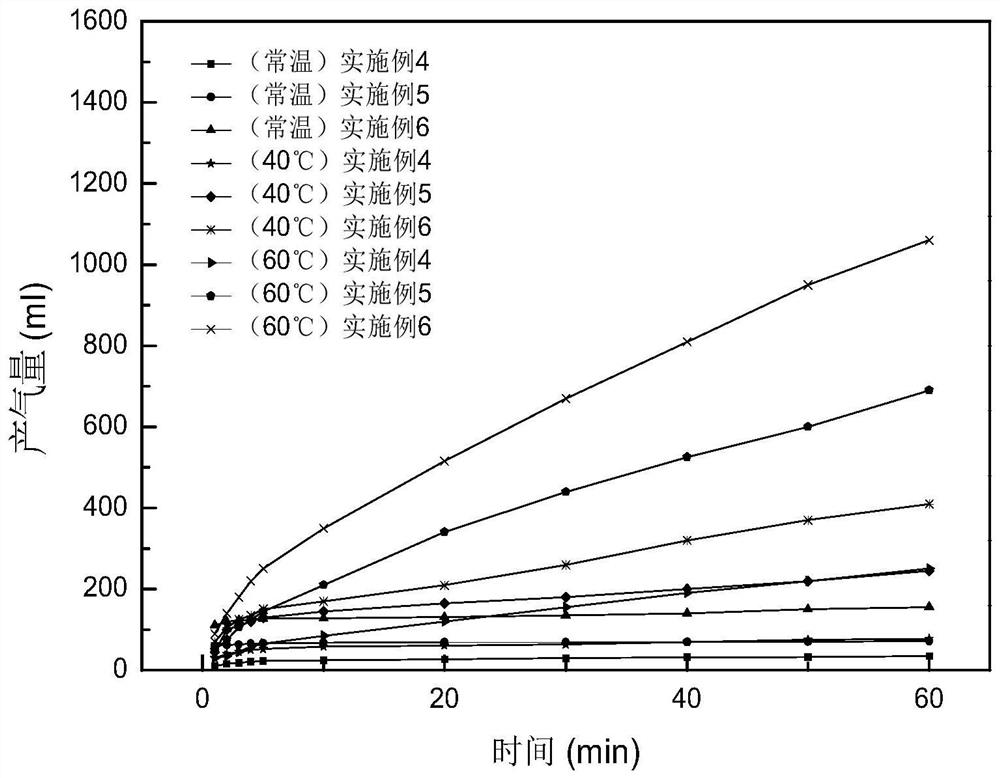

Gas-producing system capable of improving permeability of tight oil reservoir and application thereof

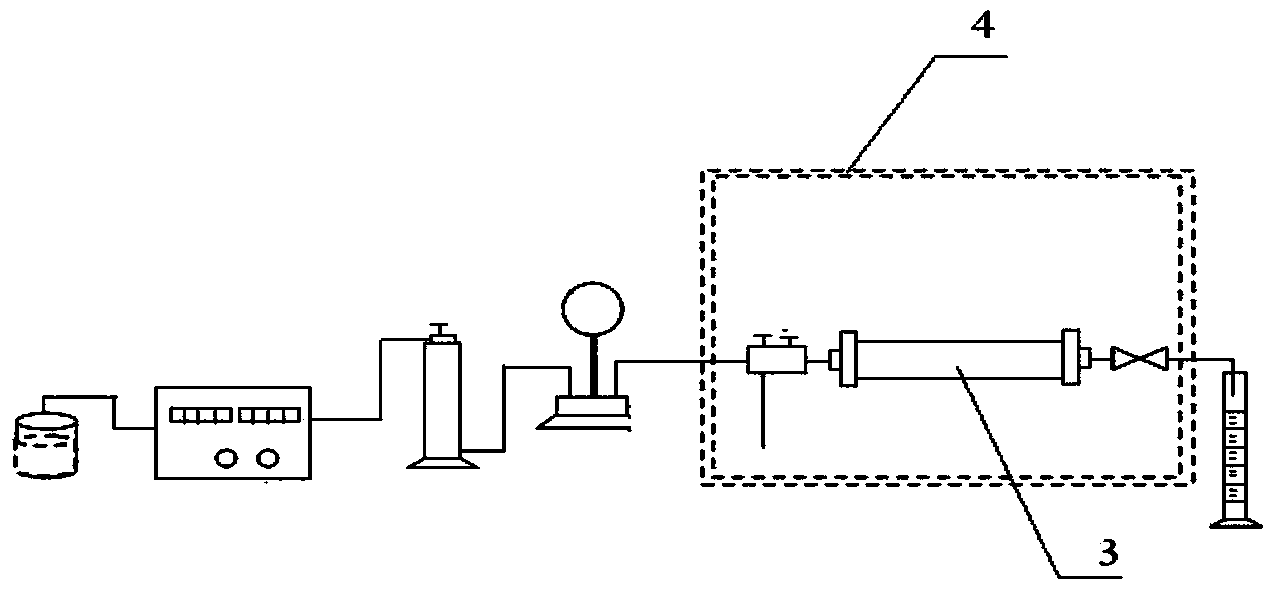

ActiveCN105838347AImprove flowback rateImprove seepage capacityFluid removalDrilling compositionChemical reactionHigh pressure

The invention provides a gas-producing system capable of improving permeability of a tight oil reservoir and application thereof, belonging to the technical field of oilfield development. The gas-producing system comprises a microcapsule and hydrochloric acid; the microcapsule uses a mixture of urea and sodium nitrite as a core material and a mixture of azodiisobutyronitrile, styrene, methyl methacrylate and methacrylic acid as a capsule dressing. In operation, nitrite and the microcapsule are injected into a stratum to a predetermined depth; and the microcapsule undergoes corrosion under stratum conditions and chemically reacts with hydrochloric acid to produce a great amount of gas and release a great amount of heat, so local high pressure is formed in a predetermined part. According to the invention, effective seepage channels of difficult-to-produce reserves such as an ultralow-permeability oil reservoir and the tight oil reservoir are increased so as to improve permeability, increase local energy of reservoirs and the flowback rate of raffinate, and reduce reservoir contamination, so the purpose of improving the recovery efficiency of the difficult-to-produce reserves is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving thick oil recovery ratio

The invention discloses a method for improving thick oil recovery ratio. The method comprises the followings steps of: first, injecting 5 to 10 mass percent crude oil extracting agent aqueous solution; then, injecting 10 to 50 m<3> of 40 to 50 mass percent urea aqueous solution; and finally, injecting steam, and simultaneously injecting an crude oil extracting agent dropwise in the process of injecting the 20 to 80 percent of steam or injecting an oil deposit protective agent accomplished with the injection of the crude oil extracting agent each time. By utilizing the characteristics of the crude oil extracting agent, the crude oil extracting agent can search thick oil automatically; because the composition particles of the crude oil extracting agent are close to nano-scale, the functionsof compatibilization and catalysis of the thick oil are derived; and the crude oil extracting agent can rapidly search the thick oil and oil dirt, adsorb on the surfaces of the thick oil and the oil dirt, penetrate and decompose the thick oil and the oil dirt so as to be brought out of the stratum.

Owner:SUNCOO PETROLEUM TECH

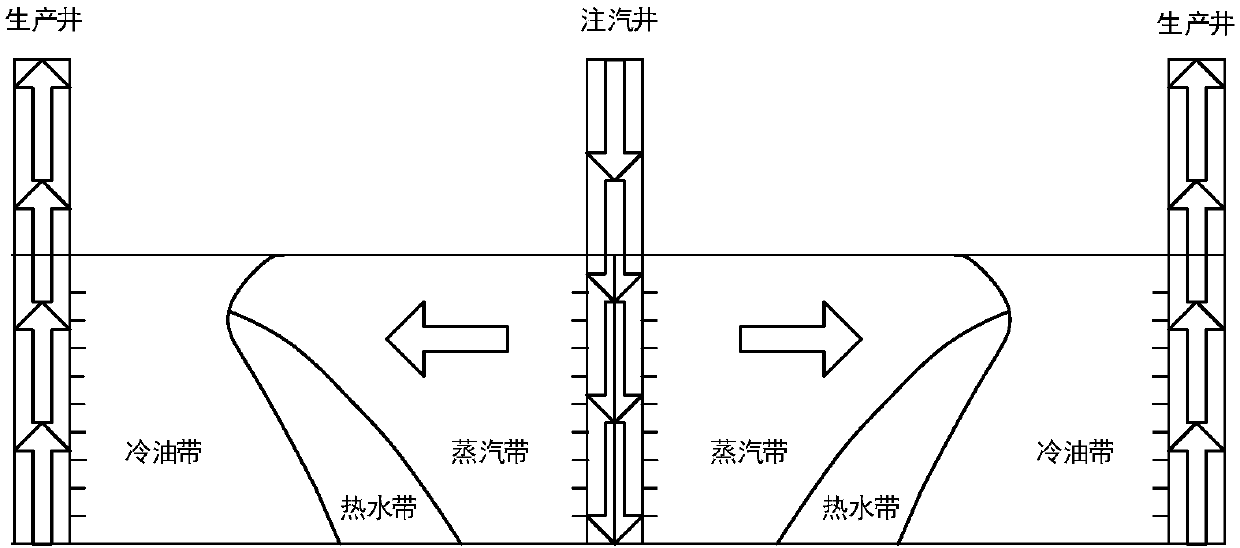

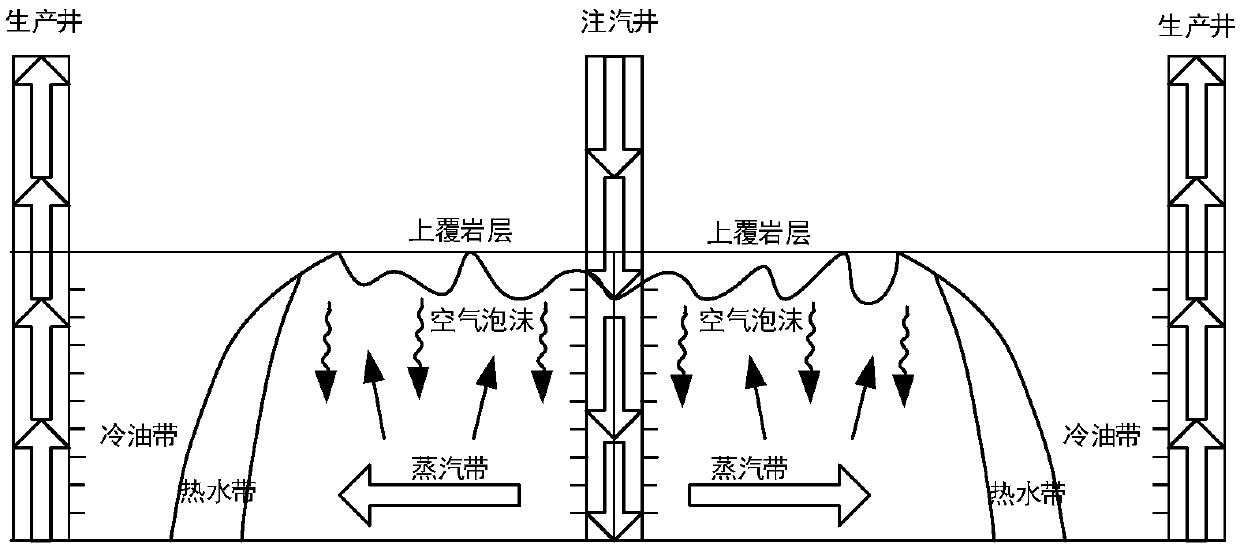

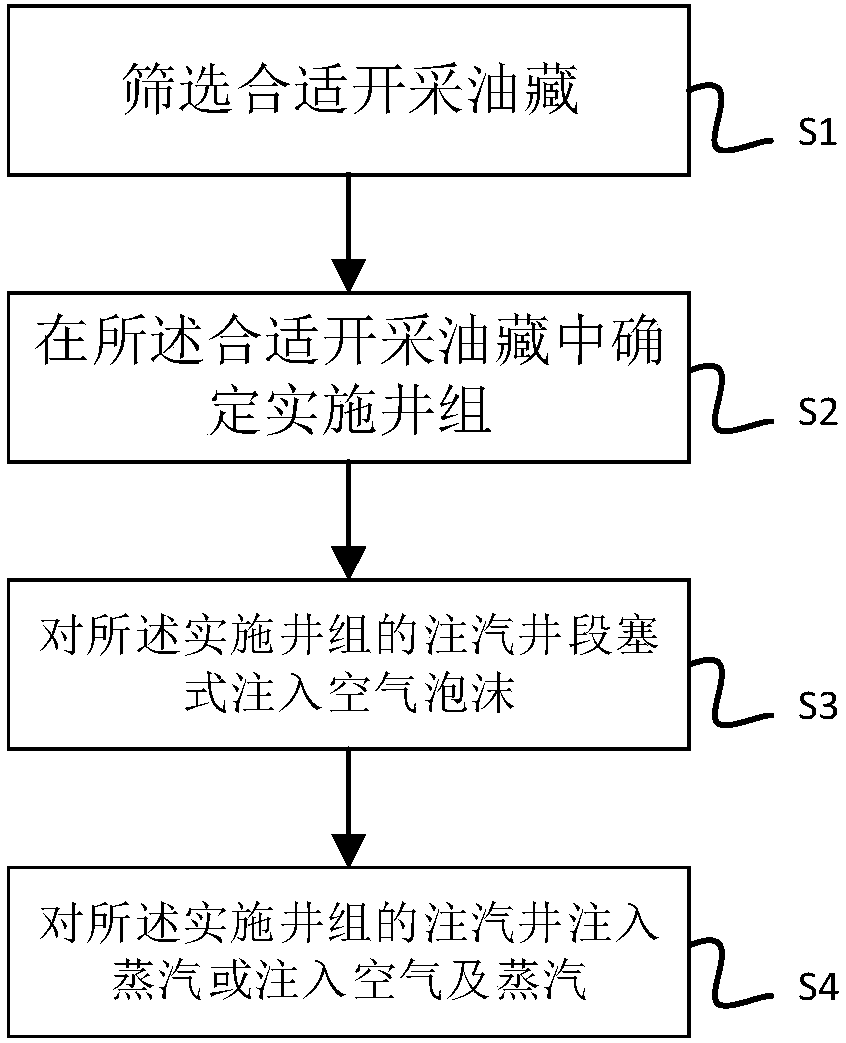

Method and system of air foam to assist steam flooding to exploit heavy oil reservoir

InactiveCN107893647AWide variety of sourcesNo pollution in the processFluid removalHigh water contentSteam injection

The invention discloses a method and system of air foam to assist steam flooding to exploit a heavy oil reservoir. The method of air foam to assist steam flooding to exploit the heavy oil reservoir comprises the steps that an appropriately exploited oil reservoir is screened; an implemented well group is determined in the appropriately exploited oil reservoir; a steam injection well section of theimplemented well group is injected with air foam in a plugged mode; and steam or air and steam are injected into a steam injection well of the implemented well group. The method and system of air foam to assist steam flooding to exploit the heavy oil reservoir are suitable for heavy oil reservoir profile controlling and flooding with a high water content and serious heterogeneous, and accordinglythe purposes that gas channeling of a high permeability layer is blocked, and the oil recovery rate is improved are achieved.

Owner:PETROCHINA CO LTD

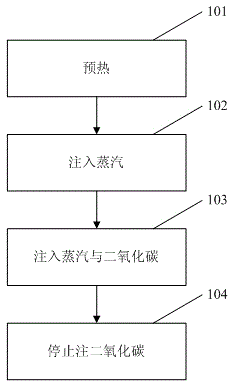

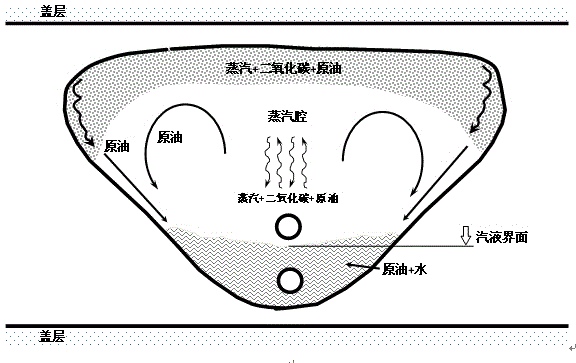

Steam-carbon dioxide assisted gravity oil drainage oil production method

InactiveCN104975834AEnhanced overall recoverySlow down condensationFluid removalHorizontal wellsHeat losses

The invention provides a steam-carbon dioxide assisted gravity oil drainage oil production method, which comprises the following steps of: 1, preheating two horizontal wells in parallel distribution; 2, injecting steam into the upper part horizontal well, and maintaining the original formation pressure in the lower part horizontal well for production; 3, simultaneously injecting the steam and carbon dioxide into an oil layer through the upper part horizontal well, and maintaining the original formation pressure in the lower part horizontal well for production; and 4, stopping the carbon dioxide injection, continuously injecting the steam into the upper part horizontal well, and continuously performing production in the lower part horizontal well. The steam-carbon dioxide assisted gravity oil drainage oil production method has the advantage that through a steam assisted gravity oil discharge technology for reducing the crude oil viscosity, reducing the shaft heat loss and improving the steam enthalpy through adding the carbon dioxide, the recovery ratio of a super-heavy oil reservoir can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

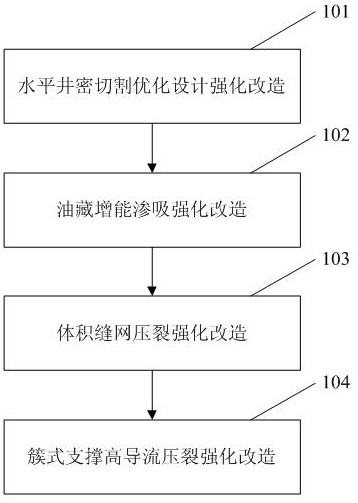

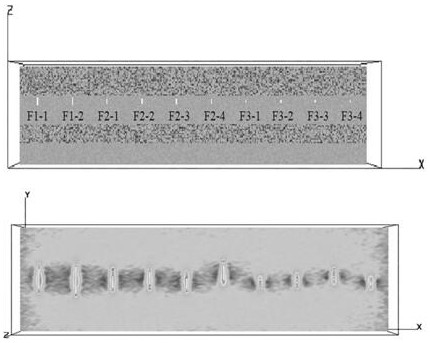

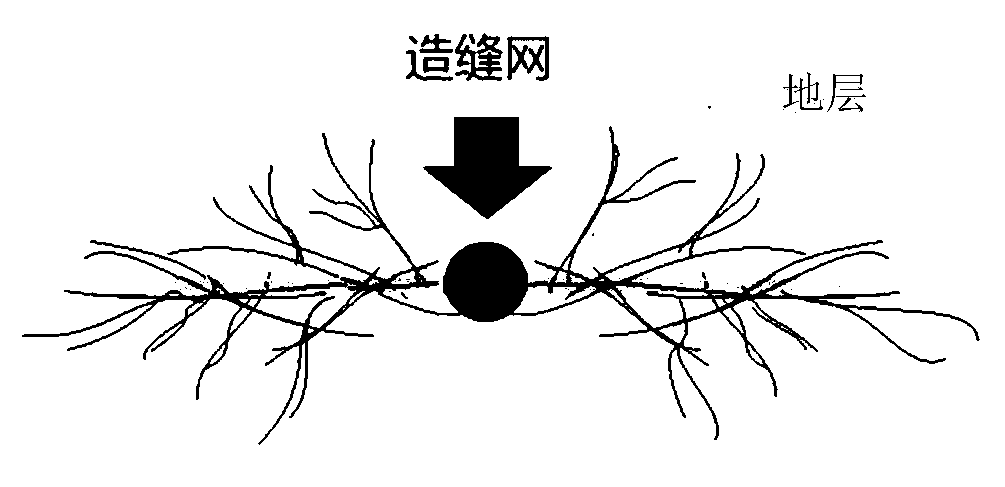

Continental facies tight oil reservoir volume transformation strengthening fracture network fracturing method

ActiveCN113417616AAchieve transformationTransformation is effectiveSurveyOther gas emission reduction technologiesMining engineeringHorizontal wells

The invention provides a continental facies tight oil reservoir volume transformation strengthening fracture network fracturing method. The continental facies tight oil reservoir volume transformation strengthening fracture network fracturing method comprises the steps that step 1, a tight oil reservoir full-three-dimensional horizontal well fracturing geomechanical model containing a single fracturing section is established, and horizontal well close cutting optimization design strengthening transformation is carried out; step 2, energy-increasing imbibition reinforced transformation is carried out on the oil reservoir; step 3, a full-three-dimensional horizontal well fracturing geomechanical model of the tight oil reservoir block is established, and volume fracture net fracturing strengthening transformation is carried out; and step 4, main crack cluster type support high flow guide fracturing strengthening transformation is carried out. According to the continental facies tight oil reservoir volume transformation strengthening fracture network fracturing method, the volume transformation strengthening fracture network fracturing technology is developed on the basis of the volume fracturing technology, namely, the technological means for improving the initial yield and the final recovery efficiency of the oil reservoir are fully considered in all links of the fracturing technology, and the effective reservoir transformation volume maximization is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

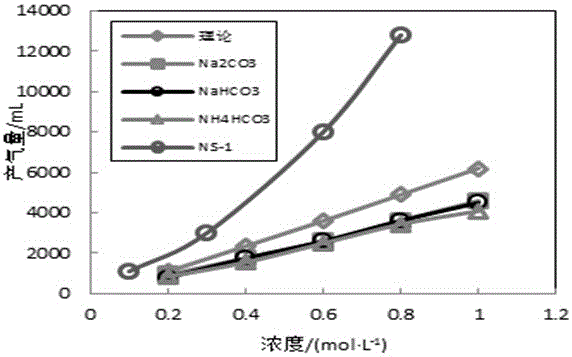

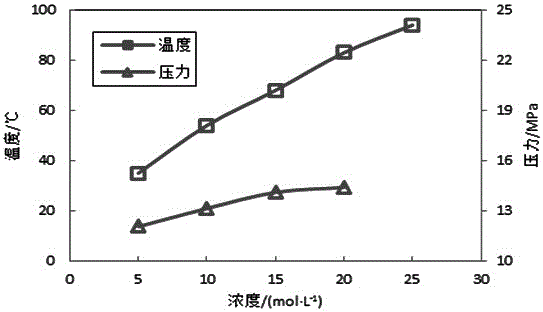

Self energy generating type clean fracturing fluid and preparation method thereof

InactiveCN108531160ALow costReduce manufacturing costDrilling compositionSodium bicarbonatePotassium

The invention discloses self energy generating type clean fracturing fluid which is prepared from the following raw materials in weight percentage: 1.5% to 5.5% of C12 to C22 quaternary ammonium saltcationic surface active agent, 0.25% to 0.70% of salicylic acid, 1.0% to 4.0% of chloride, 2.0% to 4.5% of carbon dioxide releasing agent and the balance of water, when the chloride is potassium chloride and / or ammonium chloride, and the carbon dioxide releasing agent is sodium carbonate or sodium bicarbonate. In addition, the invention further discloses a preparation method of the fracturing fluid. Compared with existing clean fracturing fluid, preparation cost of the self energy generating type clean fracturing fluid is remarkably reduced; the raw materials react to generate a micelle accelerant and release a lot of CO2 gas at the same time to form gel foam, and the gel foam has the performance characteristics of the foam fracturing fluid; meanwhile, stratum energy is increased, and flowback of gel breaking fluid is facilitated; the fracturing fluid has no residue and low harm and is especially suitable for fracturing increasing and production increasing of low-pressure, low-permeation and low-temperature oil gas.

Owner:XI'AN PETROLEUM UNIVERSITY

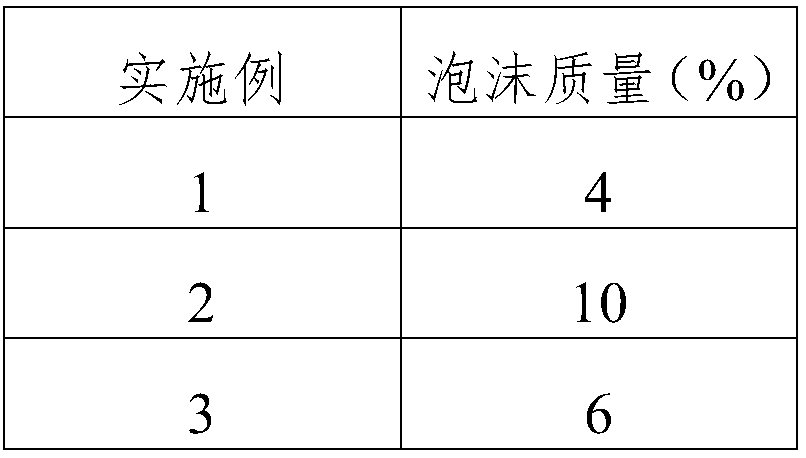

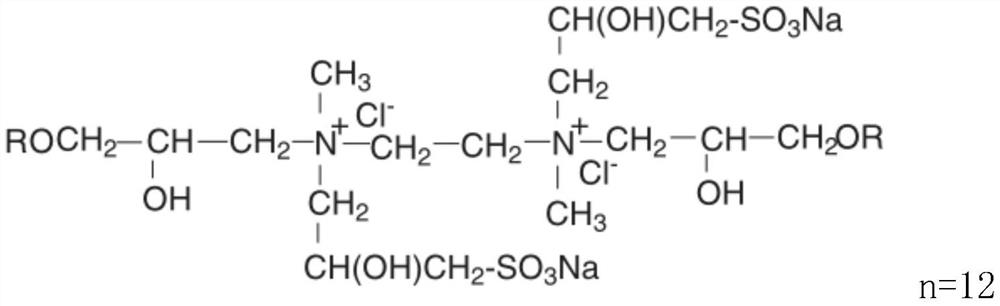

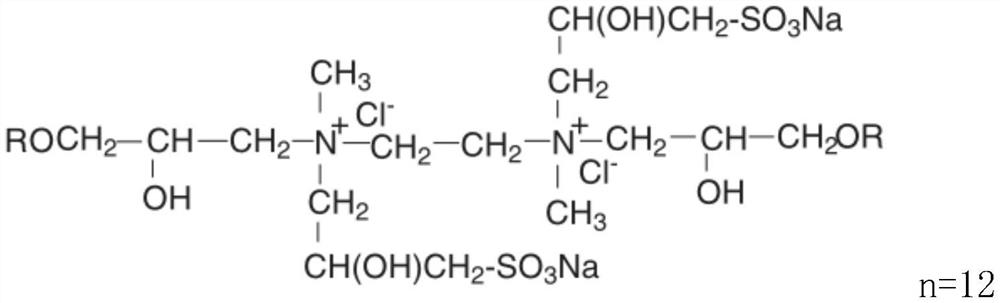

Ultra-low interfacial tension self-assembly carbon dioxide foam oil-displacing agent suitable for low-permeability reservoir as well as preparation method and application of oil-displacing agent

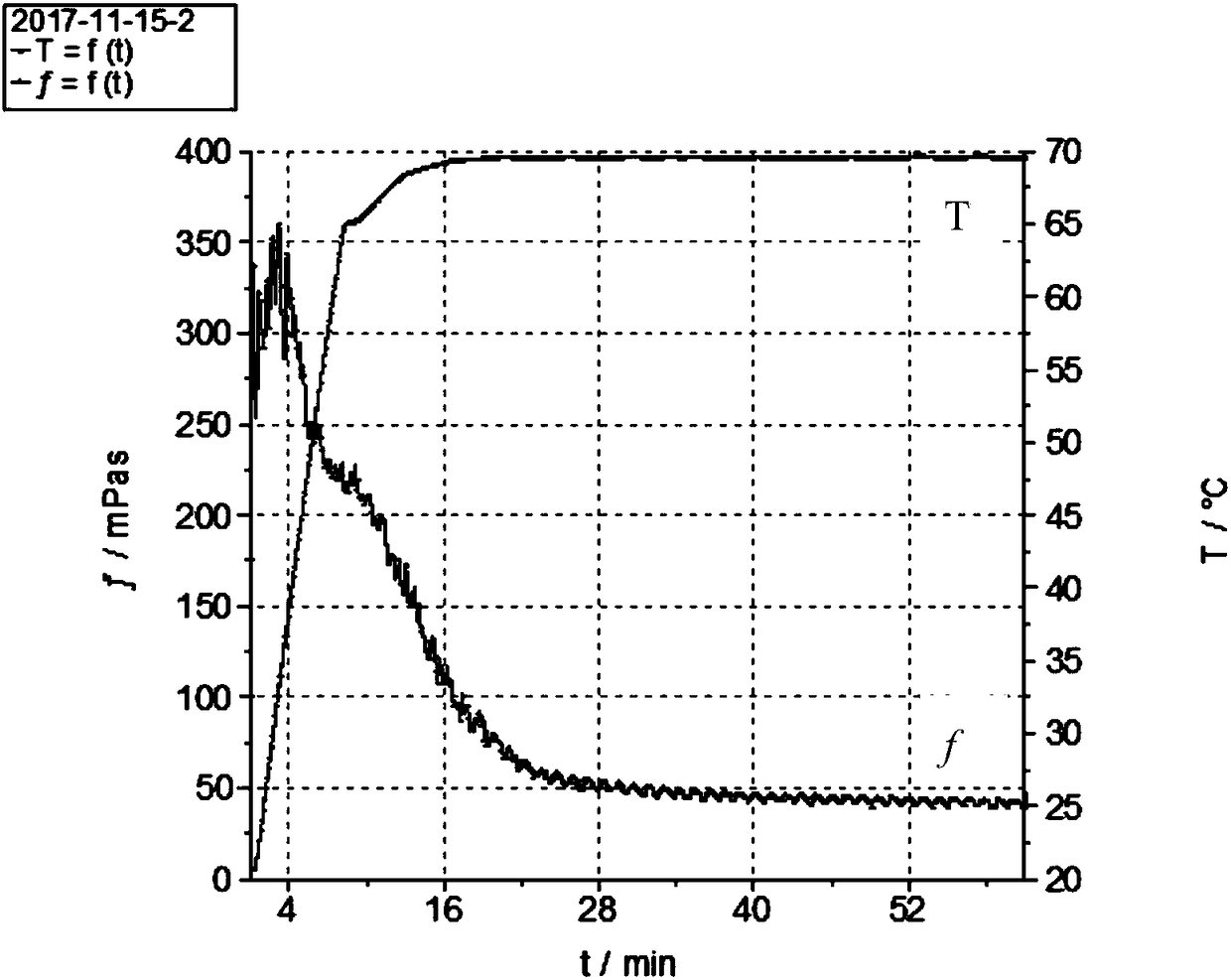

ActiveCN114196389AExtended half-lifeFine foamFluid removalDrilling compositionBetaineLiquid viscosity

The invention provides an ultralow interfacial tension self-assembly carbon dioxide foam oil displacement agent suitable for a low-permeability reservoir. The oil displacement agent is prepared from the following components in percentage by weight: 0.2-0.3% of {bis [N-methyl-N-(3-dodecyloxy-2-hydroxyl) propyl-N-(2-hydroxy-3-sodium sulfonate) propyl] ammonium chloride} ethane, 0.2-0.3% of cocamidopropyl betaine, 0.2-0.3% of sodium dodecyl benzene sulfonate and the balance of water. The cleaning agent is prepared from the following components in percentage by weight: 0.1 to 0.35 percent of dodecyl dimethyl amine oxide, 0.02 to 0.07 percent of sodium salicylate, 0.04 to 0.14 percent of chelating agent, 5 to 7 percent of inorganic salt and the balance of water. The invention also provides a preparation method and application of the self-assembled carbon dioxide foam oil-displacing agent with ultralow interfacial tension. The self-assembled carbon dioxide foam oil-displacing agent is good in salt resistance and acid resistance and high in foaming liquid viscosity, enables oil-water interfacial tension to reach 10 <-3 > mN / m order of magnitude and below, generates fine and rich foam, is good in stability, is good in injectability in a low-permeability reservoir, and can improve the oil-water mobility ratio, remarkably increase the sweep efficiency, reduce the oil-water interfacial tension and remarkably improve the oil washing efficiency; the foaming agent does not generate a salting-out phenomenon, and does not generate chemical reaction with calcium and magnesium ions to generate precipitates.

Owner:YANCHANG OIL FIELD +2

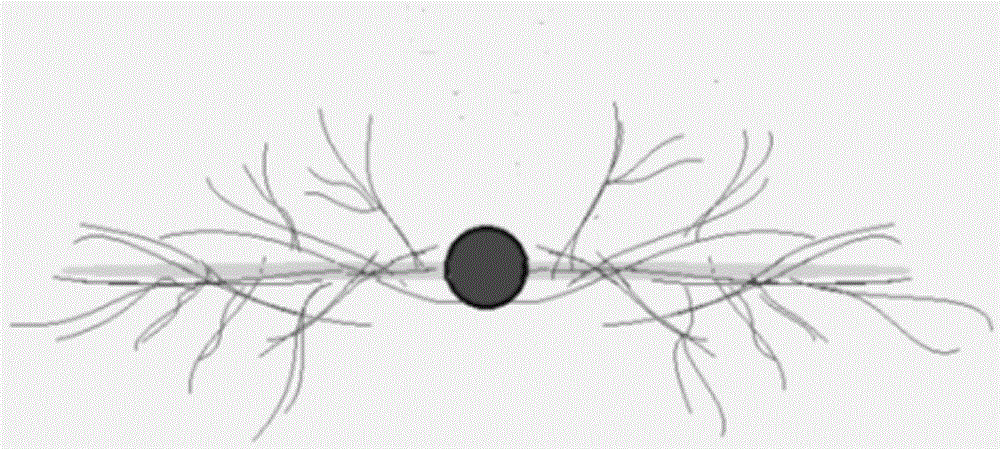

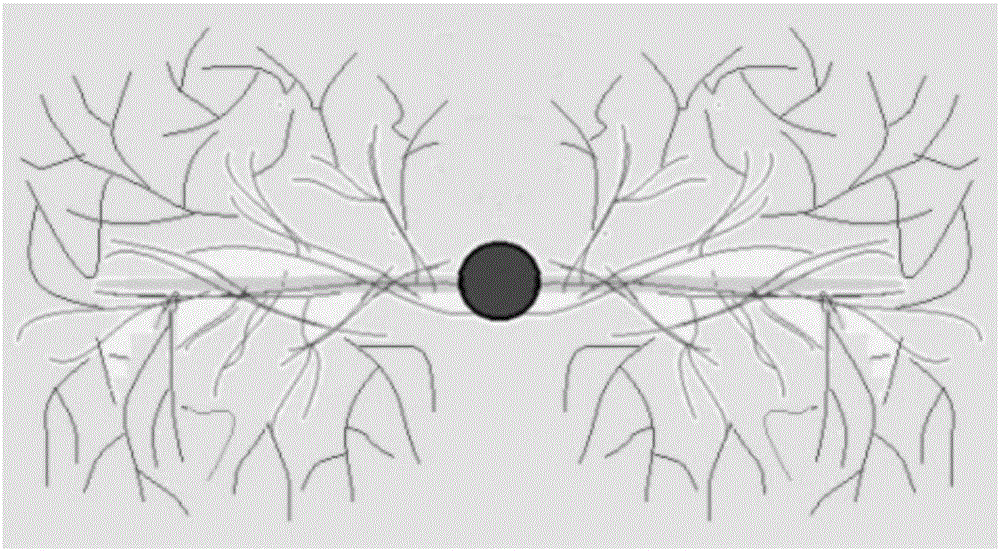

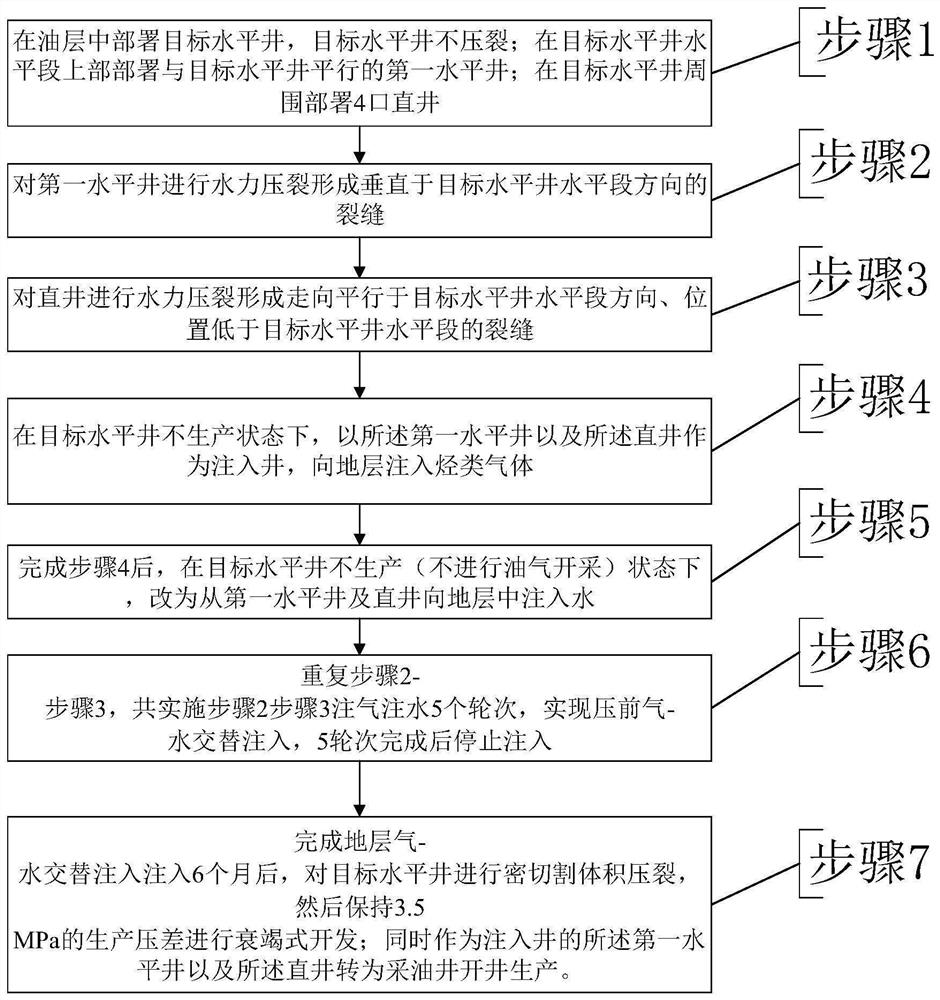

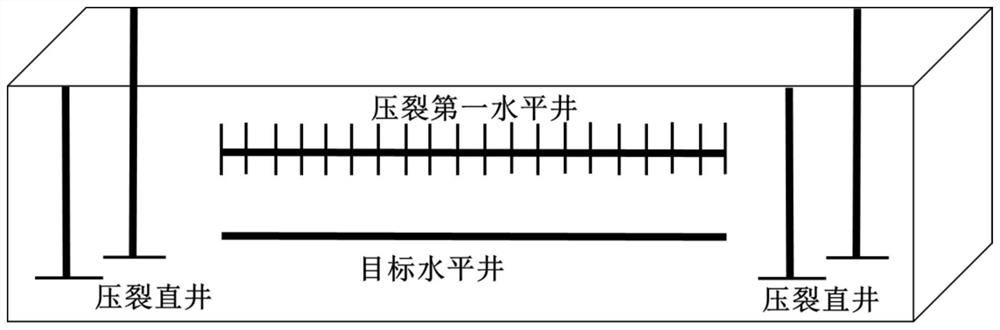

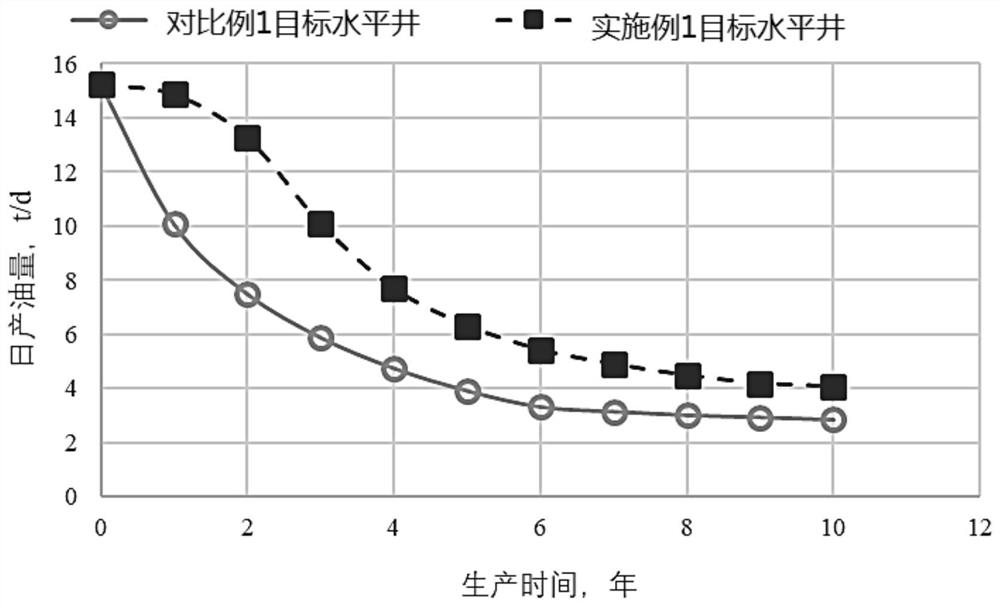

Horizontal well pre-fracturing injection fluid development method based on three-dimensional fracturing well pattern

ActiveCN112302608AImprove liquidityIncrease formation energyFluid removalHorizontal wellsEngineering

The invention provides a horizontal well pre-fracturing injection fluid development method based on a three-dimensional fracturing well pattern. The method comprises the steps that 1, a target horizontal well is deployed in an oil layer, and the target horizontal well is not fractured, a first horizontal well parallel to the target horizontal well is deployed at the upper part of the horizontal section of the target horizontal well, and fracturing is carried out on the first horizontal well to form a crack perpendicular to the direction of the horizontal section of the target horizontal well,a vertical well is deployed around the target horizontal well, and fracturing is carried out on the vertical well to form another crack of which the trend is parallel to the direction of the horizontal section of the target horizontal well and the position is lower than that of the horizontal section of the target horizontal well; 2, under the condition that the target horizontal well is not fractured and does not produce, the first horizontal well and the vertical well serve as injection wells, and energy supplementing fluid is injected into a stratum; and 3, after stratum energy supplementing fluid injection is completed, fracturing is carried out on the target horizontal well, and well opening production is carried out, and meanwhile, the first horizontal well and the vertical well which sever as the injection wells are converted into oil production well for well opening production.

Owner:PETROCHINA CO LTD

Super guar gum foamed fracturing fluid injected with liquid nitrogen for low-permeability gas reservoir and preparation method thereof

ActiveCN102093875BImprove performanceLow residue contentDrilling compositionSwelling capacityFracturing fluid

The invention relates to the technical field of fracturing fluid used in a compression fracture yield increasing process of an oil well or a natural gas well, in particular relating to super guar gum foamed fracturing fluid injected with liquid nitrogen for a low-permeability gas reservoir. The preparation method of the super guar gum foamed fracturing fluid comprises the following steps: homogeneously mixing a base solution with a crosslinking solution to obtain a semi-finished product of the super guar gum foamed fracturing fluid; and adding a viscosity breaking agent and injecting liquid nitrogen into the semi-finished product to obtain the super guar gum foamed fracturing fluid injected with liquid nitrogen for on-site construction. The super guar gum foamed fracturing fluid provided by the invention has the advantages of good swelling capacity, stable nature of foam, low content of fracturing fluid residue and good viscosity breaking performance, and can be used for reducing the damage to reservoir bed, increasing the strata energy after fracturing, and improving the flowback efficiency.

Owner:CNPC XIBU DRILLING ENG

Staged fracturing transformation process for increasing single well yield of ultra-low permeability reservoir horizontal well

InactiveCN108756842AReduce displacementThe scale of the transformation is smallDrilling rodsFluid removalMulti clusterSoil science

The invention provides a staged fracturing transformation process for increasing the single well yield of an ultra-low permeability reservoir horizontal well. The staged fracturing transformation process comprises the steps that according to the characteristics that natural cracks in an ultra-low permeability reservoir are not developed and artificial cracks are single cracks, the fracturing construction displacement is determined to be 3-4 m<3> / min, and then fracturing is conducted through a continuous tubing fracturing pipe string. The traditional technical idea of staged multi-cluster volume fracturing of the ultra-low permeability horizontal well is changed, meanwhile, the intra-segment double-cluster mode in the past is changed into the intra-segment single-cluster mode, the single-segment transformation scale is lowered, the operation cost is lowered, and the transformation pertinence is improved; the segment separation distance is decreased from 80-100 m under 6 m<3> / min volumefracturing in the past into 40-50 m under 4 m<3> / min fracturing, and through dense seam laying and increasing of the number of fracturing transformation segments, the contact area of the hydraulic cracks and the reservoir is greatly increased; and through the matched continuous tubing operation technology, inter-segment fracturing liquid is not sprayed, on the basis of improving the construction efficiency, the formation energy is increased, and yield decreasing is delayed.

Owner:PETROCHINA CO LTD

A liquefied petroleum gas-carbon dioxide water-enhanced composite fracturing method

InactiveCN107842351BReduce harmImprove liquidityFluid removalDrilling compositionFracturing fluidLiquid carbon

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

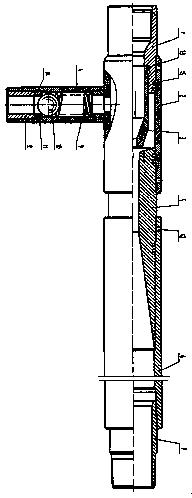

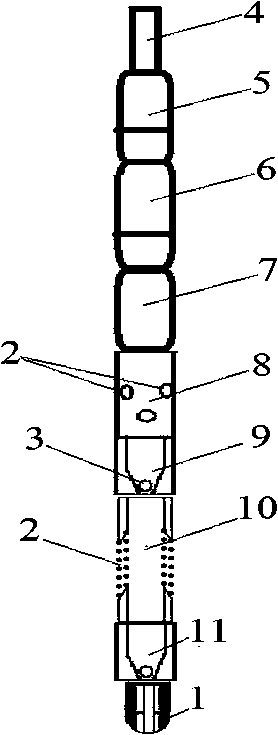

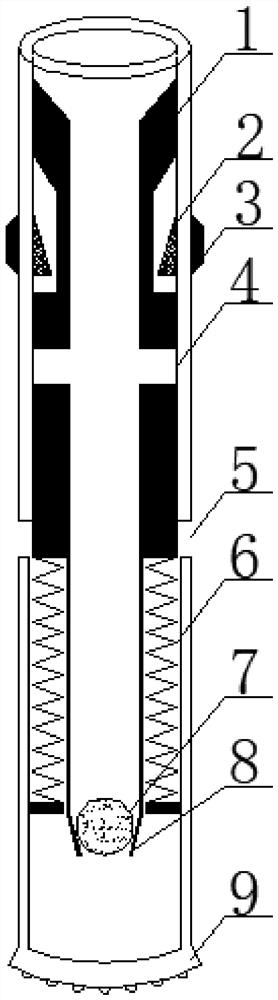

A construction tool and method for improving the recovery rate of horizontal wells in low-permeability reservoirs

ActiveCN113006750BImprove utilizationHigh yieldFluid removalWell/borehole valve arrangementsHorizontal wellsClassical mechanics

Owner:NORTHWEST UNIV +1

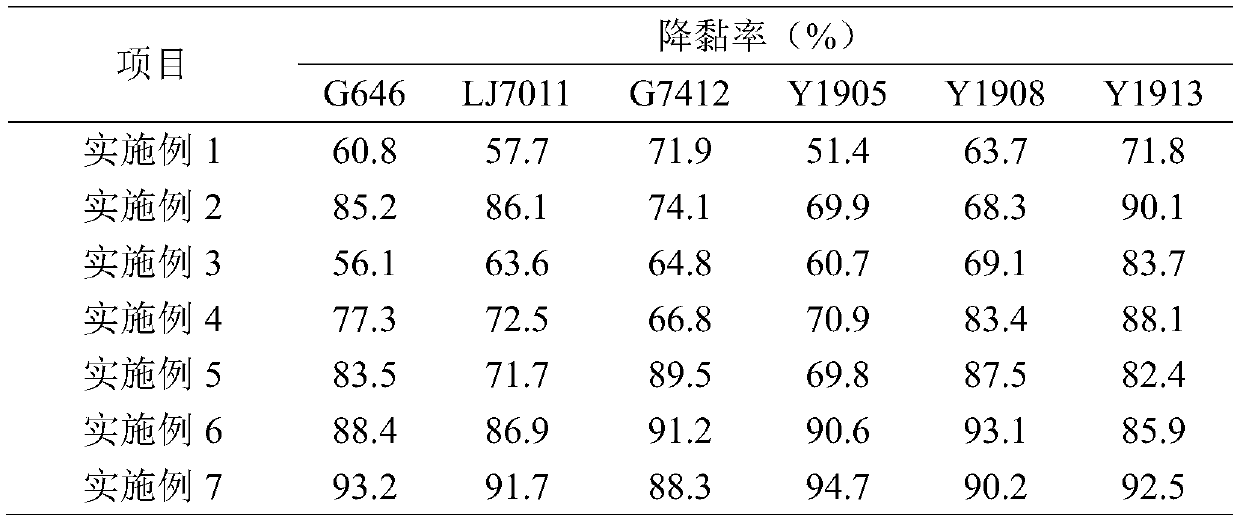

Viscosity-reducing and drainage-aiding composition for heavy oil, viscosity-reducing and drainage-aiding agent, preparation method and application

ActiveCN106967404BLower dynamic viscosityImprove wettabilityFluid removalDrilling compositionSulfonateRock core

The invention discloses a viscosity-reducing and cleanup composition for thickened oil, and a viscosity-reducing and cleanup additive and a preparation method and application thereof, belonging to the technical field of oil exploitation. The viscosity-reducing and cleanup composition comprises, by mass, 0.1 to 2 parts of a fluorocarbon surfactant, 0.5 to 1 part of a hydrocarbon surfactant, 0.25 to 1 part of an auxiliary agent and 0.05 to 0.3 part of the cleanup additive, wherein the fluorocarbon surfactant is one or more selected from a group consisting of FC-01, FC-02, FC-04-1, FC-06, FC-08 and FC-11; the hydrocarbon surfactant is one or more selected from a group consisting of sodium alpha-olefin sulfonate, SYHSY, SDBS and YN; and the cleanup additive is one or more selected from a group consisting of F370, F633 and SH6. The viscosity-reducing and cleanup composition has low surface and interfacial tension, can effectively reduce the dynamic viscosity of thickened oil, improves surface wettability of a rock core and enhances water recovery rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of gel composition and its nitrogen foam gel composite temporary plugging agent

ActiveCN103030916BSimple structureImprove stabilityFluid removalDrilling compositionPolymer scienceChemical composition

The invention provides a gel composition and a nitrogen-foamed gel composite temporary plugging agent containing the same. The gel composition comprises the following components in percentage by mass: 1.0% of partially hydrolyzed polyacrylamide, 1.5% of formaldehyde, 0.5% of hydroquinone and the balance of water. The nitrogen-foamed gel composite temporary plugging agent comprises nitrogen and foamed gel, wherein the foamed gel is a mixture of the gel composition and a high-temperature-resistant foaming agent; and the volume ratio of the nitrogen to the foamed gel is (40-60):1. The invention also provides a coupled internal / external swirl foam generator which can be used as a facility for preparing the nitrogen-foamed gel composite temporary plugging agent. The invention also provides a method for inhibiting high-throughput-frequency well steam channeling interference of thick oil, which has the characteristics of small formation damage, strong selectivity for measures and the like and has the effect of gas energization.

Owner:PETROCHINA CO LTD

Plug-removing agent for low-permeability heterogeneous sandstone reservoir and its application method

ActiveCN104031625BImprove permeabilityHigh viscosityFluid removalDrilling compositionOrganic acidFoaming agent

The invention discloses a blocking remover for hypotonic inhomogeneous sandstone reservoir and a using method of the blocking remover. The blocking remover comprises an agent A, an agent B and an agent C, wherein the agent A consists of the following components in percentage by weight: 10%-25% of oxidant, 8%-12% of activator and the balance of water; the agent B consists of 10%-15% of a reducing agent, 0.3%-1.2% of a foaming agent, 0.3%-0.6% of a foam stabilizer, and the balance of water; the agent C consists of 8%-12% of HCL, 6%-10% of organic acid, 2%-5% of NH4HF2, 0.5%-1.5% of a corrosion inhibitor, 0.5%-1.5% of an iron ion stabilizer and the balance of water. The using method comprises the steps of step one, preparing the agent A, the agent B and the agent C; and step two, injecting the agent A into a ground layer by a pipeline, then injecting the agent B into the ground layer, and finally injecting the agent C into the ground layer. The blocking remover disclosed by the invention has beneficial effects that the blocking remover disclosed by the invention can be applied to decompression and augmented injection of a water injecting well and deep unblocking of an oil well; and the blocking remover has better effect while being applied to augmented injection of the water well in a reservoir non-homogeneous oil-field block.

Owner:CHINA PETROLEUM & CHEM CORP

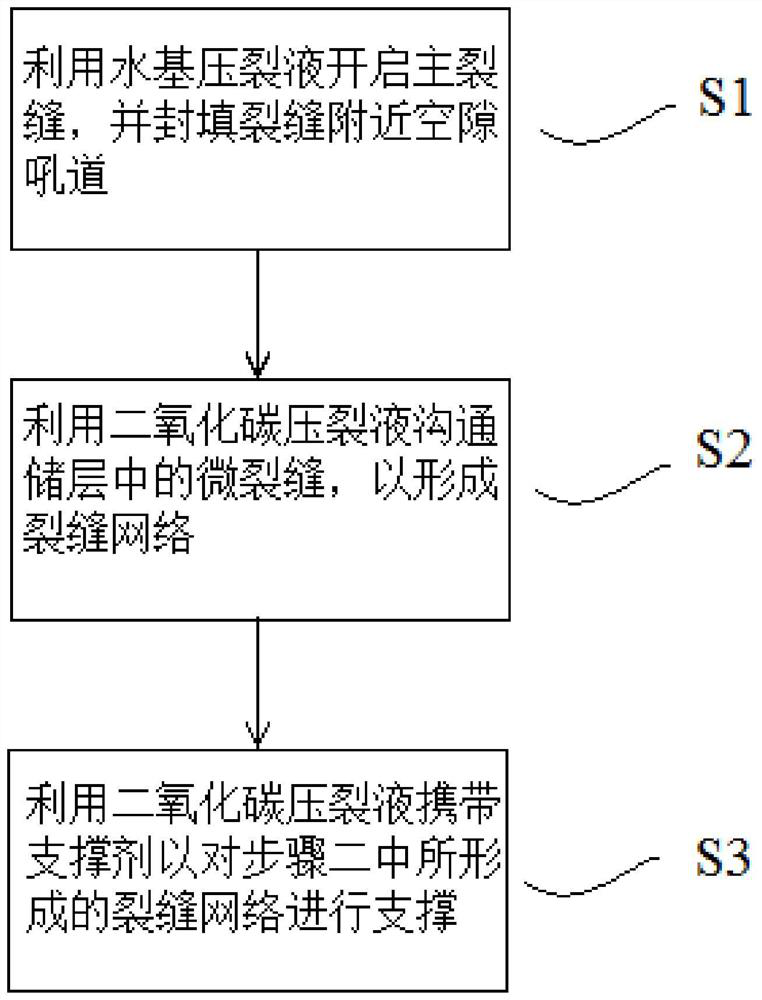

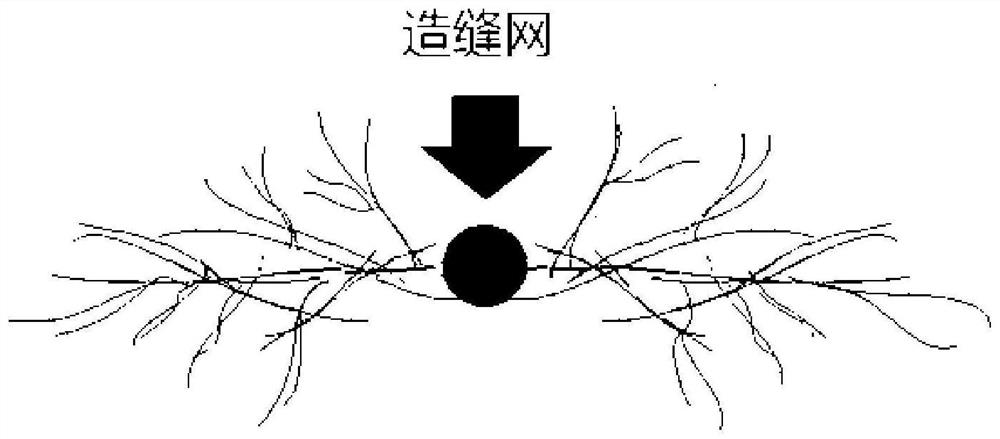

Fracturing method

PendingCN113356820AExpand well control areaIncrease formation energyFluid removalMicro fractureEnvironmental geology

The invention provides a fracturing method. The fracturing method comprises the following steps of: 1, opening a main crack by using water-based fracturing fluid, and sealing and filling a gap throat near the crack; 2, using the carbon dioxide fracturing fluid for communicating with micro-fractures in the reservoir to form a fracture network; and 3, using carbon dioxide fracturing fluid for carrying a proppant to support the crack network formed in the step 2. The fracturing method combines the water-based fracturing technology and the liquid carbon dioxide fracturing technology, a main crack is firstly made, then the carbon dioxide fracturing fluid is used for forming the crack network, and the crack network is formed. A slug sand adding mode is used for supporting the crack network, so that a longitudinal and transverse'net-shaped crack 'system taking the main crack as a trunk is formed in the construction mode, and the well control area is enlarged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A low-corrosion self-generating energized fracturing fluid and its preparation method

ActiveCN111100624BImprove utilization efficiencyReduce corrosionDrilling compositionThermodynamicsFracturing fluid

The invention provides a low-corrosion self-generating energized fracturing fluid and a preparation method thereof. The fracturing fluid of the present invention is prepared by mixing an air generator solution and an initiator solution; 0.2-1 part of joint agent, 0.02-0.1 part of gel breaker, 0.05-0.2 part of bactericide, 25-43 parts of water; the initiator solution includes the following raw materials in parts by weight: 0.02-0.1 part of drag reducing agent, 3 parts of methyl formate -20 parts, 1.5-10 parts of ammonium chloride, 0.5-1.2 parts of methanol, 21-45 parts of water. The fracturing fluid of the present invention has the characteristics of self-gasification, low corrosion, no reaction or slight reaction at normal temperature, good stability, easy control of reaction, rapid response at formation temperature, full and effective use of fracturing fluid, no harmful gas generation, safety and environmental protection, And it has the advantages of little impact on the reservoir near the wellbore.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A high-efficiency self-produced gas foam fracturing fluid and its construction method

ActiveCN109762549BImprove liquiditySimplify field processesFluid removalDrilling compositionToxic gasThermodynamics

The present invention provides a high-efficiency self-generated gas foam fracturing fluid and a construction method. The foam fracturing fluid is composed of a base fluid, a gas-generating fluid and a heat-generating agent, wherein the mass ratio of the base fluid, gas-generating fluid, and heat-generating agent is 100: (30‑42): (5‑9). During construction, the base fluid and the gas-producing fluid are pumped downhole together through the suction of the sand mixing truck according to the mass ratio, and the heat generating agent is pumped into the downhole along with the proppant. The invention does not need liquid nitrogen accompanying injection, simplifies the on-site process and reduces the construction cost, and a large amount of gas generated through the chemical reaction achieves the purpose of increasing the energy of the formation, improving the flow capacity of the reservoir liquid, and increasing the output. It can quickly generate a large amount of inert and safe gas, and will not produce toxic gas of nitrogen oxides, reducing construction risks. At the same time, the alkaline environment generated by the reaction product is conducive to the formation of fracturing fluid gel and the corrosion protection of downhole pipe strings. By generating foam, the Jiamin effect is used to increase the net pressure of the formation, which can quickly flow back, generate heat in the deep formation to promote gel breaking, and reduce the damage of fracturing fluid to the reservoir.

Owner:PETROCHINA CO LTD

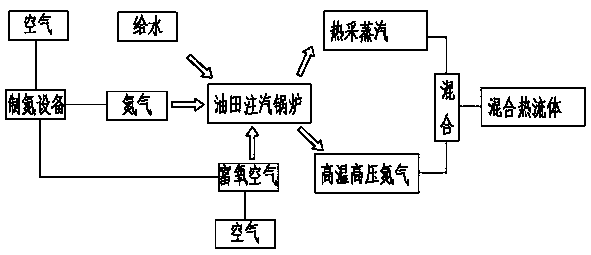

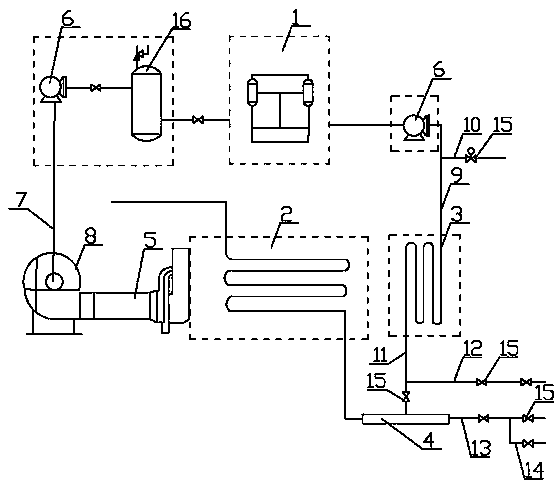

Method for increasing production of heavy oil by steam-nitrogen mixed injection and special device

InactiveCN111577226AReduce mining costsIncrease formation energyFluid removalSteam condensationNitrogen gas

The invention relates to the technical field of heavy oil thermal recovery, and particularly relates to a method for increasing production of heavy oil by steam-nitrogen mixed injection and a specialdevice. The method comprises the following steps of: pressurizing and heating high-purity nitrogen, mixing the pressurized and heated high-purity nitrogen with thermal recovery steam to form thermal recovery mixed fluid, and injecting the thermal recovery mixed fluid into a stratum through a steam injection pipeline for heavy oil recovery. Compared with a water injection steam thermal recovery technology, the method has the advantages that: the injected and heated high-purity nitrogen and water steam mixed fluid can carry heat for reducing the viscosity of crude oil, supplement stratum pressure, increase stratum energy and avoid pressure loss caused by volume reduction after water steam is condensed; and the nitrogen can carry the water steam to diffuse in a wider range, so that the oil displacement effect is improved, and the heavy oil recovery cost is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A self-assembled ultrafine foam oil displacement agent and its preparation method and application

ActiveCN107502330BExtended half-lifeWith viscosityFluid removalDrilling compositionDodecaneActive agent

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com