Gel composition and nitrogen-foamed gel composite temporary plugging agent containing same

A technology of gel composition and nitrogen foam, which is applied in the direction of drilling composition, production fluid, wellbore/well components, etc., can solve the problems of weak foam profile control, easy to be broken by steam, and large formation damage. Achieve the effects of reducing damage, strong measure selectivity, and small formation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

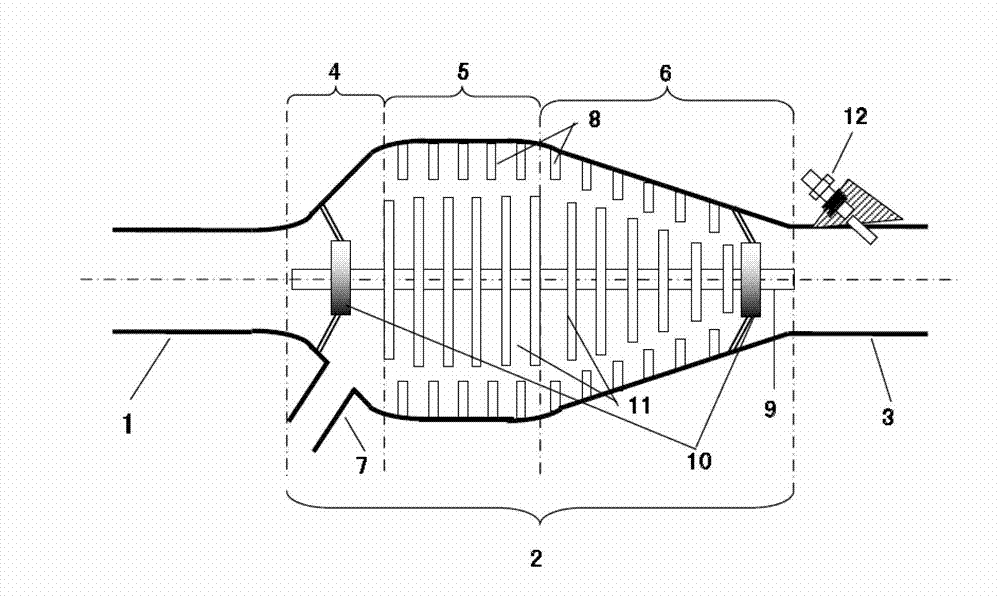

Method used

Image

Examples

Embodiment

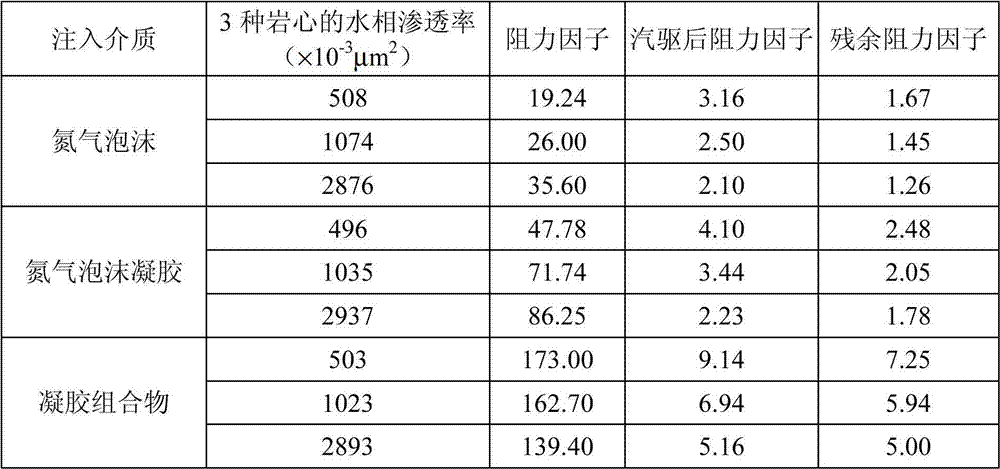

[0032] This embodiment provides a gel composition, which includes: 1.0 wt% partially hydrolyzed polyacrylamide (the degree of hydrolysis is 25%, and the degree of polymerization is 16×10 4 , with a molecular weight of 1200×10 4 ), 1.5wt% formaldehyde, 0.5wt% hydroquinone, and the remainder being water. The gel composition is obtained by uniformly mixing the above-mentioned materials in proportion.

[0033] This embodiment also provides a nitrogen foam gel composite temporary plugging agent, which includes: nitrogen and foam gel, the volume ratio of the two is nitrogen:foam gel=50:1 (under standard atmospheric pressure). Wherein, the foam gel is a mixture of the above-mentioned gel composition and a high-temperature-resistant foaming agent, and, based on the volume of the gel composition, the concentration of the high-temperature-resistant foaming agent is 12 g / L. In terms of mass percentage, the high temperature resistant foaming agent includes 99.7% tall oil fatty acid sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com