Carbon dioxide-anti-drag water compound fracturing method

A technology of carbon dioxide and composite fracturing, which is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of increased difficulty in crude oil extraction, poor production increase effect, water lock effect, etc., and achieve water reduction The use of resources, the increase of the effect of cracks, the effect of suppressing the expansion of clay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

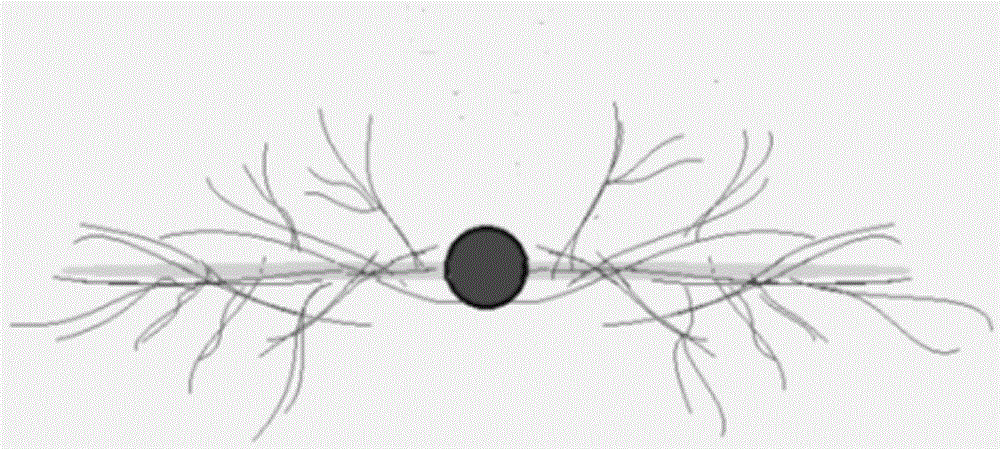

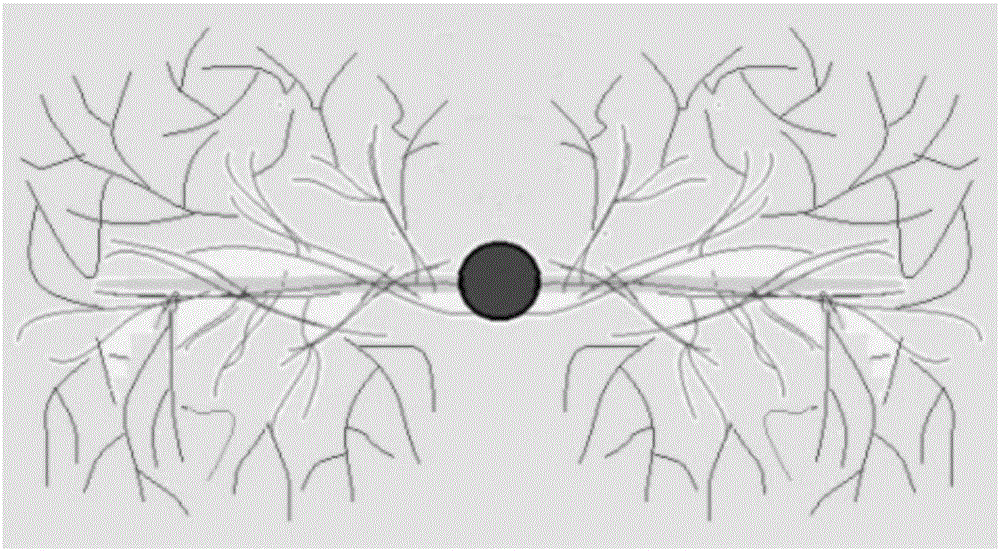

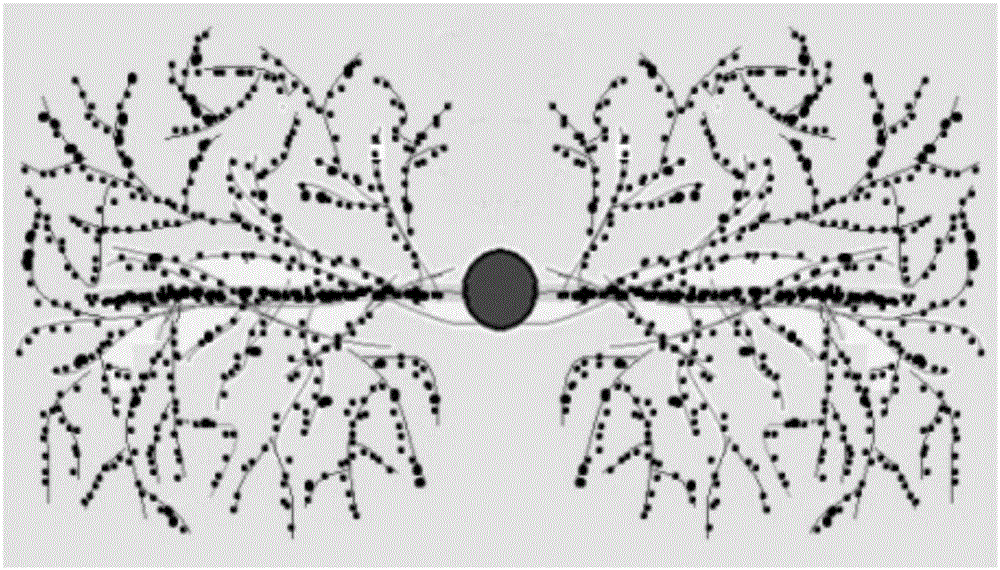

Image

Examples

Embodiment 1

[0033] This embodiment provides a carbon dioxide-drag reducing water composite fracturing method. The working fluid used in this method is divided into liquid carbon dioxide fracturing fluid without proppant added, drag reducing water fracturing fluid without proppant added, and proppant added There are three types of drag reducing water fracturing fluids. Wherein, the liquid carbon dioxide fracturing fluid is 100% pure liquid carbon dioxide. The raw material composition of the drag-reducing water fracturing fluid without adding proppant is (based on the total weight of the fracturing fluid): 0.010% molecular weight is 6×10 6 Cationic polyacrylamide, 0.020% ethoxylated C16-18 alcohol, 0.050% PTA clay stabilizer, 0.050% tetrasodium hydroxyethylidene diphosphonate, 0.007% 2,2-dibromo-3- Nitrilopropionamide (DBNPA) and the balance of water. The proppant-added drag-reducing water fracturing fluid is prepared by using the above-mentioned drag-reducing water fracturing fluid witho...

Embodiment 2

[0042] This embodiment provides a carbon dioxide-drag reducing water composite fracturing method. The working fluid used in this method is divided into liquid carbon dioxide fracturing fluid without proppant added, drag reducing water fracturing fluid without proppant added, and proppant added There are three types of drag reducing water fracturing fluids. Wherein, the liquid carbon dioxide fracturing fluid is 100% pure liquid carbon dioxide. The raw material composition of the drag-reducing water fracturing fluid without proppant added is (based on the total weight of the fracturing fluid): 0.015% molecular weight is 6×10 6 Cationic polyacrylamide, 0.040% ethoxylated C16-18 alcohol, 0.080% PTA clay stabilizer, 0.030% tetrasodium aminotrimethylene phosphonate, 0.005% tetrakis hydroxymethyl phosphorus sulfate (THPS) and water balance. The proppant-added drag-reducing water fracturing fluid is prepared by using the above-mentioned drag-reducing water fracturing fluid without p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com