Steam huff and puff exploitation method

A production method and steam technology, applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc., can solve the problems of poor huff and puff effect of oil wells, less injection volume, limited level, etc., to improve fluid flowback capacity, The effect of improving production efficiency and improving the degree of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

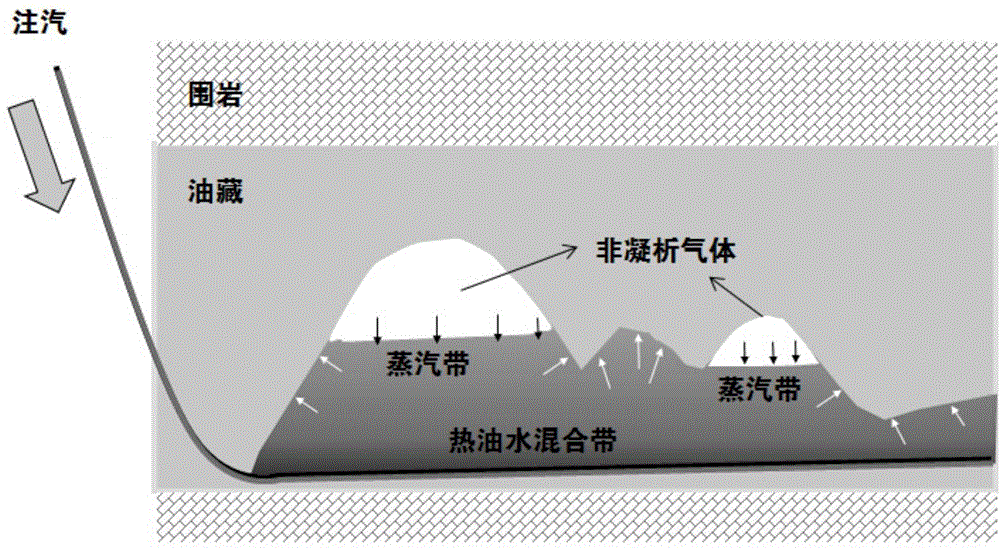

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for steam stimulation mining, the method includes the following steps:

[0045] Step 1: Select horizontal well A as the injection-production well pattern. The vertical depth of the horizontal section of this horizontal well pattern is 761.0m, the length of the horizontal section is 252m, the thickness of the oil layer is 6.8m, and the controlled geological reserves are 5.0×10 4 t. Developed with other steam stimulation methods, when the stimulation reaches the sixth cycle, the formation pressure drops from 12MPa to 2.5-3MPa, the cycle output drops from 2,500 tons to about 1,200 tons, the oil-steam ratio drops from 0.4 to 0.2, and the formation deficit is 6,493m 3 ;

[0046] Step 2: Inject non-condensable non-hydrocarbon gas into the horizontal well, due to the liquid CO 2 The injection speed is fast and the price is low. This embodiment chooses to inject liquid CO 2 , by Q=AV / T (wherein (A takes 9669, V is 6493m 3 , T is 393K) Calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com