Air injection-assisted super heavy oil underground cracking improvement technology based on shaft heating modes

A heating mode and air injection technology, which is applied in underground mining, coal gasification, wellbore/well components, etc., can solve the problems that crude oil cannot be effectively displaced to production wells, insufficient reservoir energy, and long heating time, etc. Achieve the effects of shortening the crude oil upgrading time, reducing water resource consumption and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

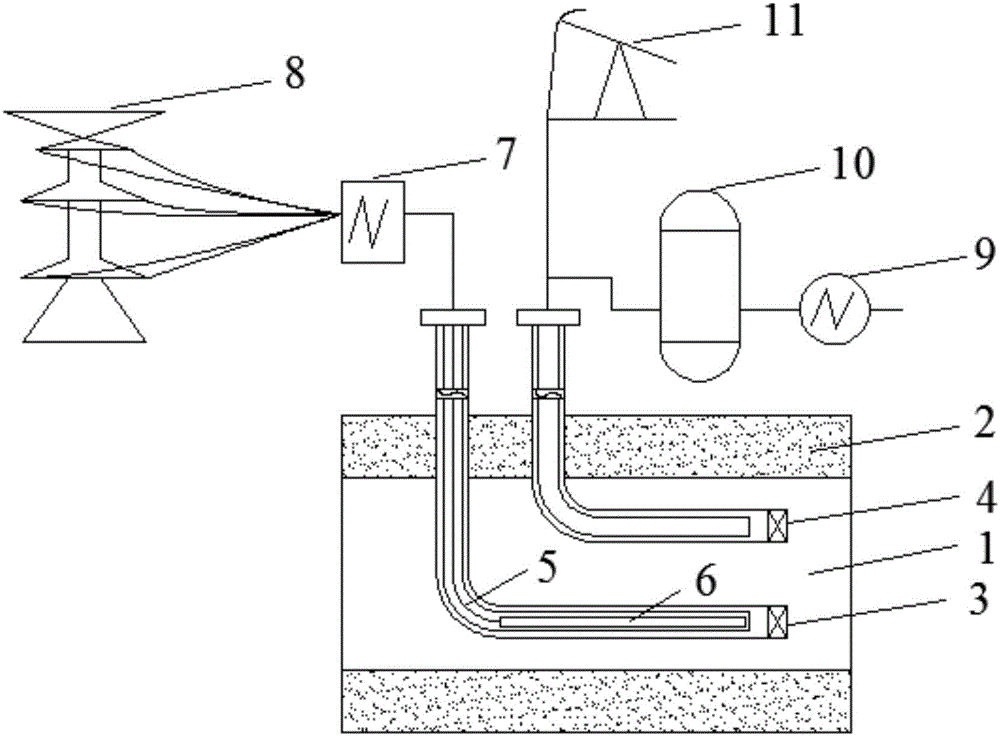

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] An air injection-assisted underground cracking and upgrading process for ultra-heavy oil based on wellbore heating mode, the specific steps are as follows:

[0015] (1) For the production layer 1 of the target oil reservoir, use conventional drilling tools to drill horizontal well groups (3 and 4). rate, etc.), crude oil physical properties (viscosity and density, etc.) and technical feasibility;

[0016] (2) Install the heating cable 5 in the shaft of the heating well 3, and connect the heating cable to the electric heating rod 6 in the shaft of the horizontal section. The heating cable 5 is lowered into the wellbore in combination with the coiled tubing process, and the heating cable 5 can be pre-assembled into the coiled tubing outside the well site, and then transported to the wellhead for installation. The heating cable 5 can be connected to the grid 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com