Patents

Literature

44results about How to "Increase net pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fracturing method for increasing complexity of high-temperature stratum artificial crack net

ActiveCN108661617AReduce construction pressureIncrease the complexity of artificial fracturesFluid removalHorizontal wellsFracturing fluid

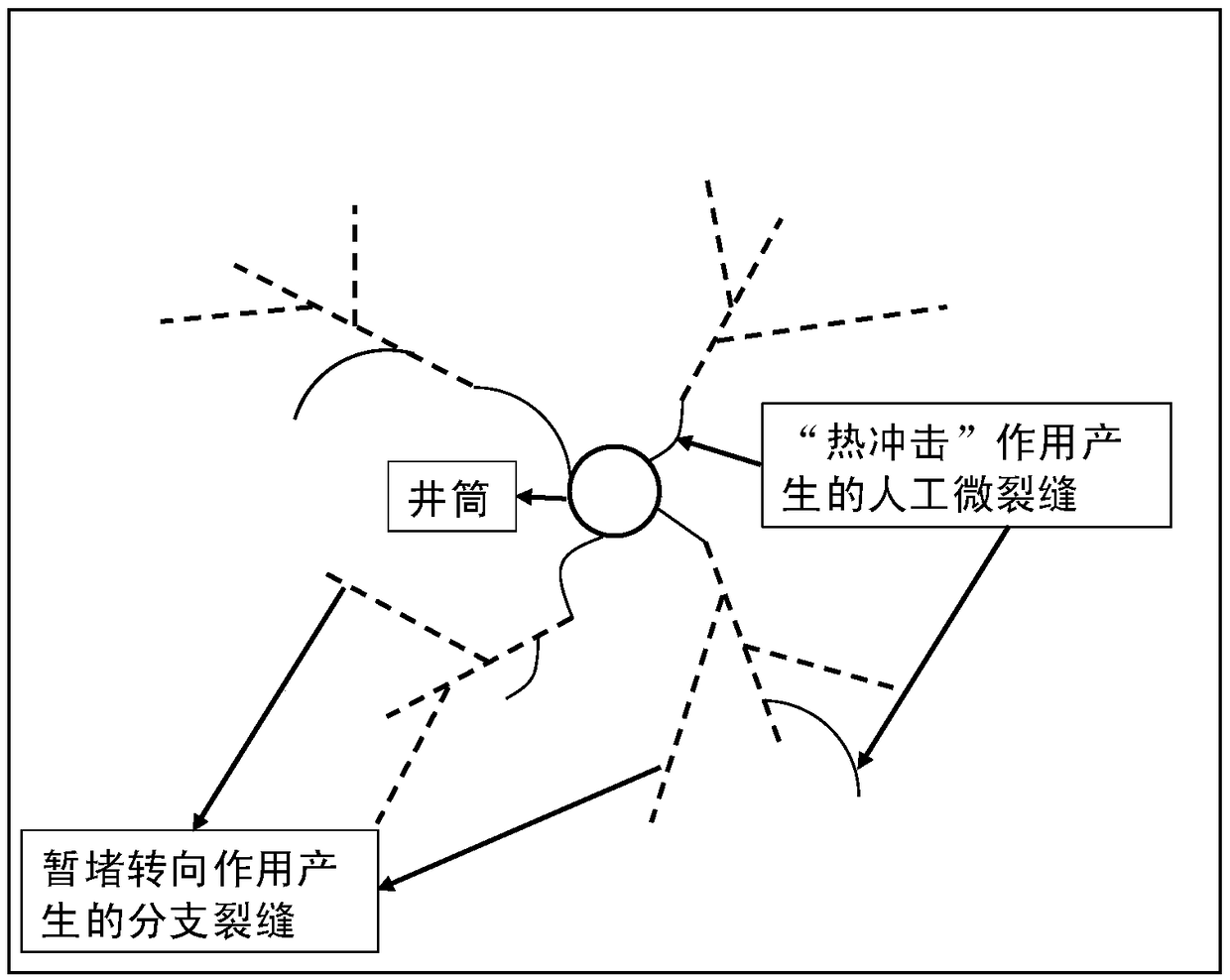

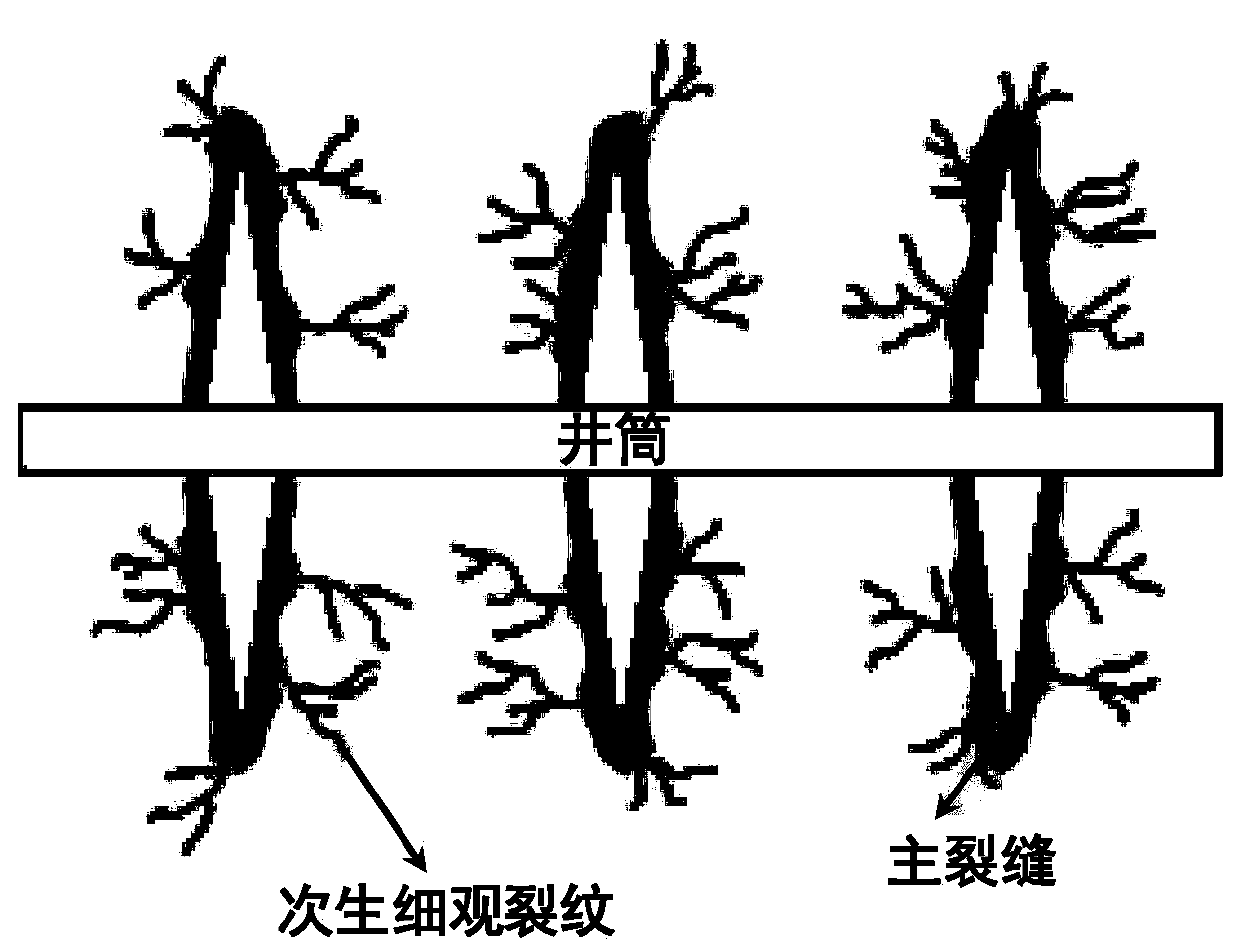

The invention discloses a fracturing method for increasing the complexity of a high-temperature stratum artificial crack net and belongs to the technical field of petroleum and natural gas engineeringexploitation. The method comprises the following steps that low-temperature work liquid is injected into a high-temperature stratum, a strong cold-hot stress impacting effect is generated through thehigh-temperature difference between the low-temperature work liquid and the high-temperature stratum, rock around a well is induced to generate micro cracks, then fracturing liquid is injected to enable the micro cracks to continue to expand forwards, finally temporary plugging steering liquid is injected to conduct bridge plugging on the artificial cracks to force the cracks to steer to form multi-branch cracks, and the steps are executed at least once. Through the fracturing method, the multiple artificial cracks can be formed, the seepage area is enlarged, the single-well yield and economic benefits are increased, the bursting pressure can be lowered, the fracturing construction risk caused by high temporary plugging steering pressure in the high-temperature stratum is avoided, and safe construction is ensured. The fracturing method is suitable for the high-temperature strata such as hot dry rock, deep-layer shale gas and deep-layer compact oil gas, can be used for vertical well fracturing construction and can also be applied to fracturing construction of horizontal wells, oblique wells and the like.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Deep compact gas pool fracturing liquid

A deep compaction gas-pool pressure-crack liquid is composed : thickener 0.2-1.0%, surfactant 0.05-0.2%, clay stabilizer 0.1-1%, germicide0.01-0.2%, buffering agent 0.05-0.2%, the temperature stabilizer 0.1-0.5%, the high temperature cross linker 0.1-0.5%, the cross linking control agent 0.1-0.5%, the broker gum agent 0.001-0.01%, the broken gum catalyst 0.0001-0.001%, the antifoam agent 0.01-0.1%, the falling filter-lossing agent 1-5%, water: the rest. The liquid is of thermal resistance and shearing performance and It can decrease the nowel of the pressure-crack liquid and the filting loss, also it can improve efficiency.

Owner:PETROCHINA CO LTD +1

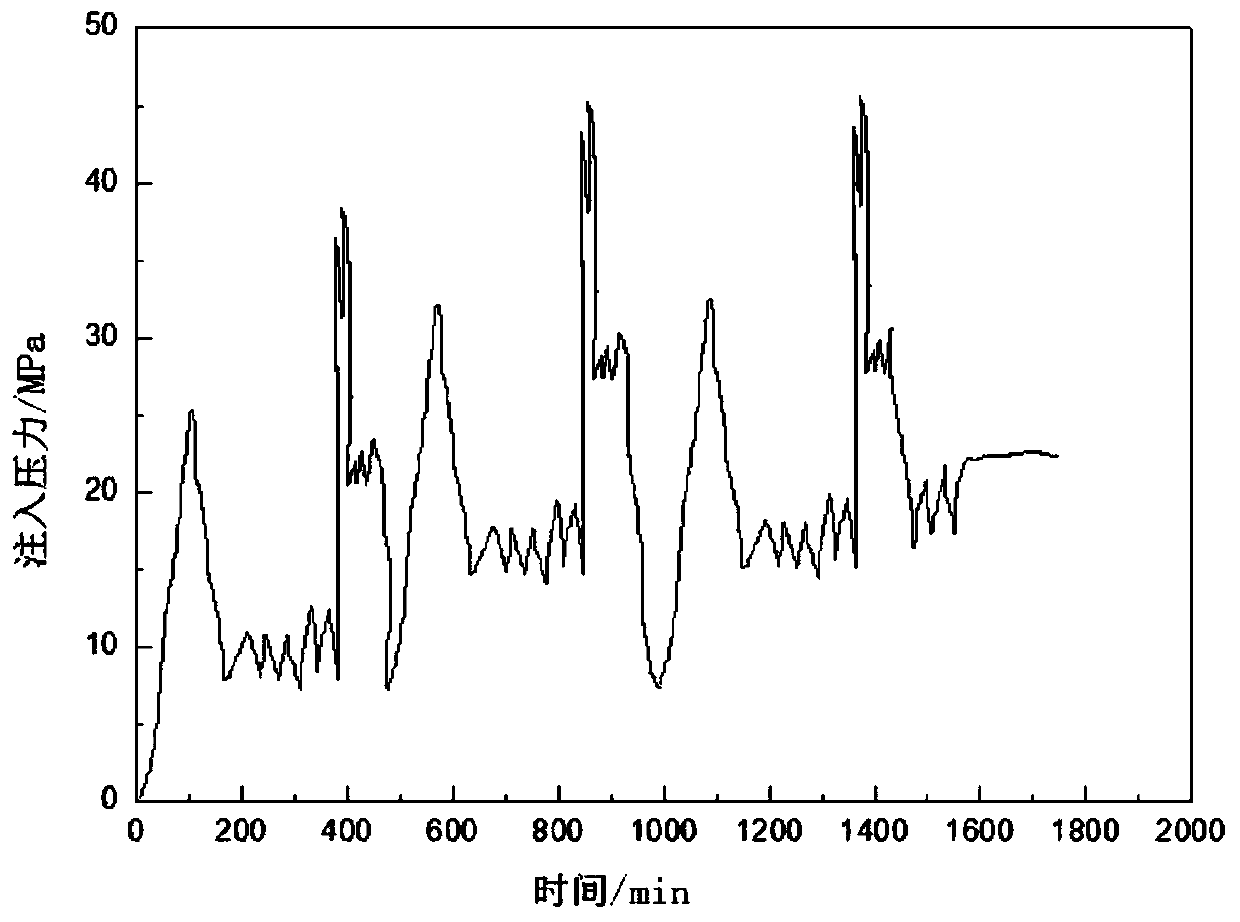

Volume fracturing method for greatly improving filling efficiency of micro-support system through deep shale gas

ActiveCN110608024AIncrease net pressureImprove fracturing effectFluid removalFracturing fluidSystem optimization

The invention discloses a volume fracturing method for greatly improving the filling efficiency of a micro-support system through deep shale gas. The volume fracturing method comprises (1) deep shalekey parameter evaluation; (2) geotechnical engineering comprehensive sweet point evaluation and section cluster perforation position determination; (3) crack parameter system optimization; (4) fracturing construction parameter optimization; (5) different-viscosity smooth water and smooth water, carbon dioxide foam fracturing fluid and pretreatment acid solution formula optimization; (6) perforation operation; (7) acid pretreatment; (8) supercritical carbon dioxide multi-scale crack construction; (9) low-viscosity smooth water branch crack and micro crack expanding and main crack producing construction; (10) alternative injection through supercritical carbon dioxide and smooth water; (11) smooth water and carbon dioxide foam fracturing fluid small particle size supporting agent injection; and (12) displacement operation. By means of the volume fracturing method, the net pressure of a main crack can be improved to the greatest extent, the width of a multi-scale crack is expanded, the flow guiding capability is improved, and therefore the purpose of improving the deep shale gas fracturing effect and increasing the yield is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Volume fracturing method for activating natural fractures on large scale

The invention discloses a volume fracturing method for activating natural fractures on a large scale. The volume fracturing method comprises the steps that step (1) parameter evaluation and optimization are performed; step (2) run bridge plug perforation joint operation is performed; step (3) acid pretreatment operation is performed; step (4) fracture making construction by low-viscosity slipperywater or acid slippery water is performed; step (5) major fracture blocking construction by mixed proppants and sand is performed; step (6) stepped displacement increase construction is performed; step (7) mixed injection construction of the 140-210 mesh proppant and the 70-140 mesh proppant is performed; step (8) major fracture flushing construction by high-viscosity fracturing fluid without sandis performed; step (9) second and third major fracture blocking and subsequent construction are performed, the steps (5)-(8) are repeated, and then the steps (5)-(7) are repeated; step (10) construction of a major fracture by high-viscosity fracturing fluid with sand is performed; and step (11) displacement operation is performed. According to the volume fracturing method, the complexity of the fractures and the reconstruction volume can be increased during reconstruction of a reservoir, and thus, efficient production increase of a shale gas well is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Deep shale gas stepless variable-parameter slope type injection fracturing method

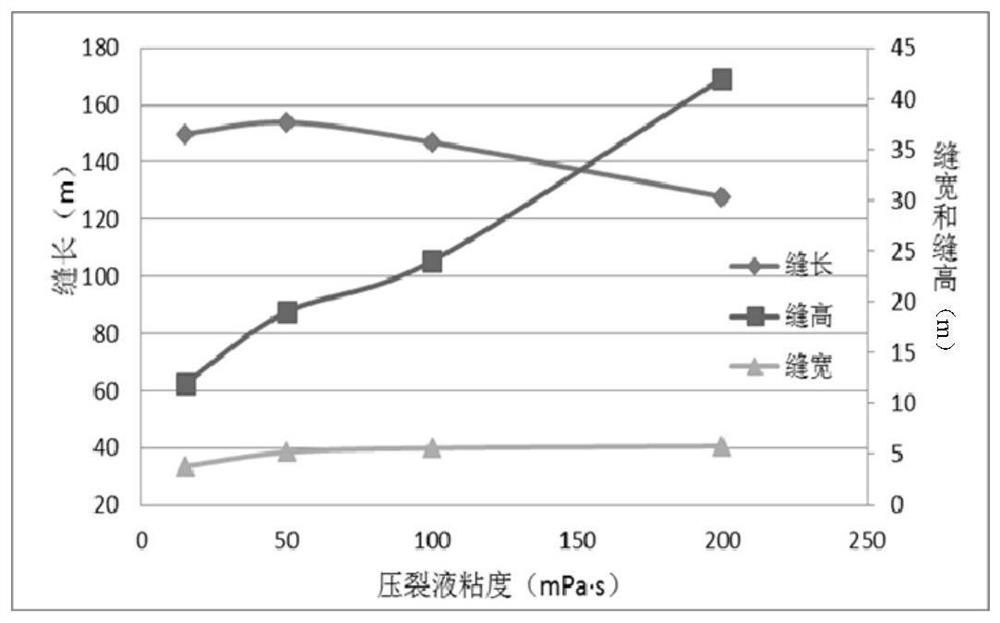

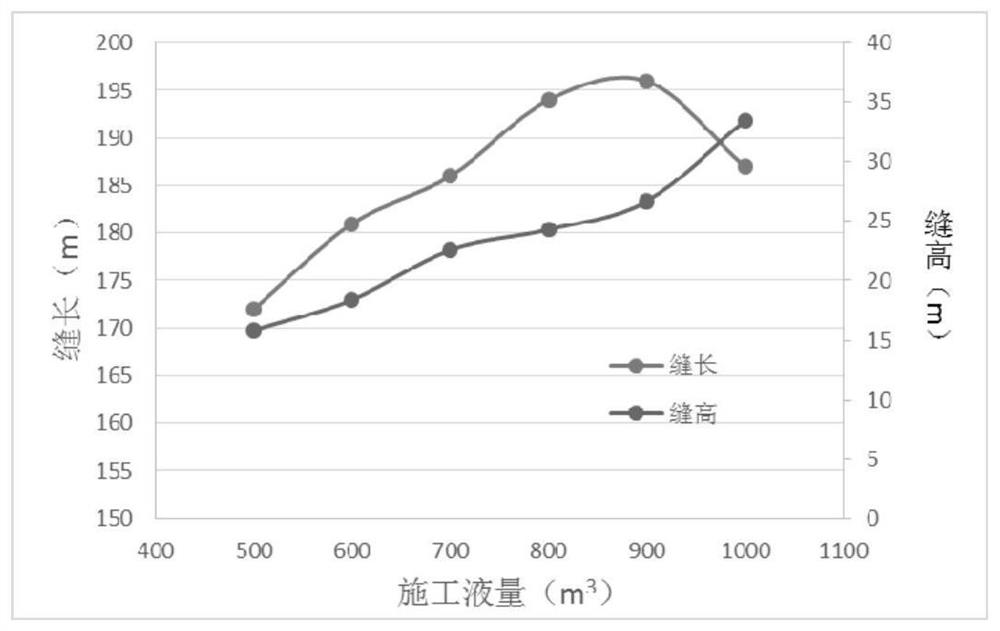

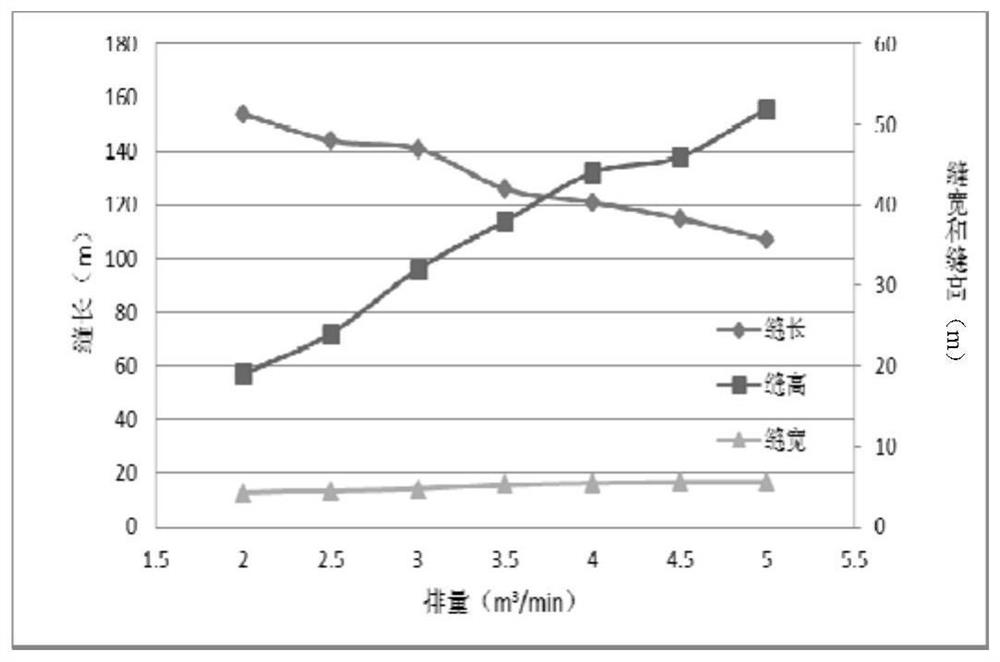

InactiveCN109424346AIncrease net pressureReasonable designFluid removalLiquid ratioProduction effect

The invention discloses a deep shale gas stepless variable-parameter slope type injection fracturing method. The method includes the steps of (1) evaluation of key shale parameters; (2) determinationof a perforation cluster position; (3) optimization of crack parameters; (4) optimization of fracturing construction parameters; (5) preparation of slick water variable in viscosity; (6) preparation of glue variable in viscosity; (7) combined construction of perforation and running of bridge plugs; (8) acid pretreatment operation; (9) glue crack formation or crack height control construction of the low-viscosity slick water carrying sand; (10) main crack formation construction of the low-viscosity slick water; (11) variable-parameter injection and sand addition construction; (12) displacing operation. The method is reasonable in design and high in feasibility, and the filling degree of cracks at all levels is maximized according to four parameters including the fracturing fluid viscosity,the injection discharge mount, the construction sand-liquid ratio and the segmental sand addition mode or the continuous sand addition mode, so that high output in the early period is guaranteed to acertain extent, and meanwhile a stable production effect after fracturing can be stabilized.

Owner:CHINA PETROLEUM & CHEM CORP +1

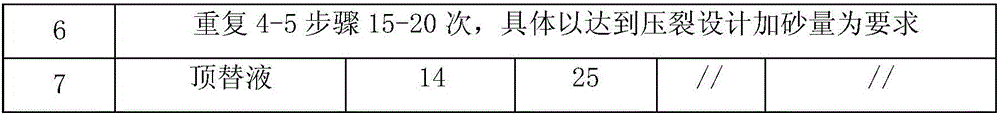

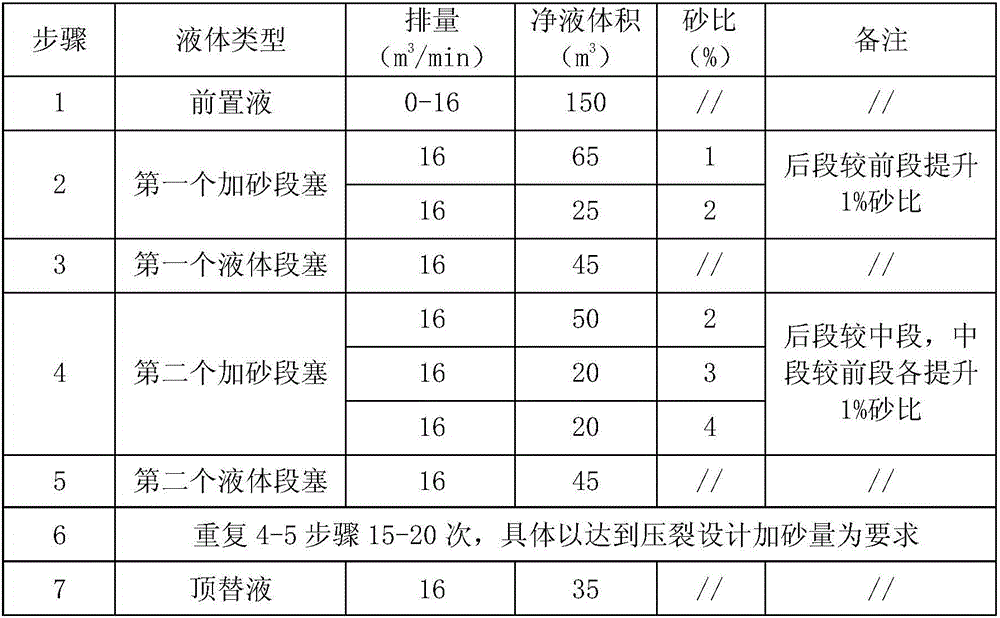

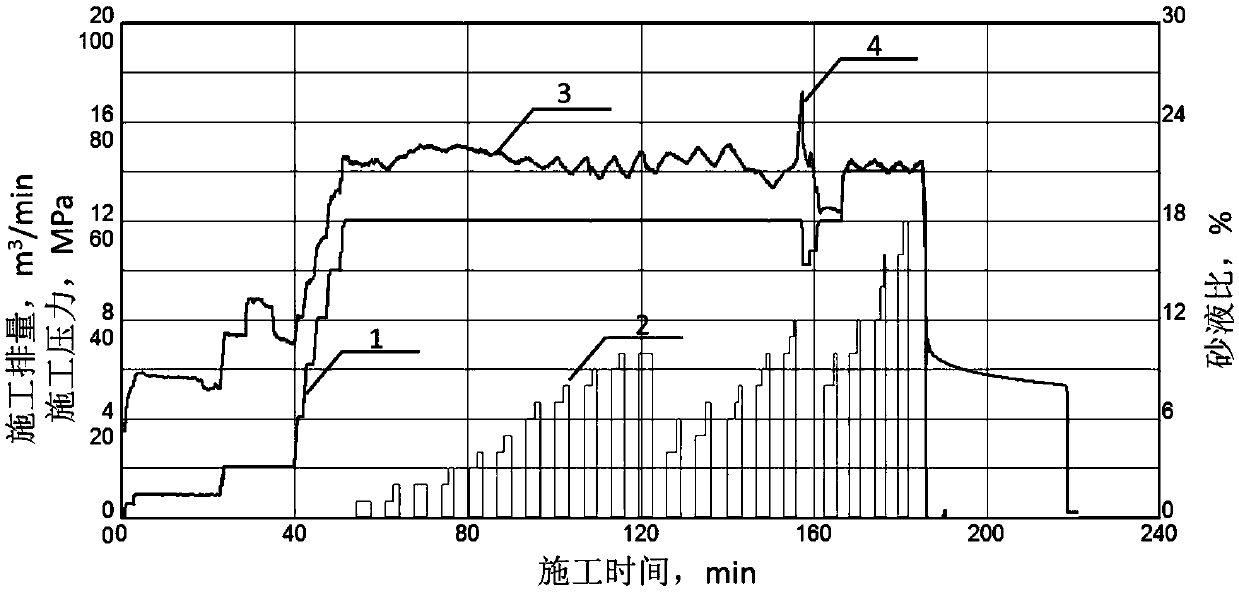

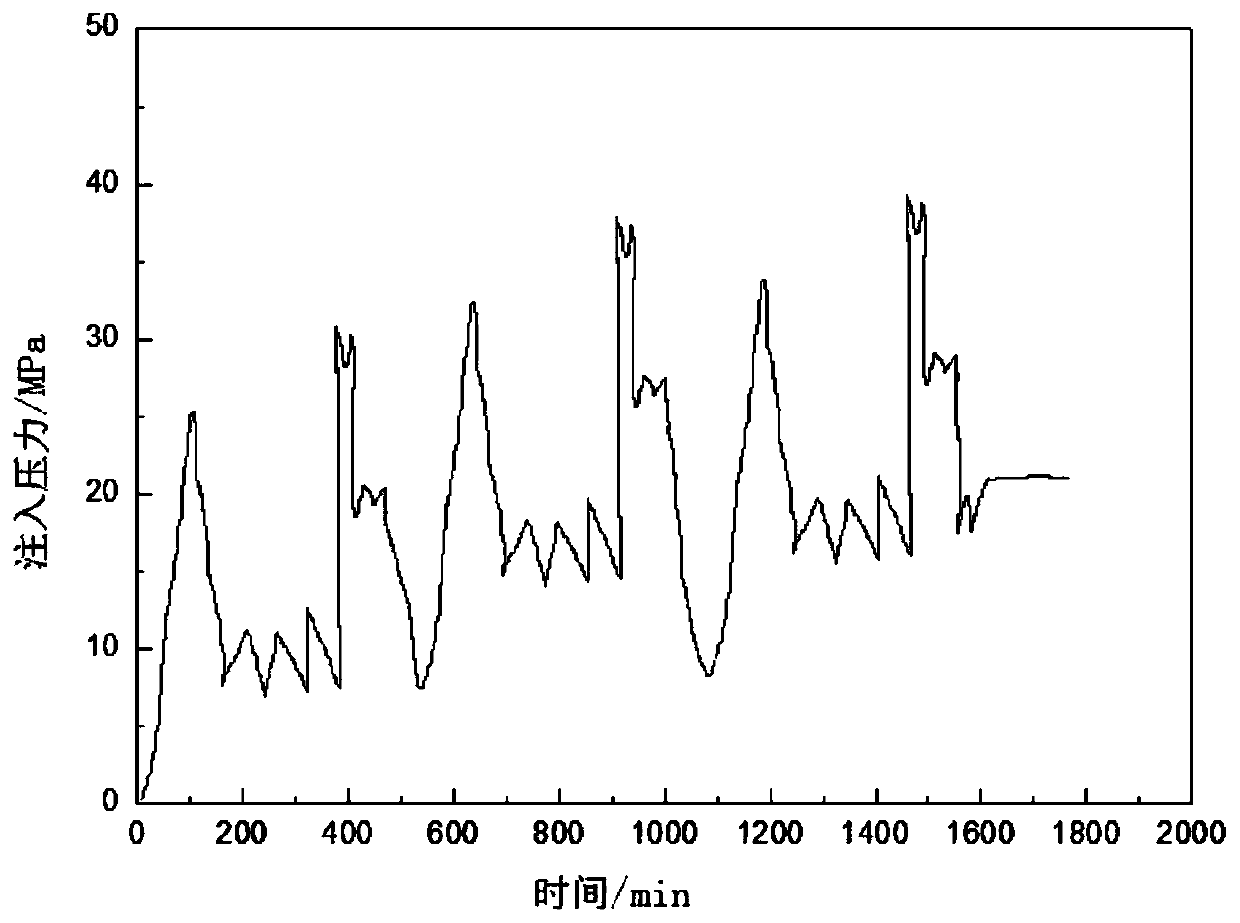

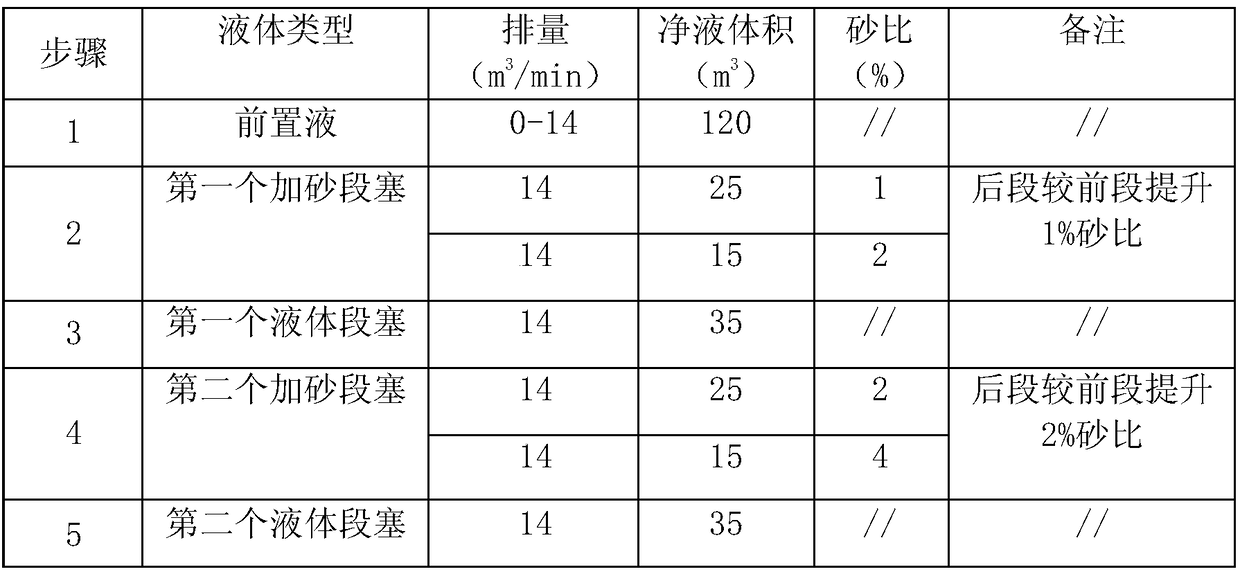

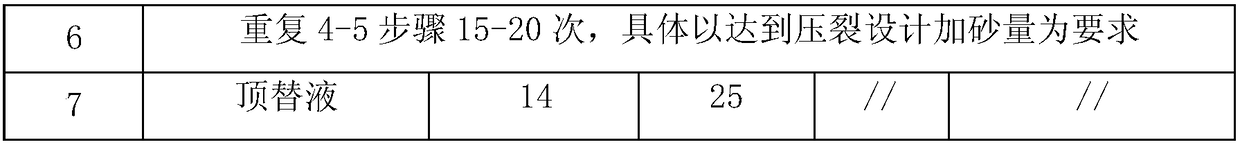

Shale gas fracturing stepping sand-adding method

InactiveCN106593394AImprove the efficiency of liquid sand carryingIncrease net pressureFluid removalShale gasEnvironmental geology

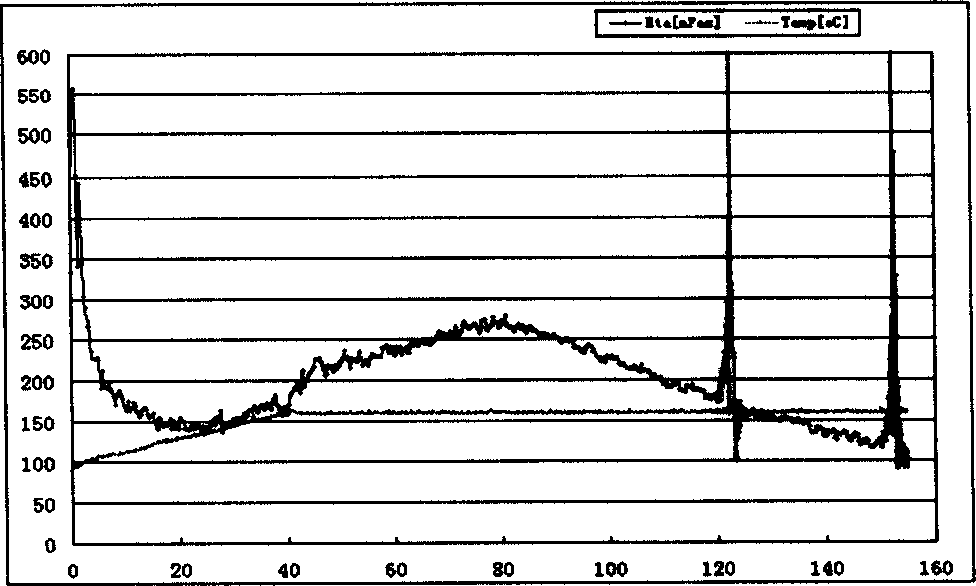

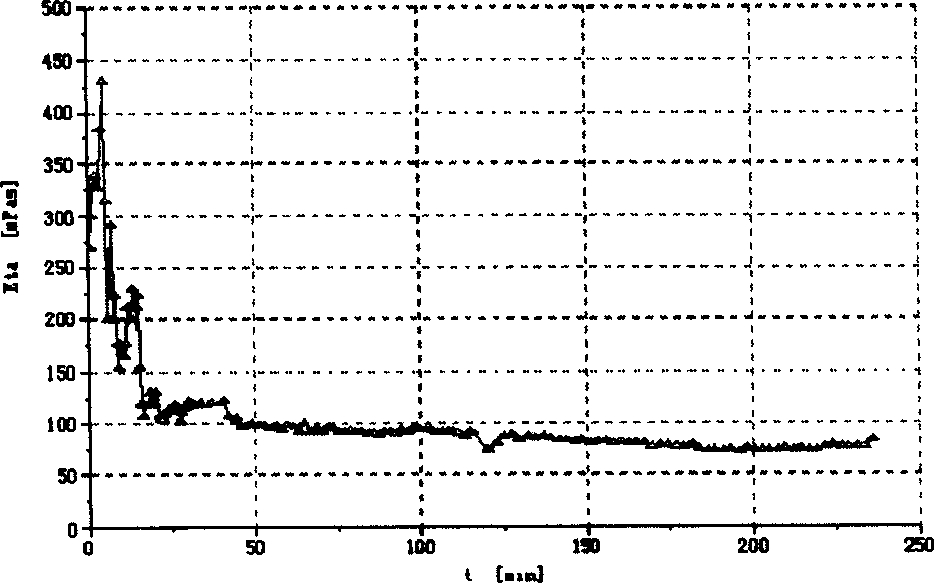

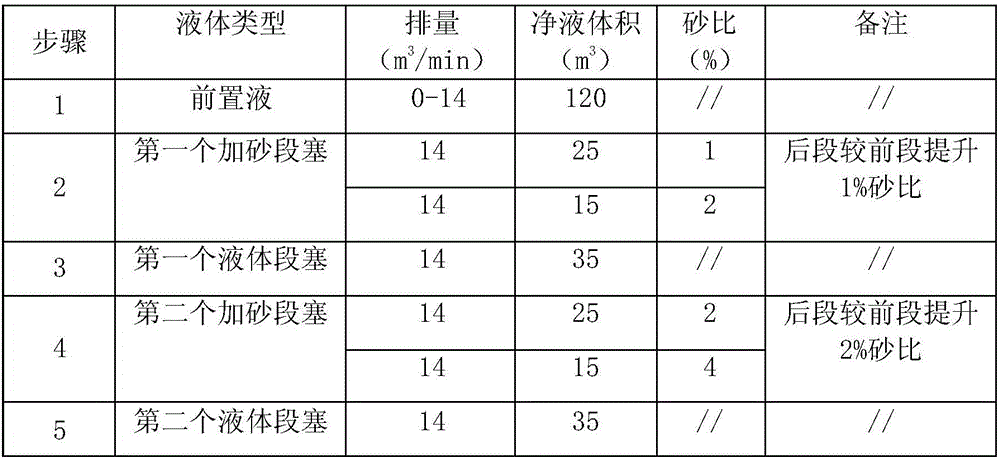

The invention relates to a shale gas fracturing stepping sand-adding method which comprises the following steps: (1) pumping a prepared fluid into a shaft and causing the fluid enter into ground gaps; (2) pumping a first sand-adding section plug and performing the stepping sand adding; (3) pumping a first fluid section plug, and if the pressure shows as diagonal rising, confirming that the pressure change is mild and the sand ratio has a rising potential, and then skipping to the step (4), and if the pressure shows as the sand ratio rising unsuitable for the present stage, further pumping the fracturing fluid for forming gaps and then skipping to the step (1); (4) pumping a second sand-adding section plug and performing the stepping sand adding; (5) pumping a second fluid section plug and observing the pressure variation trend of the sand-adding section plug at different sand ratios after entering into the stratum; and (6) repeating the steps (4)-(5) for 15-20 times till meeting the requirement for designed fracturing sand-adding volume, completing the sand adding in each stage, and lastly, pumping the displacing liquid and completing the whole fracturing construction task. According to the invention, the stepping sand-adding method is adopted for effectively preventing reservoir sand blocking, reducing the construction risk and guaranteeing the smooth construction.

Owner:重庆矿产资源开发有限公司 +1

Critical sand plug fracturing method for improving crack complexity

ActiveCN110344799AIncrease net pressureImprove steering performanceFluid removalHorizontal stressCalcium in biology

The invention discloses a critical sand plug fracturing method for improving crack complexity. The method includes the following steps: (1) formation evaluation before fracturing; (2) preferable selection of viscosity of pre-crack generation fracturing fluid; (3) application of different viscosity fracturing fluid to generate cracks of different sizes at different stages; (4) preferable selectionof dosage proportion and particle size of a proppant matching the different crack sizes; (5) design of a bench type slug sanding mode; (6) implementation of a critical sand plug fracturing process; and (7) other construction steps and a flowback and production process. The method realizes the effective promotion of net pressure and an induced stress field in the whole process of one-time sand fracturing, thereby reducing a horizontal stress difference of two directions of a formation at different positions of a main crack to make the opening of natural cracks or micro cracks filled with calcium easier. The main crack turns and then communicates and intersects with the natural cracks or the micro cracks, thereby maximizing the complexity of the whole crack system and further improving the crack reconstruction volume and single well production.

Owner:CHINA PETROLEUM & CHEM CORP +1

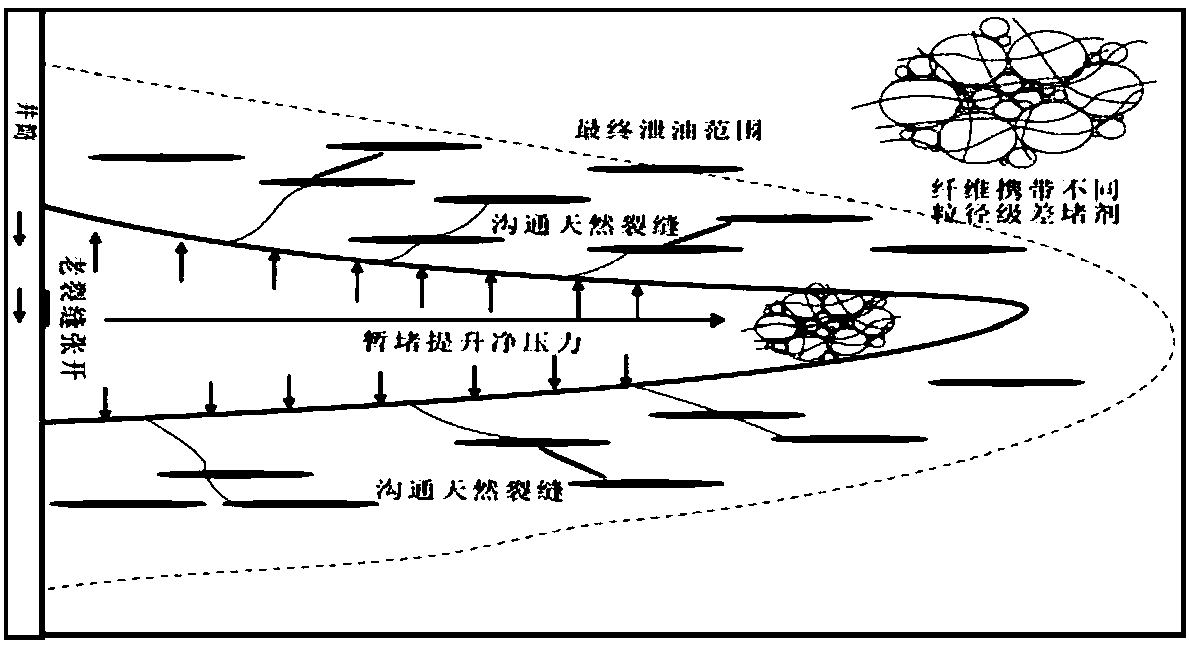

Fracturing technique for achieving complex crack through multiple particle class differential temporary blocking

ActiveCN107558981AIncrease net pressureSolve the problem that the effect of increasing the net pressure is poorFluid removalDrilling compositionFiberFracturing fluid

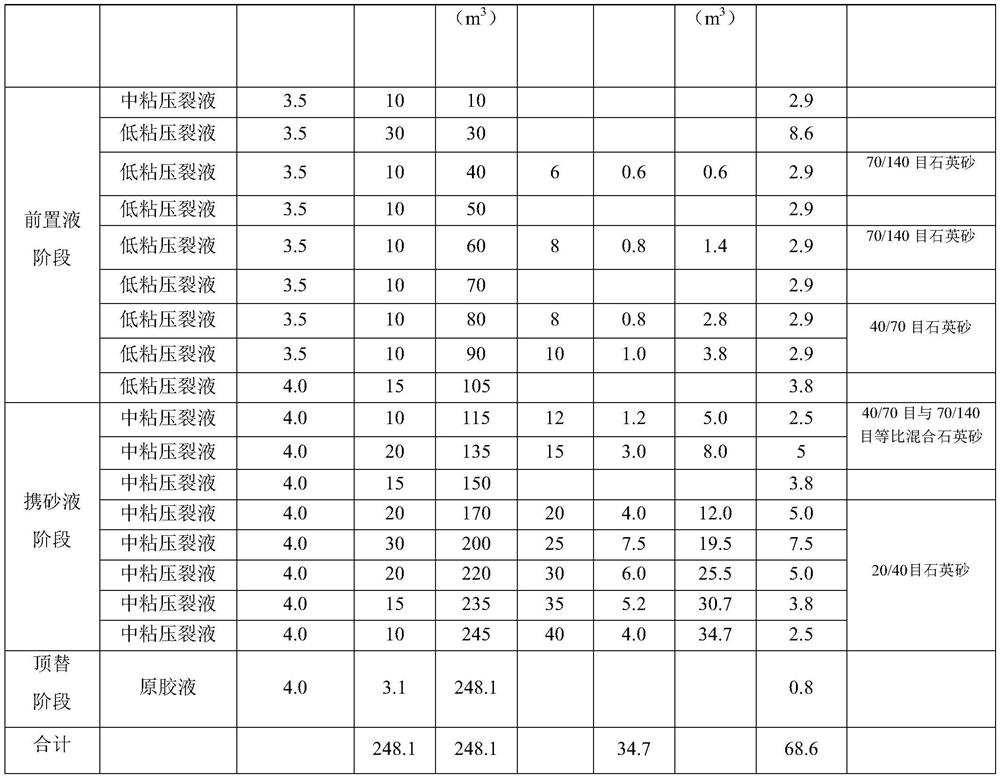

The invention discloses a fracturing technique for achieving a complex crack through multiple particle class differential temporary blocking, which is fracturing technique that a primary artificial crack is temporarily blocked through rigid temporary plugging agent composition with particle size class differential carried by a fracturing fluid, net pressure in the crack is improved, and a new sidecrack is opened. The fracturing technique comprises the steps that the rigid temporary blocking agent carried by a biodegradable polylactic acid resin-like fiber fracturing fluid with four kinds of particle size class differential combination is fast injected according to the sand mulling concentration of 350-500-650g / cm3, and crack deep part temporary blocking is carried out; the net pressure inthe crack is improved, and the side natural crack is opened, and side remaining oil is effective used; and the oil well single well production and final recovery ratio are improved. The fracturing technique has the advantages that the operability of the construction technique is high, a complex fracture system is fractured to be formed, the using degree of the oil well side remaining oil is improved, the cost is low, and the oilfield development benefit is greatly improved, and solves the difficult problem of the poor repeated fracturing effect of low-permeability reservoirs.

Owner:PETROCHINA CO LTD

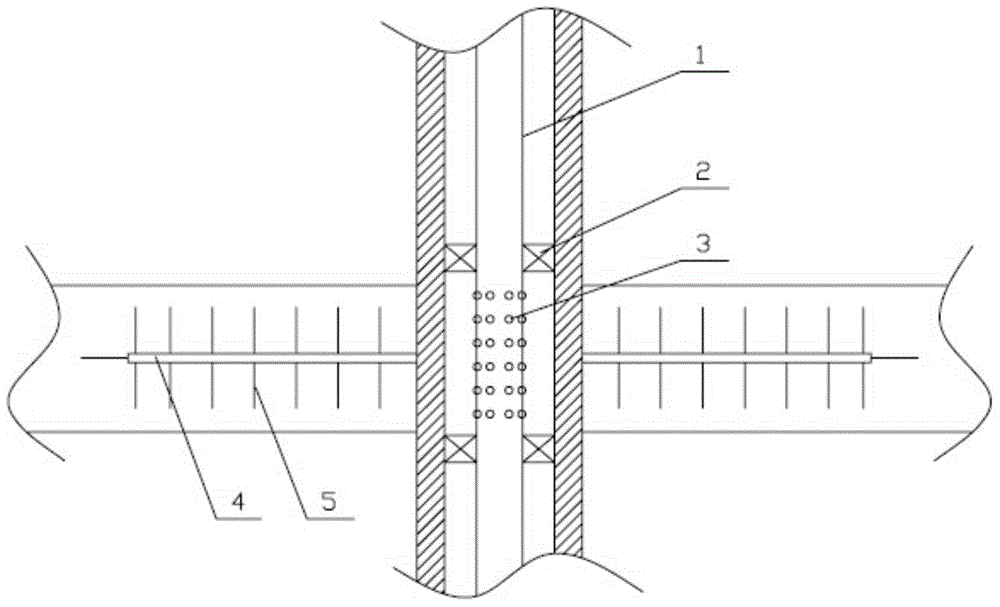

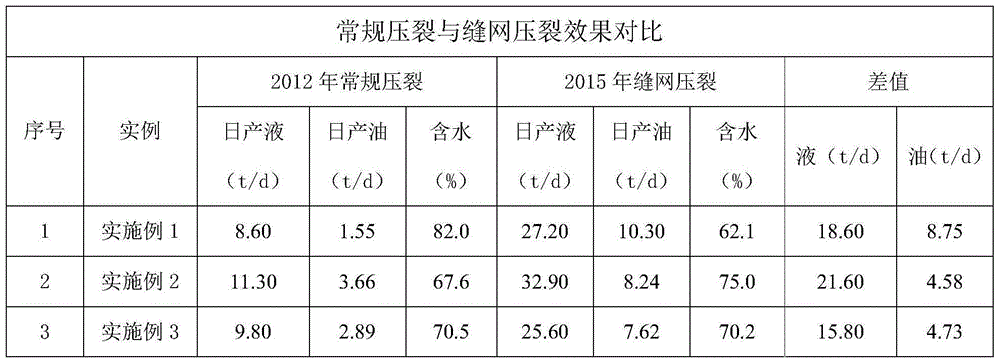

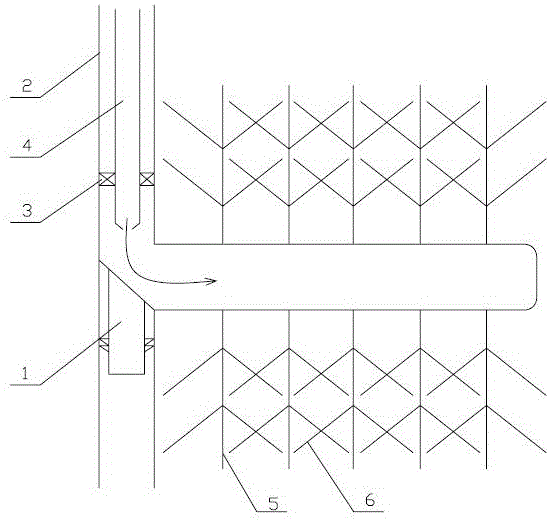

Oil and gas well fracture network system fracturing technology

InactiveCN105201478AStable supportIncrease net pressureFluid removalFracturing fluidMaterial Perforation

The invention relates to an oil and gas well fracture network system fracturing technology. The method comprises the following steps that perforation is carried out on an oil pipe; packers are utilized for blocking the upper end and the lower end of a perforated hole; fracturing liquid is injected through the perforated hole to enable a stratum to form a main fracture; a temporary plugging agent is used for plugging the main fracture; pressure of the fracturing liquid is increased to 5-10 MPa, the fracturing liquid is injected again by means of the perforated hole to enable the stratum to form a larger number of secondary fractures around the main fracture. The fracture network system fracturing technology is provided for increasing the yield of an oil and gas field, natural fractures around a shaft and the artificial fractures can be distributed in a staggered mode to form an artificial fracture three-dimensional network, the swept volume of the fractured fractures in a reservoir can be maximized, and the well seepage size after fracturing is increased by folds, so that the purpose of increasing the yield and the injection amount is achieved.

Owner:DAQING JINGTAI PETROLEUM ENG TECH

Efficient self-produced gas foam fracturing fluid and construction method thereof

ActiveCN109762549AReduce construction riskIncrease net pressureFluid removalDrilling compositionTruckCorrosion

The invention provides efficient self-produced gas foam fracturing fluid and a construction method thereof. The foam fracturing fluid is composed of base fluid, gas-producing fluid and a heat-producing agent, wherein the mass ratio of the base liquid, the gas-producing liquid and the heat-producing agent is 100:(30 to 42):(5 to 9). During construction, the base liquid and the gas-producing liquidare sucked and pumped into the underground together through a sand mixing truck at the mass ratio, and the heat-producing agent is pumped into the underground along with a propping agent. According tothe efficient self-produced gas foam fracturing fluid and the construction method thereof, liquid nitrogen accompanying injection is not required, the field process is simplified, the construction cost is reduced, and the purpose of increasing formation energy, improving the reservoir fluid flow capacity and increasing production are achieved through a large amount of gas produced by a chemical reaction; a large amount of inert safety gas can be quickly produced, and toxic gas of nitrogen oxide cannot be produced, the construction risks are lowered, and meanwhile, the alkaline environment produced by reaction products is conducive to rubber forming of the fracturing fluid and corrosion protection of down-hole strings; and by producing foam, the net formation pressure is increased througha Jamin effect, fast flowback can be achieved, heat is produced by deep formation to promote rubber breaking, and damage of the fracturing fluid to reservoir is lowered.

Owner:PETROCHINA CO LTD

Fracturing method for shale reservoir microfracture self-supporting

PendingCN112211608AImprove fracture conductivityImprove stabilityFluid removalSoil sciencePre treatment

Owner:CHINA PETROLEUM & CHEM CORP +1

Fracturing process for development and application of low permeability heterogeneous sandstone oil and gas reservoir

ActiveCN110792421AExpand the affected volumeSolve the problems of poor connectivity and poor seepage capacityFluid removalFracturing fluidExpanded clay aggregate

The invention belongs to the field of oil field development, and particularly relates to a fracturing process for the development and application of a low permeability heterogeneous sandstone oil andgas reservoir. The fracturing process for the development and application of the low permeability heterogeneous sandstone oil and gas reservoir includes the following steps that (1), a slickwater leak-off and energization stage is carried out, specifically, slickwater and quartz sand or ceramsite are pumped into a reservoir to form micro-cracks to improve the seepage ability of a stratum; and (2),a main fracture stage of long cracks formed by fracturing fluid is carried out, specifically, the low viscosity fracturing fluid and the ceramsite are pumped into the stratum to form the long crackswith high conductivity, and the long cracks communicate the micro-cracks in the step (1) to establish a near-wellbore high seepage zone and reduce the seepage pressure. According to the fracturing process for the development and application of the low permeability heterogeneous sandstone oil and gas reservoir, a process method of slickwater leak-off energization+high conductivity main cracks formed by the fracturing fluid+large displacement is adopted. Compared with the prior art of using frozen-gel fracturing, the swept volume of the cracks is greatly increased, and the problems of poor connectivity of the heterogeneous sandstone reservoir and poor seepage capacity are solved; the stratum energy is replenished; and the long cracks with high flow conductivity are established, the stratum seepage field is improved, and the fracturing modification effect is improved.

Owner:DAGANG OIL FIELD GRP +1

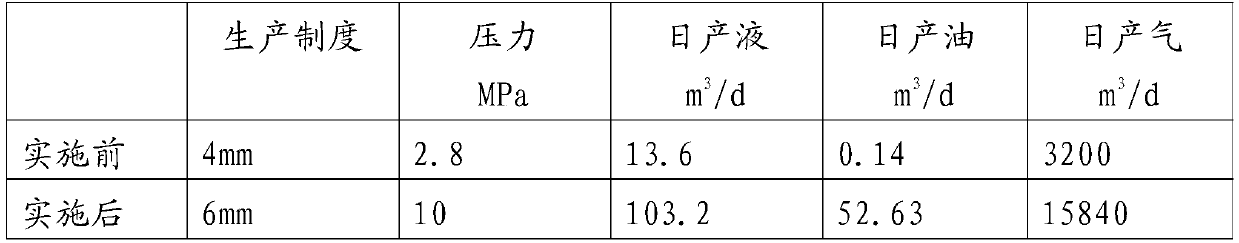

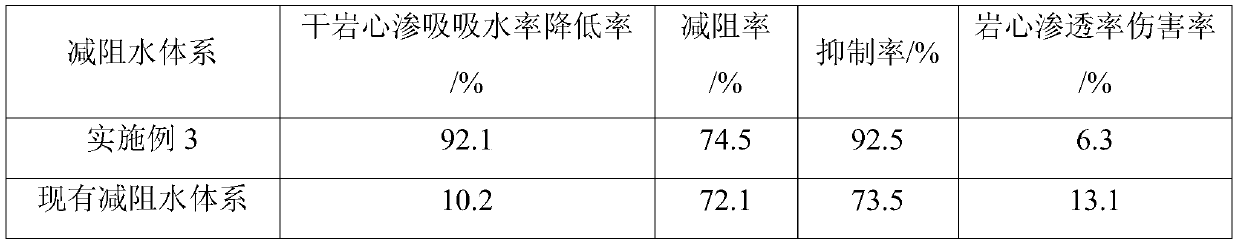

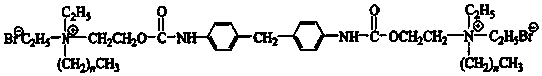

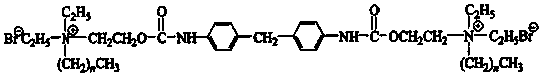

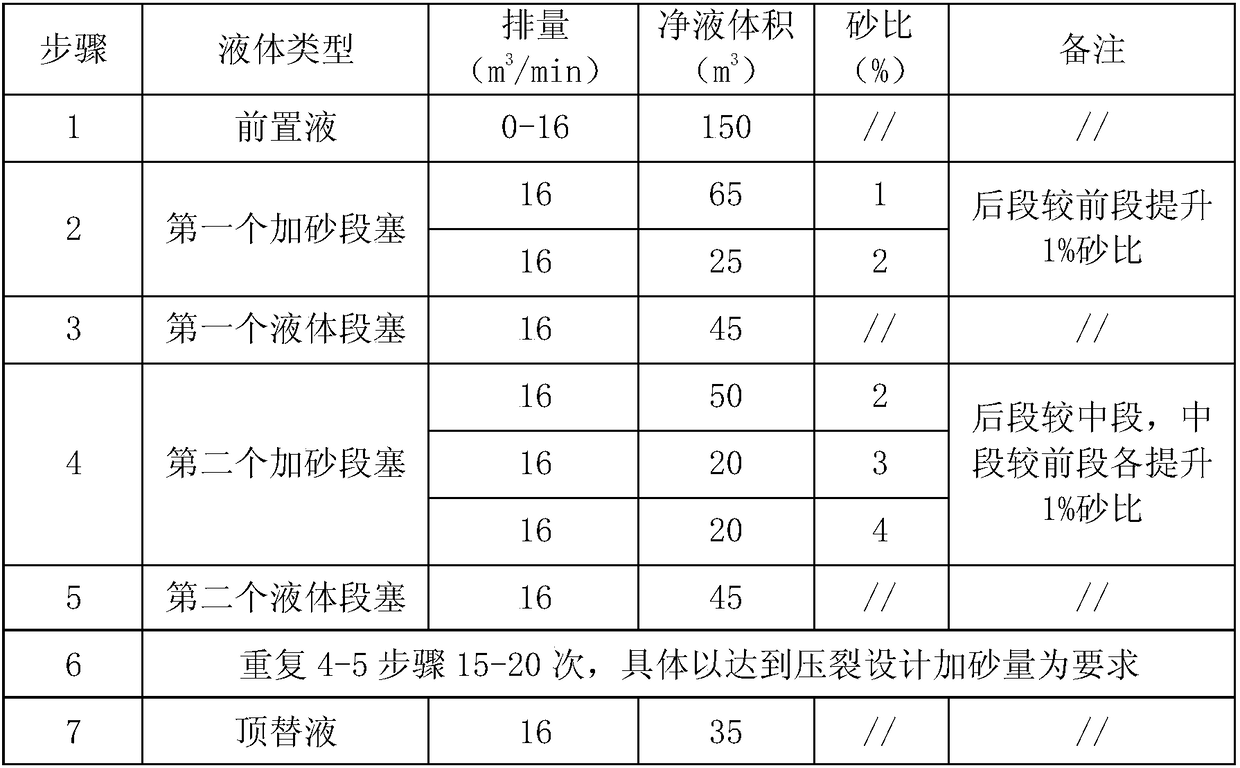

Multifunctional drag reduction water system for continental shale gas fracturing and preparation method thereof

ActiveCN110760299AReduce harmConducive to promoting green developmentDrilling compositionClay mineralsChemical reaction

The invention relates to a multifunctional drag reduction water system for continental shale gas fracturing and a preparation method thereof. The multifunctional drag reduction water system for continental shale gas fracturing comprises the following components in percentages by mass: 0.02% to 0.05% of a resistance reducing agent, 0.5% to 1% of an inhibitor, 0.1% to 0.3% of an antiscaling agent, 0.001% to 0.003% of a synergist, 0.2% to 0.5% of a regulator and the balance of water. The multifunctional drag reduction water system provided by the invention has the characteristics of high drag reduction rate, high inhibition, permeability reduction, adsorption reduction and the like, clay mineral expansion and clay particle migration can be inhibited, a seepage channel is kept smooth, water-rock physical and chemical reactions are effectively inhibited, a fracturing fluid is promoted to flow back quickly, the adsorption damage of the fracturing fluid is reduced, the requirement of continental shale gas fracturing construction is met, the damage of the drag reduction water fracturing fluid to a reservoir is reduced, and efficient development of terrestrial shale gas is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Efficient imbibition and drag-reducing water system applicable to atmospheric pressure shale gas reservoir and preparation method and application thereof

ActiveCN108822825AConducive to fracturing constructionRapid hydration and dispersionDrilling compositionSoil scienceDesorption

The invention discloses an efficient imbibition and drag-reducing water system applicable to an atmospheric pressure shale gas reservoir. The efficient imbibition and drag-reducing water system applicable to the atmospheric pressure shale gas reservoir comprises the following components: 0.04-0.1 percent of a high-molecular polymer drag reducer, 0.05-0.2 percent of a moisture regulator, 0.1-0.3 percent of an efficient shale inhibitor, 0.01-0.03 percent of an environment-friendly fungicide, 0.05-0.1 percent of an imbibition conditioner and the balance of water. The efficient imbibition and drag-reducing water system applicable to the atmospheric pressure shale gas reservoir has the advantages that the efficient imbibition and drag-reducing water system is prepared by using a low molecular weight high-molecular polymer as a drag reducer and introducing the moisture regulator, the imbibition conditioner, the efficient shale inhibitor and the environment-friendly fungicide. Therefore, therock core spontaneous imbibition amount can be effectively increased, the imbibition of a fracturing fluid to a deep ground mass can be promoted; smoothness of a spontaneous imbibition passage can bekept; the desorption of adsorbed gas can be promoted; effects of water soluble replacement of the adsorbed gas, energy increasing and drainage are achieved; atmospheric pressure shale fracking construction requirements are satisfied; the drainage of atmospheric pressure shale gas drag-reducing water fracturing fluid flow-back fluid is reduced; and the development of economic benefits of an atmospheric pressure shale gas field is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fracturing method for transforming hot dry rock reservoir through nanometer emulsion

ActiveCN110173250AIncreased complexityIncrease net pressureFluid removalDrilling compositionEmulsionFracturing fluid

The invention relates to a fracturing method for transforming a hot dry rock reservoir through nanometer emulsion. The fracturing method comprises the following steps that fracturing fluid is poured to activate and communicate with a natural fracture system in hot dry rock at first, then, the nanometer emulsion is poured into the hot dry rock stratum, by utilizing the mesomechanics effect generated when the fine particles of the nanometer emulsion are poured into the hot dry rock, the rock generates a lot of microscomic fracture systems, and finally, temporary blocking steering fluid is poured, fractures are subjected to bridge blinding, and the fractures are forced to steer and divided into branch fractures; and the steps are performed by at least one time. According to the fracturing method, on the one hand, through the mesomechanics effect of the nanometer emulsion, the contact area of the nanometer emulsion and the natural fracture system in the hot dry rock is increased, and meanwhile, the new microscomic fracture systems are generated through the capillary force; and on the other hand, through the bridge blinding effect of the temporary material on the interiors of the fractures, the fracture interior net pressure is improved, the fractures are forced to steer, forming of the branch fractures is promoted, and by combining the two aspects, high-diversion multi-fracture forming can be facilitated.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Multi-dimensional pipe fracturing method for low-yield well in low permeability oilfield

ActiveCN108643876AIncrease productionIncrease net pressureFluid removalDrilling compositionFiltrationMicro fracture

The invention relates to a multi-dimensional pipe fracturing method for a low-yield well in a low permeability oilfield. The multi-dimensional pipe fracturing method is characterized by comprising thefollowing steps that (1) fracturing liquid is injected through a low-displacement pump to displace oil and water or oil and water mixtures in initial fracturing artificial fractures; (2) the construction displacement is increased, and propping agents in the initial fracturing artificial fractures are suspended in the fracturing liquid; (3) through filtration of the fracturing liquid in a stratum,the propping agents are transported to the ends of the initial fracturing artificial fractures to be accumulated; (4) the construction displacement is increased to increase the net pressure in the fractures, and the micro fractures are opened; (5) after the fracturing liquid capable of carrying acid liquor corrodes the wall faces of the main fractures and the micro fractures, sand fracturing is conducted; (6) after fracturing operation is completed, blowout is controlled; and (7) construction is completed. According to the multi-dimensional pipe fracturing method, repeated fracturing of the low-yield well in the oilfield is achieved through optimization of the process method to open the micro fractures to form a multi-dimensional pipe fracturing system, and the target of increasing the single well yield of the low-yield well in the oilfield is achieved.

Owner:SHAANXI YOUBANG PETROLEUM ENG TECH CO LTD

Casing deformation well chemical packer segmented volume fracturing method

InactiveCN110242269AVolumetric Fracturing RealizedRealize layered transformationFluid removalSealing/packingFracturing fluidMaterial Perforation

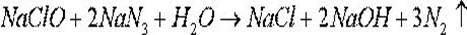

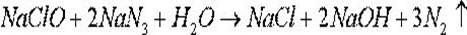

The invention discloses a casing deformation well chemical packer segmented volume fracturing method. The casing deformation well chemical packer segmented volume fracturing method includes the steps that S1, the perforation position is determined and perforation is conducted according to stratum physical properties and logging data; S2, fracturing sequence is set according to stress intensity, the chemical packer use level and particle size combination are determined, and fracturing process parameters are designed; S3, a chemical packer is injected into a stratum to seal a crack opening and a perforation eyelet in a last fractured well section; S4, fracturing fluid is injected, at the same time, an in-seam supercharging agent is added, a first artificial crack is formed; S5, the chemical packer is injected to seal a first artificial crack opening and a perforation eyelet; S6, the fracturing fluid is injected again, at the same time, the in-seam supercharging agent is added, and a second artificial crack is formed; and S7, the chemical packer and fracturing fluid are repeatedly injected until fracturing of a casing deformation well section is completed. According to the casing deformation well chemical packer segmented volume fracturing method, segmented fracturing of a casing deformation well is realized, so that all well sections are adequately remolded, at the same time, the crack complexity can be improved by using the technology of in-seam pressurization, and the purposes of fracturing and stimulation are achieved.

Owner:BEIJING GEPETTO OIL TECH

Perforation fracturing method for longitudinal residual oil dig-down of old well of single-sand body oil reservoir

The invention discloses a perforation fracturing method for longitudinal residual oil dig-down of an old well of a single-sand body oil reservoir, which comprises the following steps: perforating a longitudinal oil layer section by utilizing a fixed surface perforation technology, then putting a separate layer fracturing drilling tool, and adopting fracturing working fluid composed of 0.3% of cross-linking liquid, 0.6%-0.8% of degradable fiber, a rigid temporary plugging agent (2mm, 3mm and 4mm) with multiple particle size differences and a 20 / 40-mesh low-density selective wetting proppant (1.5g / cm<3>); fracturing is conducted on the perforation section, injecting fracturing fluid composed of fibers and a multi-particle-size rigid temporary plugging agent, local rapid pressure rise is formed in the near-wellbore zone, the crack net pressure is increased, natural micro cracks are opened, the transformation size is increased, and the purpose of fully using longitudinal remaining oil is achieved; at the later stage of sand adding, a selective wetting agent is added to form a package in a near-wellbore zone, and the water content of an oil well is prevented from rising by utilizing thecharacteristics of oil permeability and water resistance. The technological process is high in operability, low in cost and remarkable in oil field development benefit. The problems that water is prone to being seen in conventional perforation fracturing cracks, longitudinal transformation is not sufficient, and remaining oil is difficult to use effectively are solved.

Owner:PETROCHINA CO LTD

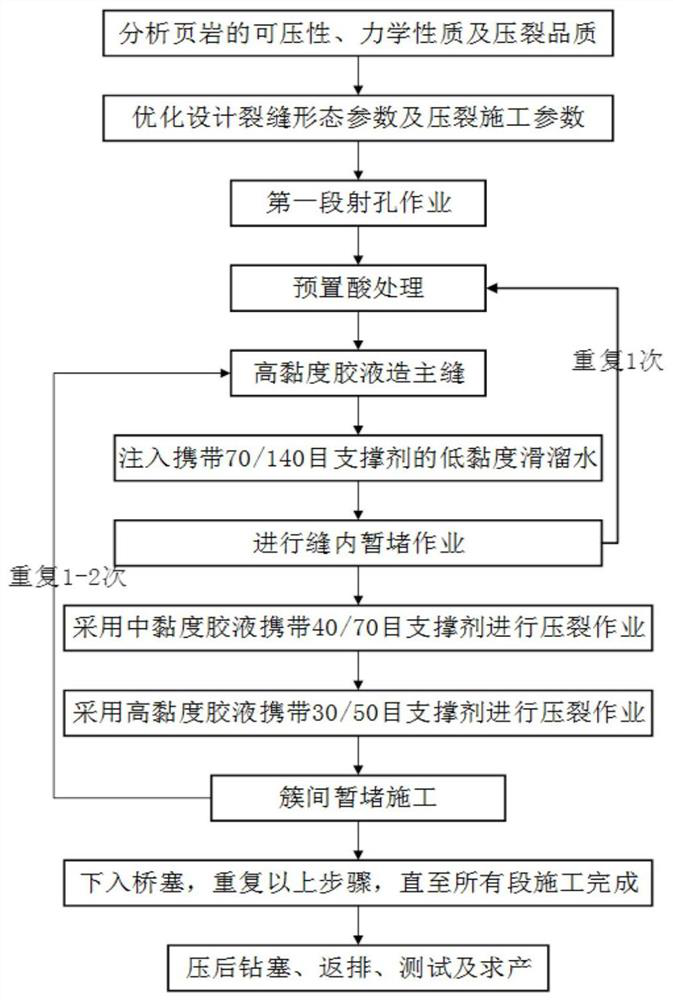

Effective volume fracturing method for shale with high clay content

ActiveCN112065349AIncreased stress disturbance effectIncreased complexityFluid removalSealing/packingThermodynamicsMechanics

The invention discloses an effective volume fracturing method for shale with high clay content. The effective volume fracturing method comprises the following steps that (1) compressibility, mechanical properties and fracturing quality of the shale are analyzed; (2) fracture morphological parameters and fracturing construction parameters are optimally designed; (3) perforation operation is carriedout on a first section; (4) acid treatment is carried out; (5) a main crack is formed by adopting a high-viscosity glue solution; (6) low-viscosity slickwater carrying 70-140 meshes of a propping agent is injected; (7) inter-crack temporary plugging construction is carried out by adopting the high-viscosity glue solution in cooperation with a temporary plugging agent; (8) a medium-viscosity gluesolution carrying 40-70 meshes of the propping agent is injected; (9) the high-viscosity glue solution carrying 30-50 meshes of the propping agent of is injected; (10) inter-cluster temporary pluggingconstruction is carried out by adopting the high-viscosity glue solution in cooperation with temporary plugging balls; and (11) displacement construction is carried out. According to the effective volume fracturing method for the shale with high clay content, the problems existing in an existing fracturing process can be solved, so that the effective transformation volume of the shale with high clay content is increased, and the crack complexity is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A stepwise sand adding method for shale gas fracturing

InactiveCN106593394BImprove the transformation effectImprove sand carrying efficiencyFluid removalFracturing fluidShale gas

The invention relates to a shale gas fracturing stepping sand-adding method which comprises the following steps: (1) pumping a prepared fluid into a shaft and causing the fluid enter into ground gaps; (2) pumping a first sand-adding section plug and performing the stepping sand adding; (3) pumping a first fluid section plug, and if the pressure shows as diagonal rising, confirming that the pressure change is mild and the sand ratio has a rising potential, and then skipping to the step (4), and if the pressure shows as the sand ratio rising unsuitable for the present stage, further pumping the fracturing fluid for forming gaps and then skipping to the step (1); (4) pumping a second sand-adding section plug and performing the stepping sand adding; (5) pumping a second fluid section plug and observing the pressure variation trend of the sand-adding section plug at different sand ratios after entering into the stratum; and (6) repeating the steps (4)-(5) for 15-20 times till meeting the requirement for designed fracturing sand-adding volume, completing the sand adding in each stage, and lastly, pumping the displacing liquid and completing the whole fracturing construction task. According to the invention, the stepping sand-adding method is adopted for effectively preventing reservoir sand blocking, reducing the construction risk and guaranteeing the smooth construction.

Owner:重庆矿产资源开发有限公司 +1

A kind of multifunctional drag reducing water system and preparation method for continental shale gas fracturing

ActiveCN110760299BReduce harmConducive to promoting green developmentDrilling compositionClay mineralsChemical reaction

The present invention relates to a multifunctional drag-reducing water system for continental shale gas fracturing and a preparation method thereof. The components and mass percentages of the multifunctional drag-reducing water system for continental shale gas fracturing are as follows: Drag reducer 0.02-0.05%, inhibitor 0.5-1%, anti-scaling agent 0.1-0.3%, synergist 0.001-0.003%, regulator 0.2-0.5%, and the balance is water. The multi-functional drag-reducing water system provided by the present invention has the characteristics of high drag-reducing rate, strong suppression, reduced imbibition, and reduced adsorption. , chemical reaction, promote the rapid flowback of fracturing fluid, reduce the adsorption damage of fracturing fluid, meet the requirements of continental shale gas fracturing construction, reduce the damage of drag-reducing water fracturing fluid to reservoirs, and realize continental shale Efficient development of gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of oil and gas reservoir fracturing construction method

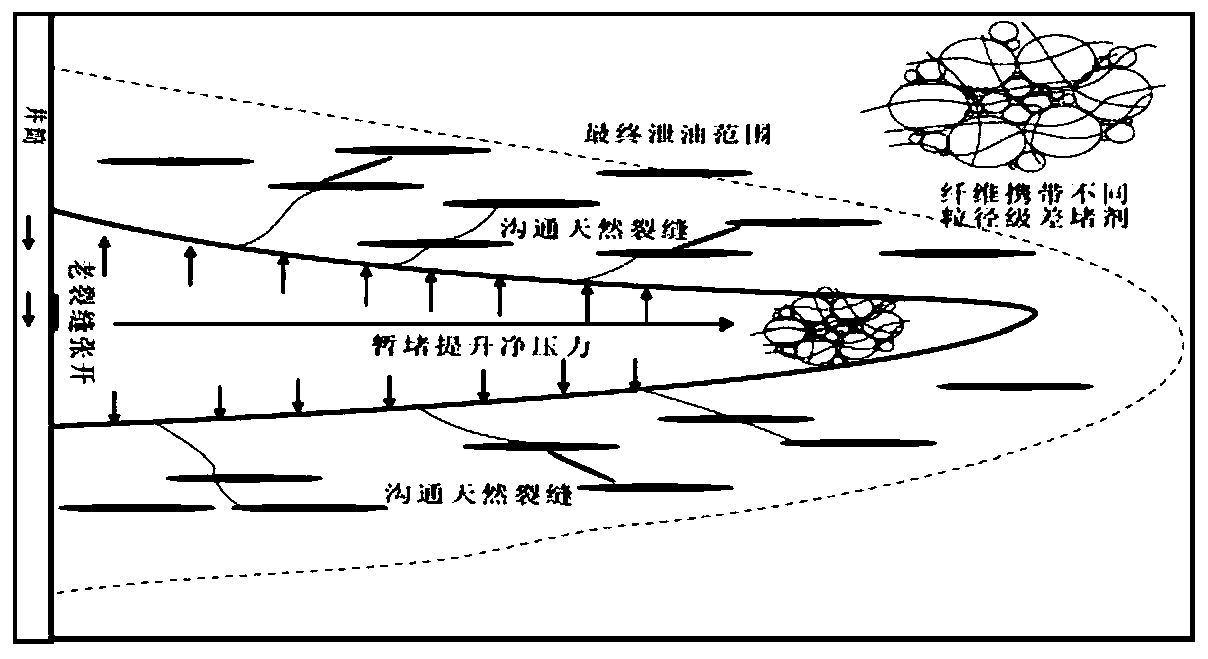

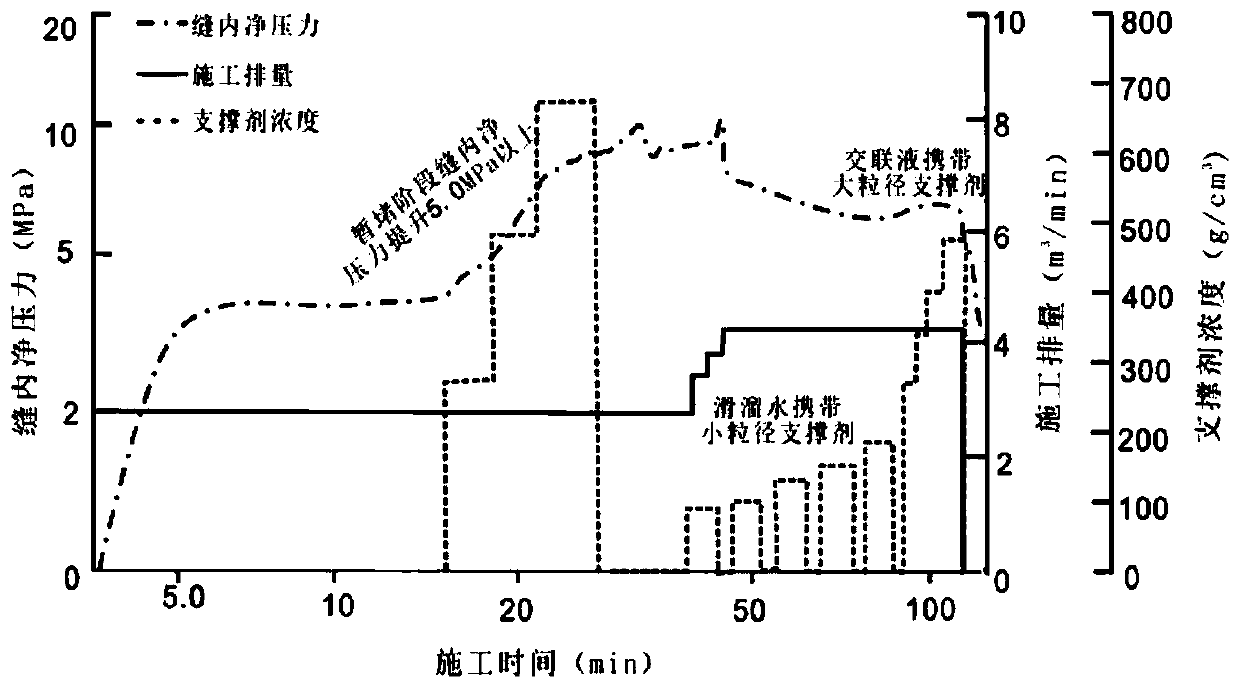

ActiveCN108316909BIncrease net pressureReduce support height dropFluid removalLiquid viscosityFracturing fluid

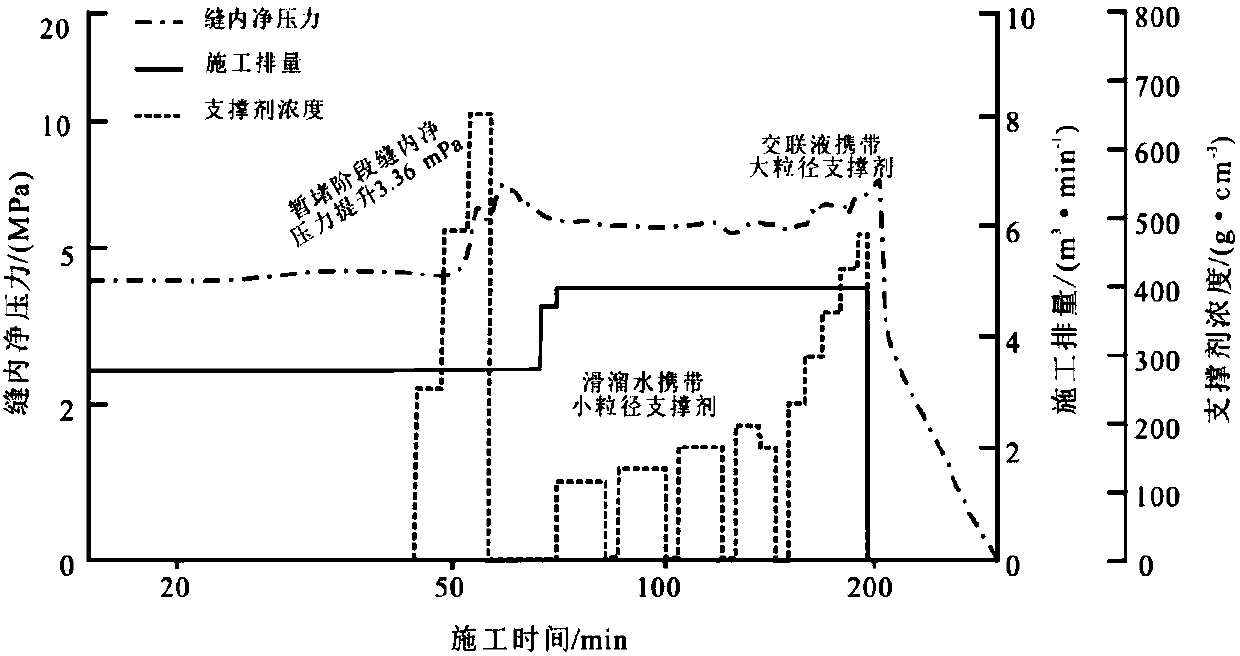

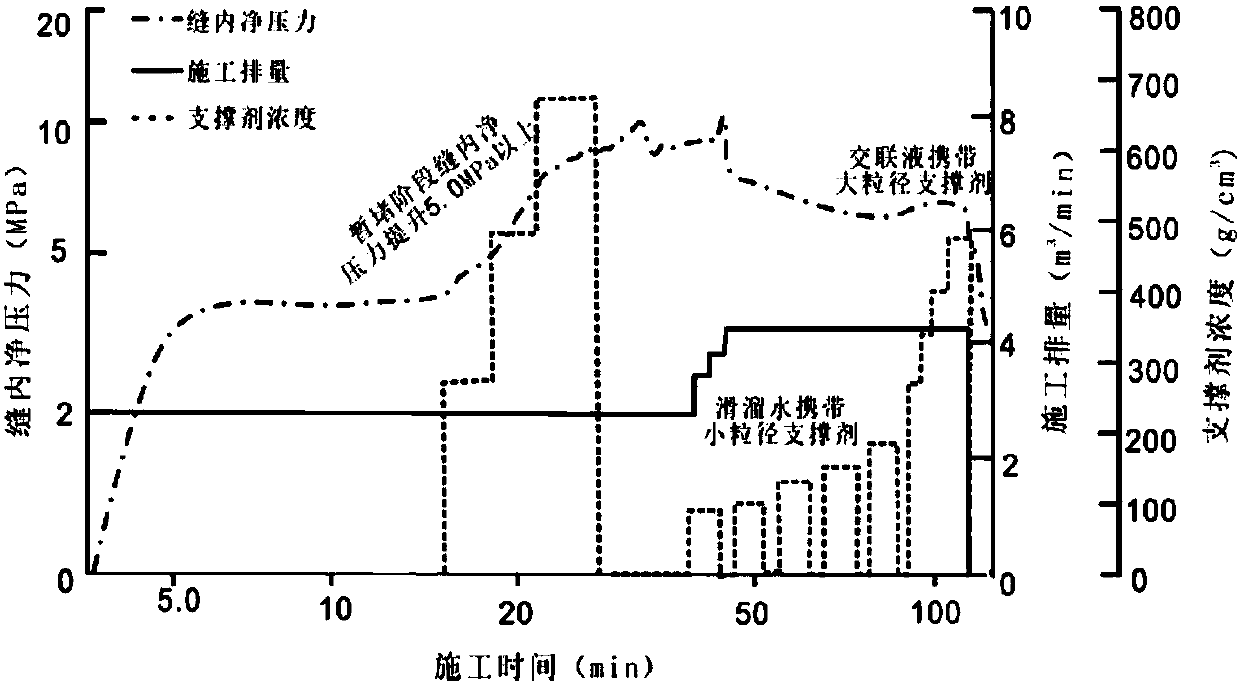

The invention belongs to the field of oil exploitation and particularly provides an oil-gas reservoir fracturing construction method. The oil-gas reservoir fracturing construction method comprises a prepad fluid stage and a main sand adding stage. According to the prepad fluid stage, fracturing liquid is injected at multiple levels of construction displacement which is increased level by level from the lowest construction displacement to the highest construction displacement; and according to the main sand adding stage, sand-carried liquid is injected at the highest construction displacement,wherein the lowest construction displacement is 45-65 % of the highest construction displacement. In the preferably-selected implementation mode, design is conducted according to different construction sections, the different fracturing liquid displacement and corresponding fracturing liquid viscosities and using quantities are adopted, the mode of different-particle-diameter variable density sandadding is adopted, by utilizing the setting effect of a supporting agent, the net pressure in cracks at the supporting agent non-setting position is increased, thus the seam making height and the supporting height of remote well cracks are increased, the flow guiding capacity of the cracks at remote wells is improved, and the progressively-decreasing speed of the single-well capacity is decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

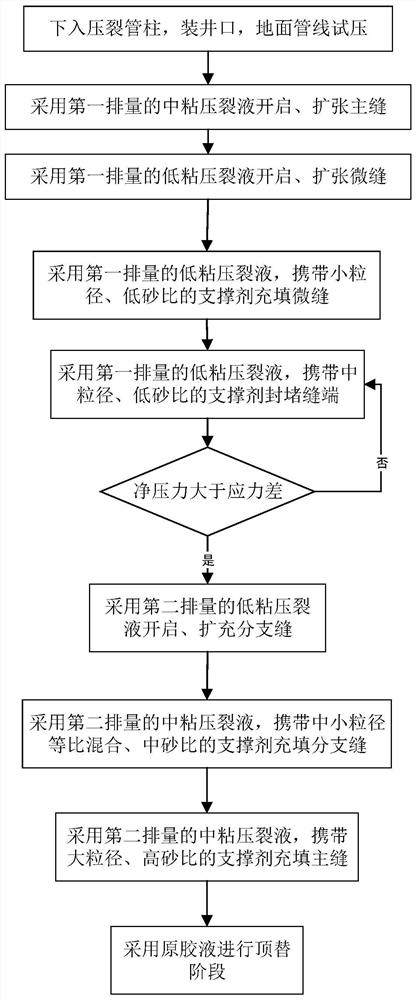

Fracturing method for shallow layer dense oil reservoir horizontal seam

The invention relates to a fracturing method for a shallow layer dense oil reservoir horizontal seam, and belongs to the technical field of oil-gas well fracturing yield increase. The fracturing method comprises the following steps that a main seam is opened and expanded; micro-seams are opened and expanded; the micro-seams are filled; seam ends are plugged; when the net pressure is larger than the difference between the maximum stress and the minimum stress, branch seams are opened and expanded; the branch seams are filled; the main seam is filled; and displacement operation is conducted, andfracturing of the horizontal seam is completed. According to the method, the micro-seams are formed in the main seam of the horizontal seam, the micro-seams are expanded and filled, and the seam endsare plugged, so that the branch seams are formed, then the branch seams and the main seam are filled, and fracturing of the horizontal seam is completed; and through fracturing of the horizontal seam, complex seams such as a vertical seam or a T-shaped seam are formed on the basis of the horizontal seam, so that the effective transformation size is increased, a reservoir is fully transformed, thelongitudinal and planar reserve utilization degree of an oil layer of a shallow layer dense oil reservoir is improved, and the oil yield of an oil well is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

A fracturing process for realizing complex fractures by temporary plugging with multi-grain size difference

ActiveCN107558981BIncrease net pressureSolve the problem that the effect of increasing the net pressure is poorFluid removalDrilling compositionFiberThermodynamics

The invention discloses a fracturing technique for achieving a complex crack through multiple particle class differential temporary blocking, which is fracturing technique that a primary artificial crack is temporarily blocked through rigid temporary plugging agent composition with particle size class differential carried by a fracturing fluid, net pressure in the crack is improved, and a new sidecrack is opened. The fracturing technique comprises the steps that the rigid temporary blocking agent carried by a biodegradable polylactic acid resin-like fiber fracturing fluid with four kinds of particle size class differential combination is fast injected according to the sand mulling concentration of 350-500-650g / cm3, and crack deep part temporary blocking is carried out; the net pressure inthe crack is improved, and the side natural crack is opened, and side remaining oil is effective used; and the oil well single well production and final recovery ratio are improved. The fracturing technique has the advantages that the operability of the construction technique is high, a complex fracture system is fractured to be formed, the using degree of the oil well side remaining oil is improved, the cost is low, and the oilfield development benefit is greatly improved, and solves the difficult problem of the poor repeated fracturing effect of low-permeability reservoirs.

Owner:PETROCHINA CO LTD

Fracturing method for opening new crack through crack saturated filling sand

PendingCN112943208AIncrease utilizationImprove single well productionFluid removalGeotechnical engineeringOil field

The invention belongs to the technical field of oilfield development downhole operation fracturing, and particularly provides a fracturing method for opening a new crack through crack saturated filling sand. A proppant is continuously injected into a primary artificial crack according to a sand-liquid ratio of 20%, 30% and 40%, and a gel breaker is added in a process of adding the proppant, so that the saturated filling sand inside the primary artificial crack is enabled to cause sand plugging in the crack; meanwhile, the net pressure in the crack is further improved by improving the construction displacement, a lateral new crack is opened, effective support is formed for the new crack, the purposes of forming a complex crack system, expanding the using degree of lateral remaining oil and improving the single well yield and the final recovery efficiency of an oil well are achieved. The technological process is simple and easy to implement, the cost is lower, and the characteristics of high on-site temporary plugging and rising amplitude controllability can greatly improve the production benefit of an oil field, and has wide application prospects in the aspects of increasing the single-well yield of lateral low-yield oil wells of ultra-low permeability reservoirs and ultra-low permeability reservoirs and improving the water drive effect of the low permeability reservoirs.

Owner:PETROCHINA CO LTD

Horizontal drilling and coring of directional window cutting and matching methods

The invention relates to horizontal drilling and coring of directional window cutting and matching methods. The process comprises the steps: (1) drilling a horizontal hole using an ultra-short radius radial horizontal drilling tool guided by a whipstock; (2) plugging the position of a casing above the whipstock by using a packer; (3) injecting a fracturing fluid by using a fracturing string to form a major fracture in the stratum; (4) plugging the major fracture with a temporary plugging agent; and (5) improving the pressure of the fracturing liquid by 5-10 MPa, and injecting once more the fracturing liquid via the fracturing string to form a great quantity of secondary fractures around the major fracture in the stratum. According to the invention, ultra-short radius radial horizontal drilling and fracture network fracturing are combined so that the direction of a horizontal hole can be determined and a drilling diameter and a drilling length can be increased on the basis of the existing techniques; common fracturing is replaced by fracture network fracturing; thus, a new production-increasing and efficiency-raising technique is provided in the aspects of excavating potential remaining oil, improving low permeability reservoirs, etc., allowing tenfold increase or more in per-well production.

Owner:DAQING JINGTAI PETROLEUM ENG TECH

Repeated transformation method for improving crack plugging effect

ActiveCN112392455APlay a blocking roleGrowth inhibitionGeothermal energy generationFluid removalThermodynamicsSealant

The invention discloses a repeated transformation method for improving the crack plugging effect. A differential pressure chemical plugging technology and a repeated fracturing technology are combined, a differential pressure activating sealant A is injected into a target layer, the sealant filters out pores of a reservoir matrix through primary fracturing artificial cracks of the target layer, acertain throttling pressure difference can be formed, under the action of the pressure difference, the differential pressure activating sealant A is polymerized to form a high-temperature-resistant and high-pressure-resistant tough solid, and thus reservoir pores are plugged; a differential pressure activating sealant B is injected into the target layer, a certain throttling pressure difference can be formed when the sealant passes through a pore passage between the artificial cracks and a propping agent, polymerizing can be conducted under the action of the pressure difference to form a high-temperature-resistant and high-pressure-resistant tough solid, and thus the artificial cracks and a large pore passage are plugged; and repeated fracturing is conducted on the target layer, under theplugging effect of the differential pressure activating sealants, the cracks are inhibited from extending along the primary artificial cracks, the net pressure is increased, new cracks are forced to be opened, the original artificial cracks with water are avoided, and remaining oil is used.

Owner:PETROCHINA CO LTD

A high-efficiency self-produced gas foam fracturing fluid and its construction method

ActiveCN109762549BImprove liquiditySimplify field processesFluid removalDrilling compositionToxic gasThermodynamics

The present invention provides a high-efficiency self-generated gas foam fracturing fluid and a construction method. The foam fracturing fluid is composed of a base fluid, a gas-generating fluid and a heat-generating agent, wherein the mass ratio of the base fluid, gas-generating fluid, and heat-generating agent is 100: (30‑42): (5‑9). During construction, the base fluid and the gas-producing fluid are pumped downhole together through the suction of the sand mixing truck according to the mass ratio, and the heat generating agent is pumped into the downhole along with the proppant. The invention does not need liquid nitrogen accompanying injection, simplifies the on-site process and reduces the construction cost, and a large amount of gas generated through the chemical reaction achieves the purpose of increasing the energy of the formation, improving the flow capacity of the reservoir liquid, and increasing the output. It can quickly generate a large amount of inert and safe gas, and will not produce toxic gas of nitrogen oxides, reducing construction risks. At the same time, the alkaline environment generated by the reaction product is conducive to the formation of fracturing fluid gel and the corrosion protection of downhole pipe strings. By generating foam, the Jiamin effect is used to increase the net pressure of the formation, which can quickly flow back, generate heat in the deep formation to promote gel breaking, and reduce the damage of fracturing fluid to the reservoir.

Owner:PETROCHINA CO LTD

Composite acid fracturing method for improving flow conductivity of ultra-deep carbonate reservoir and application

The invention discloses a composite acid fracturing method for improving flow conductivity of an ultra-deep carbonate reservoir and application. The method comprises the steps that firstly, low-viscosity low-friction neutral slickwater is injected to form cracks, then low-viscosity low-friction strong-acid slickwater is injected to etch the formed cracks, the displacement is gradually increased, the neutral slickwater and the acid slickwater are injected in a circulating mode, after the corrosion range and the crack width of acid liquor are gradually enlarged, self-suspension propping agents with different particle sizes are added from small to large to support formed main crack and branch crack micro-crack systems, and finally displacement operation is conducted. According to the method, the construction displacement and the net pressure in the cracks can be effectively increased, the transformation range and the corrosion width of the acid liquor are enlarged, adding of the self-suspension propping agents is facilitated, the flow conductivity of the multiple types of acid etching cracks under the ultra-deep condition is improved, and the production stability and the long-term performance are kept.

Owner:CHINA PETROLEUM & CHEM CORP +1

A volumetric fracturing method for activating natural fractures on a large scale

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com