Deep compact gas pool fracturing liquid

A technology of tight gas and fracturing fluid, applied in the field of fracturing fluid, can solve problems such as low construction success rate, opening of fracturing cracks, and research limitations of extension mechanism fracturing working fluids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

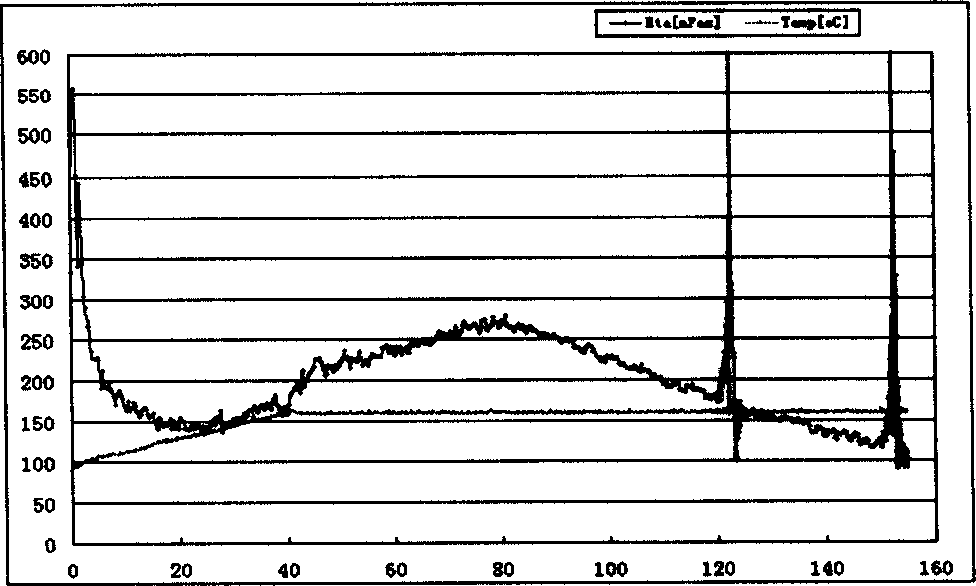

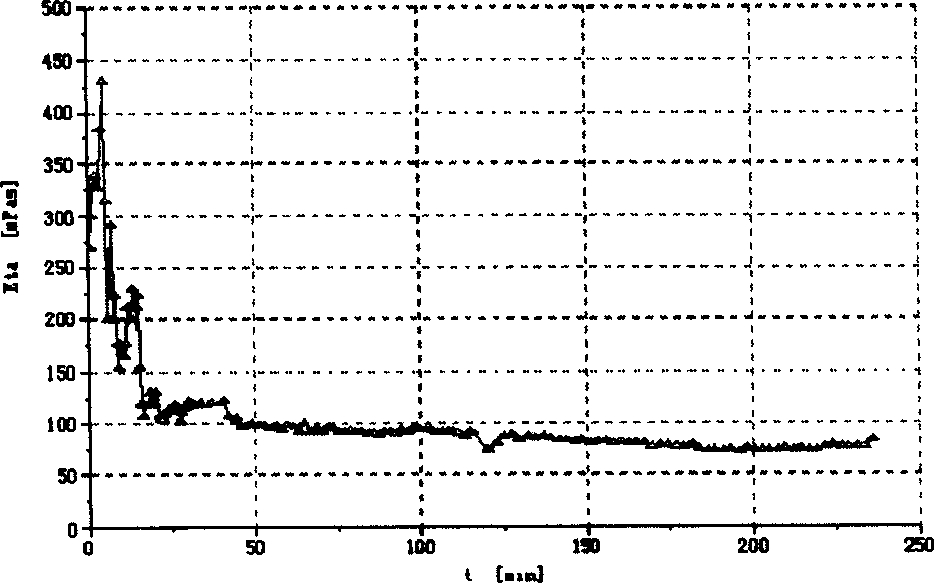

Image

Examples

specific Embodiment approach 1

[0004] Specific embodiment one: The fracturing fluid of this embodiment is mixed by the following components by weight percentage: thickener 0.2~1.0%, surfactant 0.05~0.2%, clay stabilizer 0.1~1%, bactericide 0.01~ 0.2%, buffering agent 0.05-0.2%, temperature stabilizer 0.1-0.5%, high-temperature cross-linking agent 0.1-0.5%, cross-linking control agent 0.1-0.5%, gel breaker 0.001-0.01%, gel-breaking catalyst 0.0001-0.001 %, defoamer 0.01-0.15%, fluid loss reducer 1-5%, and the balance is water. The thickener is hydroxypropyl modified guar gum, guar gum, hydroxypropyl modified guar gum, carboxymethyl hydroxypropyl modified guar gum, coumarin, xanthan gum or carboxymethyl cellulose ; The surfactant is a fluorine-containing surfactant or an anionic surfactant; the clay stabilizer is a small molecular weight clay stabilizer or KCl; The buffer is an organic acid-base buffer; the temperature stabilizer is a complex of sodium thiosulfate and low molecular weight alcohol; the high-t...

specific Embodiment approach 2

[0005] Specific embodiment two: The fracturing fluid of this embodiment is mixed by the following components by weight percentage: thickener 0.3~0.5%, surfactant 0.06~0.1%, clay stabilizer 0.2~0.5%, bactericide 0.02~ 0.1%, buffering agent 0.06-0.12%, temperature stabilizer 0.15-0.3%, high-temperature cross-linking agent 0.15-0.25%, cross-linking control agent 0.2-0.3%, gel breaker 0.002-0.05%, gel-breaking catalyst 0.0002-0.0005 %, defoamer 0.02-0.05%, fluid loss reducer 1.5-3%, and the balance is water.

specific Embodiment approach 3

[0006] Specific embodiment three: The fracturing fluid of this embodiment is mixed by the following components by weight percentage: thickener 0.6~0.9%, surfactant 0.12~0.18%, clay stabilizer 0.6~0.9%, bactericide 0.12~ 0.18%, buffering agent 0.15~0.19%, temperature stabilizer 0.32~0.48%, high temperature crosslinking agent 0.35~0.45%, crosslinking control agent 0.35~0.4%, gel breaker 0.06~0.09%, gel breaking catalyst 0.0006~0.0009 %, defoamer 0.06-0.09%, fluid loss reducer 3.5-4.5%, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com