Shale gas fracturing stepping sand-adding method

A kind of air pressure and ladder technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of sand plugging, increase construction process and engineering cost, affect the effect of reservoir transformation, etc., and achieve enhanced effect and improved Liquid sand-carrying efficiency and the effect of increasing net pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

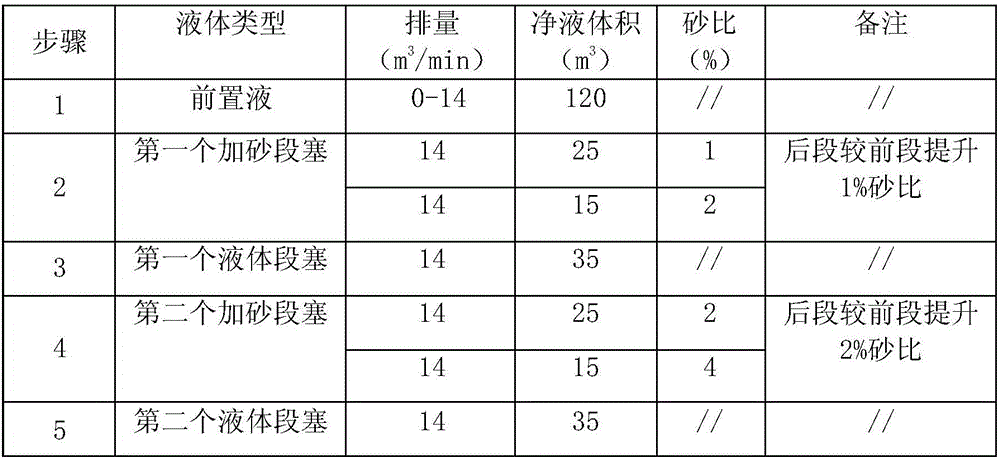

[0017] Table 1 uses the stepwise sand injection pumping procedure (overview) for fracturing a certain shale gas well as a specific description.

[0018] This embodiment includes the following steps:

[0019] (1) Pumping pre-fluid: use surface high-pressure pumping equipment to pump 120 cubic meters (6 wellbore volumes) of pre-fluid into the wellbore, and the liquid enters the formation to create fractures.

[0020] (2) Pump the first sand-adding slug, and after the pre-fluid enters the formation to create fractures, start to add proppant quartz sand to the fracturing fluid to fill the fractures, with 40 cubic meters (2 wellbore volumes) of sand fluid As a sand-adding slug, 62.5% of the volume before the first sand-adding slug is added with sand at a ratio of 1%, and the sand ratio is constant. After the first sand-added slug, 37.5% of the volume is added with sand at a ratio of 2%.

[0021] (3) Pump the first liquid slug, use 35 cubic meters (1.7 wellbore volume) of fracturin...

Embodiment 2

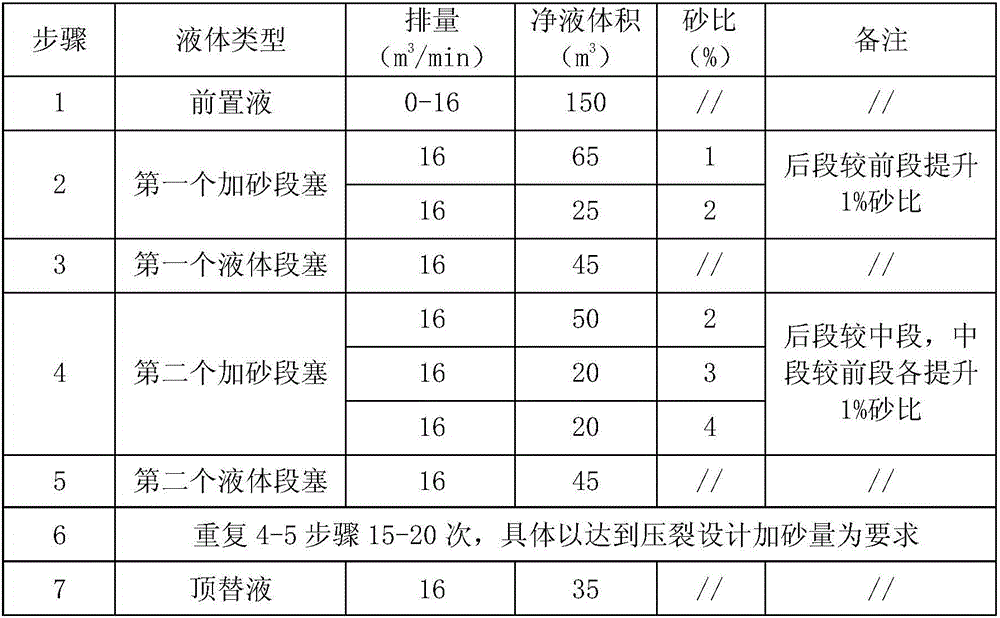

[0029] In this embodiment, the stepwise sand addition method for fracturing is shown in the table below, and the pumping procedure is as follows:

[0030]

[0031] The well is a shale gas horizontal well in the southeastern area of Chongqing. Through the stepped sanding fracturing process, the subsequent sanding space of the wellbore passing through different formations can be effectively predicted, the sand-carrying efficiency of the liquid is improved, and the potential of different formations is initially explored. The critical sanding point provides a reliable basis for subsequent drilling trajectory design and fracturing scheme design. At the same time, at the second sanding slug, the construction pressure is stable and basically remains unchanged, indicating that the formation has good sanding properties and increases Up to 3 different sand ratios, gradually increasing in increments of 1%, increase the sand volume and liquid sand-carrying efficiency in fracturing sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com