Horizontal drilling and coring of directional window cutting and matching methods

A technology of horizontal drilling and horizontal drilling, which is used in the production of fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of poor oil field stimulation effect, etc., to improve the single well production, increase the diameter and length of the borehole Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

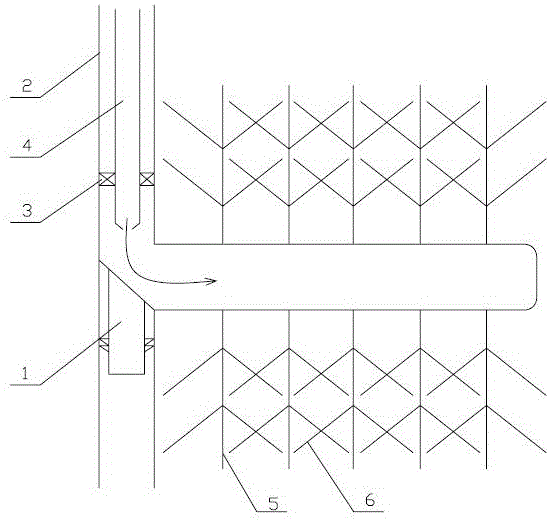

[0017] figure 1 It is a schematic diagram of the structure of the present invention. The arrow in the figure shows the injection direction of the fracturing fluid. The directional windowing horizontal drilling, coring and supporting methods of the present invention are tested in an oil field, and the well depth is 1762.39 meters. The method includes the following steps during use :

[0018] (1) Use ultra-short radius radial horizontal drilling tools to drill wells, and form horizontal wellbore under the guidance of the skewer 1;

[0019] (2) Use packer 3 to seal off casing 2 above inclined device 1;

[0020] (3) Use the fracturing string 4 to inject fracturing fluid with a pressure of 36MPa to form main fractures 5 in the formation;

[0021] (4) Block the main crack 5 with a temporary plugging agent;

[0022] (5) Increase the pressure of the fracturing fluid by 5-10 MPa, and inject it again through the fracturing string 4 to form a large number of secondary fractures 6 arou...

Embodiment 2

[0024] The directional window-opening horizontal drilling, coring and matching method of the present invention are tested on an oil field, the well depth is 2301.9 meters, and the method comprises the following steps during use:

[0025] (1) Use ultra-short radius radial horizontal drilling tools to drill wells, and form horizontal wellbore under the guidance of the skewer 1;

[0026] (2) Use packer 3 to seal off casing 2 above inclined device 1;

[0027] (3) Use the fracturing string 4 to inject fracturing fluid with a pressure of 44.6MPa to form main fractures 5 in the formation;

[0028] (4) Block the main crack 5 with a temporary plugging agent;

[0029] (5) Increase the pressure of the fracturing fluid by 5-10 MPa, and inject it again through the fracturing string 4 to form a large number of secondary fractures 6 around the main fractures 5 in the formation.

Embodiment 3

[0031] The directional window-opening horizontal drilling, coring and supporting methods of the present invention are tested in an oil field, and the well depth is 3262.65 meters. The method comprises the following steps during use:

[0032] (1) Use ultra-short radius radial horizontal drilling tools to drill wells, and form horizontal wellbore under the guidance of the skewer 1;

[0033] (2) Use packer 3 to seal off casing 2 above inclined device 1;

[0034] (3) Use the fracturing string 4 to inject fracturing fluid with a pressure of 55.2MPa to form main fractures 5 in the formation;

[0035] (4) Block the main crack 5 with a temporary plugging agent;

[0036] (5) Increase the pressure of the fracturing fluid by 5-10 MPa, and inject it again through the fracturing string 4 to form a large number of secondary fractures 6 around the main fractures 5 in the formation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com