Oil and gas well fracture network system fracturing technology

A technology for oil and gas wells and fracture networks, which is applied in the fields of production fluids, wellbore/well components, and earth-moving drilling, etc. It can solve the problems of limited seepage area and poor oil and gas supply capacity of the fracture system, and achieve the effect of increasing the seepage volume of the well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

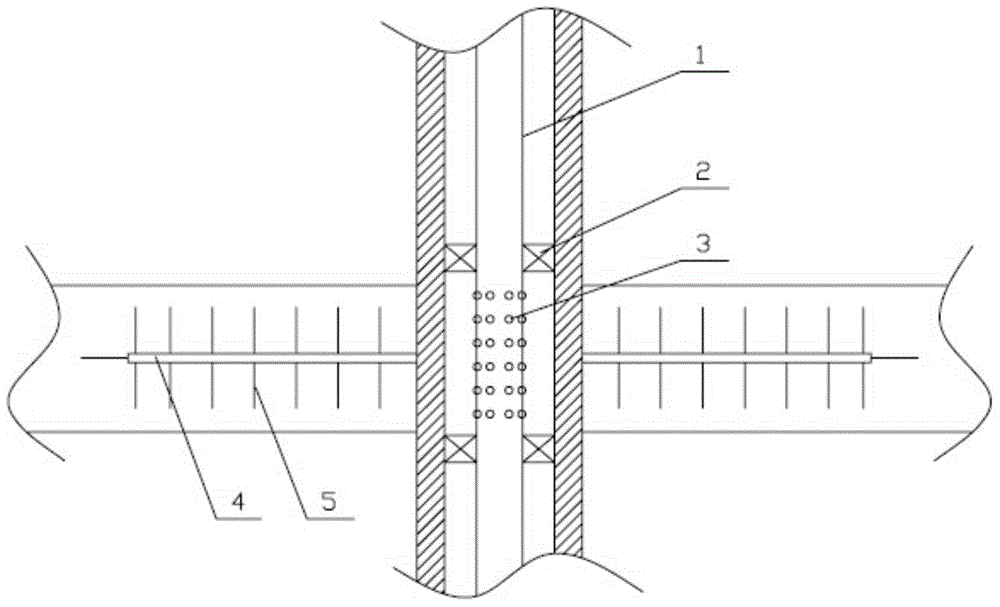

[0017] The oil and gas well fracture network system fracturing process of the present invention is tested on the oil field, the well depth is 1762.39 meters, and the method comprises the following steps during use:

[0018] (1) perforating on the tubing 1;

[0019] (2) Utilize the packer 2 to block the upper and lower ends of the perforation 3;

[0020] (3) Fracturing fluid, with a pressure of 36MPa, is injected through perforations to form main fractures 4 in the formation;

[0021] (4) Use a temporary plugging agent to block the main crack;

[0022] (5) Increase the pressure of the fracturing fluid by 5-10 MPa and inject it again through perforation to form a large number of secondary fractures 5 around the main fractures in the formation.

Embodiment 2

[0024] The oil and gas well fracture network system fracturing process of the present invention is tested on the oil field, the well depth is 2301.9 meters, and the method comprises the following steps during use:

[0025] (1) perforating on casing 1;

[0026] (2) Utilize the packer 2 to block the upper and lower ends of the perforation 3;

[0027] (3) Fracturing fluid, with a pressure of 44.6MPa, is injected through perforations to form main fractures 4 in the formation;

[0028] (4) Use a temporary plugging agent to block the main crack;

[0029] (5) Increase the pressure of the fracturing fluid by 5-10 MPa and inject it again through perforation to form a large number of secondary fractures 5 around the main fractures in the formation.

Embodiment 3

[0031] The oil and gas well fracture network system fracturing process of the present invention is tested on the oil field, and the well depth is 3262.65 meters. The method includes the following steps when used:

[0032] (1) perforating on casing 1;

[0033] (2) Utilize the packer 2 to block the upper and lower ends of the perforation 3;

[0034] (3) Fracturing fluid, with a pressure of 55.2MPa, is injected through perforations to form main fractures 4 in the formation;

[0035] (4) Use a temporary plugging agent to block the main crack;

[0036] (5) Increase the pressure of the fracturing fluid by 5-10 MPa and inject it again through perforation to form a large number of secondary fractures 5 around the main fractures in the formation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com