Horizontal well pre-fracturing injection fluid development method based on three-dimensional fracturing well pattern

A technology for horizontal wells and fracturing wells, which is applied in the field of injection fluid development before horizontal well fracturing, can solve the problems of limited improvement in final recovery, limited gas flow capacity, and small swept area between wells, etc., so as to improve the flow capacity of crude oil. , the effect of enhancing formation energy and prolonging stable production period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

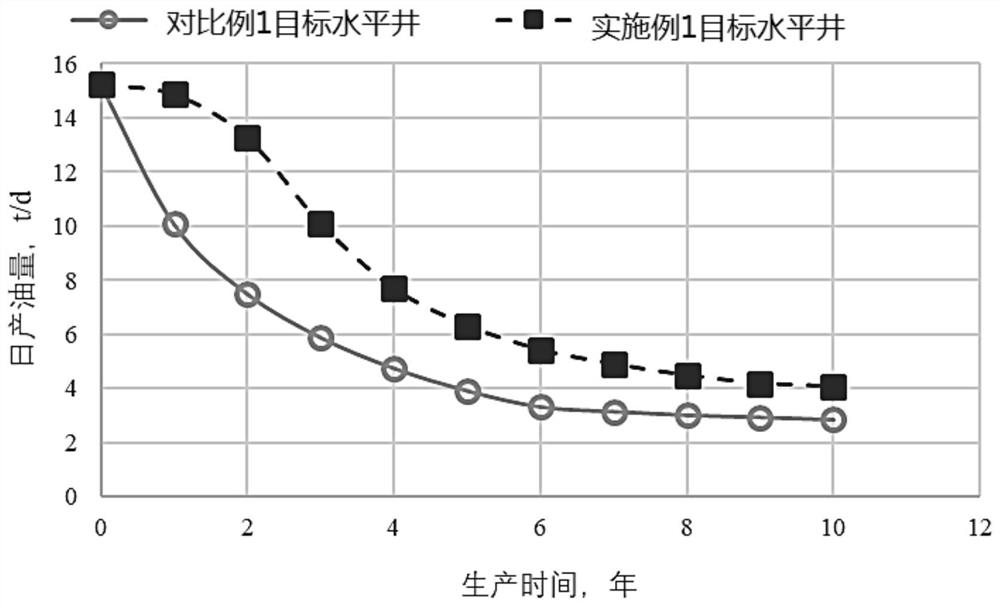

Embodiment 1

[0034] This embodiment provides a development method for injecting fluid before horizontal well pressure based on a three-dimensional fracturing well pattern, which is used for the development and production of a certain oil reservoir.

[0035] The reservoir is a tight reservoir with a porosity of 0.12, a permeability of 0.13mD, a reservoir thickness of 30m and a crude oil volume coefficient of 0.7.

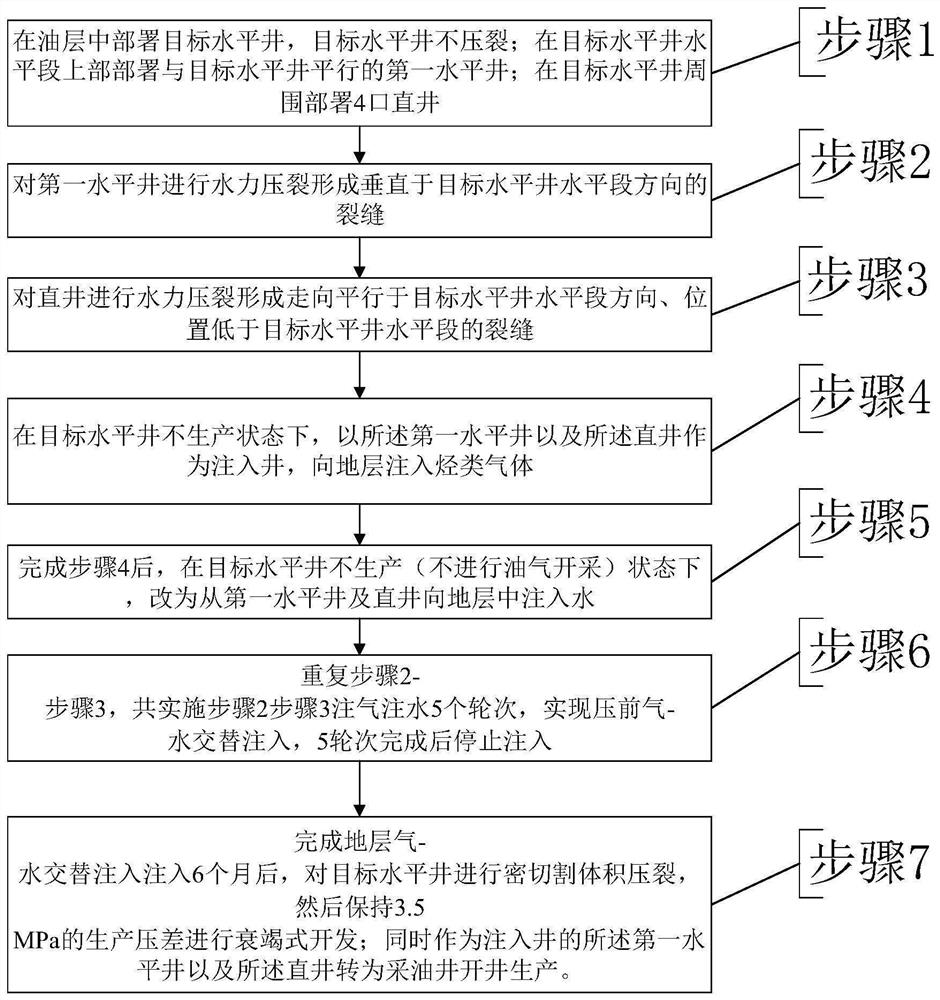

[0036] according to figure 1 As shown in the process, the development method of fluid injection before horizontal well pressure based on three-dimensional fracturing well pattern provided in this embodiment includes:

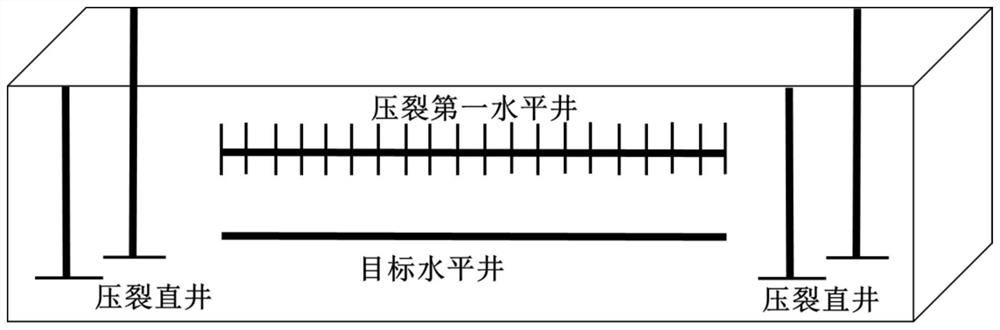

[0037] Step 1: Deploy the target horizontal well in the oil layer, and do not perform fracturing on the target horizontal well before injecting energy-enhancing fluid; deploy the first horizontal well parallel to the target horizontal well in the upper part of the horizontal section of the target horizontal well; 4 vertical wells are deployed around;

[0038] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com