Fracturing method

A fracturing and fracturing fluid technology, applied in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve problems such as poor fracturing stimulation effect, increase formation energy, and increase fracture oil and gas migration capacity, etc. Achieve the effect of improving seepage characteristics, increasing formation energy, and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described below with reference to the accompanying drawings.

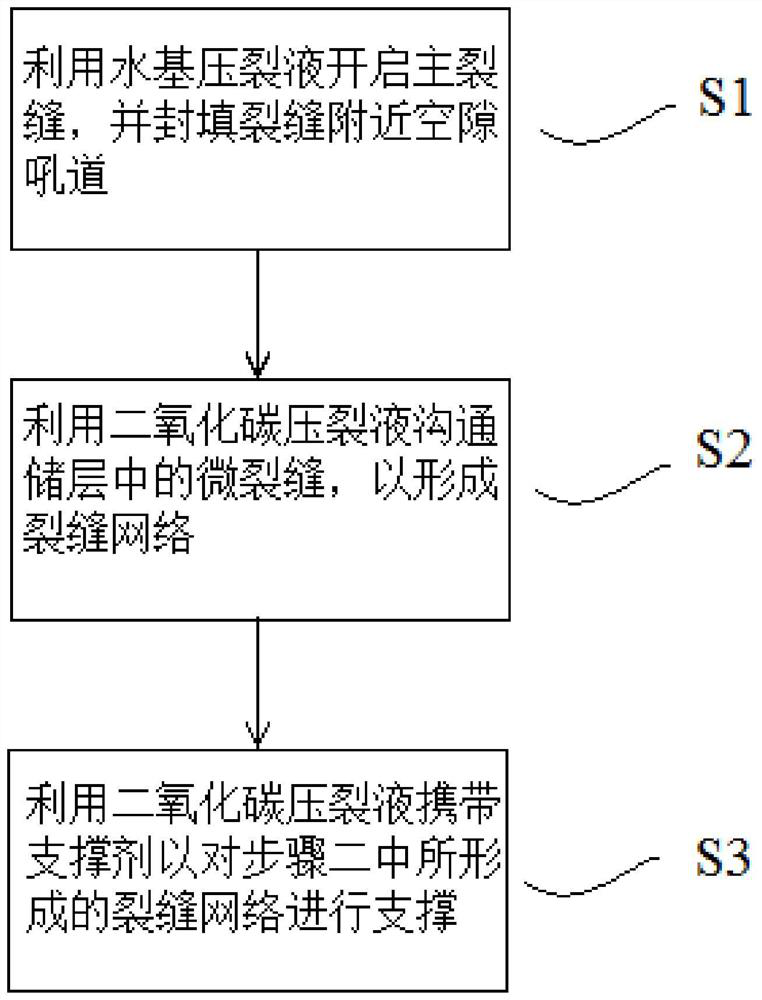

[0030] figure 1 Shows a process flow diagram of a method of fracturing of the present invention. The object is to provide a method of fracturing water-based fracturing fluid - carbon dioxide dry-energizing composite fracturing. Specifically, as a step S1, a water-based fracturing fluid to open the main crack, void fill and seal cracks in the vicinity shouted. The two step S2, first with carbon dioxide fracturing fluid communication to micro-cracks in the reservoir, network of fractures. The three step S3, carbon dioxide fracturing fluid carries the proppant to the fracture network formed in step three supports.

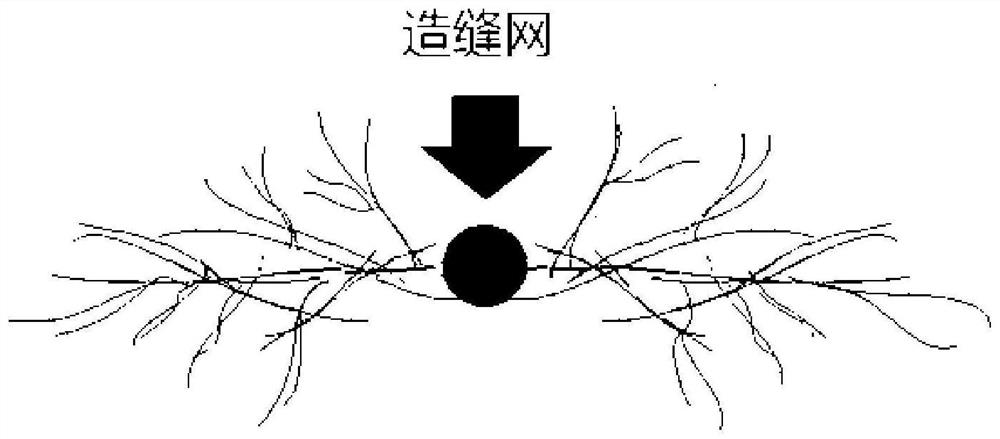

[0031] The fracturing method of fracturing multiple ways fracturing fluid composition can be formed in a tight reservoir fracture network system main slit and a plurality of branch combined fractures, increase fracture conductivity, expansion of the area control wells redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com