Method for increasing production of heavy oil by steam-nitrogen mixed injection and special device

A special device and heavy oil technology, which is applied in the field of steam-nitrogen mixed injection heavy oil production stimulation method and special device, can solve the problems of small heating radius and swept volume, serious heat loss, etc., so as to improve oil displacement effect, increase formation energy, The Effect of Reducing the Exploitation Cost of Heavy Oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

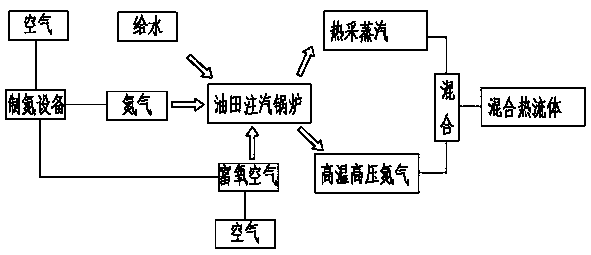

[0026] Embodiment 1: The steam-nitrogen mixed injection method for increasing production of heavy oil production is carried out as follows: utilize nitrogen-making equipment 1 to separate air to obtain high-purity nitrogen and oxygen-enriched air, the purity of high-purity nitrogen is more than 95%, and the high-purity nitrogen After the pressure of pure nitrogen is increased to the same pressure as thermal recovery steam, the pressurized high-purity nitrogen is heated to the same temperature as thermal recovery steam, and the pressurized and heated high-purity nitrogen is mixed with thermal recovery steam to obtain thermal recovery Mixed fluid, the thermal recovery mixed fluid is injected into the formation through the steam injection pipeline for heavy oil recovery.

[0027] The method described in this example mixes high-temperature, high-pressure, high-purity nitrogen with thermal recovery steam and injects it into the formation to maintain the pressure of the steam chamber...

Embodiment 2

[0032] Embodiment 2: As an optimization of Embodiment 1, the thermal recovery steam is produced by the steam injection boiler 2 in the oil field; the oxygen-enriched air is recovered, buffered and pressurized, and then the oxygen-enriched air is sent to the burner 5 of the steam injection boiler 2 in the oil field Moderate combustion, the oxygen content of oxygen-enriched air is in the range of 21% to 99%; the pressurized high-purity nitrogen can be heated to the same temperature as the thermal recovery steam through the oilfield steam injection boiler 2; the thermal recovery steam is saturated steam or superheated steam.

[0033] The production increase method described in this example realizes the generation of high-temperature and high-pressure saturated steam or superheated steam for production increase in heavy oil production, the preparation of high-purity nitrogen, the recovery of oxygen-enriched air, and the heating of nitrogen. 2 The burner 5 burns to make its combust...

Embodiment 3

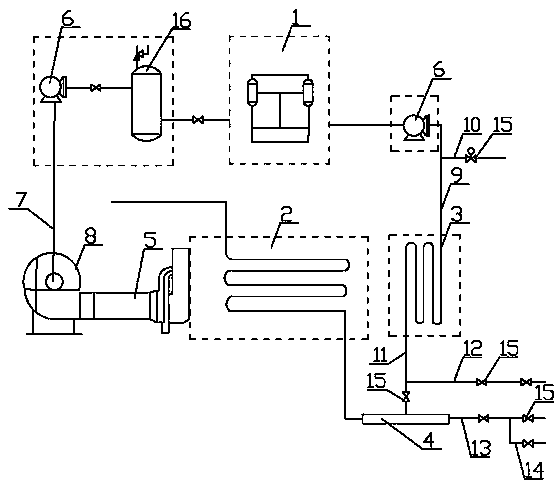

[0035] Embodiment 3: as attached figure 1 , 2 As shown, the special device for implementing the steam-nitrogen mixed injection method for increasing production of heavy oil includes nitrogen-making equipment 1, nitrogen booster equipment, oxygen-enriched recovery equipment, oil field steam injection boiler 2, nitrogen heating equipment 3 and blender 4, The nitrogen outlet end of the nitrogen making device 1 is connected with the inlet end of the nitrogen booster device, the outlet end of the nitrogen booster device is connected with the inlet end of the nitrogen heating device 3, and the outlet end of the nitrogen heating device 3 is connected with the inlet port of the blender 4. The first inlet port is connected; the mixed gas outlet port of the nitrogen making equipment 1 is connected with the inlet port of the oxygen-enriched recovery device, and the gas outlet port of the oxygen-enriched recovery device is connected with the air inlet port of the burner 5 of the steam inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com