A low-corrosion self-generating energized fracturing fluid and its preparation method

A self-generating, low-corrosion technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficient utilization of fracturing fluid, high equipment requirements, and difficult control of the reaction, so as to improve reservoir permeability Efficiency, simplification of on-site process, and reduction of filter loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

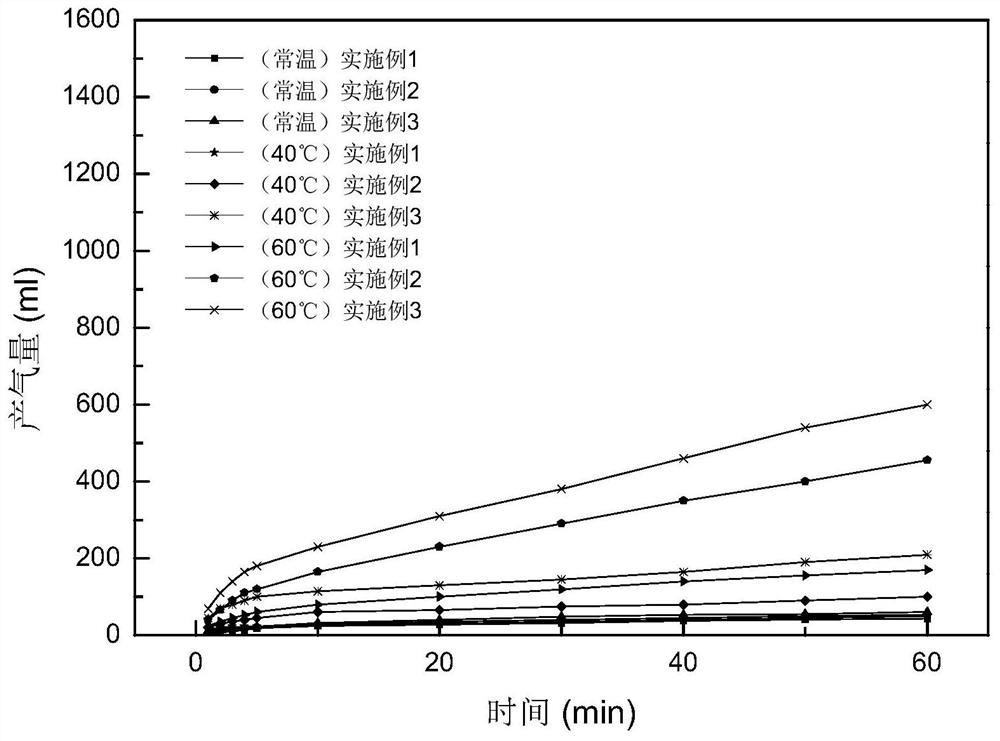

Embodiment 1

[0042] A low-corrosion self-generating energized fracturing fluid prepared by mixing an air-generating agent solution and an initiator solution; the air-generating agent solution includes the following raw materials: 2.5g of urea, 5g of sodium nitrite, and 0.4g of a polymer thickener , 0.4g of organic zirconium crosslinking agent, 0.05g of ammonium persulfate, 0.08g of formaldehyde aqueous solution with a mass concentration of 37%-40%, and 41.57g of water. The initiator solution comprises the following raw materials: 0.05 g of polyacrylamide with a weight-average molecular weight of 2 to 4 million, 3 g of methyl formate, 1.5 g of ammonium chloride, 0.8 g of methanol, and 44.65 g of water. The mass ratio of the gasifying agent solution and the initiator solution is 1:1.

[0043] The polymer thickener is formed by copolymerization of acrylamide (AM) and 2-acrylamido-2-methyl-propanesulfonate sodium (AMPS) at a mass ratio of 2.5:1. The specific preparation method As follows: Wei...

Embodiment 2

[0049] A low-corrosion self-generating energized fracturing fluid, which is prepared by mixing an air-generating agent solution and an initiator solution; the raw material composition of the air-generating agent solution is the same as in Example 1. The initiator solution comprises the following raw materials: 0.05 g of polyacrylamide with a weight average molecular weight of 2 to 4 million, 9 g of methyl formate, 4.5 g of ammonium chloride, 0.8 g of methanol, and 35.65 g of water. The mass ratio of the gasifying agent solution and the initiator solution is 1:1.

[0050] The preparation method of the above-mentioned low-corrosion self-generating energized fracturing fluid has the following steps:

[0051] (1) Weigh 2.5g of urea and 5g of sodium nitrite into 41.57g of distilled water and stir to dissolve, then slowly add 0.4g of polymer thickener, and adjust the speed of the stirrer at all times until the vortex formed by the liquid can be seen. At the top of the leaf axis, af...

Embodiment 3

[0055] A low-corrosion self-generating energized fracturing fluid, which is prepared by mixing an air-generating agent solution and an initiator solution; the raw material composition of the air-generating agent solution is the same as in Example 1. The initiator solution comprises the following raw materials: 0.05 g of polyacrylamide with a weight average molecular weight of 2 million to 4 million, 18 g of methyl formate, 9 g of ammonium chloride, 0.8 g of methanol, and 22.15 g of water. The mass ratio of the gasifying agent solution and the initiator solution is 1:1.

[0056] The preparation method of the above-mentioned low-corrosion self-generating energized fracturing fluid has the following steps:

[0057] (1) Weigh 2.5g of urea and 5g of sodium nitrite into 41.57g of distilled water and stir to dissolve, then slowly add 0.4g of polymer thickener, and adjust the speed of the stirrer at all times until the vortex formed by the liquid can be seen. At the top of the leaf a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com