A self-assembled ultrafine foam oil displacement agent and its preparation method and application

A technology of foam flooding and self-assembly, which is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc. It can solve the problems of large foam size, low viscosity, poor strength, etc., and reduce the start-up pressure and water injection Effects of increasing pressure, increasing seepage capacity, and enhancing oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

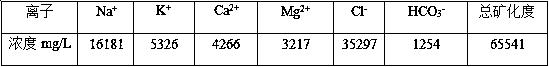

Method used

Image

Examples

Embodiment 1

[0036] 1. A kind of self-assembled microfoam oil displacement agent, comprises the component of following percentage by weight:

[0037] 2[N-methylene-N-dimethyl(1-dodecyl-1-sodium formate)-methine]ammonium bromide: 0.2%,

[0038] Sodium N-(1-dodecyloxyether-2-hydroxy)propane-N-dimethyl-N-(2-hydroxy)propanesulfonate: 0.2%,

[0039] Anionic surfactant is sodium dodecyl sulfate (SDS): 0.1%,

[0040] Triethanolamine: 0.03%,

[0041] Urea: 0.03%,

[0042] Chelating agent is EDTA: 0.14%,

[0043] Inorganic salt: 5%,

[0044] Surplus is water, total amount is 100%,

[0045] Wherein, the structural formula of the 2[N-methylene-N-dimethyl (1-dodecyl-1-sodium formate)-methine] ammonium bromide is: , n=12;

[0046] The structural formula of the N-(1-dodecyloxy ether-2-hydroxyl)propane-N-dimethyl-N-(2-hydroxyl)propanesulfonate sodium is , R=C 12 h 25 .

[0047] The 2[N-methylene-N-dimethyl(1-dodecyl-1-sodium formate)-methine]ammonium bromide and N-(1-dodecyloxyether-2- Hydrox...

Embodiment 2

[0052] 1. A kind of self-assembled microfoam oil displacement agent, comprises the component of following percentage by weight:

[0053] 2[N-methylene-N-dimethyl(1-dodecyl-1-sodium formate)-methine]ammonium bromide: 0.25%,

[0054] Sodium N-(1-dodecyloxyether-2-hydroxy)propane-N-dimethyl-N-(2-hydroxy)propanesulfonate: 0.25%,

[0055] Anionic surfactant is sodium dodecyl sulfate (SDS): 0.2%,

[0056] Triethanolamine: 0.02%,

[0057] Urea: 0.02%,

[0058] Chelating agent is EDTA: 0.04%,

[0059] Inorganic salt: 6%,

[0060] Surplus is water, total amount is 100%,

[0061] Wherein, the 2[N-methylene-N-dimethyl(1-dodecyl-1-sodium formate)-methine]ammonium bromide, N-(1-dodecyloxyether- 2-hydroxyl) propane-N-dimethyl-N-(2-hydroxyl) sodium propanesulfonate structural formula, preparation method are with embodiment 1;

[0062] The inorganic salts are sodium chloride, sodium carbonate, potassium chloride, and calcium chloride, wherein the sodium chloride, sodium carbonate, pota...

Embodiment 3

[0064] 1. A kind of self-assembled microfoam oil displacement agent, comprises the component of following percentage by weight:

[0065] 2[N-methylene-N-dimethyl(1-dodecyl-1-sodium formate)-methine]ammonium bromide: 0.3%,

[0066] Sodium N-(1-dodecyloxyether-2-hydroxy)propane-N-dimethyl-N-(2-hydroxy)propanesulfonate: 0.3%,

[0067] Anionic surfactant is sodium dodecyl sulfate (SDS): 0.35%,

[0068] Triethanolamine: 0.07%,

[0069] Urea: 0.07%,

[0070] Chelating agent is EDTA: 0.10%,

[0071] Inorganic salt: 7%,

[0072] Surplus is water, total amount is 100%,

[0073] Wherein, the 2[N-methylene-N-dimethyl(1-dodecyl-1-sodium formate)-methine]ammonium bromide, N-(1-dodecyloxyether- 2-hydroxyl) propane-N-dimethyl-N-(2-hydroxyl) sodium propanesulfonate structural formula, preparation method are the same as embodiment 1;

[0074] Described inorganic salt is sodium chloride, magnesium chloride, sodium sulfate, sodium bisulfate, sodium carbonate, potassium chloride, calcium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com