A construction tool and method for improving the recovery rate of horizontal wells in low-permeability reservoirs

A construction tool and horizontal well technology, which is applied in the direction of borehole/well valve device, production fluid, earthwork drilling and production, etc. It can solve the problem of limited increase in the overall pressure and production of horizontal well formations, difficulty in meeting differentiated energy supplement requirements, Problems such as the increase of water (gas) rate in horizontal wells can achieve the effects of improving the overall production degree and recovery rate, improving operation safety and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

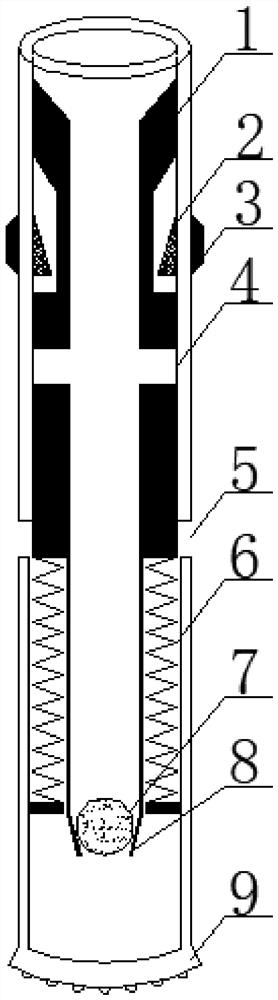

[0030] A construction tool for improving the recovery rate of a horizontal well in a low-permeability oil reservoir, comprising a pipe string, the pipe string includes an outer wall and an inner wall; a drill bit 9 is connected to the lower end of the pipe string; The upper slider 1, the sliding sleeve spring 6 and the ball seat 8; the upper slider 1 and the sliding sleeve spring 6 are located in the closed space formed by the outer wall and the inner wall; the upper part of the upper slider 1 and the outer wall form a cavity, and the middle part is provided with a sliding hole 4. The lower part is connected to the sliding sleeve spring 6;

[0031] A lower contact block 2 and a packer rubber sleeve 3 are arranged outside the pipe string, the lower contact block 2 is located in the cavity, and the packer rubber sleeve 3 is connected to the contact block and is located at the corresponding position outside the pipe string; There is also a fixed hole 5;

[0032] Also includes an...

Embodiment 2

[0043] On the basis of embodiment 1, it also includes: using liquid rubber plugs when sealing adjacent intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com