Ultra-low interfacial tension self-assembly carbon dioxide foam oil-displacing agent suitable for low-permeability reservoir as well as preparation method and application of oil-displacing agent

A technology of interfacial tension and carbon dioxide, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of low foaming liquid viscosity, lower interfacial tension, low oil displacement efficiency, etc., and achieve foaming Good performance in property and foam stability, reducing interfacial tension of oil and water, and increasing the difficulty of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. An ultra-low interfacial tension self-assembled carbon dioxide foam oil displacement agent suitable for low-permeability reservoirs, comprising the following components by weight percentage:

[0044] {Di[N-methyl-N-(3-dodecyloxy-2-hydroxy)propanyl-N-(2-hydroxy-3-sulfonate sodium)propanyl]ammonium chloride}ethane: 0.2 %,

[0045] Zwitterionic Surfactant Cocamidopropyl Betaine (CAB): 0.2%,

[0046] Nonionic surfactant lauryl dimethyl amine oxide (0B-2): 0.1%,

[0047] Sodium salicylate: 0.03%,

[0048] Chelating agent EDTA: 0.14%,

[0049] Formation water salinity: 65541mg / L,

[0050] The balance is water, the total amount is 100%,

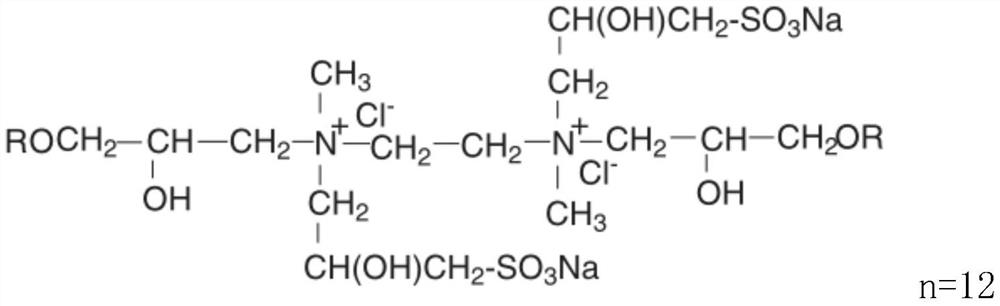

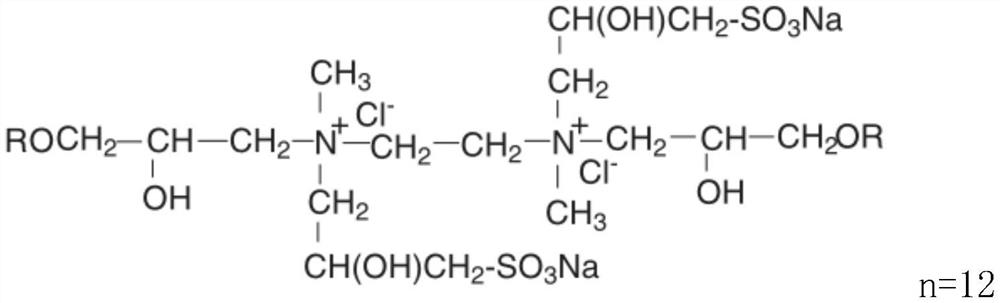

[0051] Among them, the {bis[N-methyl-N-(3-dodecyloxy-2-hydroxyl)propanyl-N-(2-hydroxyl-3-sulfonate sodium)propanyl]ammonium chloride} The structure of ethane is

[0052]

[0053] The {di[N-methyl-N-(3-dodecyloxy-2-hydroxy)propanyl-N-(2-hydroxy-3-sodium sulfonate)propanyl]ammonium chloride}ethane It is a hydroxy sultaine type Gem...

Embodiment 2

[0056] 2. An ultra-low interfacial tension self-assembled carbon dioxide foam oil displacement agent suitable for low-permeability reservoirs, comprising the following components by weight percentage:

[0057] {Di[N-methyl-N-(3-dodecyloxy-2-hydroxy)propanyl-N-(2-hydroxy-3-sulfonate sodium)propanyl]ammonium chloride}ethane: 0.25 %,

[0058] Zwitterionic Surfactant Cocamidopropyl Betaine (CAB): 0.25%,

[0059] Nonionic surfactant lauryl dimethyl amine oxide (0B-2): 0.2%,

[0060] Chelating agent EDTA: 0.04%,

[0061] Formation water salinity: 65541mg / L,,

[0062] The balance is water, the total amount is 100%,

[0063] Among them, the {bis[N-methyl-N-(3-dodecyloxy-2-hydroxyl)propanyl-N-(2-hydroxyl-3-sulfonate sodium)propanyl]ammonium chloride} The structural formula and preparation method of ethane are the same as in Example 1.

Embodiment 3

[0065] 3. An ultra-low interfacial tension self-assembled carbon dioxide foam oil displacement agent suitable for low-permeability reservoirs and its application, comprising the following components by weight percentage:

[0066] {Di[N-methyl-N-(3-dodecyloxy-2-hydroxy)propanyl-N-(2-hydroxy-3-sulfonate sodium)propanyl]ammonium chloride}ethane: 0.3 %,

[0067] Zwitterionic Surfactant Cocamidopropyl Betaine (CAB): 0.3%,

[0068] Nonionic surfactant lauryl dimethyl amine oxide (0B-2): 0.35%,

[0069] Chelating agent EDTA: 0.10%,

[0070] Formation water salinity: 65541mg / L,

[0071] The balance is water, the total amount is 100%,

[0072] Among them, the {bis[N-methyl-N-(3-dodecyloxy-2-hydroxyl)propanyl-N-(2-hydroxyl-3-sulfonate sodium)propanyl]ammonium chloride} The structural formula and preparation method of ethane are the same as in Example 1.

[0073] 1. Preparation method, performance testing and application

[0074] 1. The ultra-low interfacial tension self-assembled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com