Carbon dioxide anhydrous sand fracturing method

A carbon dioxide and sand fracturing technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of unsatisfactory stimulation effect and poor stimulation effect, and achieve good fracture shape and stability, Improve sand carrying performance, easy flowback effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a carbon dioxide anhydrous sand fracturing method, which includes the following steps:

[0032] Step 1) Select gas wells and reservoirs for carbon dioxide waterless sand fracturing: select gas wells with sand body thickness of 10-25 meters and gas layer thickness of 5-15 meters, porosity greater than 8%, permeability greater than 0.8mD, and gas-bearing Reservoirs with saturation greater than 53%;

[0033] Step 2) Fracturing joints: inject carbon dioxide prefluid and viscosity-lifting agent into the annulus of the oil jacket, and at the same time inject carbon dioxide into the tubing, so that the tubing and tubing annulus can be injected simultaneously during fracturing. The injection displacement of the liquid is greater than the injection displacement of the carbon dioxide in the tubing;

[0034] Step 3) Fill the fracture gap: inject carbon dioxide sand carrying liquid and viscosity-lifting agent into the annulus of the oil jacket;

[0035] Step 4) St...

Embodiment 2

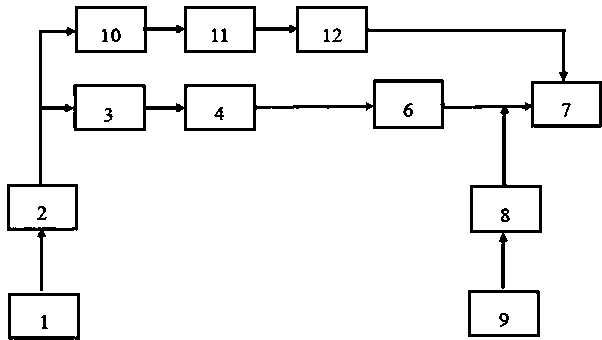

[0039] On the basis of Example 1, this example provides a carbon dioxide anhydrous sanding fracturing method. The process of injecting carbon dioxide prefluid and viscosity raising agent into the annulus of the oil jacket in step 2) is: carbon dioxide storage The liquid tank Ⅰ3 is pressurized by the nitrogen pressurization system and connected to the carbon dioxide booster pump truck Ⅰ4 through a high-pressure hose, and then pressurized to deliver the liquid carbon dioxide to the carbon dioxide fracturing pump truck unit Ⅰ6. At the same time, the carbon dioxide viscosity booster tanker 9 The viscosity-lifting agent is injected into the high-pressure pipeline through the carbon dioxide-increasing agent injection pump truck 8, and mixed with the carbon dioxide delivered by the carbon dioxide fracturing pump truck unit I6 in the high-pressure pipeline, and injected from the fractured wellhead 7 to the oil casing annulus of the wellbore.

[0040] Step 2) The process of injecting carbo...

Embodiment 3

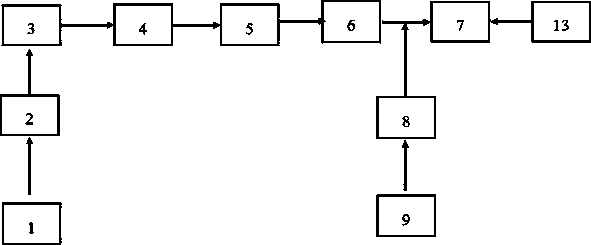

[0046] On the basis of Example 1, this example provides a carbon dioxide anhydrous sand fracturing method. The process of injecting carbon dioxide sand-carrying liquid and viscosity-lifting agent into the annulus of the oil jacket described in step 3) is: The carbon dioxide in the carbon dioxide storage tank I3 is pumped into the carbon dioxide booster pump I4 through the liquid nitrogen pressurization system, and the liquid carbon dioxide delivered by the carbon dioxide booster pump I4 enters the closed carbon dioxide sand mixing tank 5 and is mixed with proppant to form carbon dioxide carrying sand The liquid is then transported to the carbon dioxide fracturing pump unit Ⅰ6 through the high-pressure manifold, so that the carbon dioxide-carrying sand liquid is 3.5-4.0m 3 The construction displacement per minute and the 100-150L / min displacement of the viscosity-increasing agent delivered by the pump truck 8 are mixed in the high-pressure pipeline and then pumped into the oil pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com