Self energy generating type clean fracturing fluid and preparation method thereof

A clean fracturing fluid and self-generating technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of cumbersome fracturing fluid preparation process, unfavorable large-scale field application, and high cost of fracturing fluid preparation , to achieve the effect of reducing process and construction costs, reducing preparation costs, and good foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

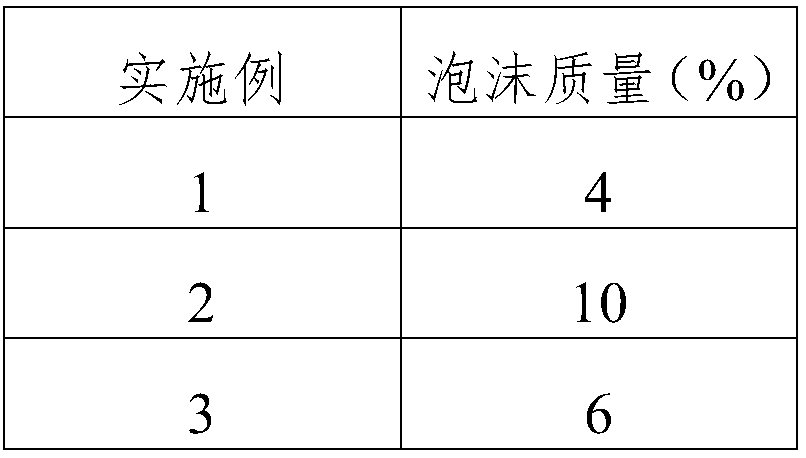

Embodiment 1

[0022] The self-generating clean fracturing fluid of the present embodiment comprises the following raw materials in weight percentage: C 12 -C 22 1.5% of quaternary ammonium cationic surfactant, 0.25% of salicylic acid, 4.0% of chloride, 2.0% of carbon dioxide releasing agent, and the balance is water; the C 12 -C 22 The quaternary ammonium salt cationic surfactant is dodecyltrimethylammonium chloride, the chloride is potassium chloride, and the carbon dioxide releasing agent is sodium bicarbonate.

[0023] The preparation method of the self-generating clean fracturing fluid of this embodiment is:

[0024] Step 1, put C 12 -C 22 Quaternary ammonium salt cationic surfactant, salicylic acid and chloride are added to water and stirred evenly to obtain component A;

[0025] Step 2, dissolving the carbon dioxide releasing agent in water to obtain component B;

[0026] Step 3: Inject component A in step 1 and component B in step 2 into the oil well at a volume ratio of 1:1. ...

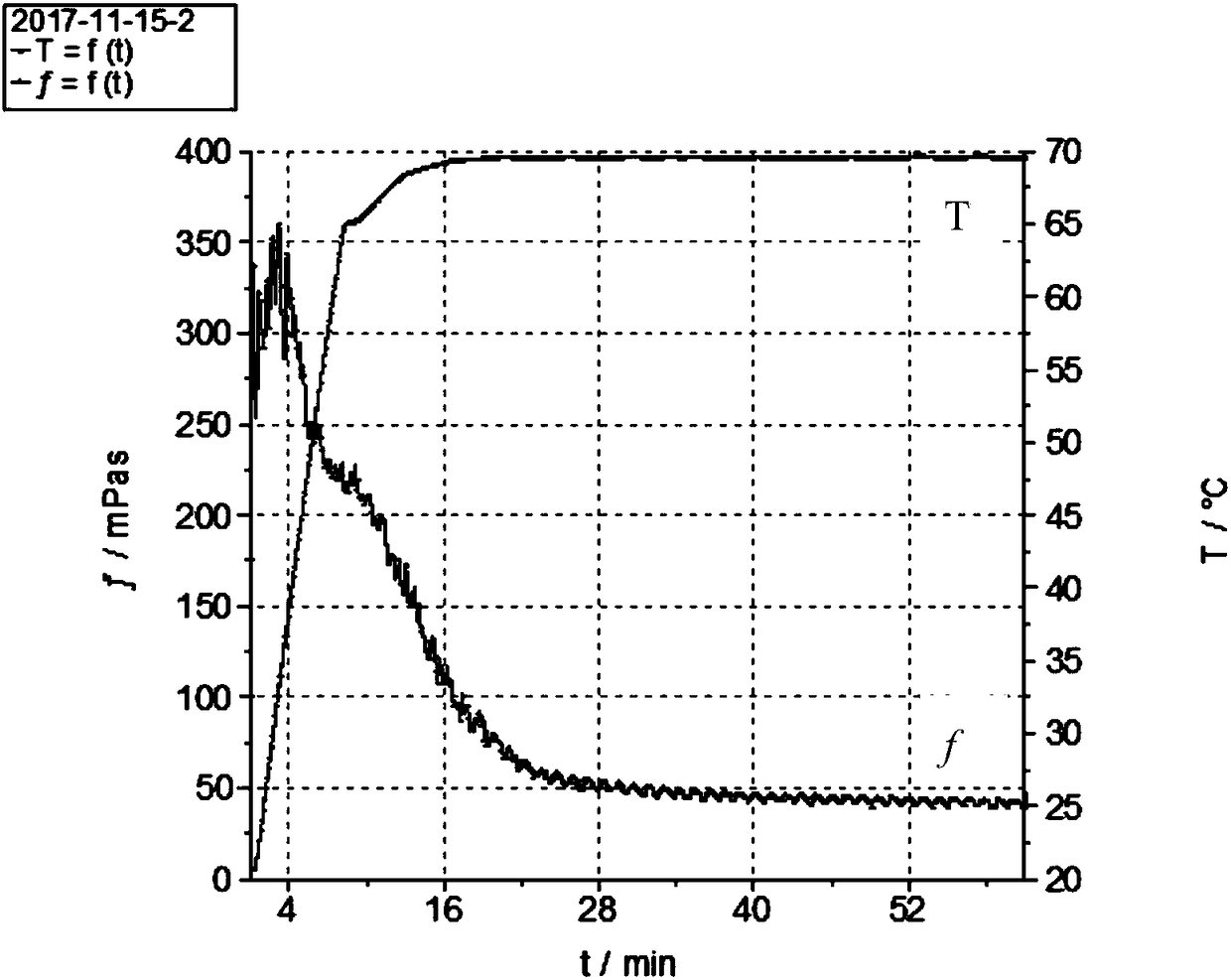

Embodiment 2

[0028] The self-generating clean fracturing fluid of the present embodiment comprises the following raw materials in weight percentage: C 12 -C 22 4.0% of quaternary ammonium cationic surfactant, 0.5% of salicylic acid, 2.0% of chloride, 4.5% of carbon dioxide release agent, and the balance is water; the C 12 -C 22 The quaternary ammonium salt cationic surfactant is octadecyl dihydroxyethyl ammonium chloride, the chloride is potassium chloride, and the carbon dioxide releasing agent is sodium bicarbonate.

[0029] The preparation method of the self-generating clean fracturing fluid in this example is the same as that in Example 1.

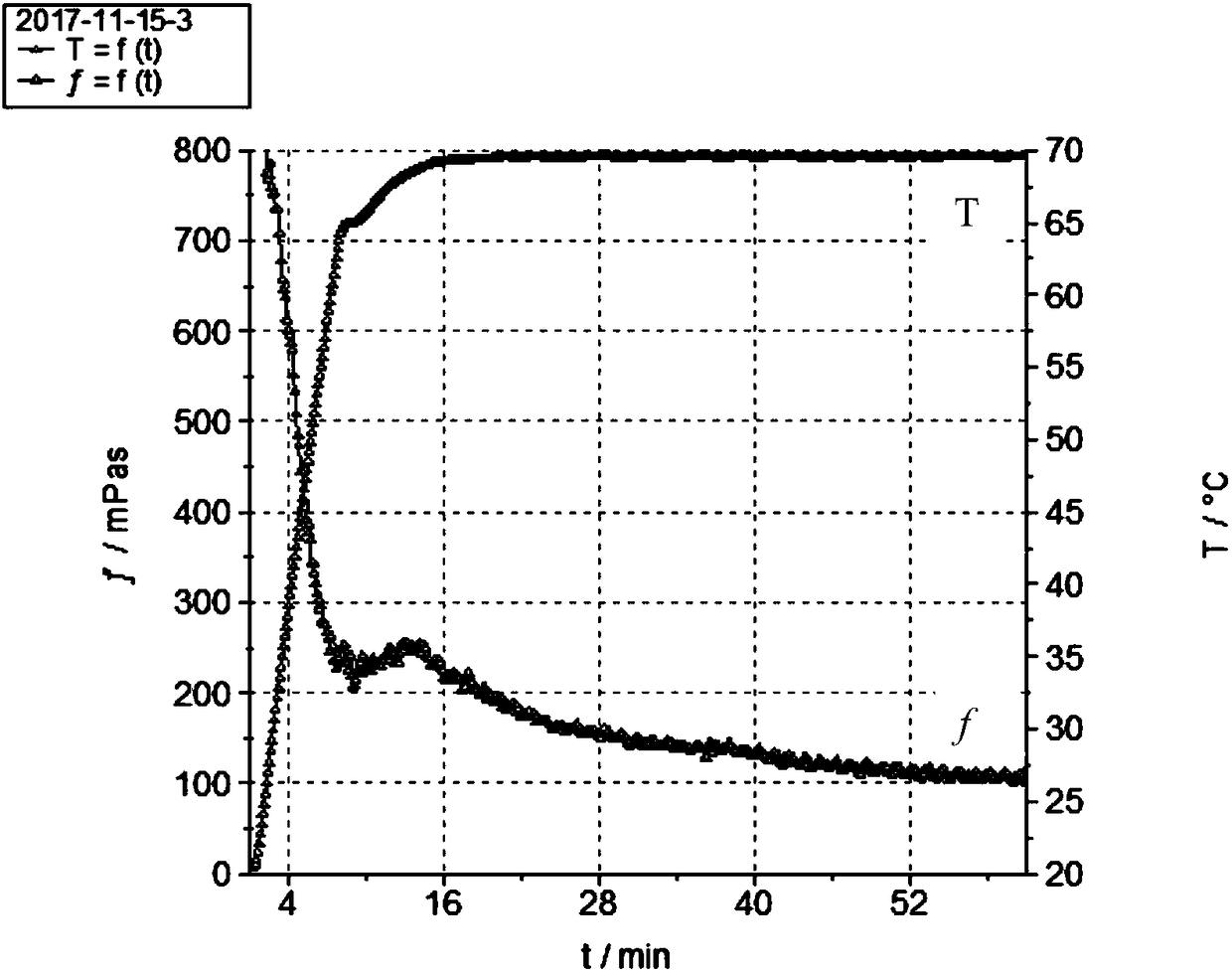

Embodiment 3

[0031] The self-generating clean fracturing fluid of the present embodiment comprises the following raw materials in weight percentage: C 12 -C 22 5.5% of quaternary ammonium cationic surfactant, 0.70% of salicylic acid, 1.0% of chloride, 3.0% of carbon dioxide releasing agent, and the balance is water; the C 12 -C 22 The quaternary ammonium salt cationic surfactant is octadecylmethyl dihydroxyethyl ammonium chloride, the chloride is potassium chloride, and the carbon dioxide releasing agent is sodium bicarbonate.

[0032] The preparation method of the self-generating clean fracturing fluid in this example is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com