Method for synthesizing TATB (triamino trinitrobenzene) by normal pressure phase-transfer catalysis and amination

A technology of phase transfer and catalysis of amines, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, preparation of amino compounds, etc., can solve the problems of unfavorable large-scale industrial production, low solubility, and difficulty in purchasing, etc., and achieve large-scale industrialization Simple production and reaction operation, and the effect of solving the problem of chlorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

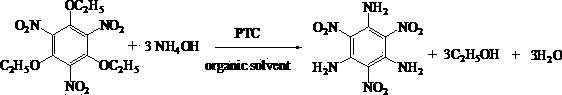

Method used

Image

Examples

Embodiment 1

[0027] Add 2.070g of 1,3,5-triethoxy-2,4,6-triaminobenzene and 15ml of xylene into a four-neck flask, heat to 50°C in a water bath while stirring, and add 15ml of ammonia water (the weight percentage is 25-28%) reflux reaction for 2 hours, after the reaction, the reaction liquid was cooled to room temperature, TATB was obtained by filtration, washed with ethanol for 2-3 times, and then dried to obtain 0.093g of TATB product with a yield of 6%. According to HPLC analysis, the purity of TATB was 98.32%, and the exothermic decomposition temperature was 386.12% according to DSC analysis.

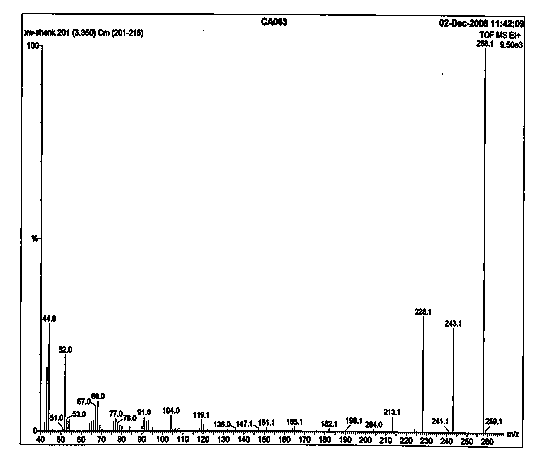

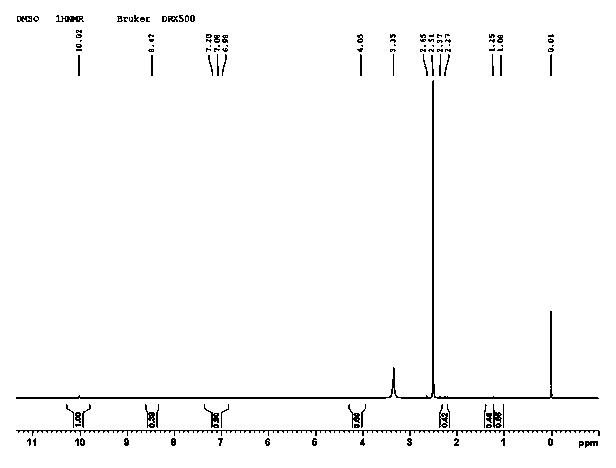

[0028] Spectral data: MS(m / z):258.1(M + ); 1 H-NMR (DMSO-d6), δ: 3.35 (m, 6H, -NH 2 ); FT-IR(KBr), ν(cm -1 ): 3320, 3216, 1604, 1571, 1444, 1217, 1166, 781, 727, 694. Example 2

Embodiment 2

[0029] Add 2.070g of 1,3,5-triethoxy-2,4,6-triaminobenzene, 15ml of xylene and 0.040g of hexadecyltrimethylammonium bromide into a four-neck flask, stir and heat in a water bath 50°C, add 15ml of ammonia water (25-28% by weight) and reflux for 2 hours. After the reaction, cool the reaction solution to room temperature, filter to obtain TATB, wash with ethanol for 2-3 times and dry to obtain TATB product 0.805. According to HPLC analysis, the purity of TATB was 98%, and the yield was 52.00%. The exothermic decomposition temperature of DSC analysis was 378.84%.

Embodiment 3

[0031] Add 2.070g of 1,3,5-triethoxy-2,4,6-triaminobenzene, 15ml of xylene and 0.40g of β-cyclodextrin into a four-neck flask, heat in a water bath to 50°C under stirring, and add 15ml of ammonia water (25-28% by weight) reflux reaction for 2 hours. After the reaction, the reaction solution was cooled to room temperature, filtered to obtain TATB, washed with acetone for 2-3 times and dried to obtain 0.09 g of TATB product with a yield of 5.8%. According to HPLC analysis, the purity of TATB was 98.15%, and the exothermic decomposition temperature was 378.84% according to DSC analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com