Ventilator arrangement for gravitational fluid discharge via high and low pressure phase

A technology of pressure and structure, applied in the field of valve structure used to discharge liquid through gravity under overpressure and negative pressure, can solve the problem that the system cannot be emptied, and achieve low structural height, small structural space requirements, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

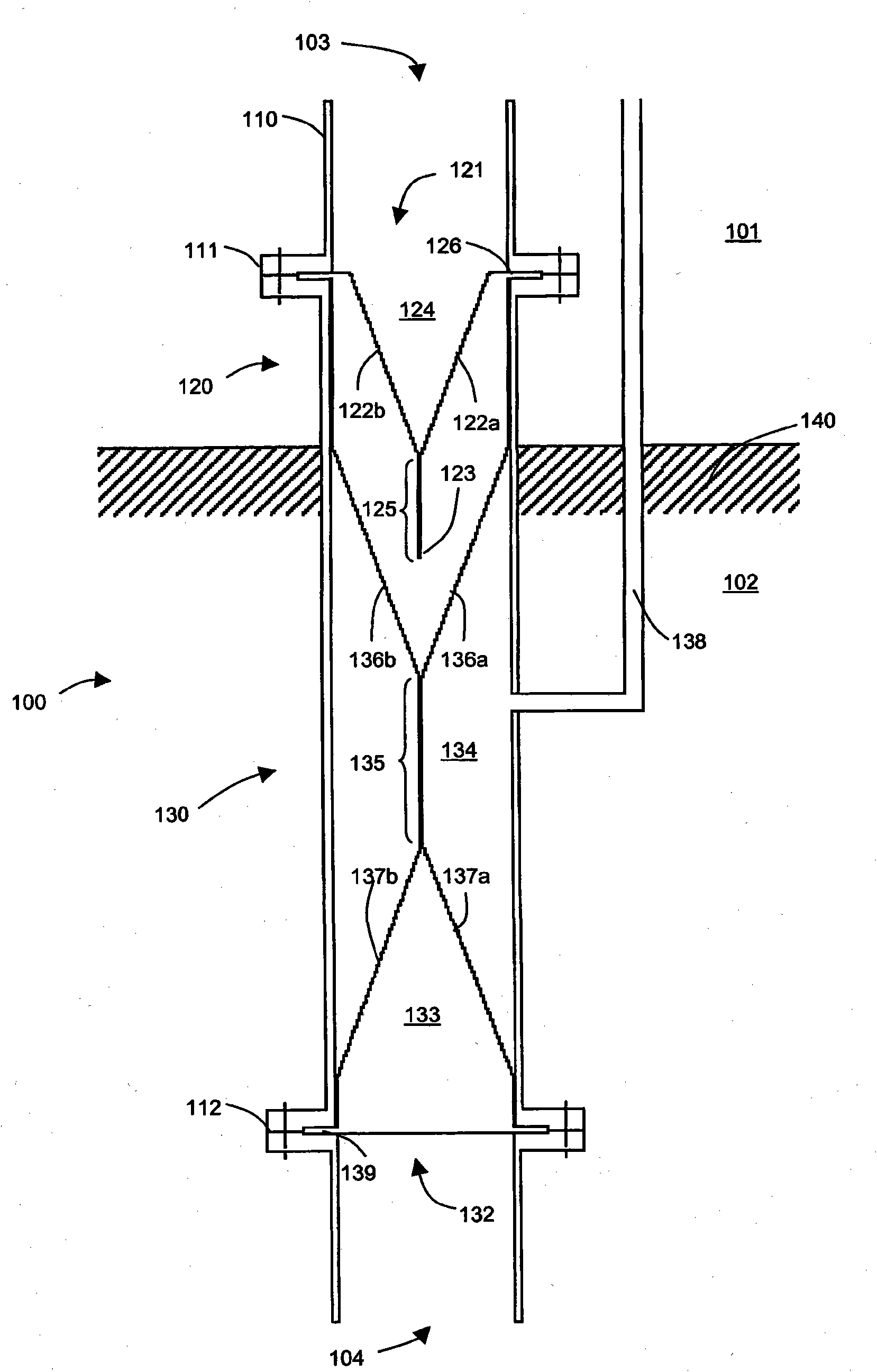

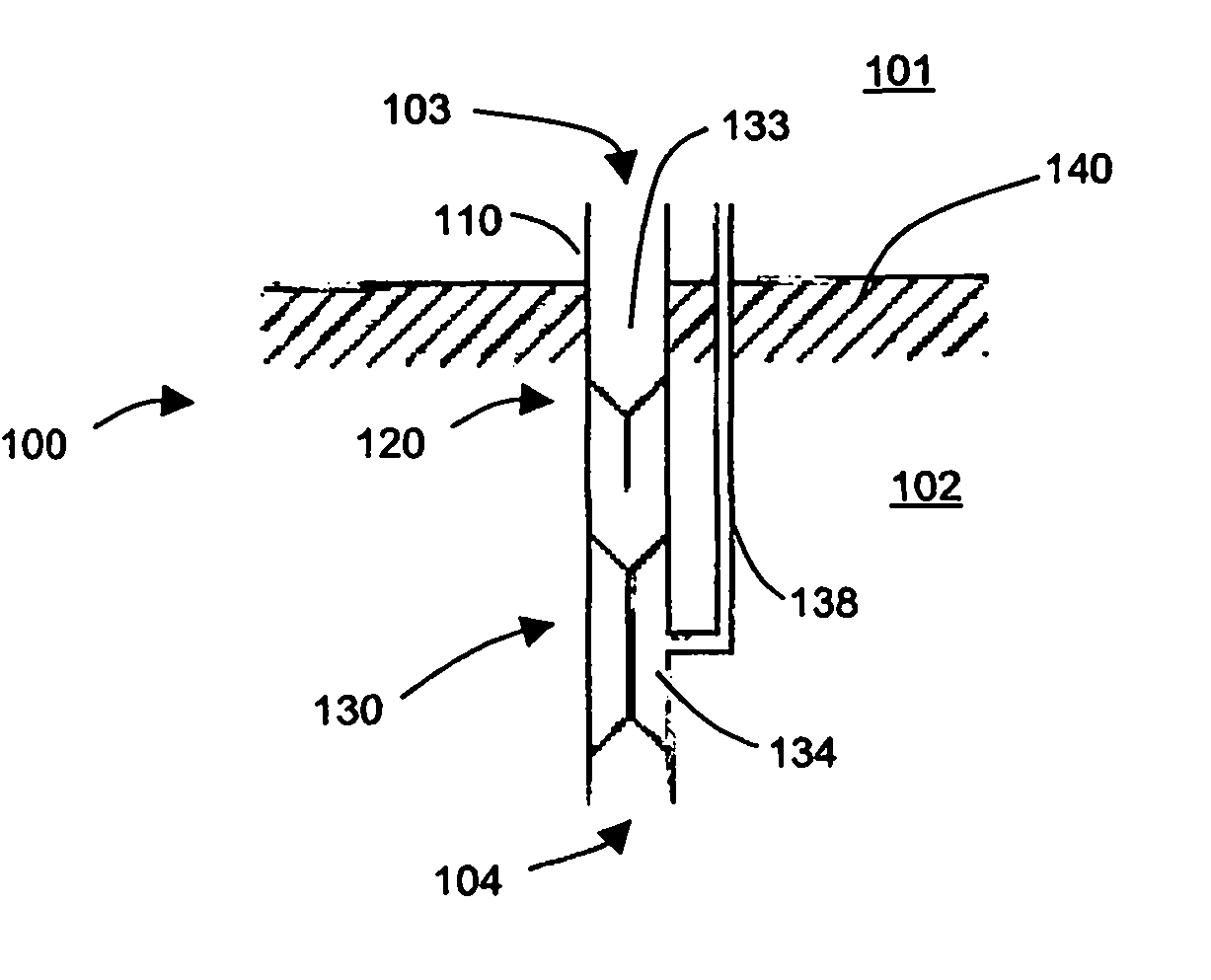

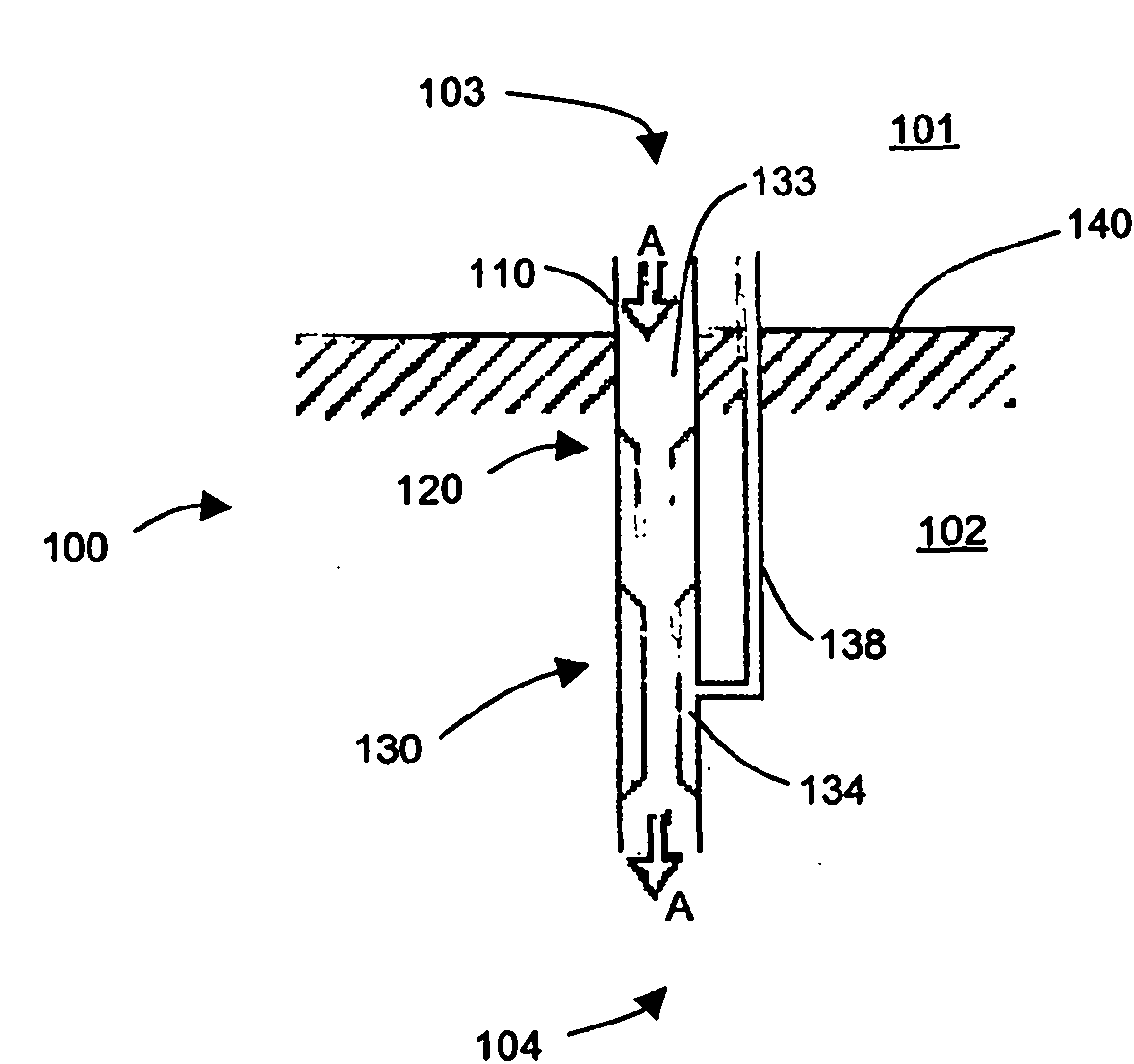

[0080] figure 1 A longitudinal sectional view of a first embodiment of a valve arrangement 100 according to the invention is shown for discharging a liquid medium from a space 101 which is pressure-damaged with respect to the environment 102 into the environment 102 . The valve configuration 100 has an inlet 103 and an outlet 104 . The pressure-attenuated space 101 is separated from the external environment 102 by a partition 140 such as the bottom of a railway car. The air pressure in the pressure-attenuated space 101 corresponds to the air pressure in the external environment 102 .

[0081] The inlet 103 is connected to the outlet 104 through a connecting pipe 110 . The same air pressure prevails at the inlet 103 as in the environment 102 . The valve configuration 100 is mounted such that a liquid medium can flow from the inlet 103 to the outlet 104 in the direction of gravity.

[0082] The valve arrangement 100 has a non-return valve 120 and a shut-off valve 130 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com