Use of polyolefins comprising atactic structural elements in floor coverings

An atactic, polyolefin-based technology for coatings, building elements, textiles and paper, with low melt viscosity and low coat weights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

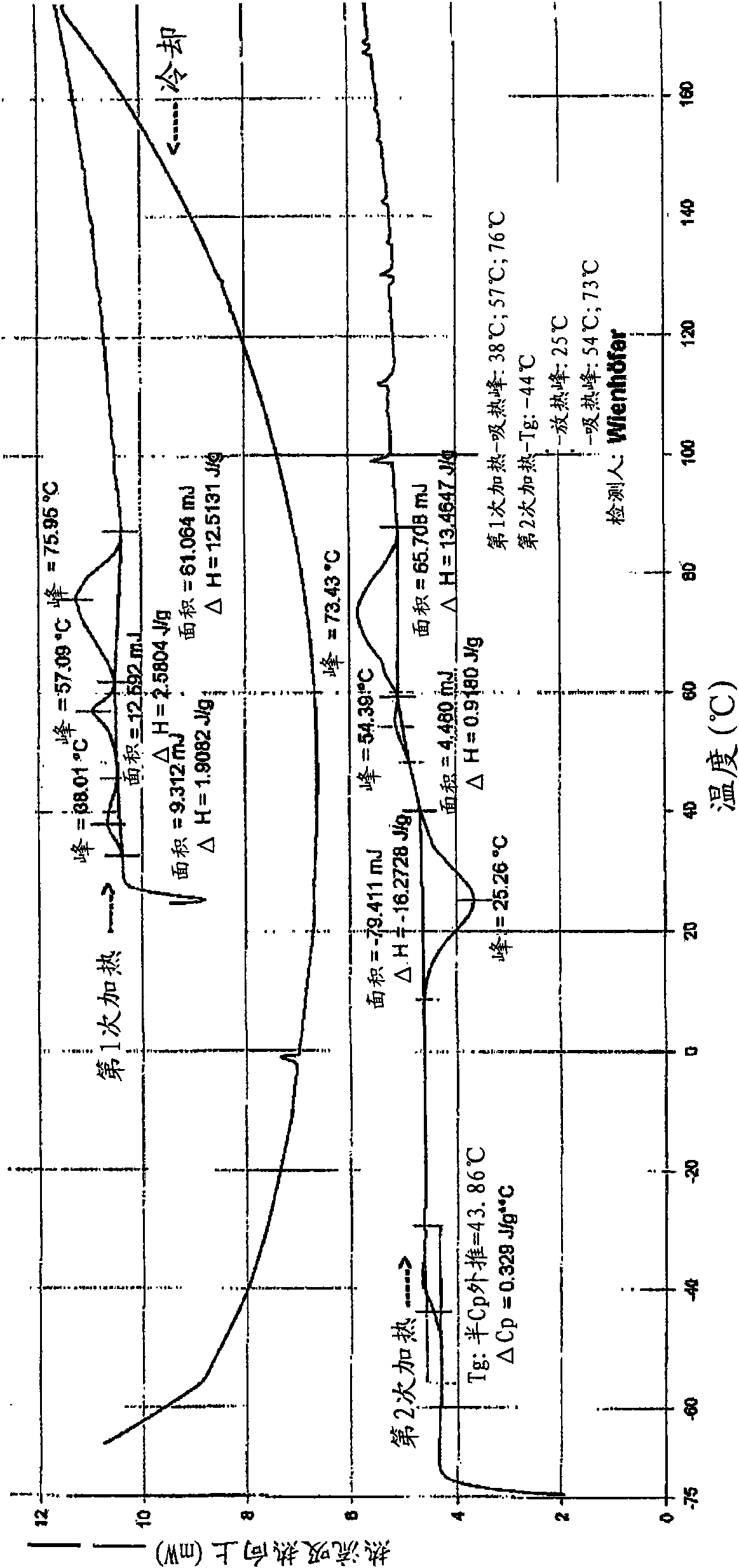

[0160] analyze:

[0161] a) High temperature- 13 C-NMR

[0162] Through high temperature- 13 The polymer composition was determined by C-NMR method. For example in the following publications on polymers 13 Description of C-NMR spectroscopic analysis:

[0163] [1] S. Berger, S. Braun, H.-O. Kalinowski, 13 C-NMR-Spektroskopie, Georg Thieme Verlag, Stuttgart, 1985

[0164] [2] A.E. Tonelli, NMR Spectroscopy and Polymer Microstructure, Verlag Chemie Weinheim 1989

[0165] [3] J.L. Koenig, Spectroscopy of Polymers, ACS Professional Reference Books, Washington 1992

[0166] [4] J.C. Randall, Polymer Sequence Determination, Academic Press, New York 1977

[0167] [5] A. Zambelli et al.: Macomolecules, 8, 687 (1975)

[0168] [6] A. Filho, G. Galland: J. Appl. Polym. Sci., 80.1880 (2001)

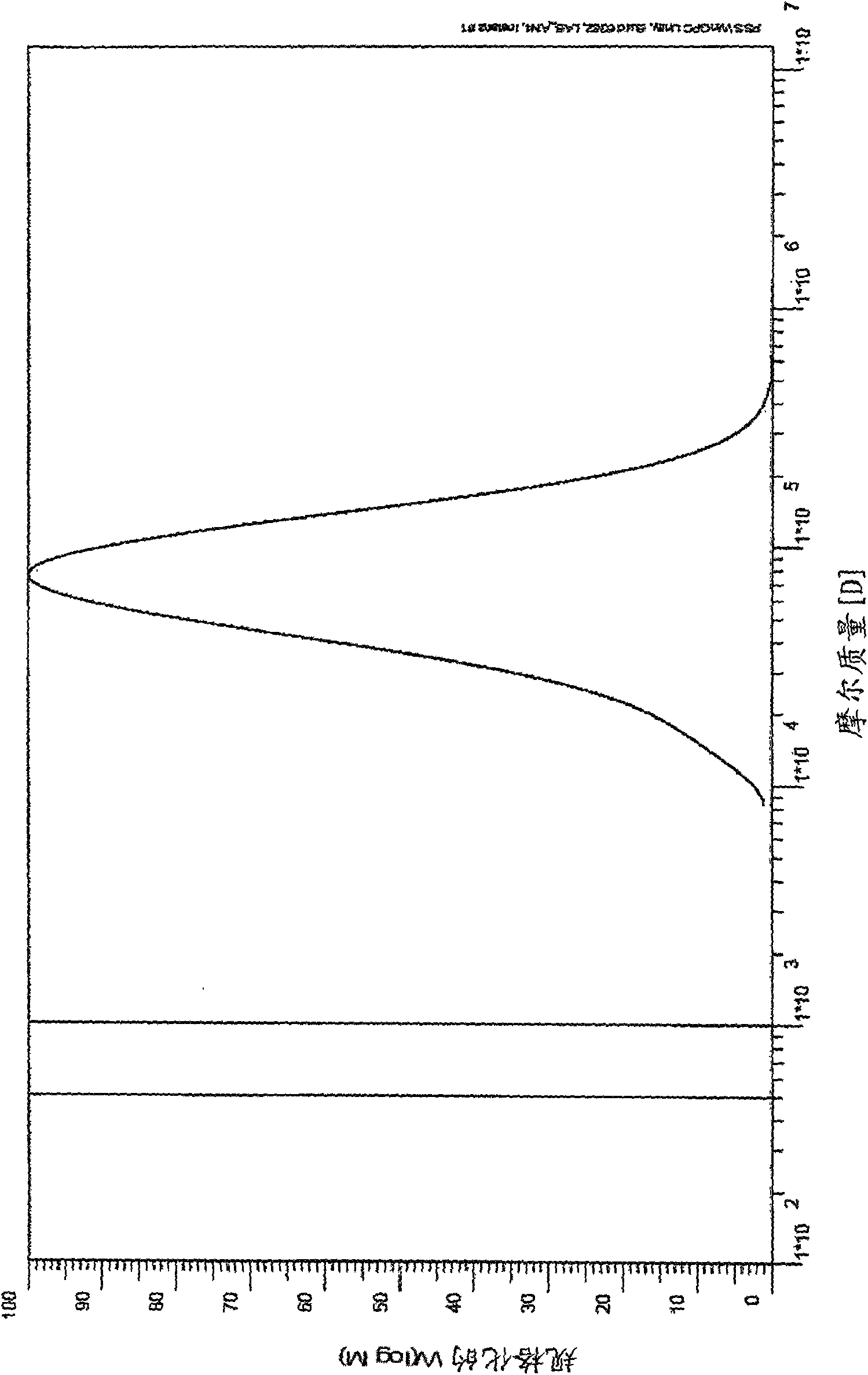

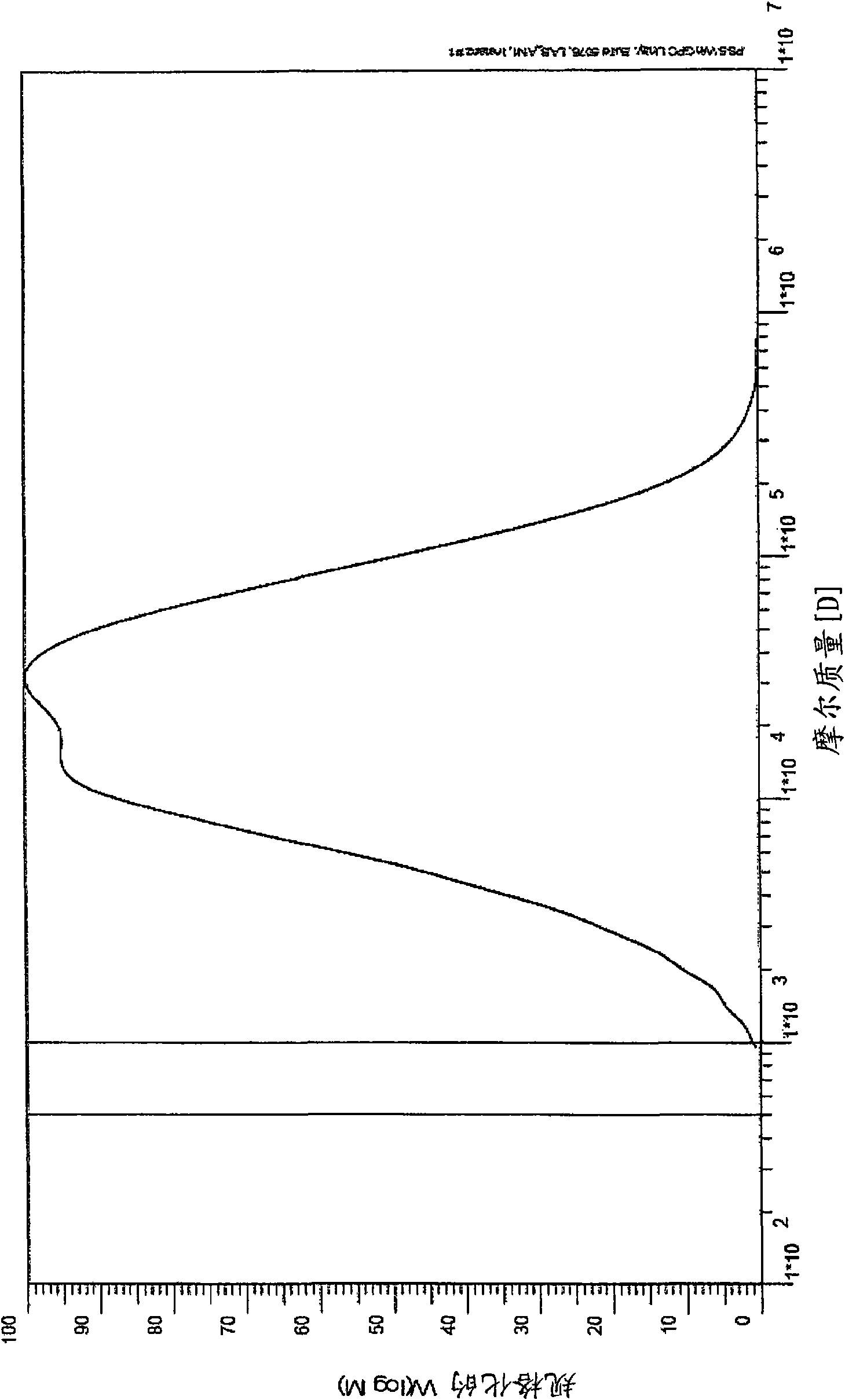

[0169] b) High temperature gel permeation chromatography

[0170]Molecular weights were determined by high temperature gel permeation chromatography.

[0171] The assay was performed acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com