Infrared air exhaust and pressure reduction material-drying device

An infrared and drying technology, which is applied in the direction of drying solid materials, drying solid materials, heating devices, etc., can solve the problems of high cost, complicated structure, difficult cleaning and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] see Figure 5 to Figure 8 , shown in the figure is the structure and manufacturing method of the embodiment of the present invention, which is for illustration purposes only, and is not limited by this embodiment in terms of protection scope.

[0078] The invention provides a device with an infrared light source for water molecules inside undried materials to generate resonance energy due to absorption of infrared rays, so as to heat up and dry the irradiated materials, which includes:

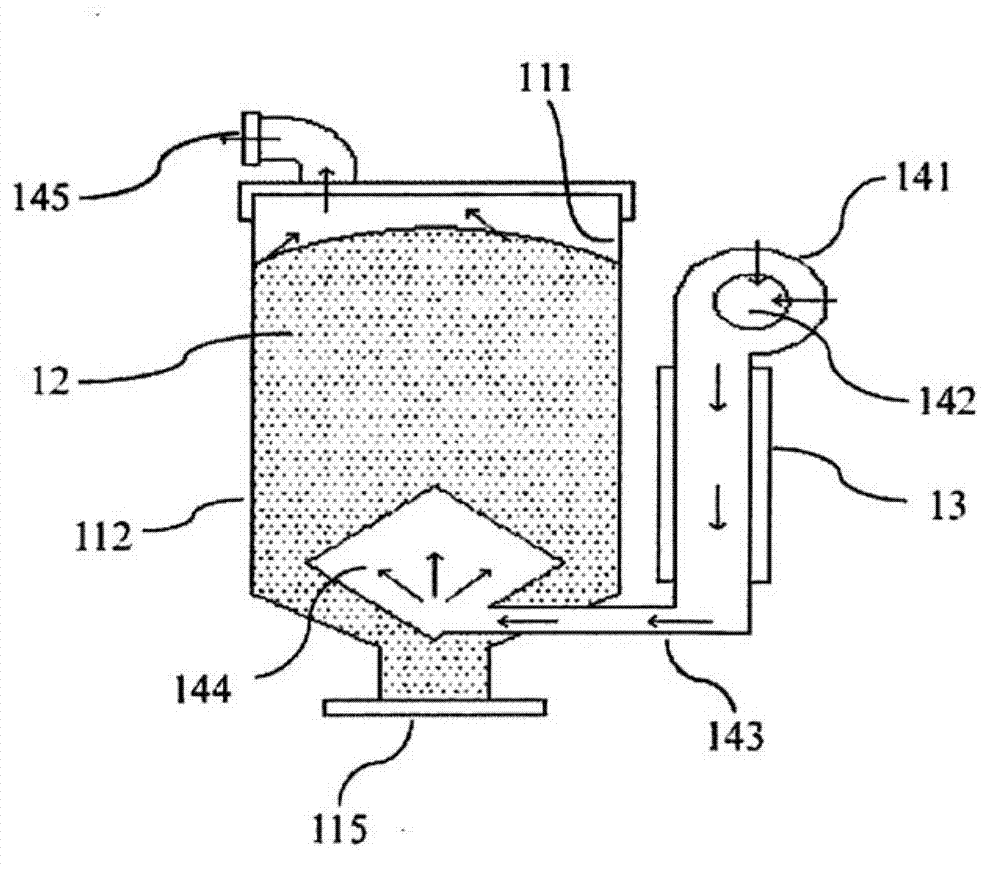

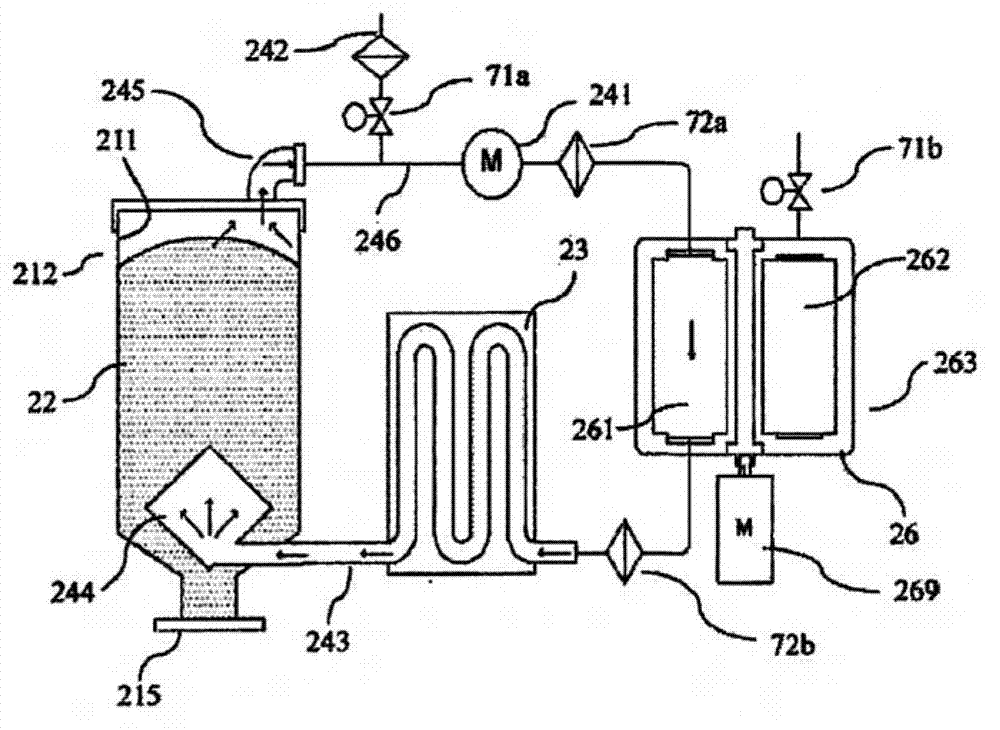

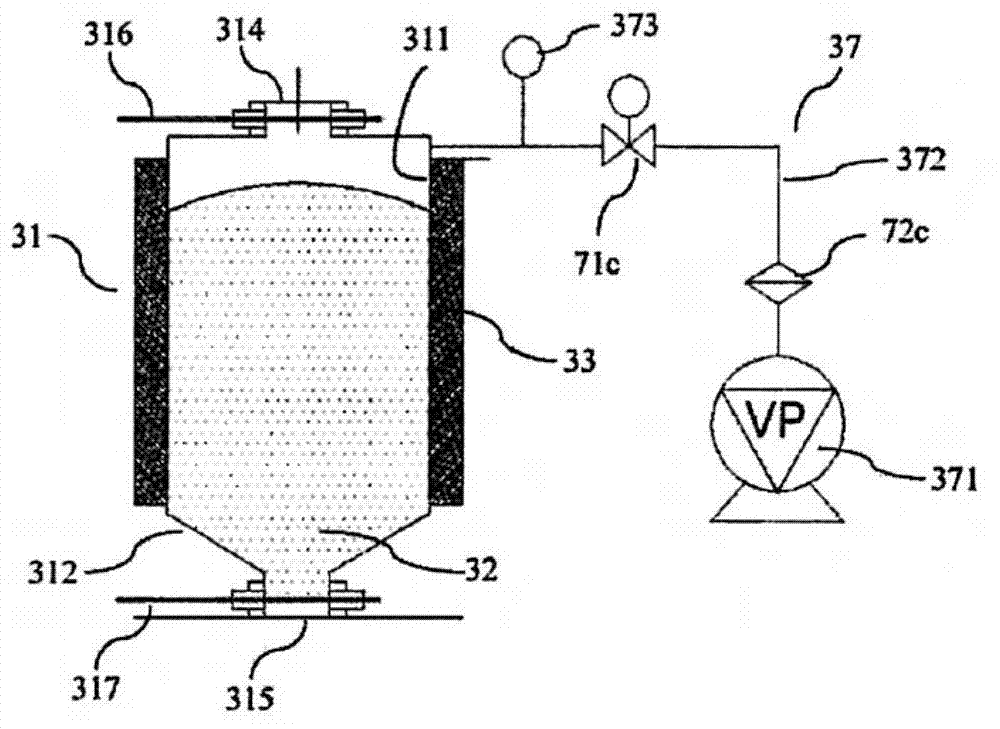

[0079] Such as Figure 5 As shown, there is an infrared ray pumping and decompression drying plastic pellet device according to the first embodiment of the present invention, which includes a sealable tank body 51 connected to an air pumping and decompression assembly 57 and an infrared light emitting source 53 is arranged in the sealable tank body; The light source 53 includes: an infrared light-emitting lamp tube 531, which is protected by a tubular body 532 mainly made of a material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com