Method for sludge drying and incineration by swill-cooked dirty oil

A technology of sludge drying and sludge incineration, which is applied in combustion methods, dehydration/drying/concentrated sludge treatment, incinerators, etc., can solve the problem of difficult control of sludge incineration operating costs, high requirements for equipment stability, Solve the problems of low calorific value of sludge, and achieve the effects of low process treatment cost, reduced equipment investment, and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

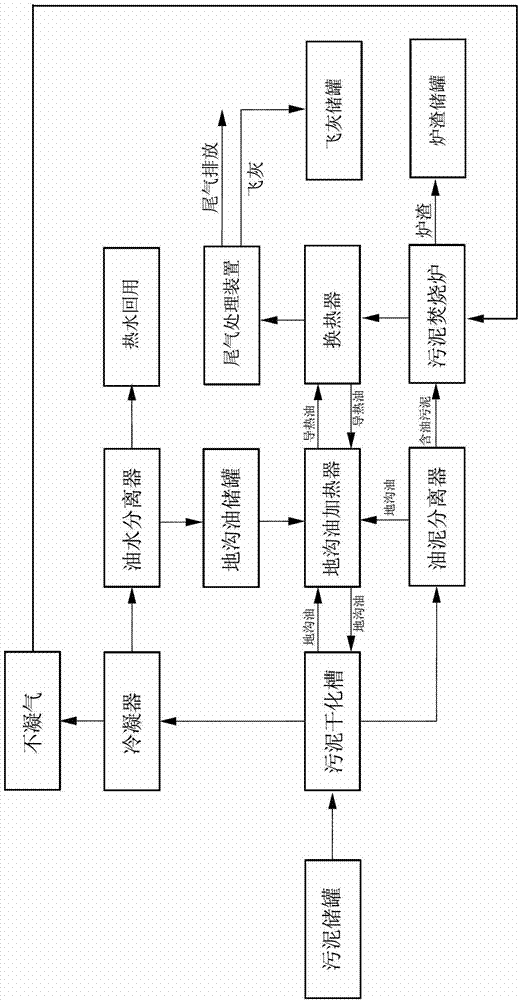

[0016] See figure 1 Shown, the present invention utilizes waste oil to carry out sludge drying and incineration method,

[0017] (1) Sludge drying: Add the waste oil stored in the waste oil storage tank into the waste oil heater, and heat the waste oil in the waste oil heater through the heat transfer medium. At the initial stage of heating the waste oil, it can be The heat transfer medium in the heat exchanger is directly heated by the sludge incinerator or external heat, and the waste oil in the waste oil heater is heated by the heat transfer medium. During operation, only the heat generated during sludge incineration conducts heat. The medium is heated to keep the oil temperature in the sludge drying tank at 100-150°C to form continuous drying of wet sludge. The invention uses a circulation pump to transport the heated waste oil to the sludge drying tank, keeps the temperature of the waste oil in the sludge drying tank at 100-150°C, and adds wet sludge to the sludge drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com