Brown coal drying equipment and method

A technology of drying equipment and lignite, which is applied in the direction of drying solid materials, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of complex system and difficult manufacture of steam compressors, and achieve simple process flow, energy saving and investment, The effect of small emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

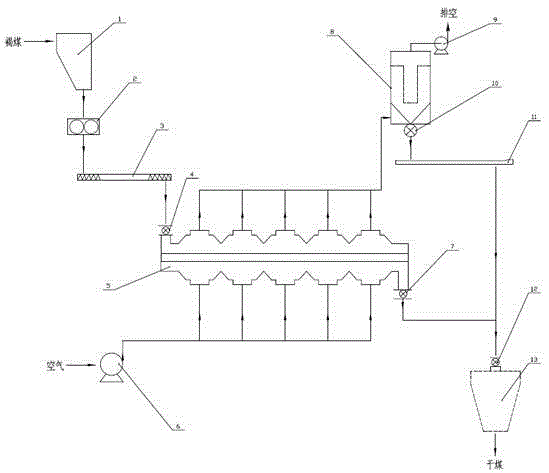

[0030] figure 1 The process flow of the present invention and a specific implementation thereof are shown. As shown in the figure, the equipment involved in the lignite ventilation drying method of the present invention includes a raw coal storage bin 1, a fine crusher 2, a screw conveyor 3, a dryer feed valve 4, a dryer 5, a blower 6, and a dryer discharge valve 7. Filter 8, induced draft fan 9, filter discharge valve 10, scraper conveyor 11, dry coal bunker feed valve 12, dry coal bunker 13.

[0031] Coal storage bin 1, fine crusher 2, screw conveyor 3 form a coal feeding and crushing system, dryer feed valve 4, dryer 5, blower 6, dryer discharge valve 7, filter 8, induced draft fan 9, filter A device discharge valve 10 and a scraper conveyor 11 form a drying and filtering system, and a dry coal bunker feed valve 12 and a dry coal bunker 13 are a dry coal storage system.

[0032] The basic process flow of the present invention is as follows: the mined lignite is stored in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com