All-fiber trolley-type drying resistance furnace

A trolley-type, resistance furnace technology, applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems affecting the production quality of processed workpieces, so as to ensure the uniformity of furnace temperature, improve the working environment, and enhance energy saving effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

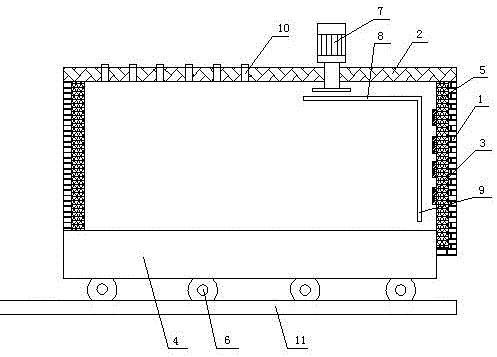

[0014] Such as figure 1 As shown, this embodiment provides an all-fiber trolley-type drying resistance furnace, including a furnace body 1, a furnace roof 2, a furnace door, a heating element 3, a hot air circulation device, and a charging car 4 for carrying workpieces and transferring them. . The trolley traction device for moving the charging trolley 4 and the temperature control system for adjusting the temperature in the furnace body 1, the furnace wall of the furnace body 1 is provided with a furnace lining 5, and the furnace lining 5 adopts a temperature-resistant grade ≤1150°C all-aluminosilicate refractory fiber, the heating element 3 adopts a tubular far-infrared electric heater, the heating element 3 is fixed on the furnace wall of the furnace body 1, and the hot air circulation device includes a fan 7, A deflector 8 and a windshie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com