Negative pressure concentration total heat type evaporation recovery system

A recovery system and negative pressure concentration technology, applied in the field of concentration systems, can solve problems such as decline, need to configure boilers, and high boiling point of evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, features and advantages of the present invention more obvious and understandable, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Several embodiments of the invention are shown in the drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that the disclosure of the present invention will be thorough and complete.

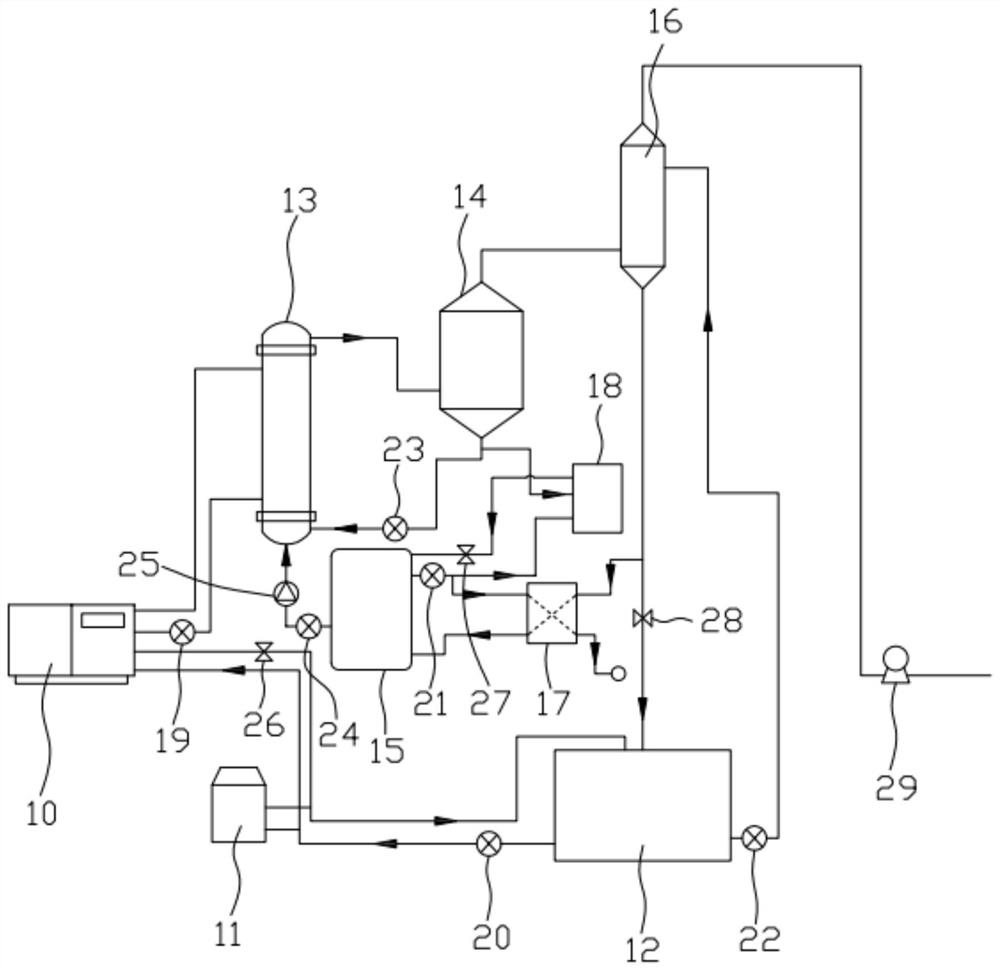

[0032] refer to Figures 1 to 3 , an embodiment of the present invention provides a negative pressure concentration total heat evaporation recovery system, including a high temperature heat pump 10, an air energy heat pump 11, a circulating heat storage tank 12, a heater 13, an evaporator 14, a preheating tank 15, a condensing Device 16, plate heat exchanger 17, finished device 18 and vacuum pump 29;

[0033] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com