A compressor suitable for linde-hampson throttling refrigerator

A technology for throttling refrigerators and compressors, which is applied in refrigerators, compressors, refrigeration and liquefaction, etc. It can solve problems such as difficulty in finding refrigerants that meet demand, increased costs, and temperature differences, so as to reduce the risk of oil-free friction, Effects of improving reliability and shortening oil discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

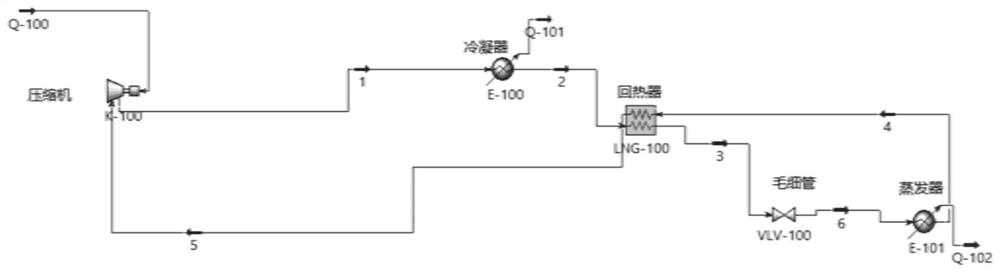

[0035] In a typical implementation of the present disclosure, such as figure 1 As shown, a refrigerant composition is provided.

[0036] It is suitable for Linde-Hampson throttling refrigerators (LHR for short), suitable for single-unit compression refrigeration systems, and does not need to use two-stage compression.

[0037] The addition of isobutane\butane can effectively reduce the exhaust pressure of the system. The single-unit compression refrigeration system has a higher energy efficiency coefficient and is simpler to manufacture.

[0038] Contains a variety of refrigerants, and by exerting the synergistic effect between the refrigerants, the refrigerant has a lower evaporation temperature, a lower exhaust pressure, a lower exhaust temperature, and a higher unit volume refrigeration capacity.

[0039] The refrigerant composition includes ethylene and a second component selected from at least one of n-butane and isobutane.

[0040] Specifically, it consists of the fol...

Embodiment 2

[0057] Another typical implementation of the present disclosure proposes a mixed working medium.

[0058] The mixed working medium includes the refrigerant composition as described in Example 1, and the mixed working medium is charged into the refrigeration system as the refrigerant.

[0059] In other embodiments, other additives can also be added to the mixed working medium according to requirements, so as to meet the operation requirements of different compressors, improve the stability of compressor operation, and the like.

Embodiment 3

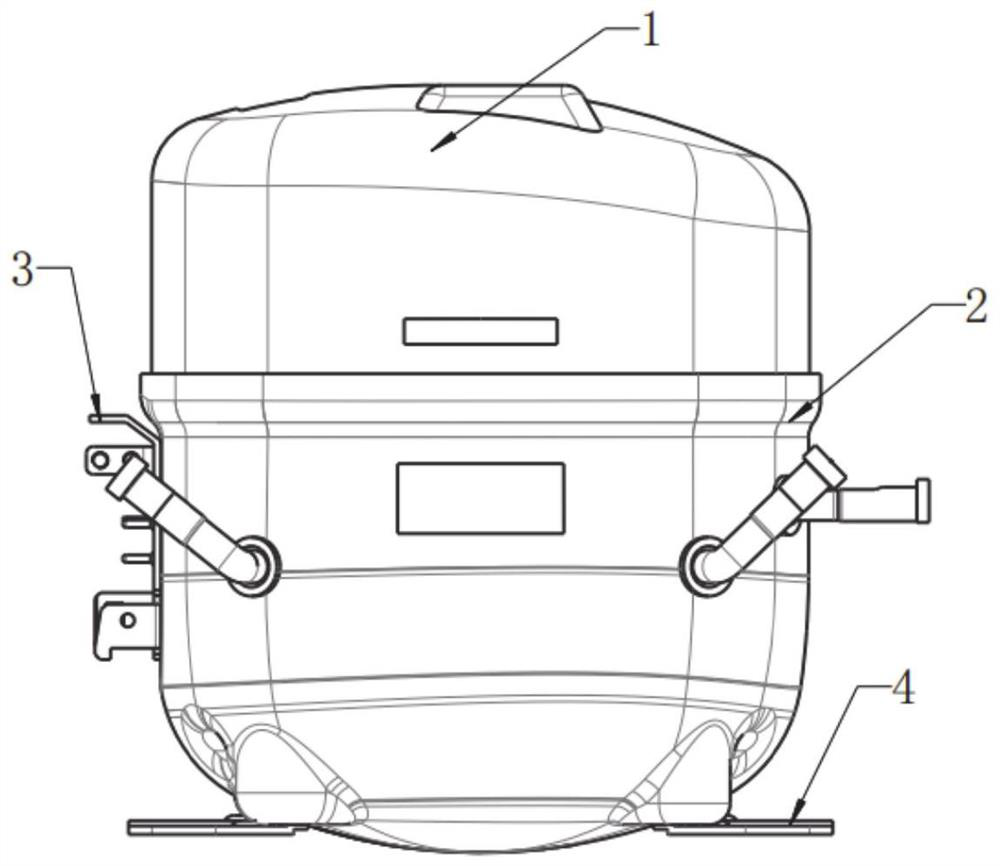

[0061] In yet another embodiment of the present disclosure, as Figure 1-Figure 5 As shown, a compressor using the refrigerant composition as described in Example 1 is proposed.

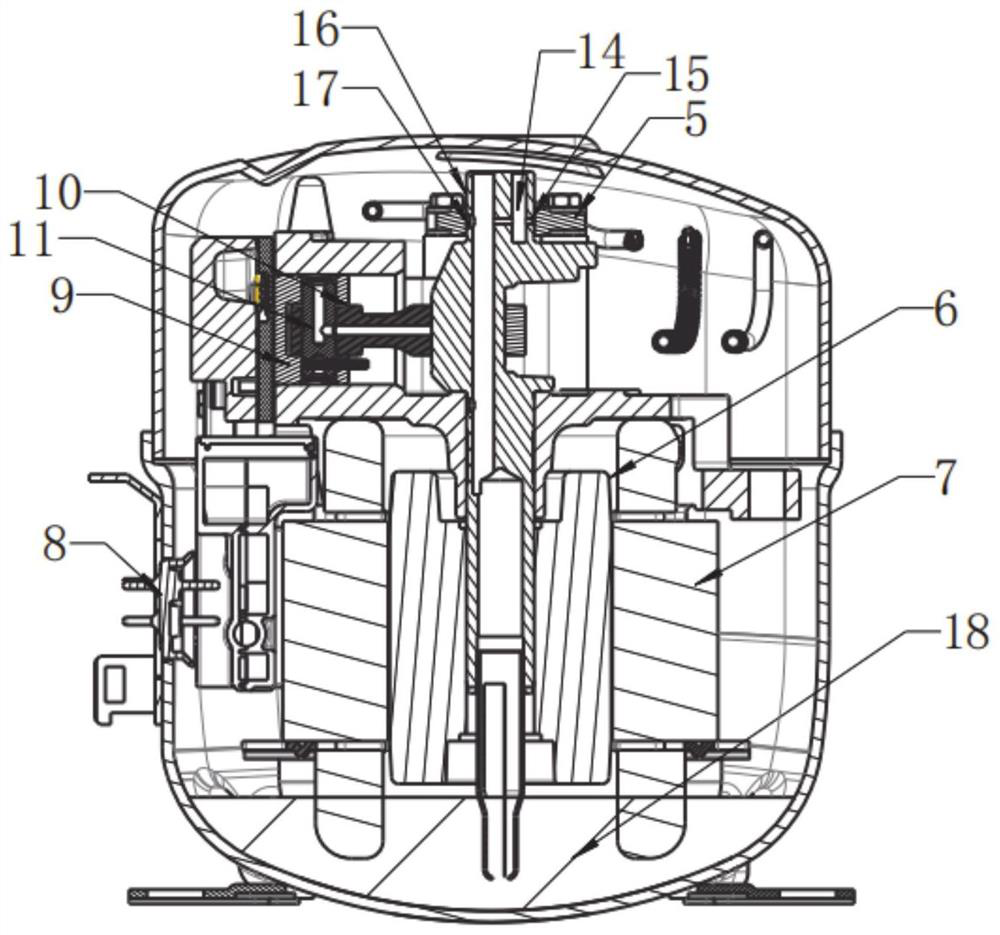

[0062] It includes a housing, a cylinder and a driving motor, the driving motor is connected to the cylinder through a crank connecting rod mechanism, and the cylinder, the driving motor and the crank connecting rod mechanism are all arranged in the housing.

[0063] The housing is provided with a bracket, and the drive motor and the cylinder are installed on the bracket. The crank linkage mechanism includes a crank and a connecting rod 10. One end of the crank is connected to the output end of the drive motor, and the other end of the drive motor is connected to the lower support 18. The connecting rod is away from the One end of the crank is connected to the cylinder piston.

[0064] The shell includes an upper shell 1 and a lower shell 2, the upper shell and the lower shell are combined to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com