Patents

Literature

130 results about "Boiling Point Temperatures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The boiling point of water is 100 C or 212 F at 1 atmosphere of pressure (sea level), but water boils at a lower temperature as you gain altitude (e.g., on a mountain) and boils at a higher temperature if you increase atmospheric pressure (lived below sea level).

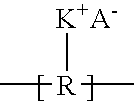

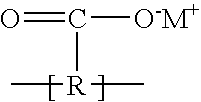

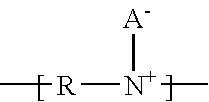

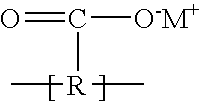

Ionic polymer membranes

InactiveUS20060049102A1Stable materialLarge specific surface areaCellsFatty/oily/floating substances removal devicesCarboxylic acidStructural unit

Compositions and processes are disclosed for economical separation of fluid mixtures. Broadly, the present invention discloses ionic polymer compositions that are useful for perm-selective membrane separations. More particularly, ionic polymers of the invention comprise a plurality of repeating structural units having as a constituent part thereof organic ionic moieties consisting of nitrogen containing anions and / or cations. In the form of non-porous membranes, ionic polymers of the invention facilitate recovery of purified organic and inorganic products from fluid mixtures by means of perm-selective membrane separations. The present invention also provides methods for forming the ionic polymers, for example by treating selected nitrogen-containing organic polymers with acids, or treating a polymeric material comprising a plurality of carboxylate groups with an amine. Ionic polymer compositions of the invention are particularly useful for simultaneous recovery of a permeate product of an increased concentration, and a desired non-permeate stream, from a fluid mixture containing at least two compounds of different boiling point temperatures.

Owner:BP CORP NORTH AMERICA INC +1

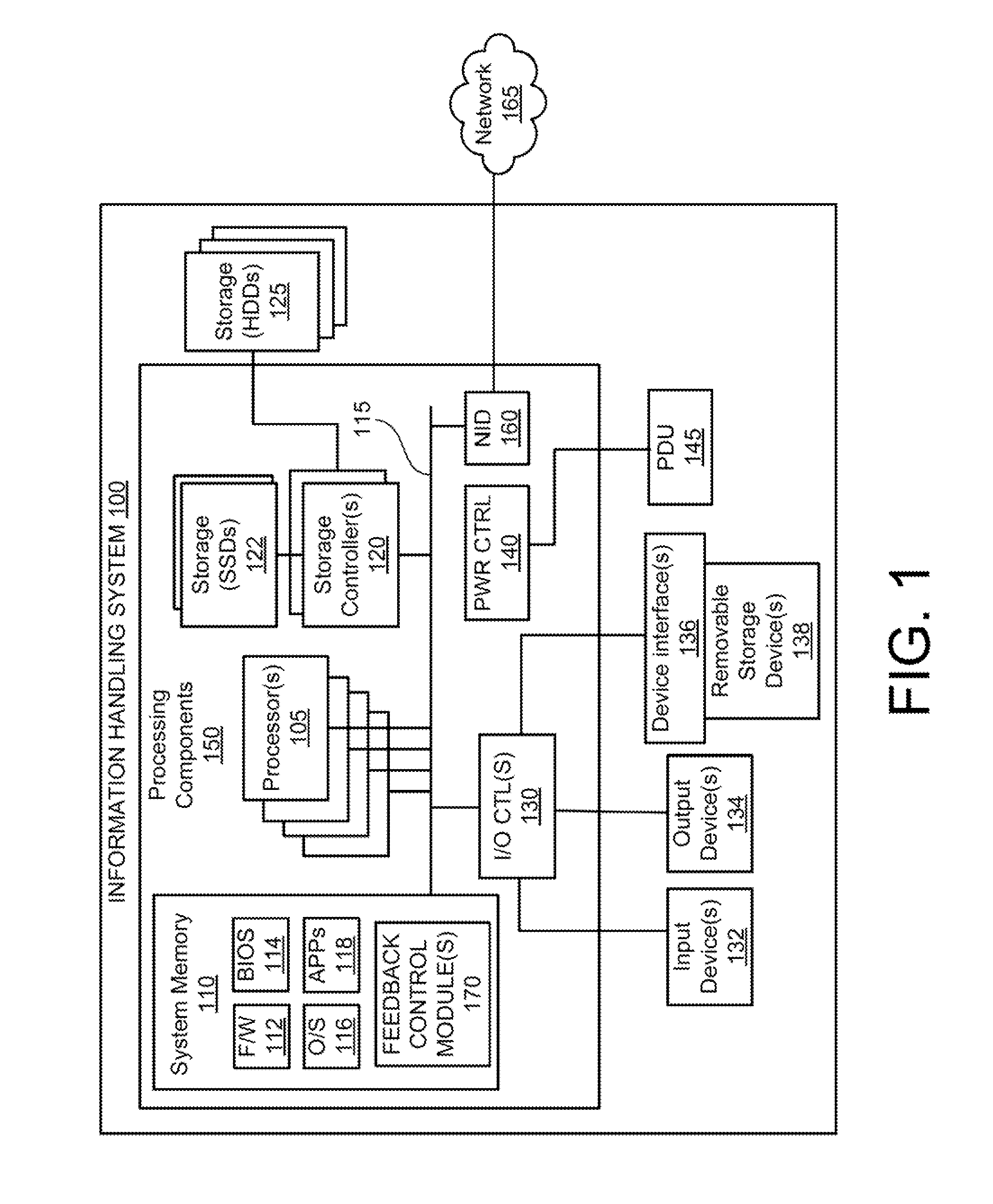

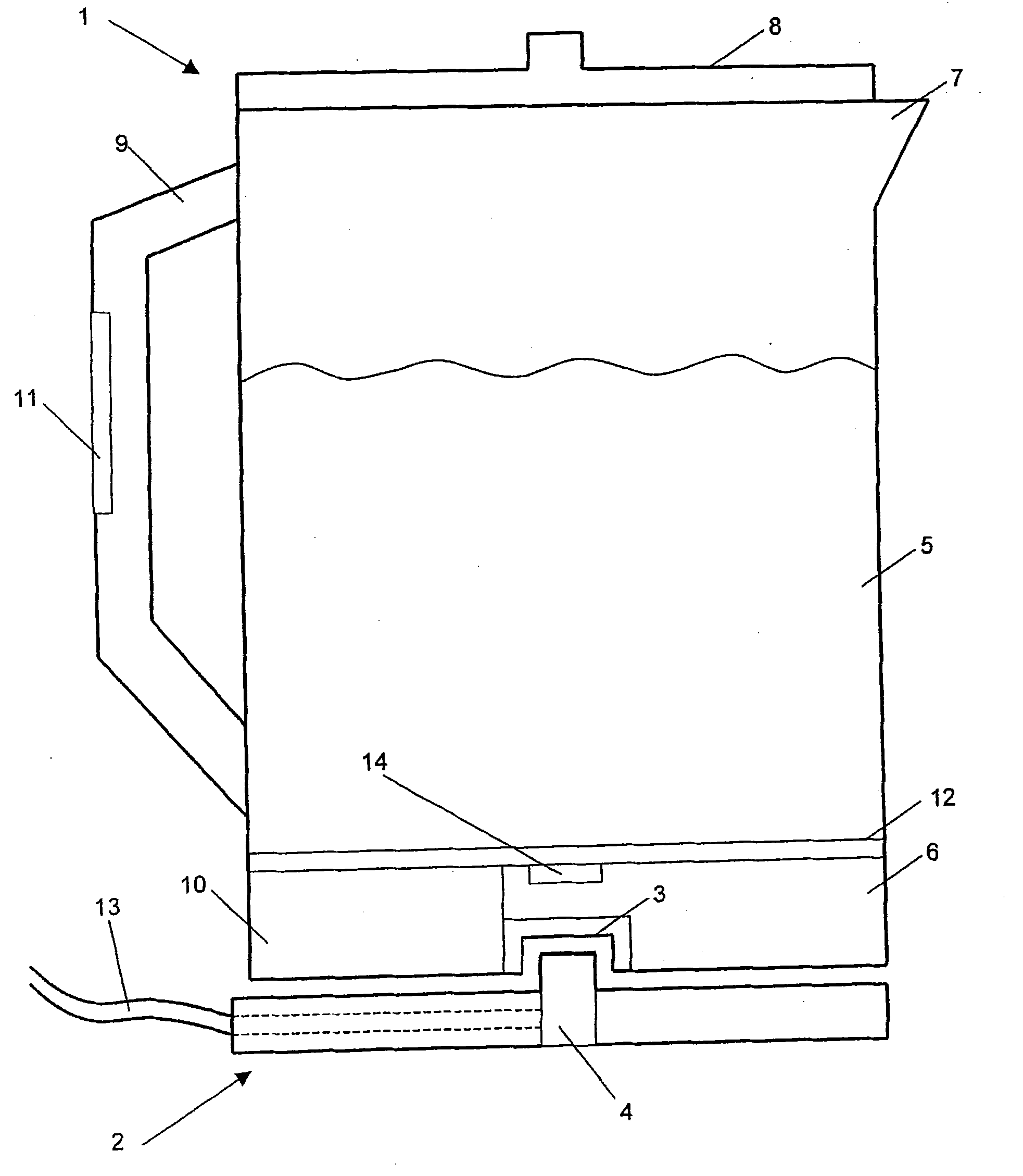

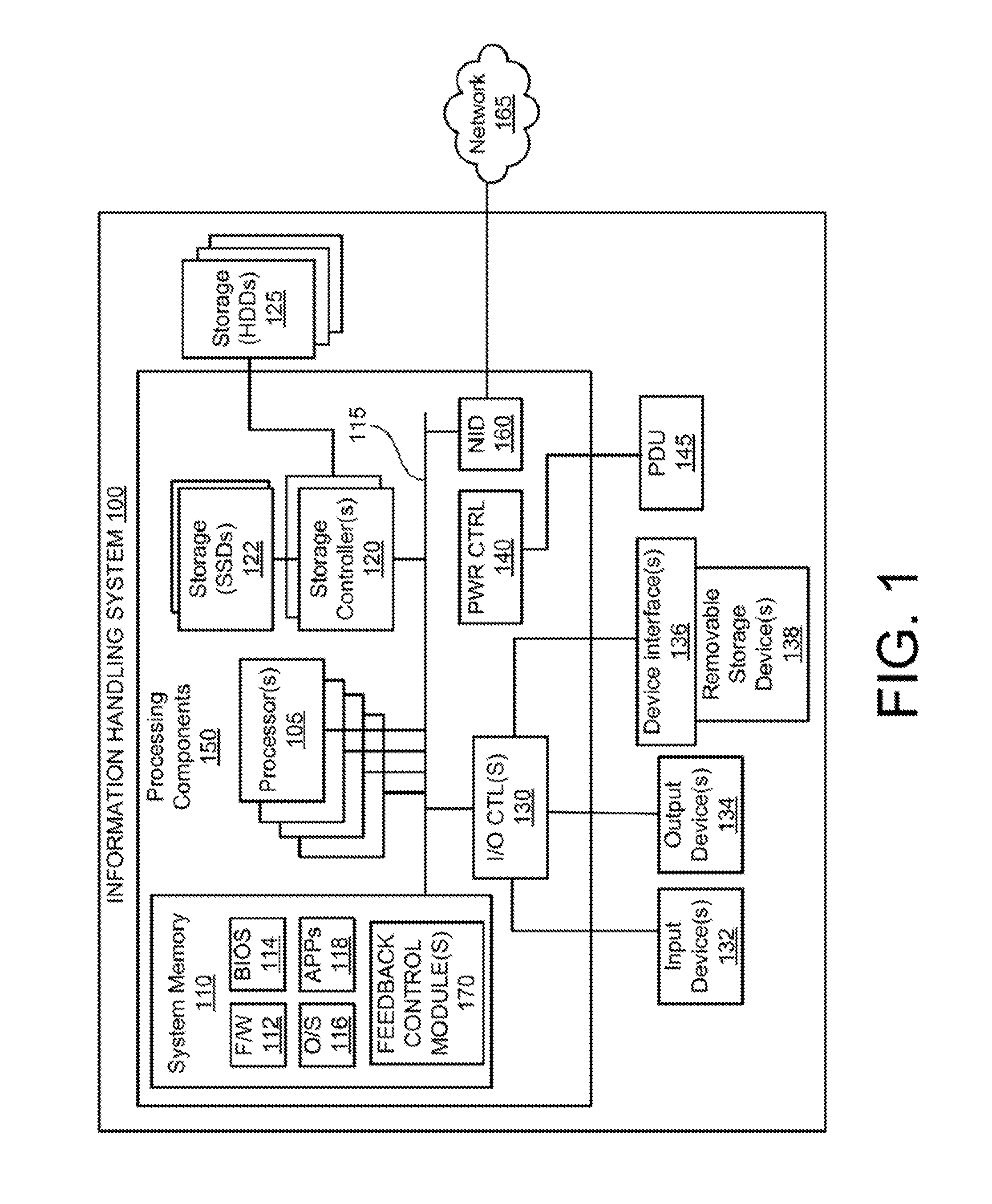

Stand Alone Immersion Tank Data Center with Contained Cooling

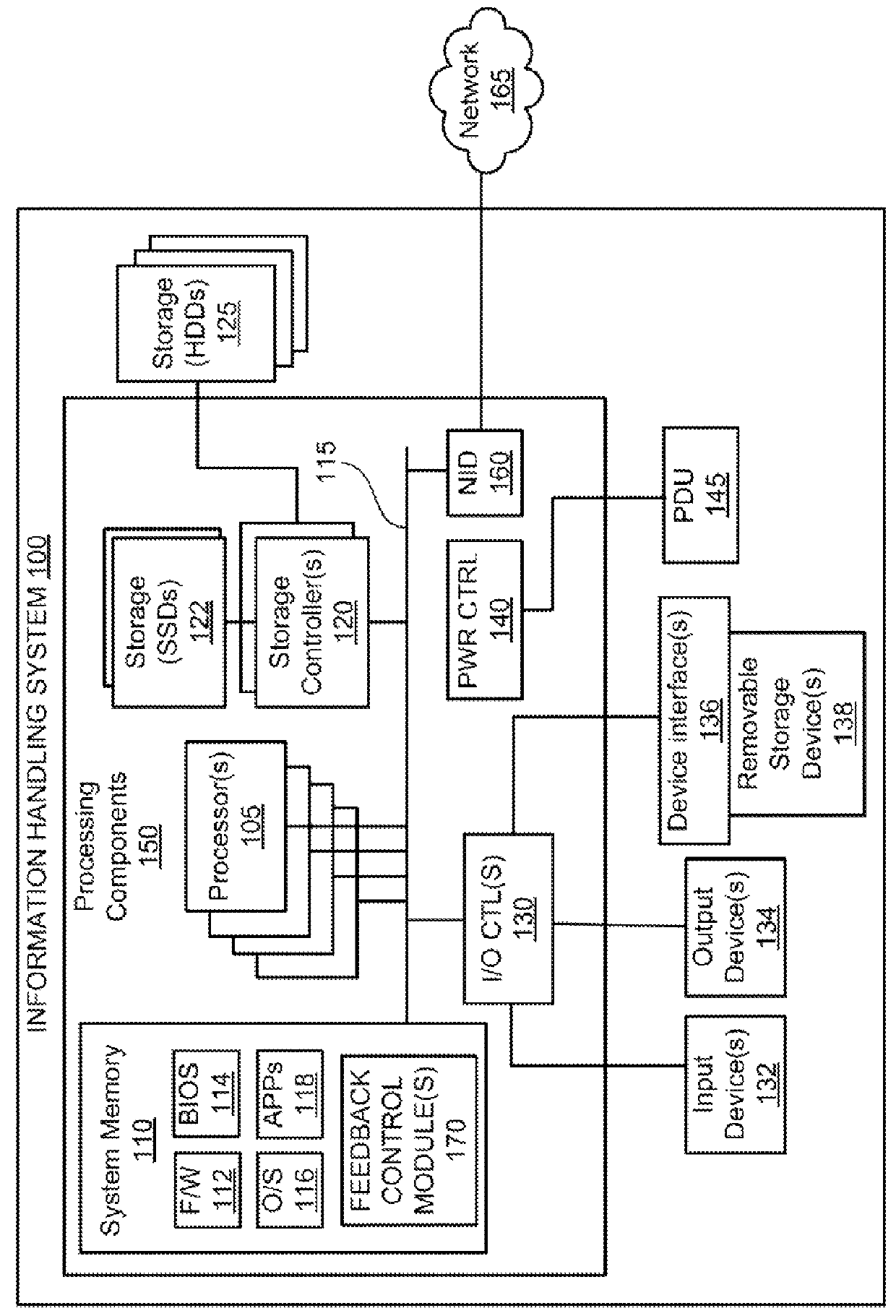

ActiveUS20140218858A1Increase circulation flowReduce heatDigital data processing detailsElectrical apparatus contructional detailsElectricityNuclear engineering

A stand-alone immersion tank datacenter (SITDC) includes: a multi-phase heat transfer immersion cooling tank having external walls surrounding a tank volume within which a dielectric liquid is maintained and heated to a boiling point temperature; a plurality of servers having one or more processing and memory components submerged within the dielectric liquid for cooling of the one or more components via heat dissipation from the one or more components into the dielectric liquid when the one or more components are connected to an electric power supply; and a condenser located vertically above the plurality of servers and in a direct path of rising dielectric vapor created when the dielectric liquid absorbs sufficient heat from the one or more components to reach a boiling point temperature of the liquid. The condenser can be a passive heat exchanger, created by providing a heat conductive material as a top lid of the tank.

Owner:DELL PROD LP

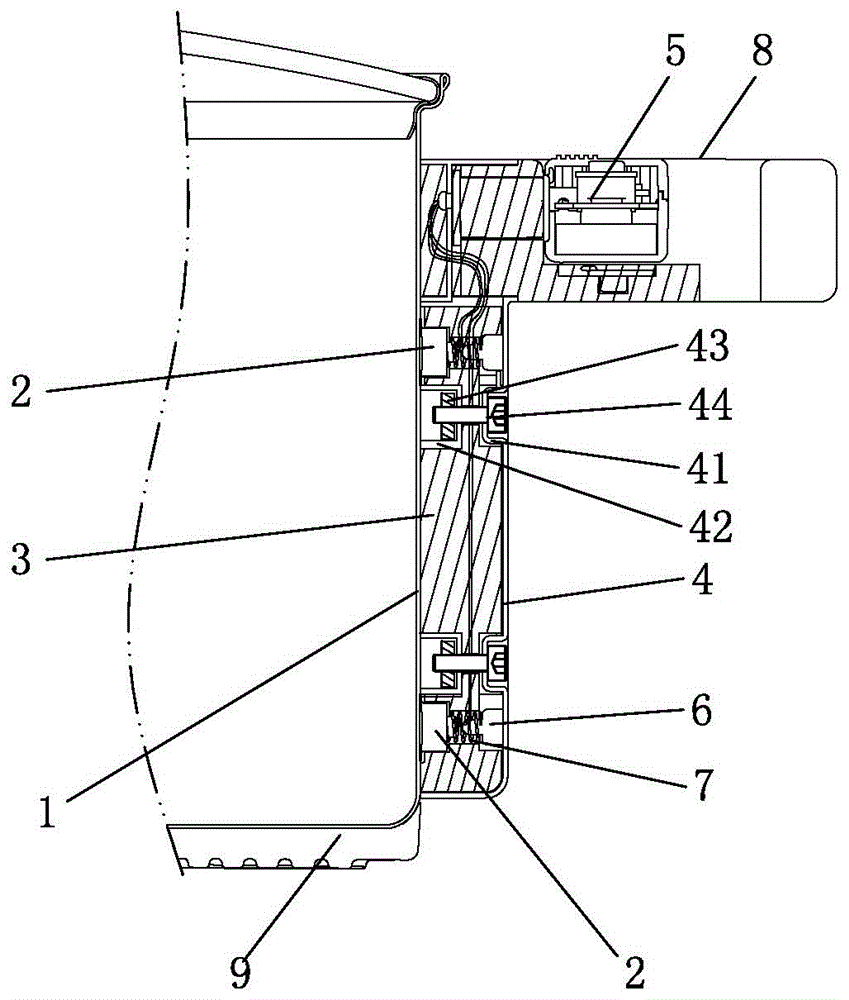

Cooker provided with multiple temperature-sensing probes and food cooking method

InactiveCN103948308AThe connection is tight and firmUndisturbedSteam cooking vesselsFood scienceThermal insulationTwo temperature

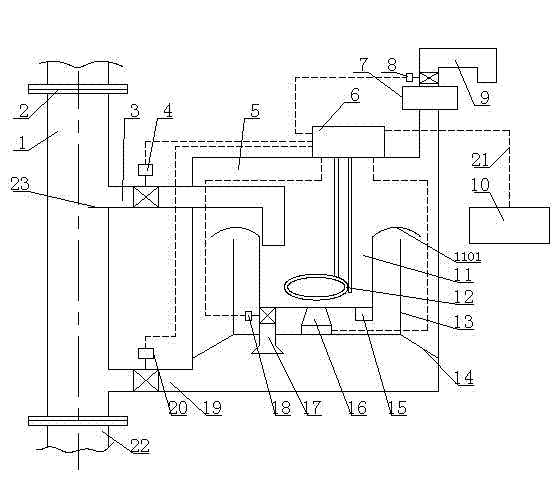

The invention relates to the technical field of cookware, in particular to a cooker provided with multiple temperature-sensing probes and a food cooking method. More than two temperature-sensing probes are arranged at different-height positions of a cooker wall, the lowest end temperature-sensing probe is arranged on the cooker wall close to the bottom of the cooker, thermal insulation materials are arranged the peripheries of the temperature-sensing probes, metal protective layers cover the outer sides of the thermal insulation materials, and the temperature-sensing probes are connected tightly, so that the interference of the outside temperature is prevented, and the sensing precision is improved; the temperature-sensing probe conductors are connected to a temperature displaying unit; through the temperature displaying unit, the temperature of the interior of the cooker is immediately known, the accurate heat control is carried out, and the scientific cooking is carried out. The invention further relates to a food cooking method by utilizing the intelligent cooker. The cooking method comprises the following steps of heating at an approximate boiling point; continuously heating till the cooker senses a set temperature t1 of temperature T1; after the temperature of the boiling point is closed, cooking on soft fire on time, so as to avoid the energy consumption waste.

Owner:GUANGDONG MASTER GROUP

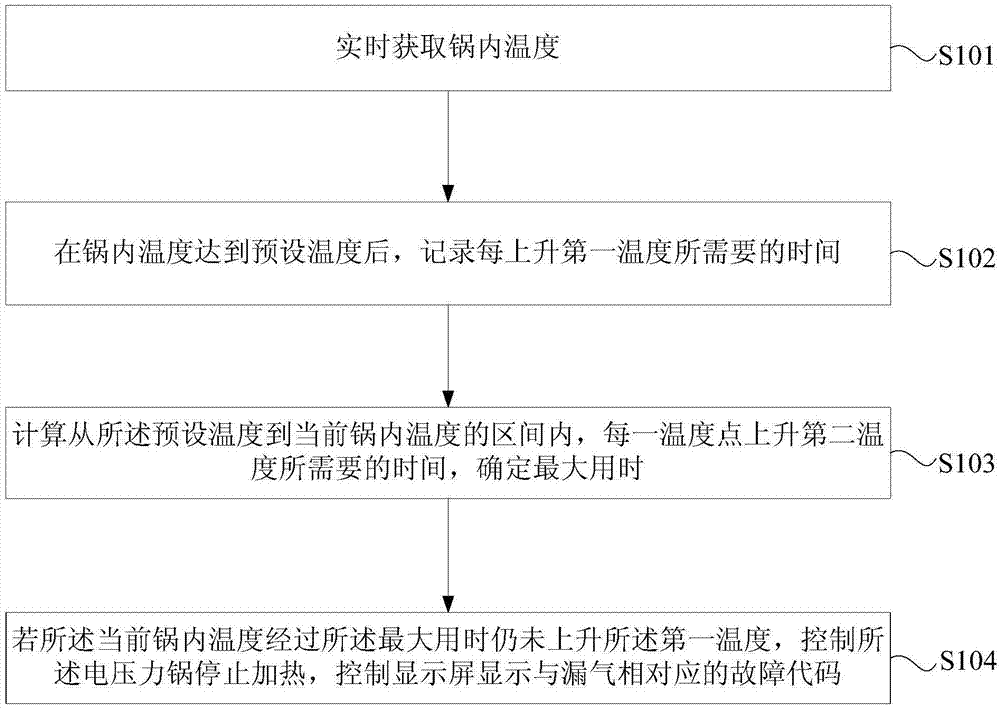

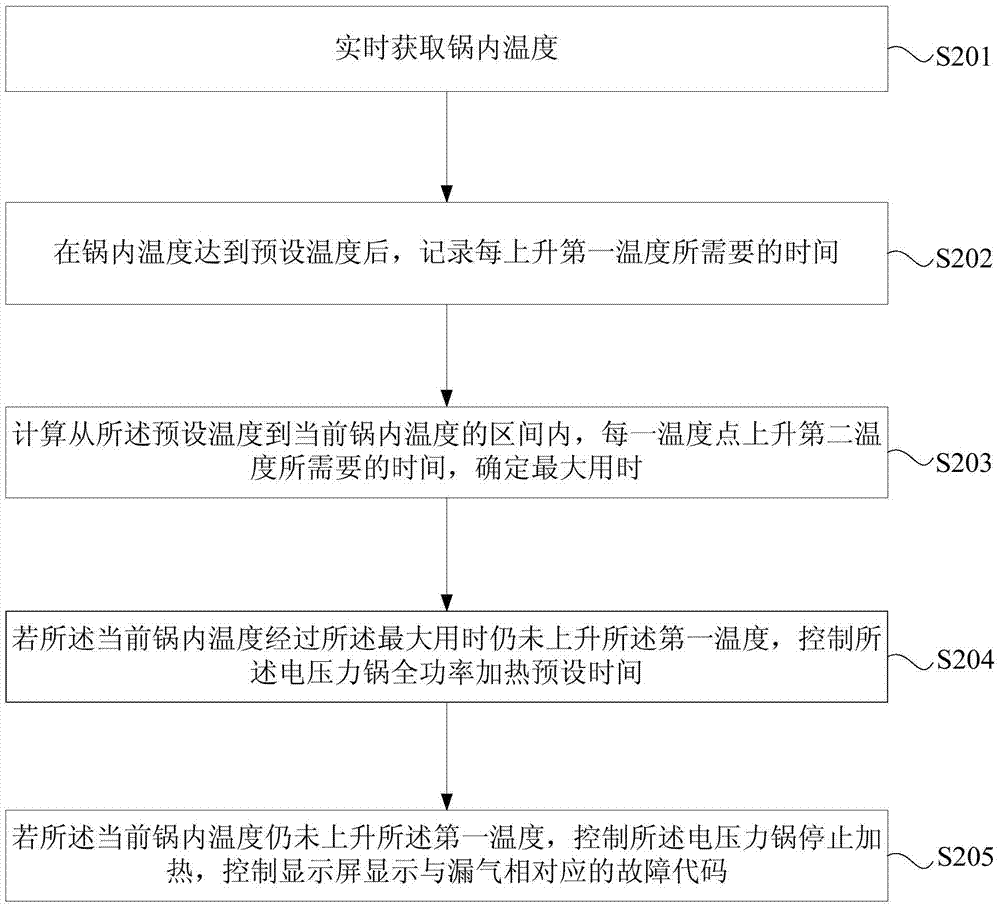

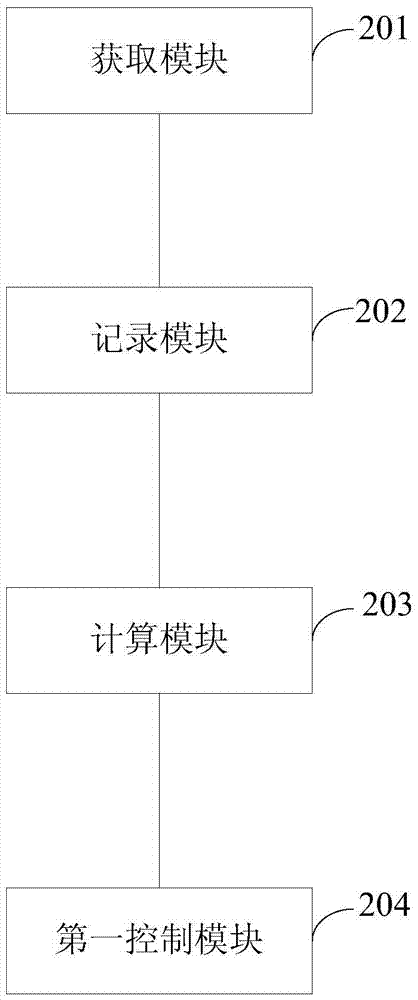

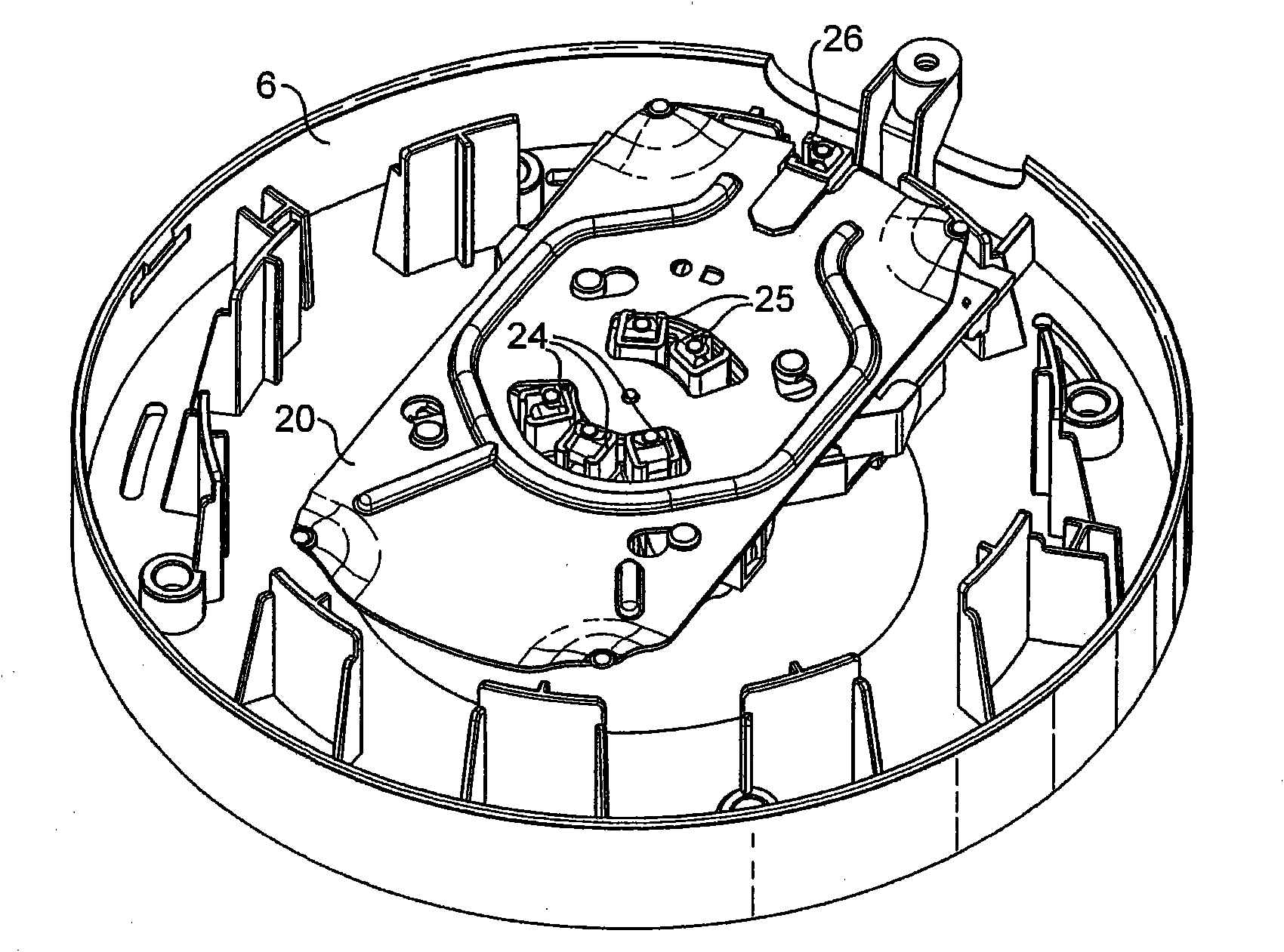

Electric pressure cooker air leakage protection control method and device and electric pressure cooker

ActiveCN105433778AAvoid damageFree from damagePressure-cookersWarming devicesEngineeringBoiling Point Temperatures

The invention discloses an electric pressure cooker air leakage protection control method and device and an electric pressure cooker. The method comprises the steps that the temperature in the cooker is acquired in real time; when the temperature in the cooker reaches a preset temperature, time needed by increasing a first temperature every time is recorded, and the preset temperature is lower than the boiling point temperature of water at the current altitude; time needed by increasing a second temperature of every temperature point within the interval ranging from the preset temperature to the current temperature in the cooker is calculated, and the maximum consumed time is determined, and the second temperature is higher than the first temperature; if the current temperature in the cooker is not increased to the first temperature yet through the maximum consumed time, the electric pressure cooker is controlled to stop heating, and a display screen is controlled to display a fault code corresponding to air leakage. According to the electric pressure cooker air leakage protection control method and device and the electric pressure cooker, air leakage of the electric pressure cooker can be found in time to execute air leakage protection operation, therefore, the electric pressure cooker is prevented from being damaged, and safety accidents are prevented from occurring.

Owner:GREE ELECTRIC APPLIANCES INC

Photopolymer for volume holographic recording and its production process

InactiveUS20120183888A1High sensitivityAvoid inconveniencePretreated surfacesCoatingsPlasticizerPhotopolymer

Owner:OLIVEIRA SERGIO ASSUMPCAO +1

Method for recovering carbon-fiber enhanced epoxy resin composite material

The invention relates to a method for recovering a carbon-fiber enhanced epoxy resin composite material. In the existing method, the requirement for equipment is high and the recovery cost is large. The method comprises the following steps of: cutting materials needing to be decomposed into blocks with the volume being 5cm<3>, putting the blocks in a backflow device containing acid liquor, heating for 5-20 minutes at the temperature of boiling point, cleaning and carrying out vacuum drying; then putting the obtained mixture into a reaction kettle, adding an organic solvent and an oxidizing agent, firstly heating, then cooling to normal temperature, and obtaining a primary product; and after cleaning, putting a solid product in the primary product into industrial acetone solution for dipping, obtaining recovered carbon fiber and carrying out pressure-reduced distillation on a liquid product to obtain phenol and derivatives thereof. In the method, reaction under low temperature and low pressure is realized and has the advantages of moderate reaction condition, easy control of reaction, fewer side products, no pollution basically and no corrosion to equipment and the like, so that the method is a green recovering method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

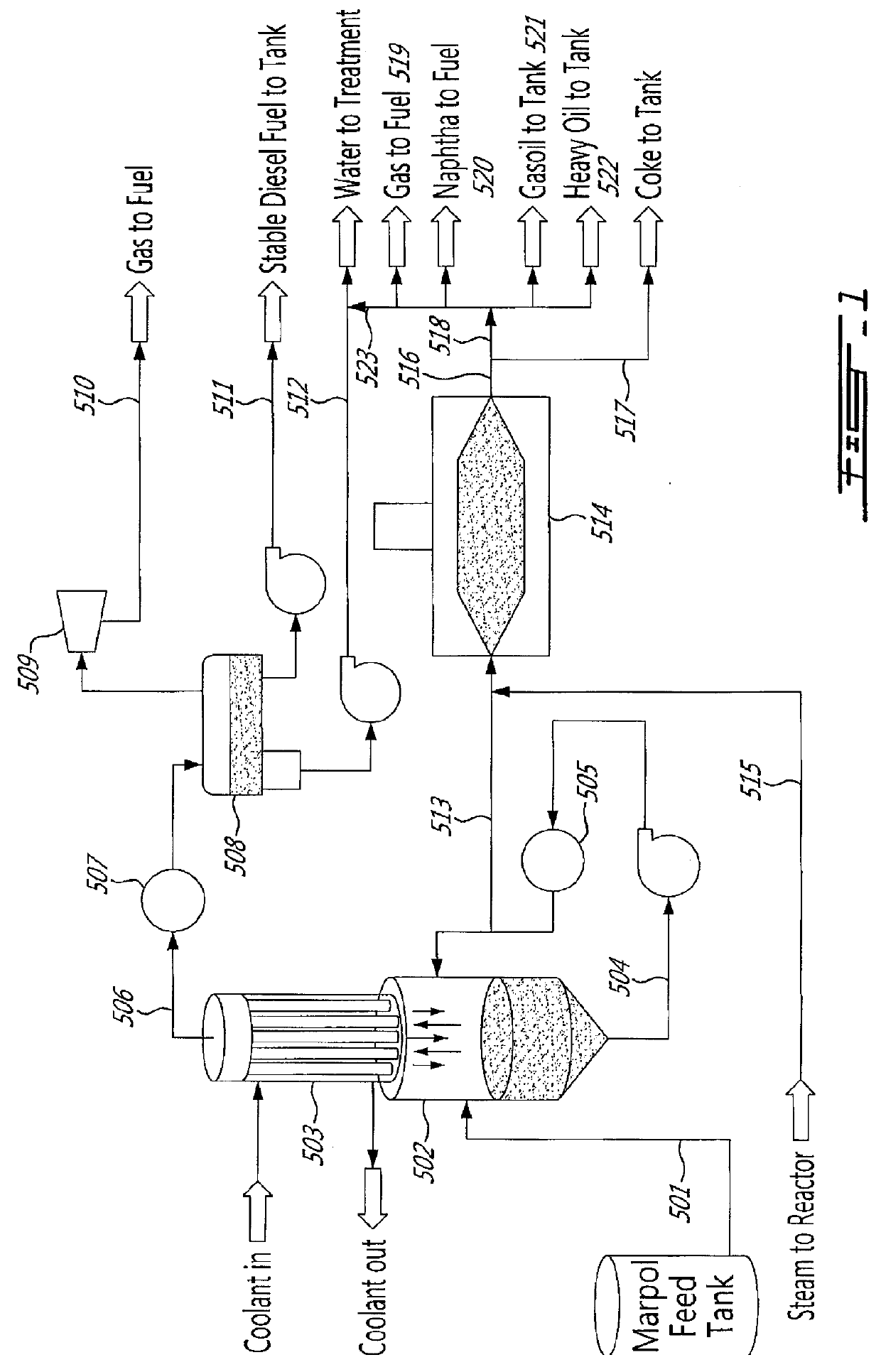

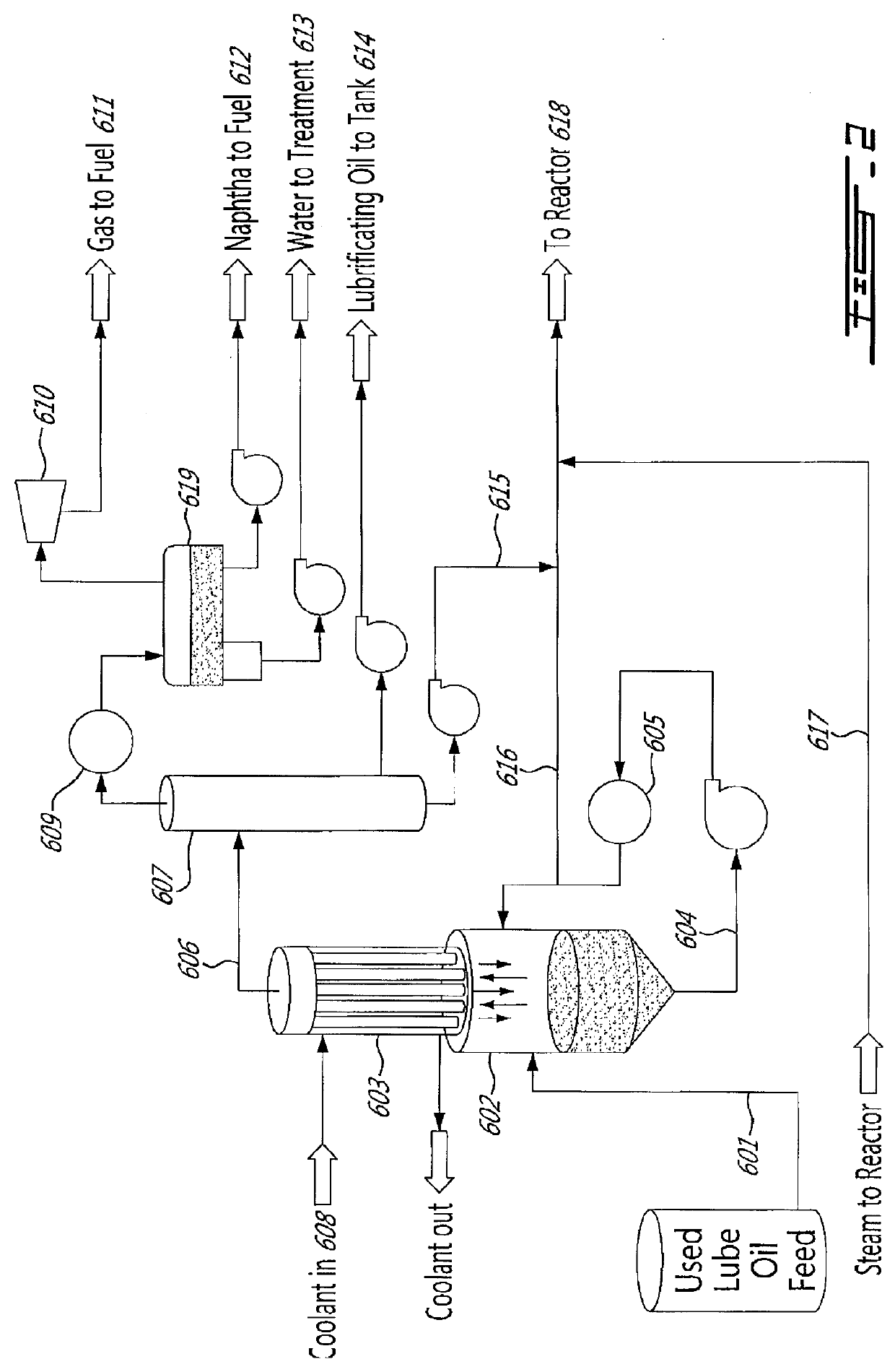

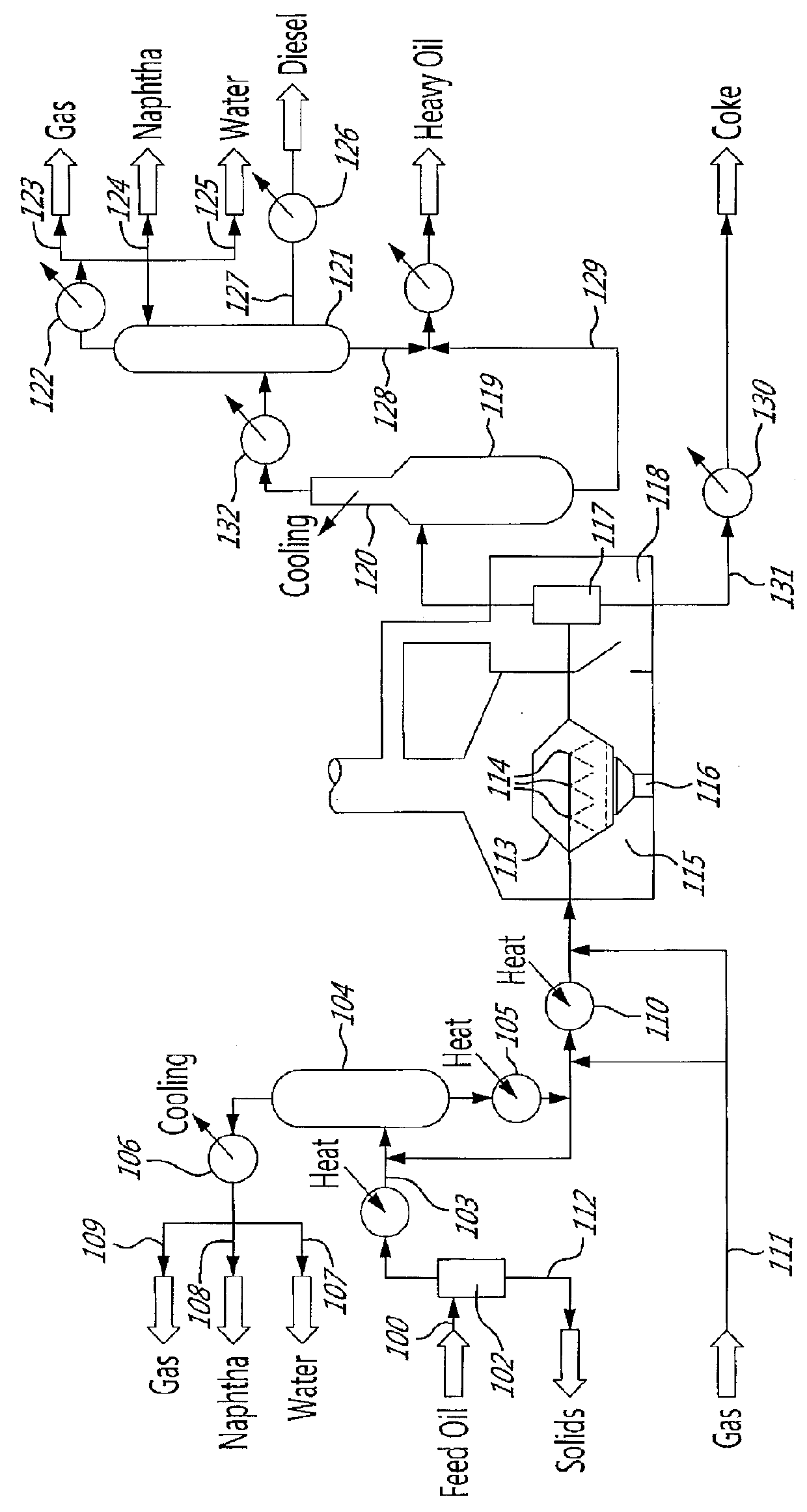

Hybrid thermal process to separate and transform contaminated or uncontaminated hydrocarbon materials into useful products, uses of the process, manufacturing of the corresponding system and plant

ActiveUS20160053184A1Increase volumeReduce contentThermal non-catalytic crackingChemical/physical/physico-chemical reactor detailsChemical compoundWaste oil

Process for reclaiming useful products from a waste oil, comprising a thermal separation step performed in a vessel at conditions, of temperature and pressure, allowing to substantially avoid cracking of the waste oil and to assure the separation of said heated waste oil into a first heavy oil fraction and into a second light oil fraction having, in comparison with the waste oil, a low content in solids and / or in other contaminants that are different from water and from inert gas. The process is further characterized in that while, during the thermal separation treatment, the waste oil is heated to a temperature about the boiling temperature of the heavy oil fraction, and below the cracking temperature of the waste oil, and at a pressure that is preferably below the atmospheric pressure, the heavy oil fraction of the vapours existing the vessel, in contact with a cooler surface, condenses and falls back into the vessel, while the second fraction, in a gaseous state, is eventually submitted to at least one further separation treatment. When water is present in the waste oil, said water is used to improve the amount of recovered light oils; and / or when no water is present in the waste oil, water or at least one inert gas or at least one component that may become an inert gas by heating may be added to the waste oil or to the thermal separation unit. Uses of the process for environmental applications and for treating used oils and to prepare oil products. Systems for reclaiming useful products from waste oils comprising at least one rotating kiln and at least one self-refluxing condenser and / or at least one dephlegmator.

Owner:ENVIROLLEA

Process for extracting high-grade rice bran oil by physical method

InactiveCN101805666AImprove retentionEmission reductionFatty-oils/fats refiningWater vaporFatty acid

The invention relates to a process for extracting high-grade rice bran oil by a physical method, which utilizes the partial pressure of water vapor to reduce the partial pressure of free fatty acids in the oil and also reduce the boiling point temperature of the free fatty acids under high vacuum conditions, so that the free fatty acids can also be gasified at a lower temperature (240 DEG C) lower and further be separated from the oil. The chemical refining aims to further reduce the acid value, and ensure the oil color; while the process adopts the three-time bleaching and deodorization combining method to achieve the purpose. The three-time bleaching is that a mixing bleaching agent is used to remove 'blue' and other pigments produced in the deacidification process, and the deodorization is that the water vapor distillation principle is utilized to further remove the free fatty acids in the oil, so that the acid value and the like meet the requirements of product quality standards. Compared with the existing refining process, the process has high yield increasing by about 2-3% under the same conditions, and large micronutrient retention capacity, greatly retains nutrients, and significantly reduces the discharge amount of sewage.

Owner:ANHUI SIRUN GRAIN OIL REFINERY

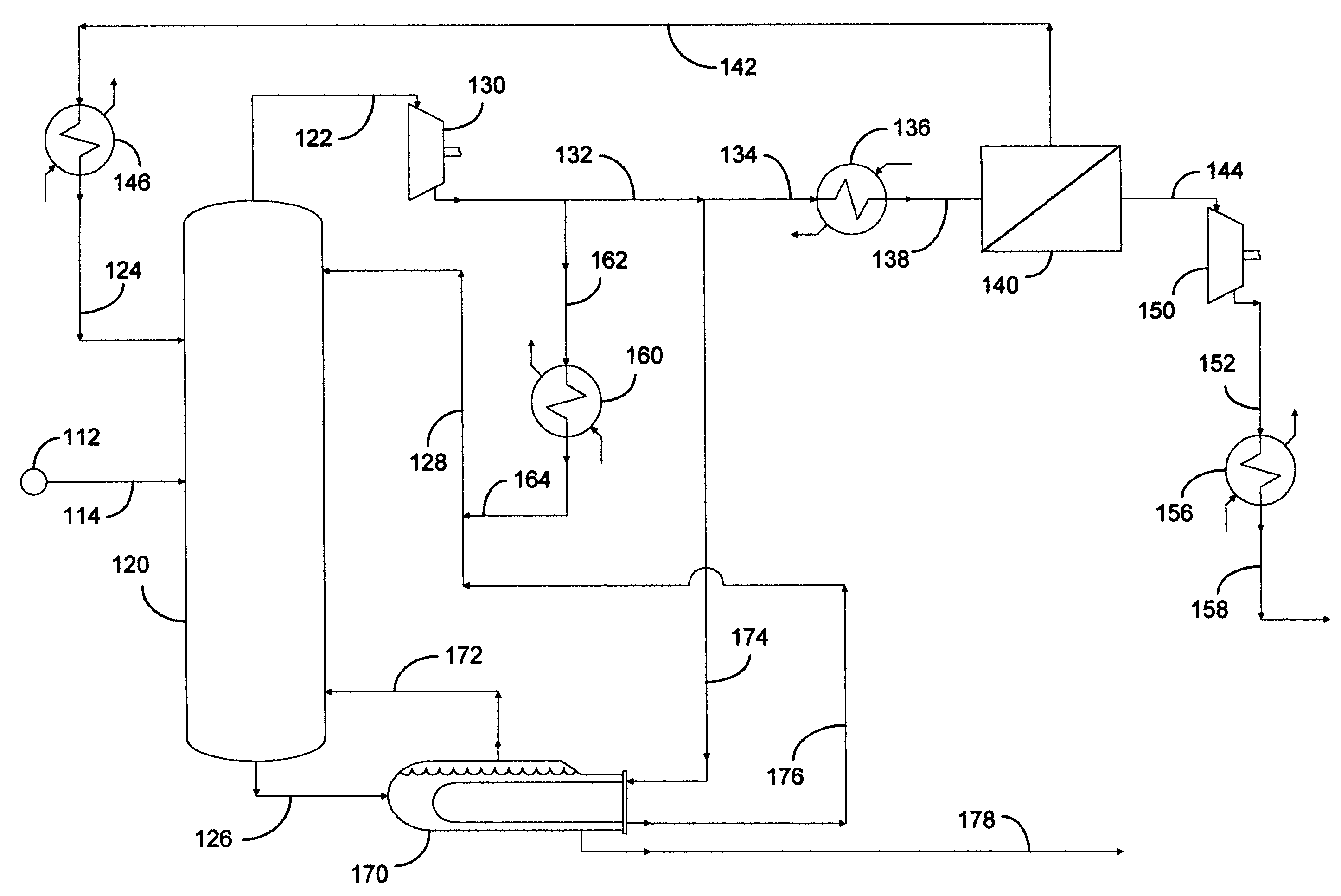

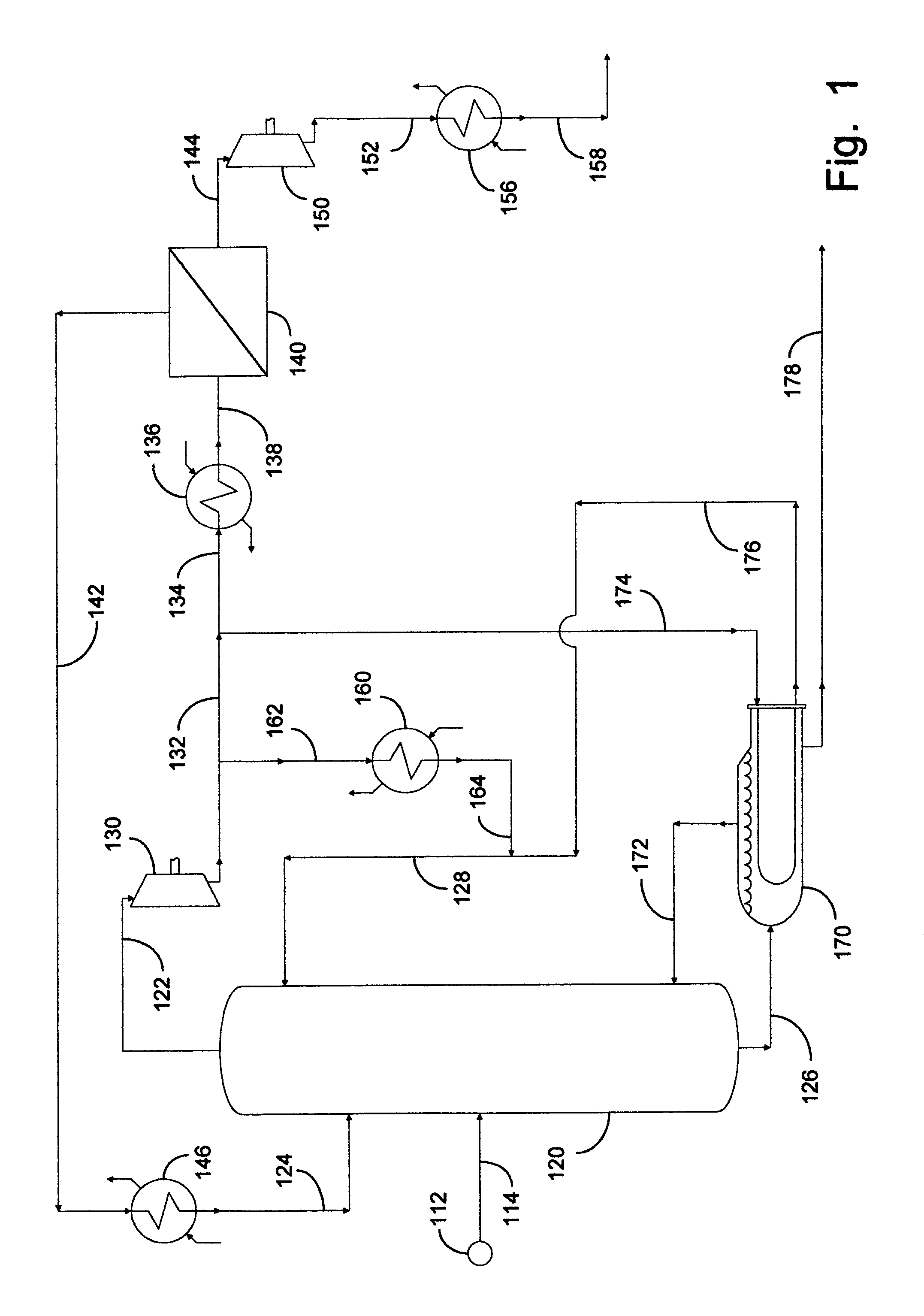

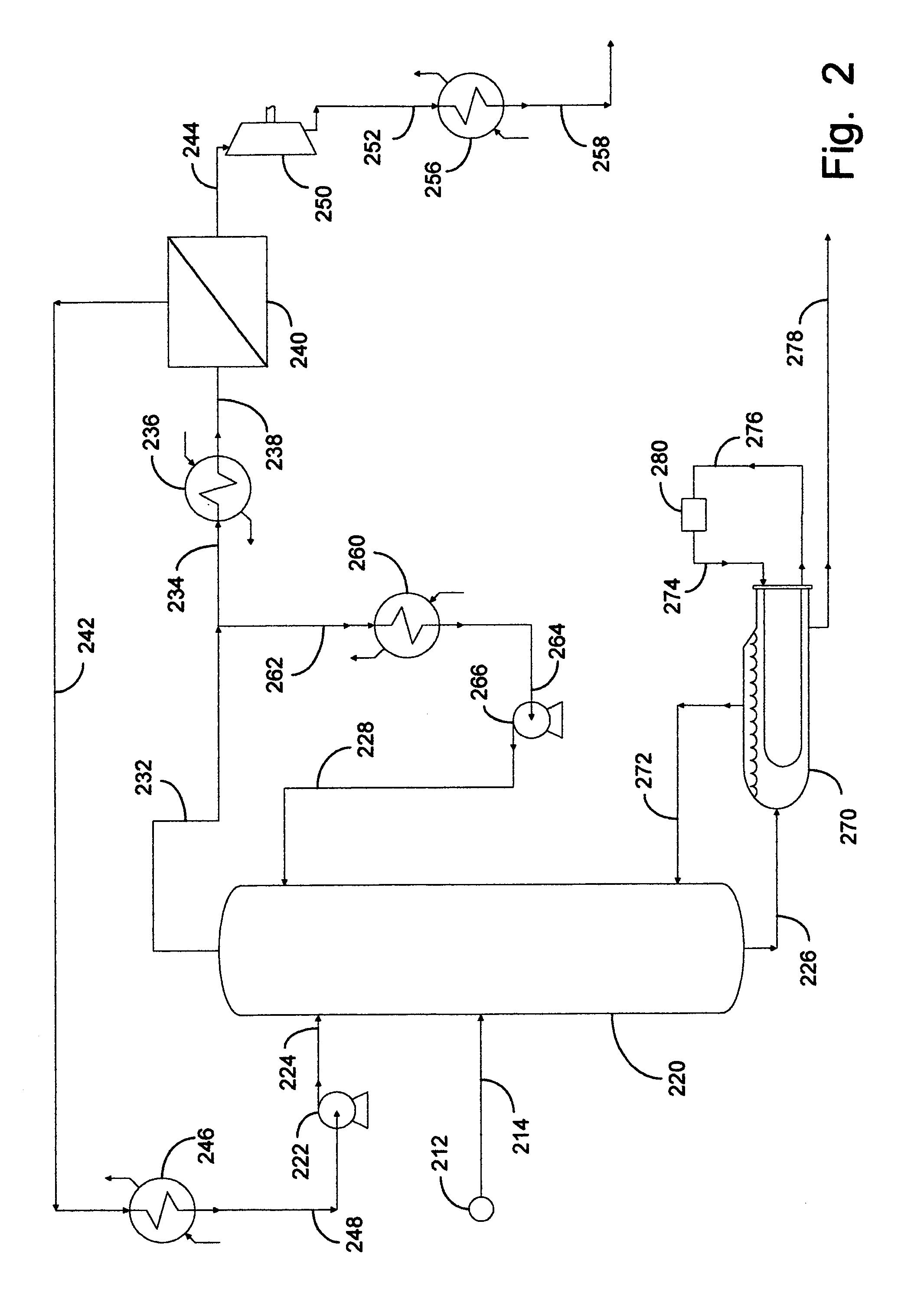

Purification of fluid compounds utilizing a distillation - membrane separation process

InactiveUS7070694B2Semi-permeable membranesOrganic compound preparationBoiling Point TemperaturesFractional distillation

Apparatus and processes are disclosed for economical separation of fluid mixtures. Broadly, apparatus of the invention is an integrated fractional distillation and perm-selective membrane separation apparatus. More particularly, the integrated apparatus comprises a fractional distillation column and one or more membrane device utilizing solid perm-selective membranes. Processes of the invention are particularly useful for simultaneous recovery of a very pure permeate product, a desired non-permeate stream, and one or more distillate products from a fluid mixture containing at least two compounds of different boiling point temperatures.

Owner:BP CORP NORTH AMERICA INC

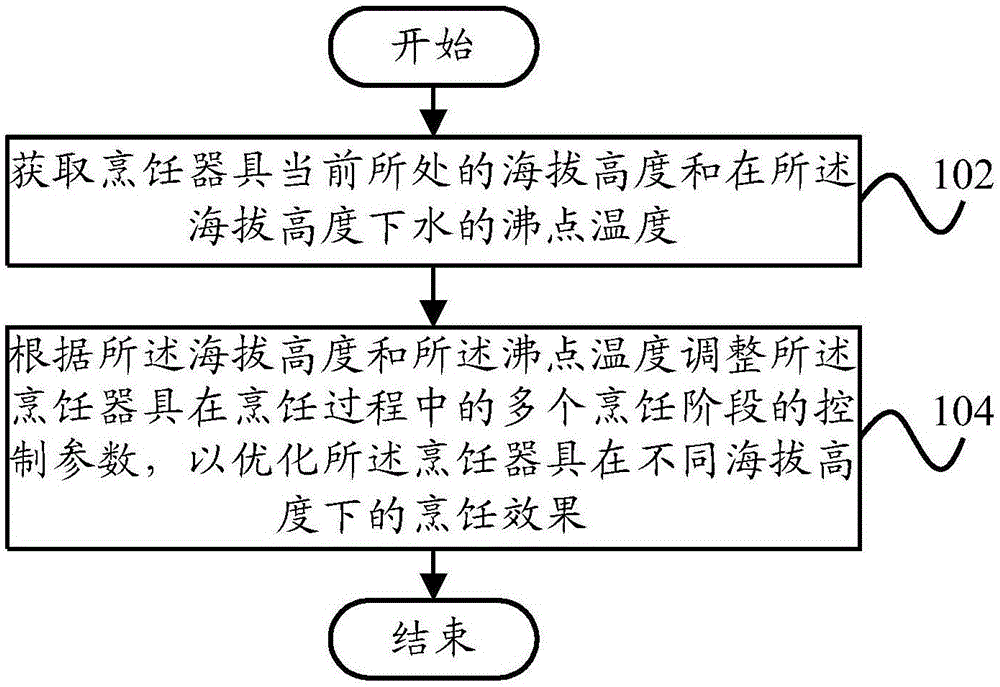

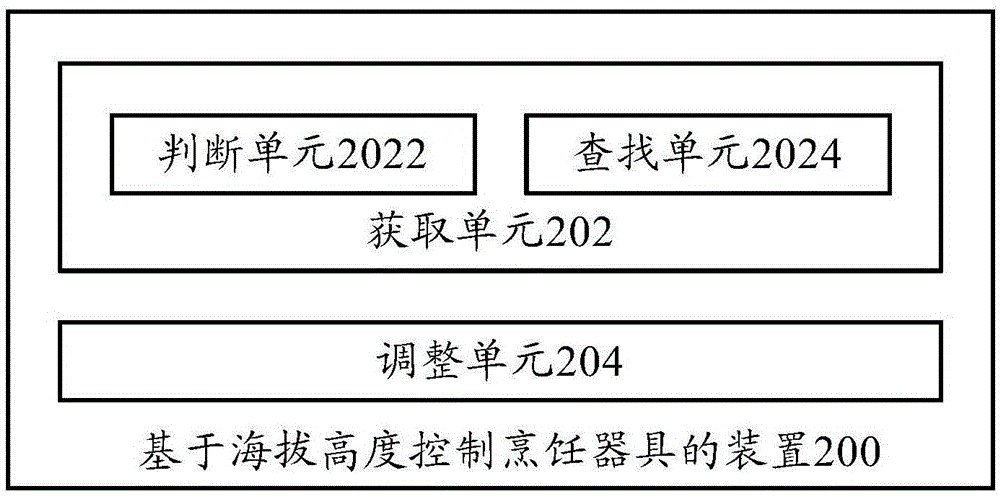

Cooking utensil control method and device, cooking utensil and terminal

ActiveCN106264072AImprove cooking resultsPrevent overflowCooking vesselsProcess engineeringFood material

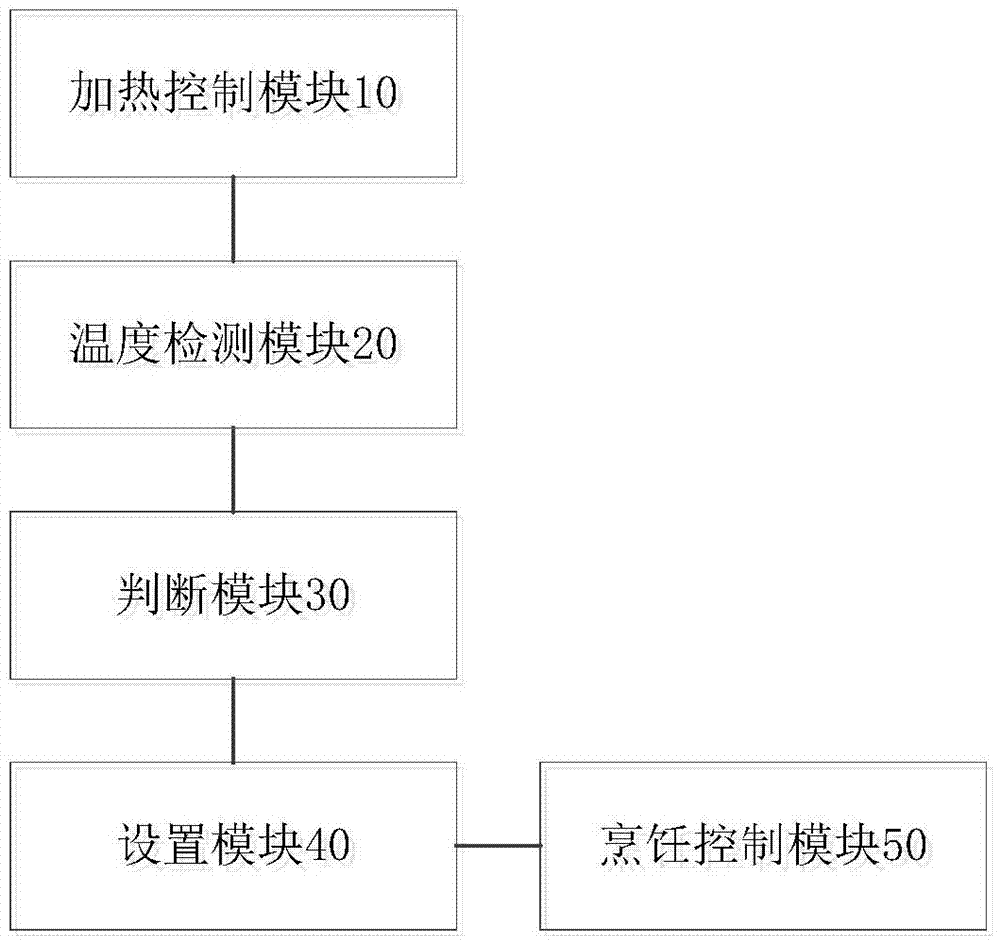

The invention provides a cooking utensil control method based on altitude height and a device, a cooking utensil and a terminal; the cooking utensil control method based on altitude height comprises the following steps; obtaining the present altitude height and water boiling point temperature of the cooking utensil under the said altitude height; adjusting control parameters of various cooking phases of the cooking utensil in a cooking process according to the altitude height and water boiling point temperature, thus optimizing the cooking effect of the cooking utensil under different altitude heights. The method can adjust control parameters of various cooking phases of the cooking utensil in the cooking process according to the altitude height and water boiling point temperature, so the cooking utensil can adjust the control parameters in real time in the working process according to the present altitude height, thus preventing food material overflowing or half-cooked problems caused by altitude height influences in the cooking process, and greatly optimizing the cooking effect of the cooking utensil.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

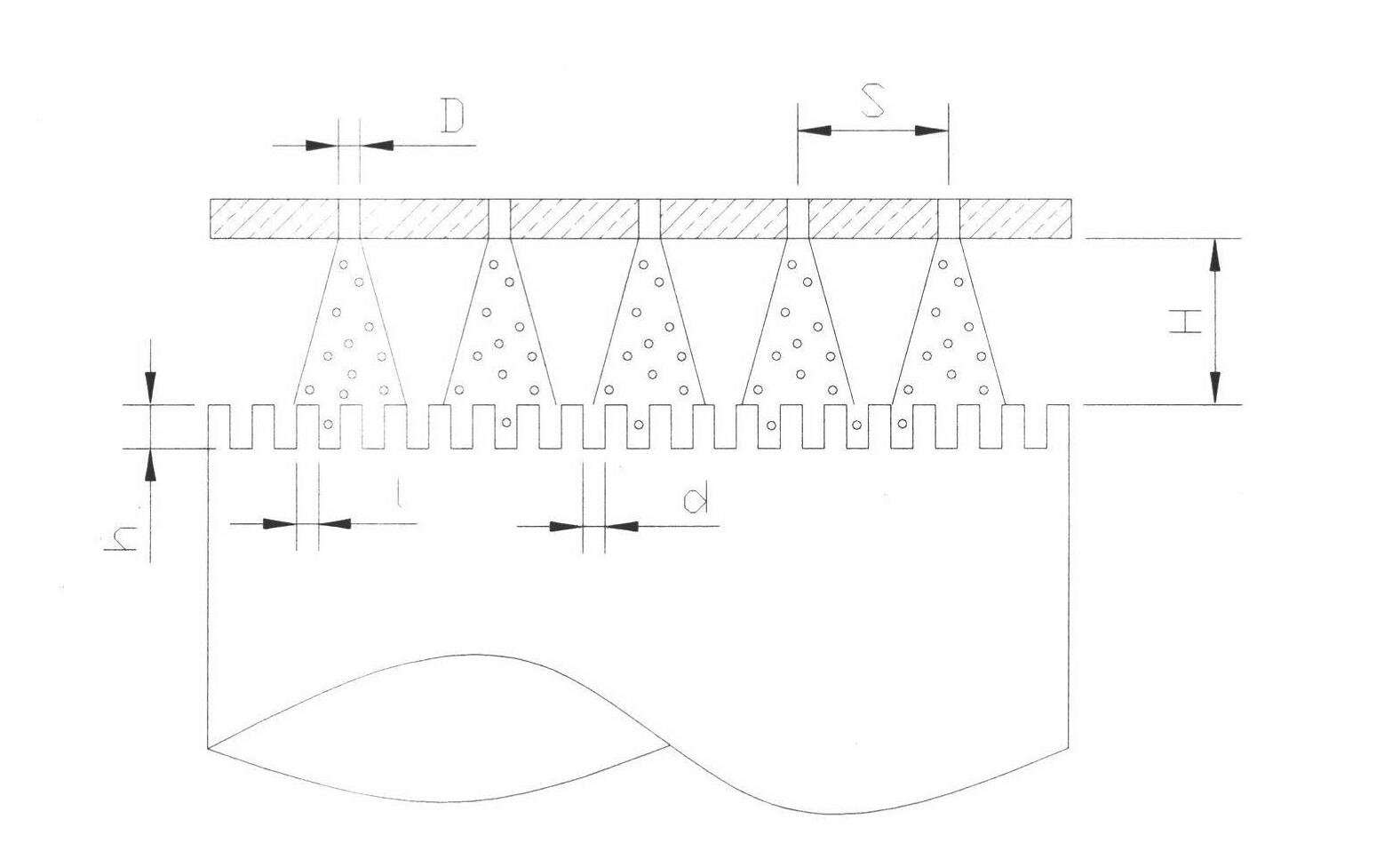

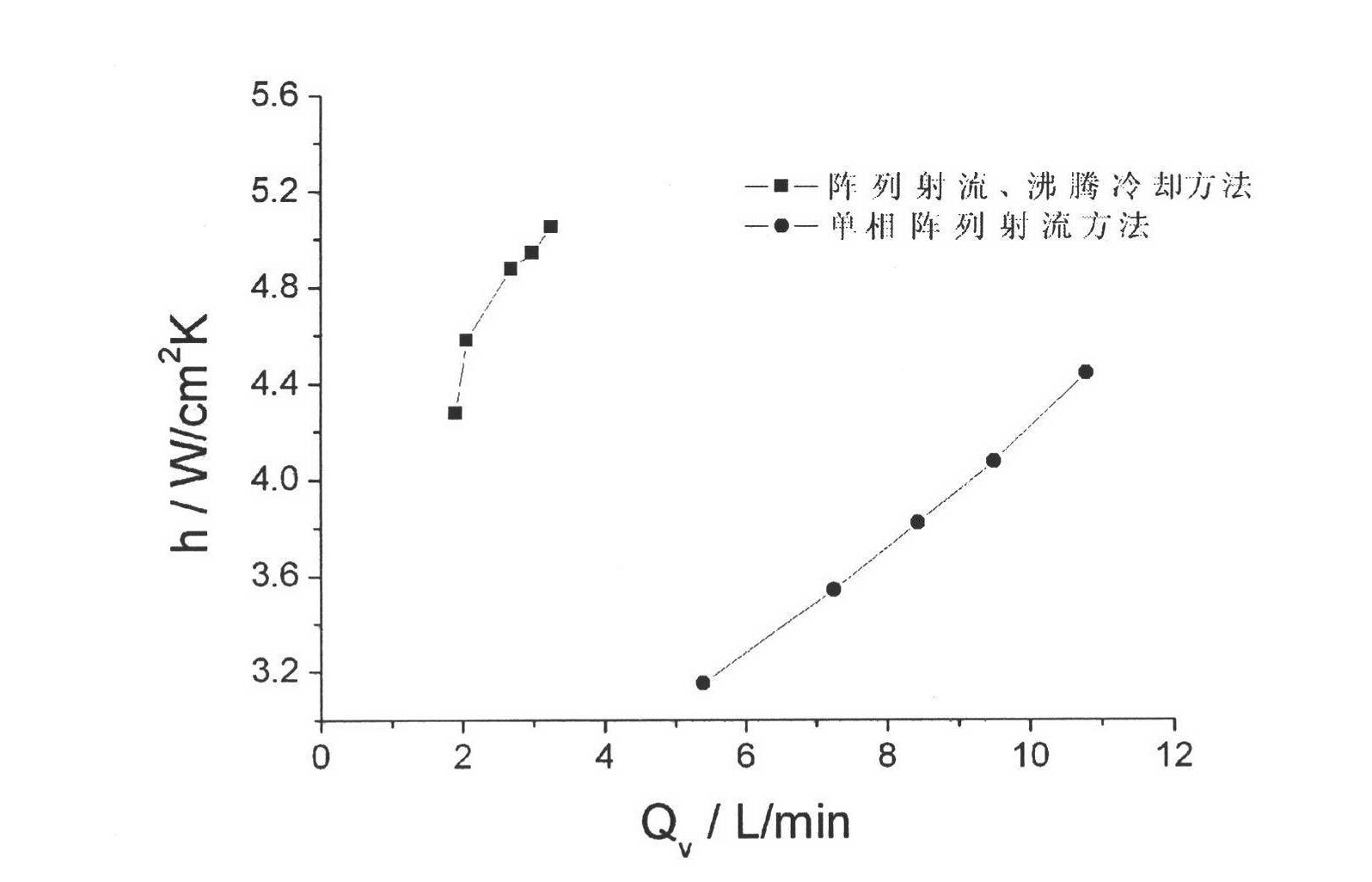

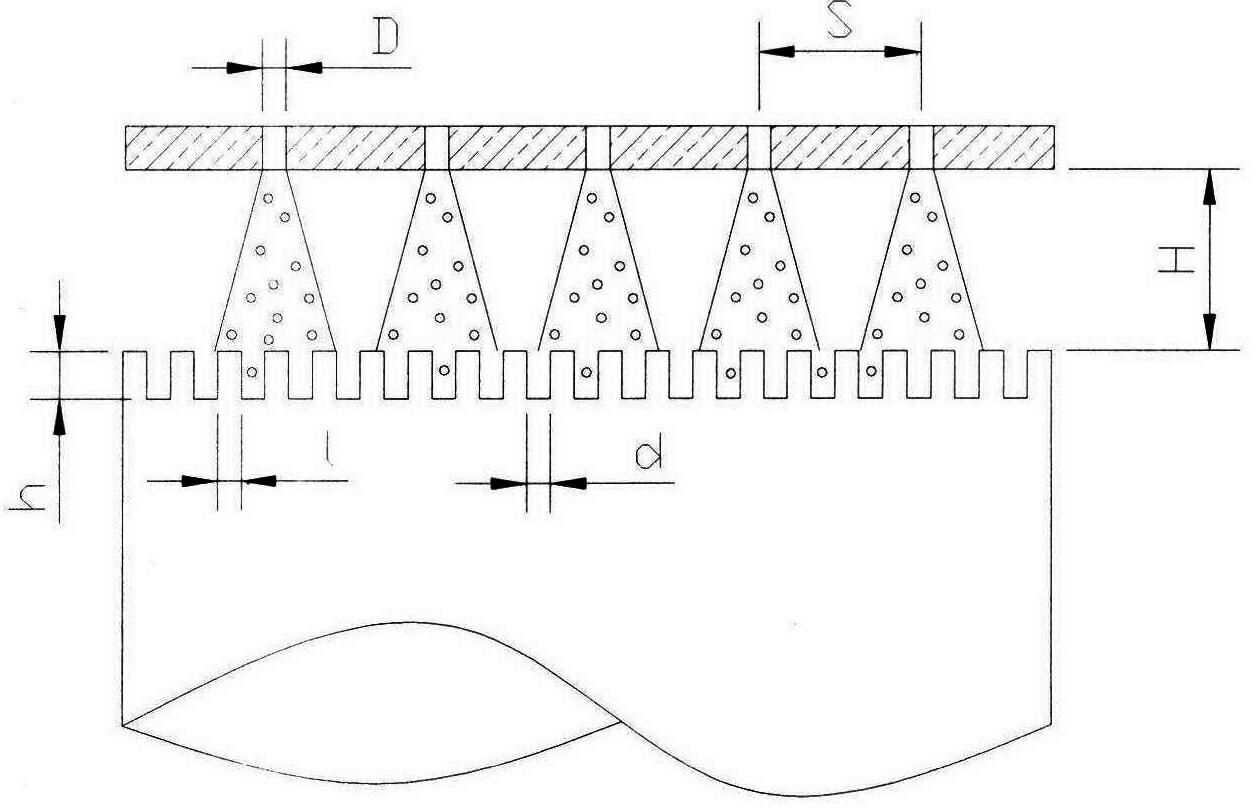

Coupling heat transfer method of array jet and boiling cooling under high heat flux

ActiveCN102271485AReduce temperature riseMeet cooling needsCooling/ventilation/heating modificationsWorking fluidEngineering

The invention discloses a coupling heat exchange method of array jet flow and boiling cooling under the condition of high heat flux, which combines single-phase array jet impact cooling and boiling heat exchange, and uses the latent heat of evaporation of cooling liquid to remove the heat of electronic devices, that is, selects the boiling point For the coolant at -20°C-30°C, by controlling the pressure of the working fluid at -0.5bar-10bar, the boiling point temperature in the required range is obtained, and the coolant is pumped to the array jet impact device, and the jet flow through the jet hole is in heat exchange On the surface, the temperature and pressure of the cooling liquid are controlled at the same time, so that the cooling liquid partially undergoes a phase change after the jet heat exchange, and the latent heat of vaporization of the cooling liquid is used to dissipate heat. The entire array jet flow, boiling cooling coupled heat transfer process. The invention realizes the heat dissipation of the electronic device under the condition of high heat flux density, thereby meeting the heat dissipation requirement of the electronic device under the condition of high heat flux density, effectively controlling the temperature of the electronic device, and meeting the working temperature requirement of the electronic device.

Owner:NANJING UNIV OF SCI & TECH

Liquid heating vessel and control

ActiveCN102160013ATemperature control without auxillary powerCooking vesselsElectronic controllerEffect light

The utility model discloses a liquid heating container including an electronic controller. The electronic controller is designed to have one or more of functions such as detecting / or controlling boiling or sub-boiling temperature, detecting volume / a horizontal plane, detecting and / or inhibiting water deposit through ultrasonic, determining the level of service efficiency, automatically removing the water deposit, and controlling light. Different beneficial lighting devices are arranged. A halogen lamp is used as a muff heater. Various modes of heating and lighting are provided by controlling a plurality of the halogen lamps.

Owner:翱泰温控器(惠州)有限公司

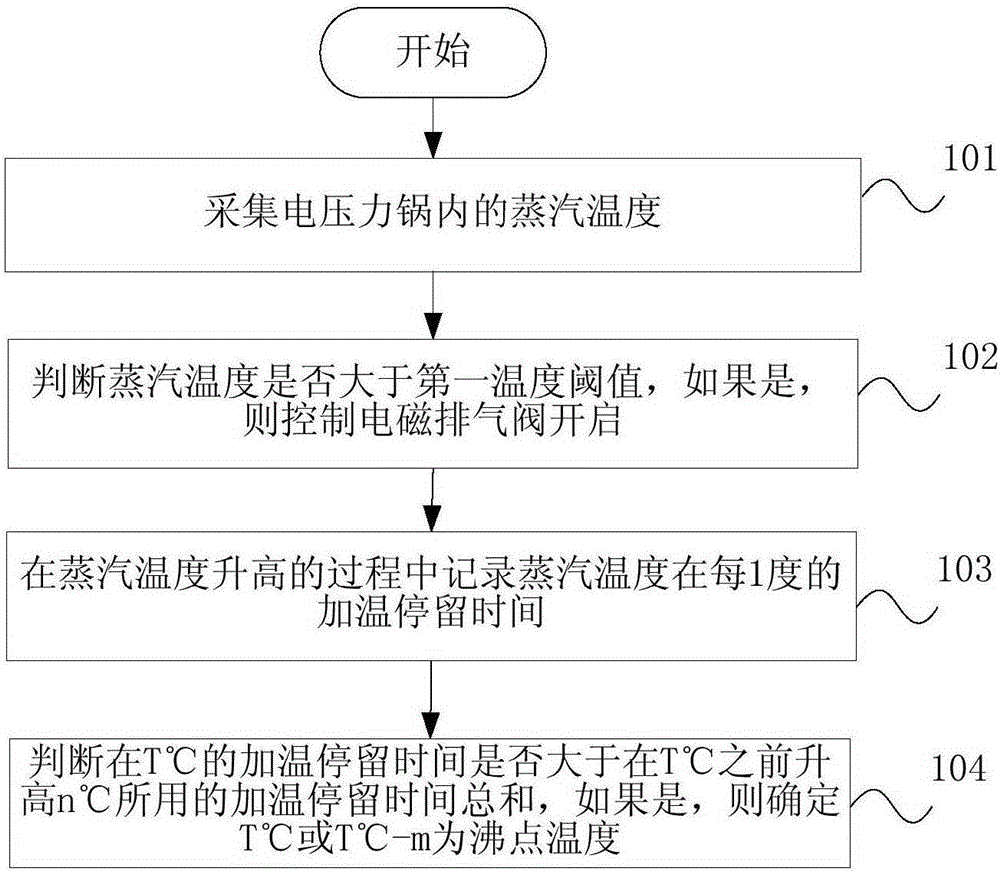

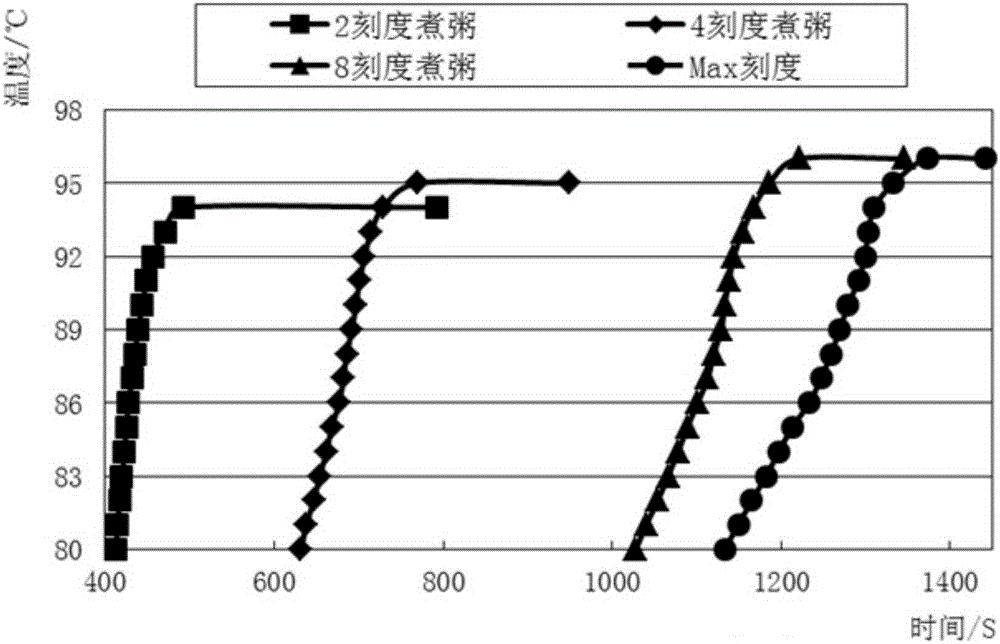

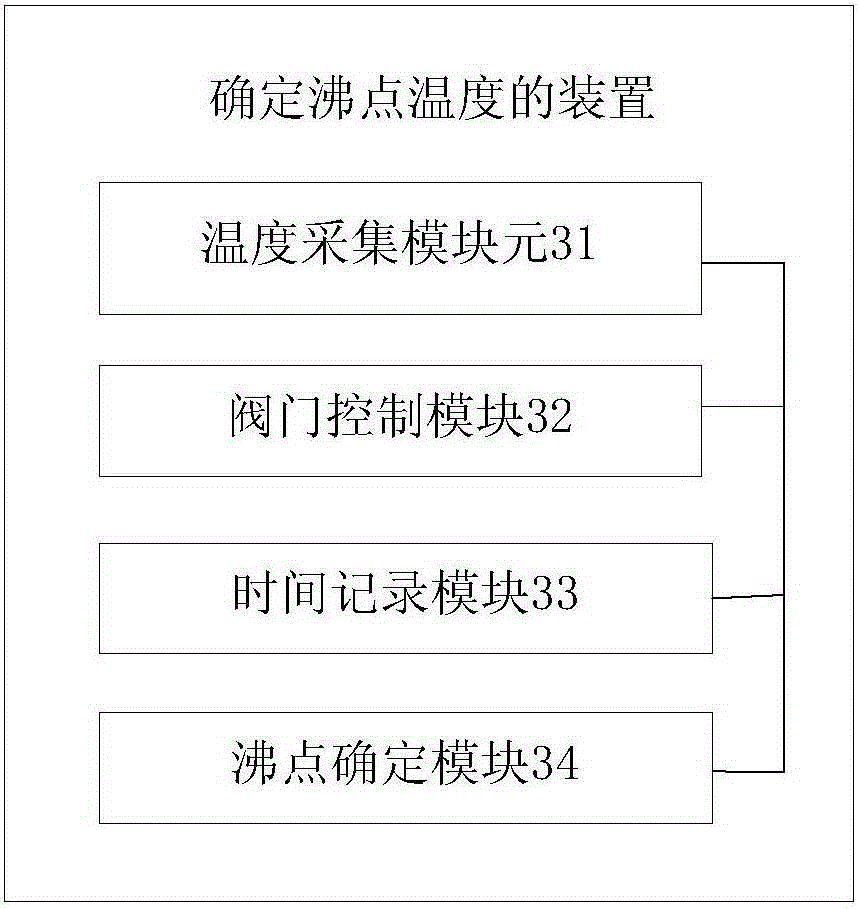

Method and apparatus for determining boiling point temperature, and electric pressure cooker

The invention discloses a method and apparatus for determining a boiling point temperature, and an electric pressure cooker. The method comprises the following steps: acquiring a steam temperature in the electric pressure cooker; determining whether the steam temperature is greater than a first temperature threshold, and if so, controlling an electromagnetic exhaust value to be open; recording heating stay time of the steam temperature at each degree when the steam temperature rises; and determining whether the heating stay time of the steam temperature at Tx DEG C is greater than the total of the heating stay time consumed when the steam temperature rises from Tx-n DEG C to Tx-1 DEG C, and if so, determining that the Tx DEG C or Tx-m DEG C is the boiling point temperature, wherein n is greater and equal to two, and m is a temperature correction value. According to the method and apparatus for determining the boiling point temperature, and the electric pressure cooker, boiling points of regions with different altitudes can be determined, the problem of difficult cleaning caused to a product or a kitchen due to food spay when air is exhausted and pressure is released and the problem of incapability of opening a top cover after the air is exhausted and the pressure is released are avoided, safety hidden risks are reduced, and application comfortableness of users is improved.

Owner:GREE ELECTRIC APPLIANCES INC

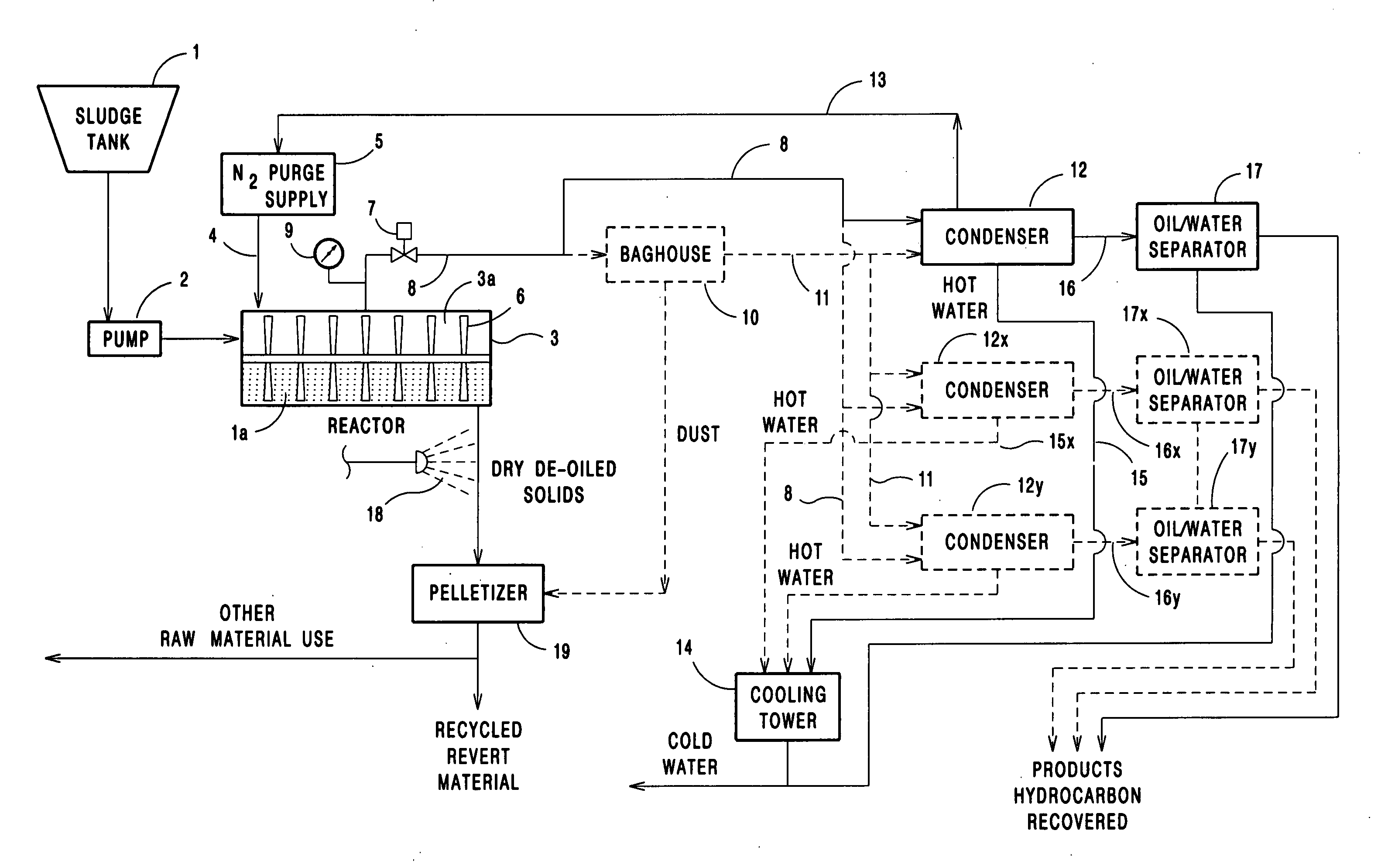

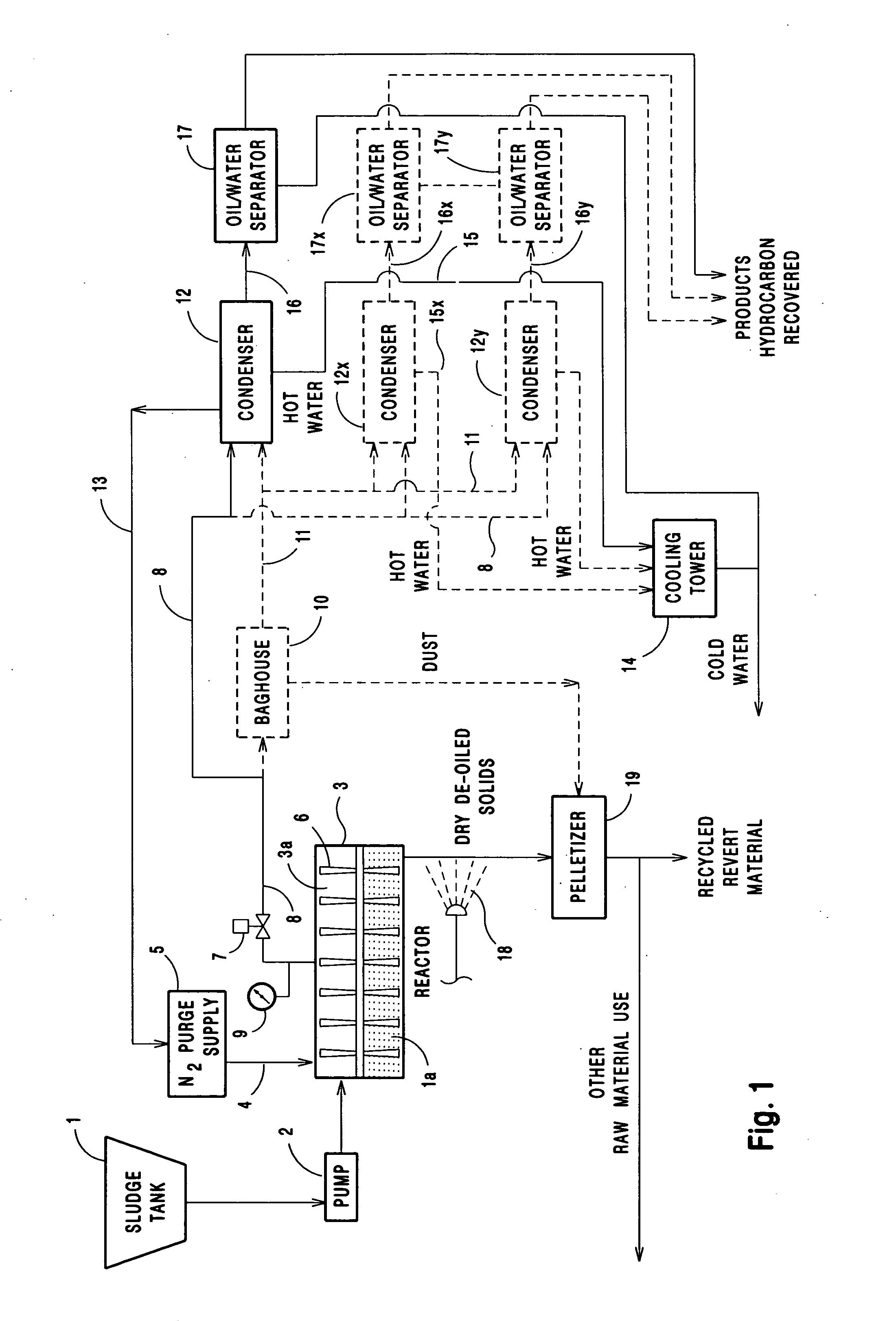

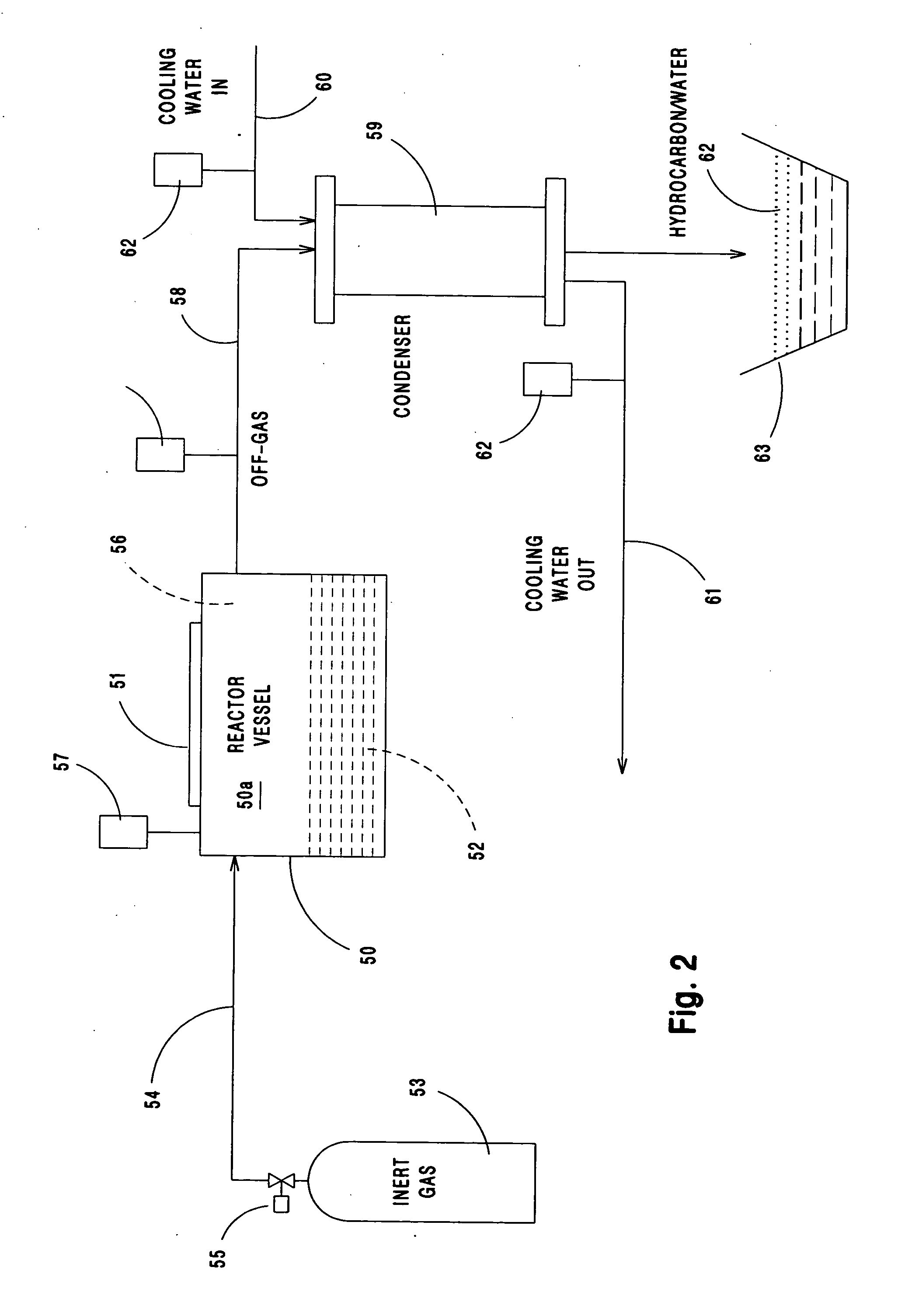

Process for de-oiling steelmaking sludges and wastewater streams

InactiveUS20060130611A1Impact processDrying using combination processesBlast furnace componentsSteelmakingSludge

The present invention is directed to a process for treating an oily mixture consisting of hydrocarbons, solid particles, and water. The steps of the process include placing the oily mixture into a reactor chamber, purging the reactor chamber with an inert gas, and creating a steam bath within the inert gas filled reactor chamber, the steam surge freeing hydrocarbon matter from the solid particles. The process further includes elevating reactor chamber temperature to a boiling point temperature corresponding to the hydrocarbons in the oily mixture, the elevated temperature vaporizing the hydrocarbons are vaporized within inert atmosphere. The reaction chamber is vented and the off-gas is processed into a hydrocarbon product while the de-oiled solid particles are discharged from the reaction chamber as a raw material or for disposal.

Owner:RECOVERY TECH LP

Ionic Polymer Membranes

InactiveUS20080223785A1Stable materialLarge specific surface areaMembranesSemi-permeable membranesPermselective membraneStructural unit

Compositions and processes are disclosed for economical separation of fluid mixtures. Broadly, the present invention discloses ionic polymer compositions that are useful for perm-selective membrane separations. More particularly, ionic polymers of the invention comprise a plurality of repeating structural units having as a constituent part thereof organic ionic moieties consisting of nitrogen containing anions and / or cations. In the form of non-porous membranes, ionic polymers of the invention facilitate recovery of purified organic and inorganic products from fluid mixtures by means of perm-selective membrane separations. The present invention also provides methods for forming the ionic polymers, for example by treating selected nitrogen-containing organic polymers with acids, or treating a polymeric material comprising a plurality of carboxylate groups with an amine. Ionic polymer compositions of the invention are particularly useful for simultaneous recovery of a permeate product of an increased concentration, and a desired non-permeate stream, from a fluid mixture containing at least two compounds of different boiling point temperatures.

Owner:MILLER JEFFREY T +3

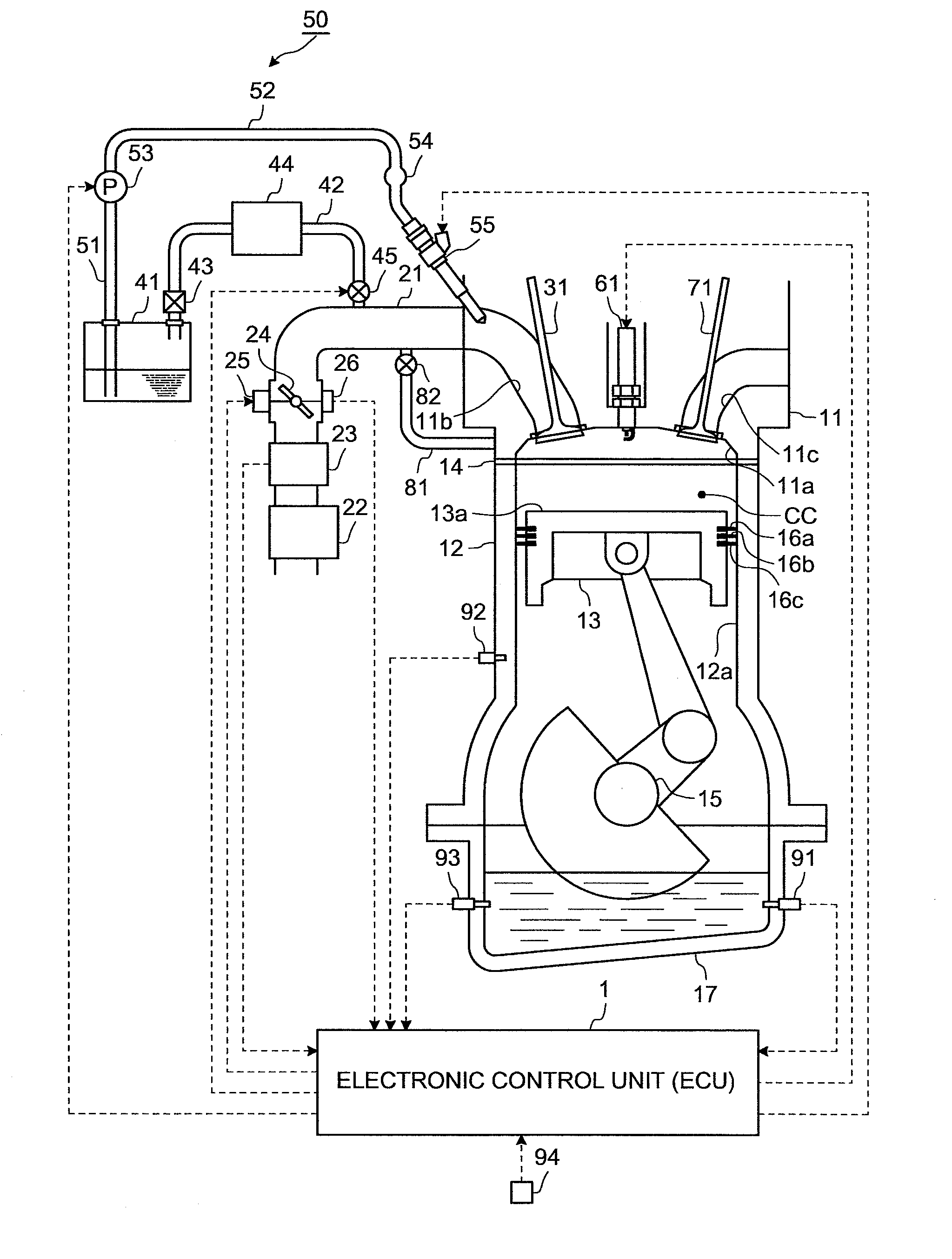

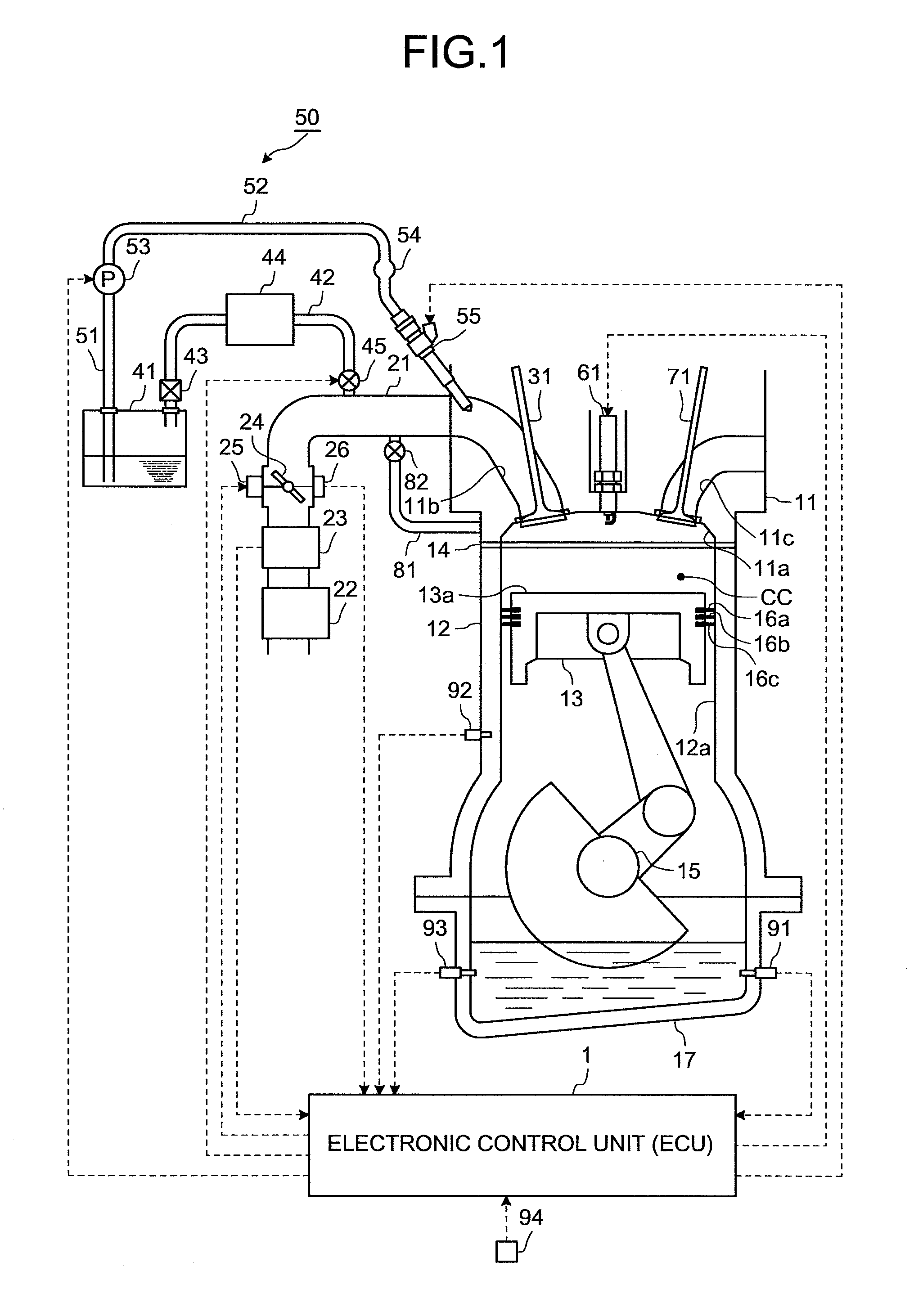

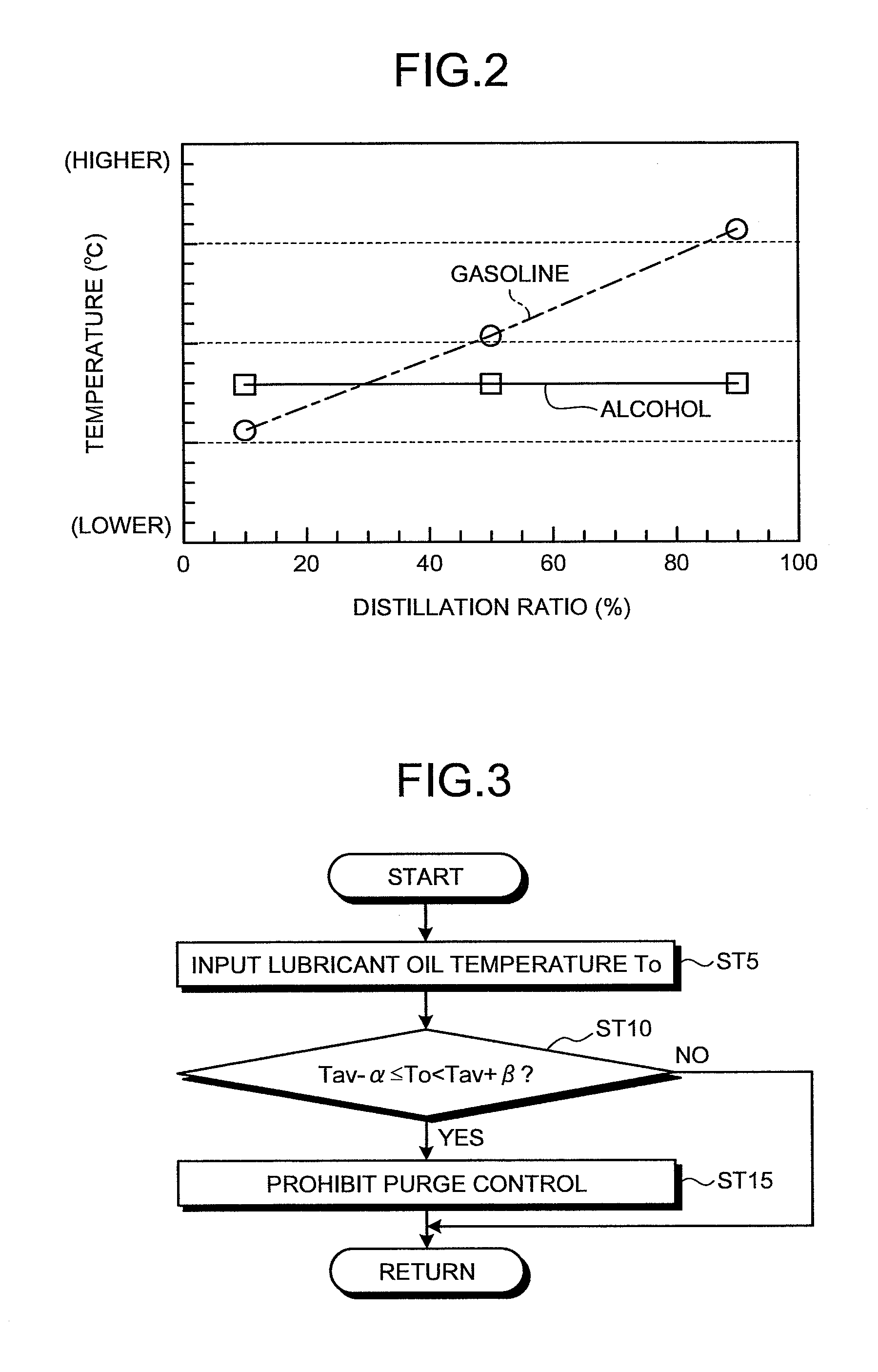

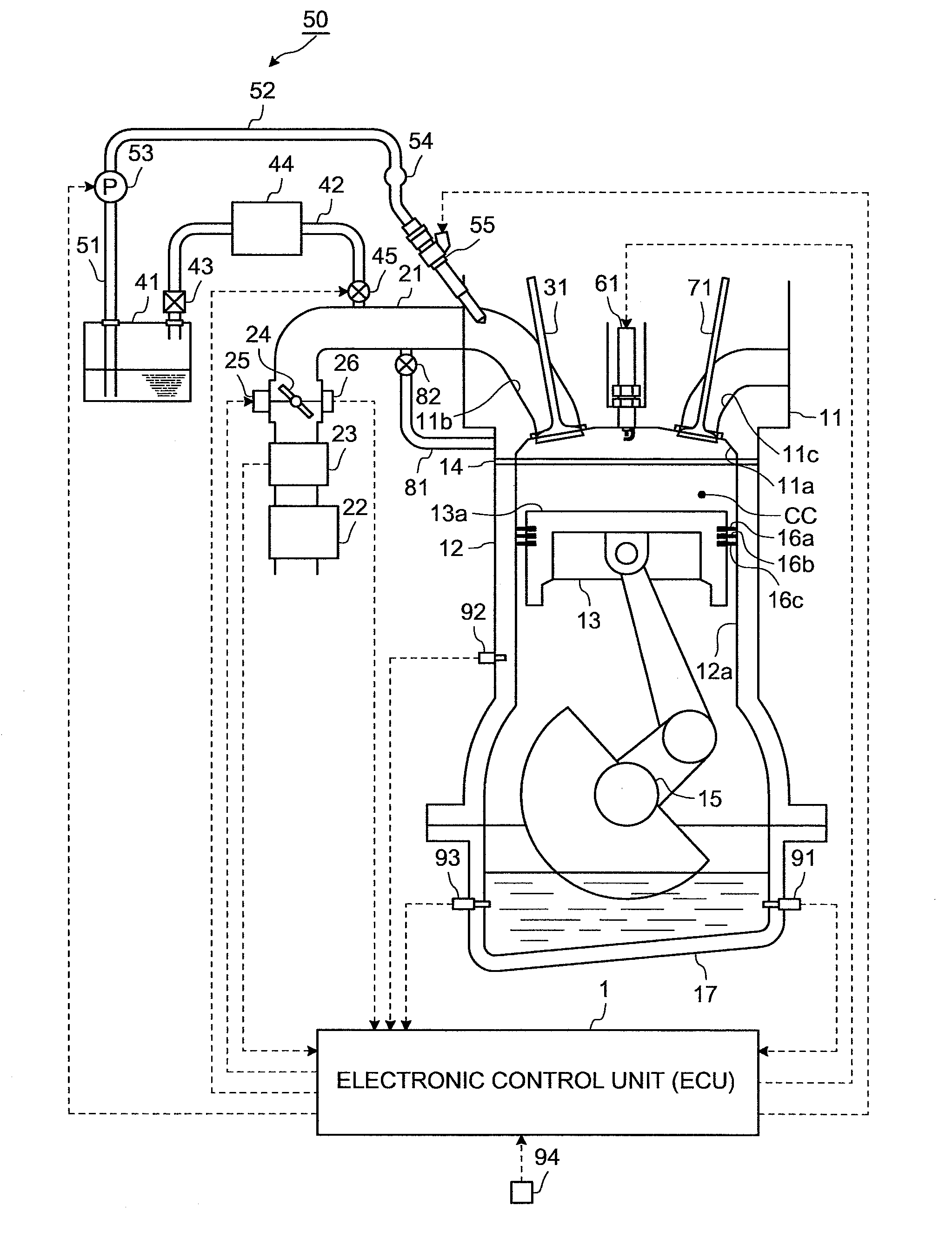

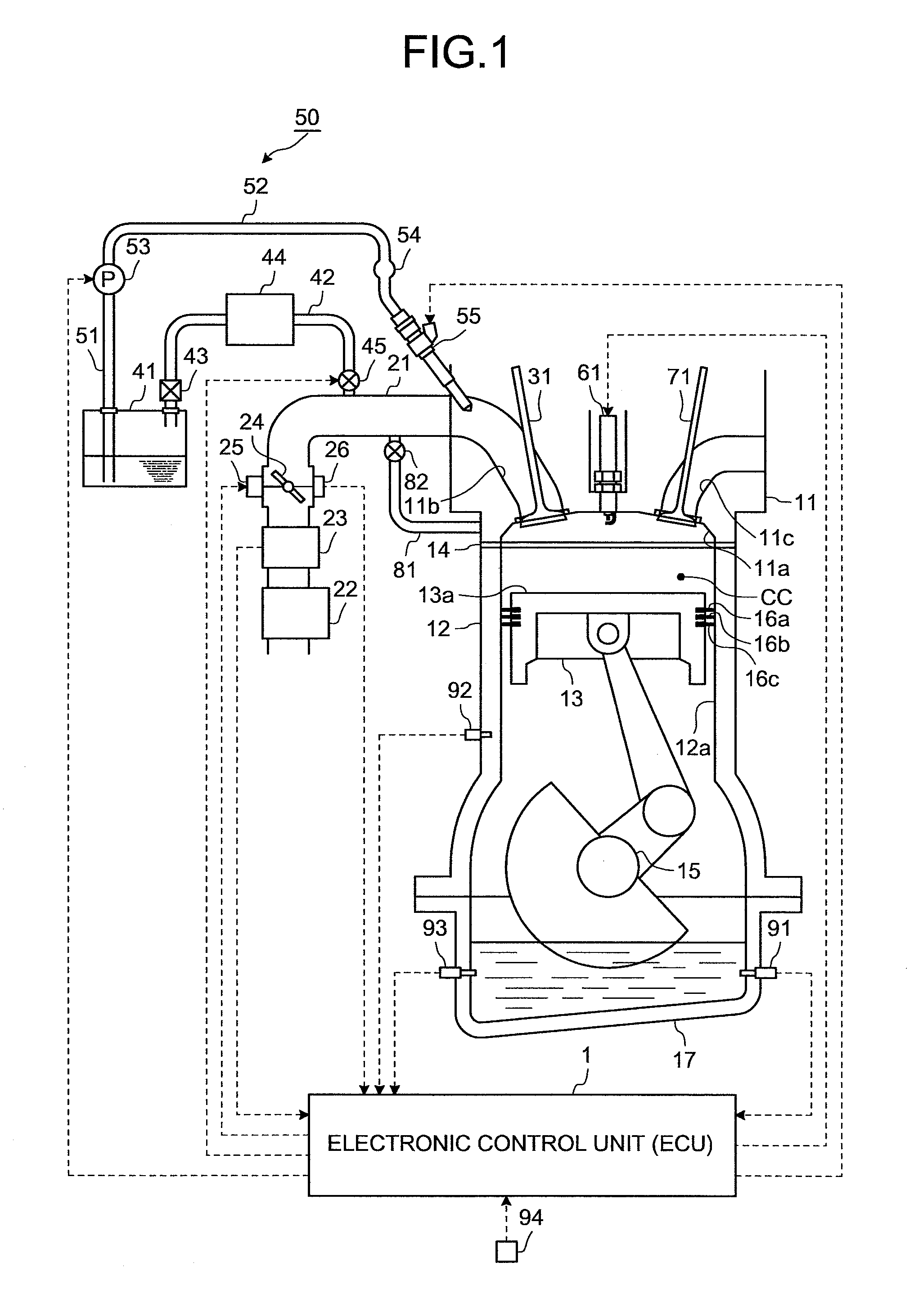

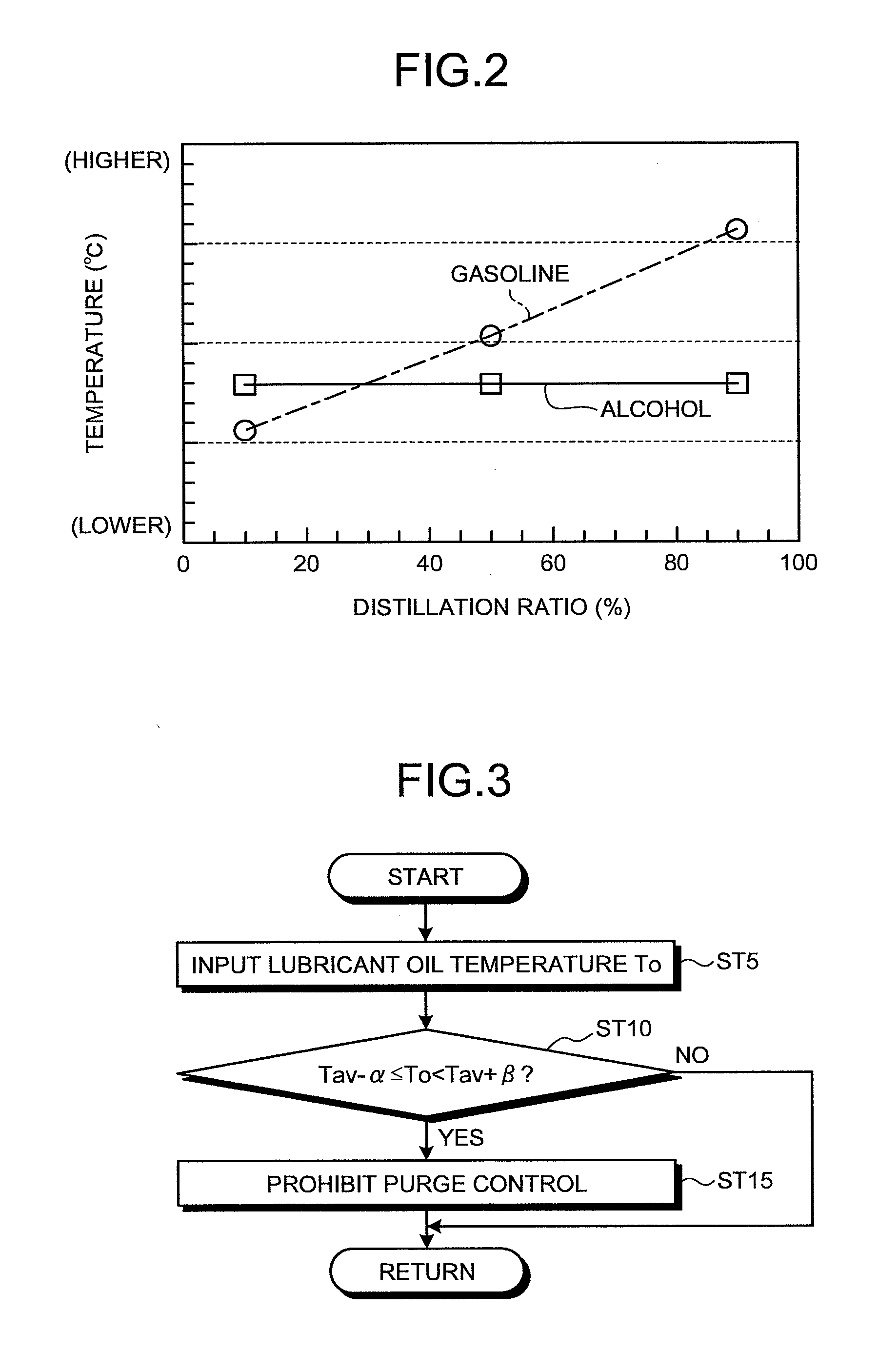

Multifuel internal combustion engine

ActiveUS8113186B2Inhibit deteriorationEasy to driveElectrical controlInternal combustion piston enginesMultifuelExternal combustion engine

Owner:TOYOTA JIDOSHA KK

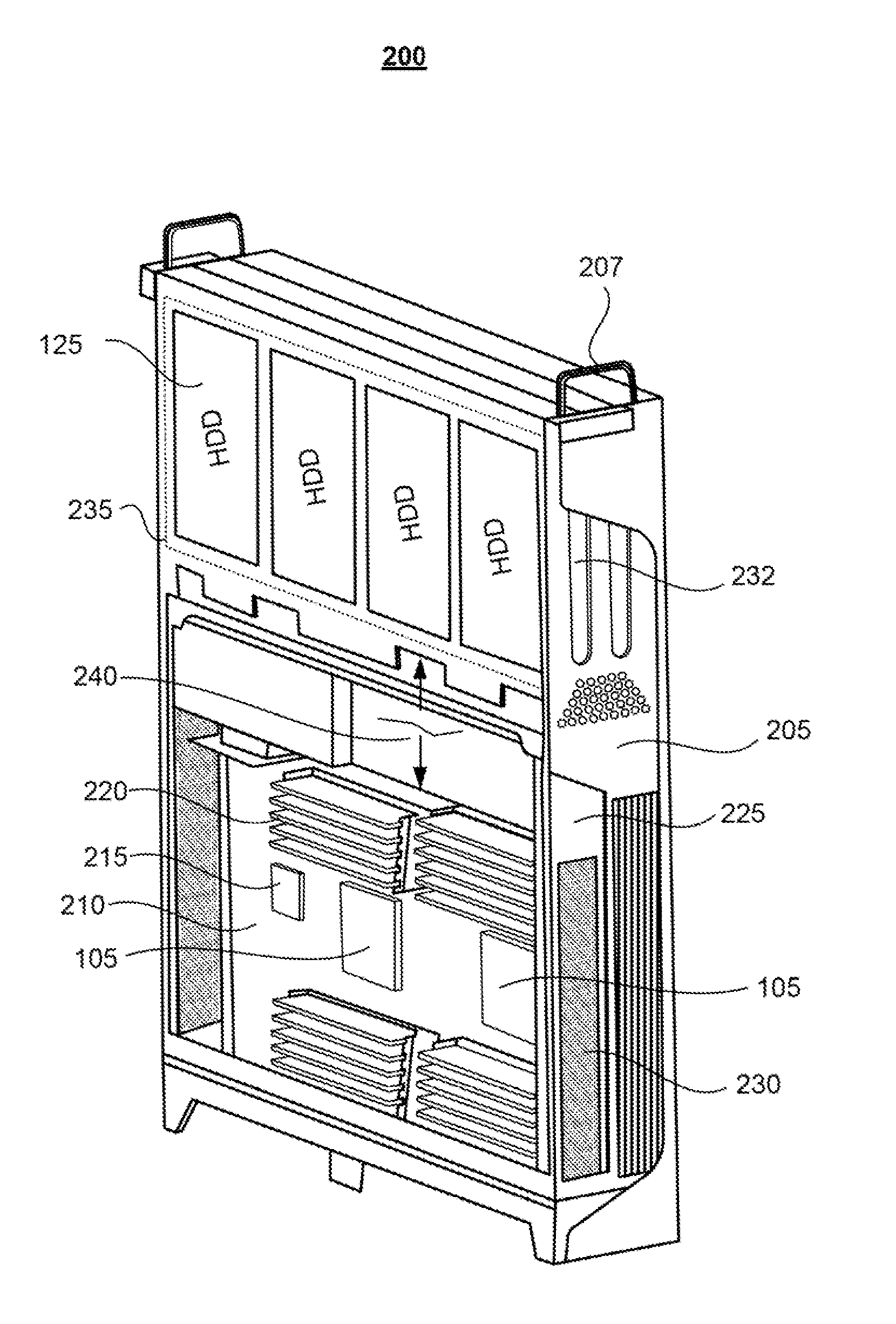

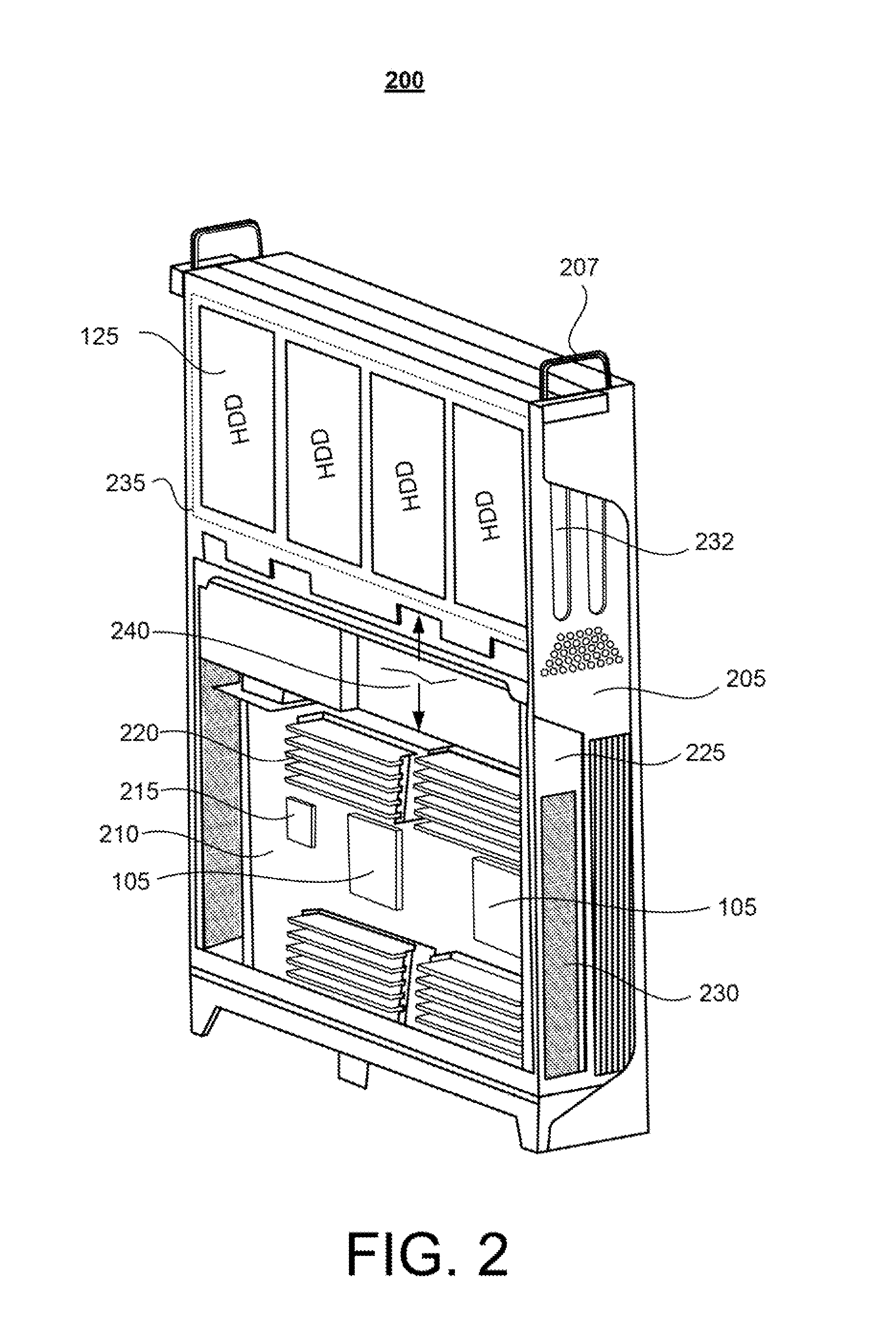

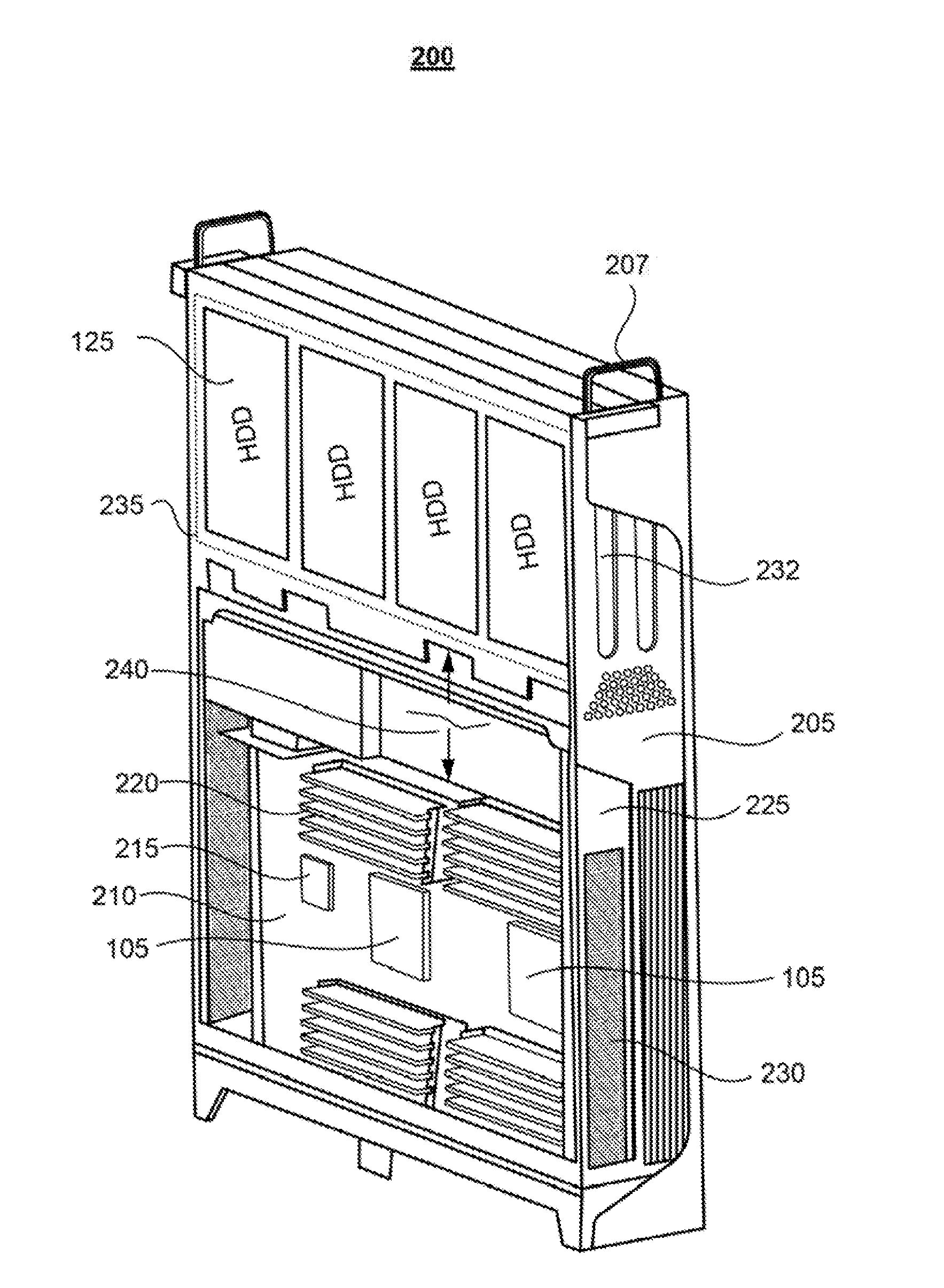

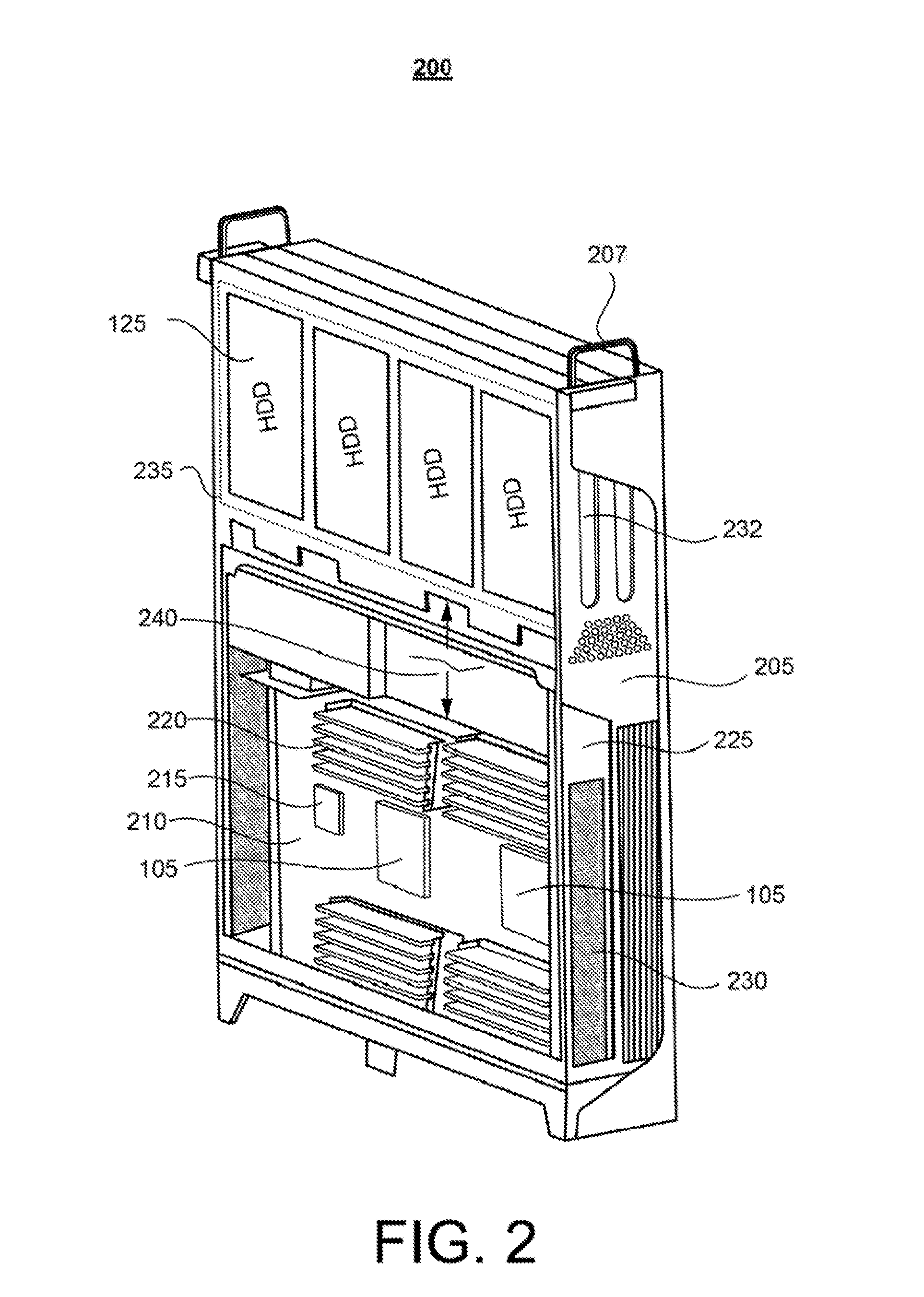

System for cooling hard disk drives using vapor momentum driven by boiling of dielectric liquid

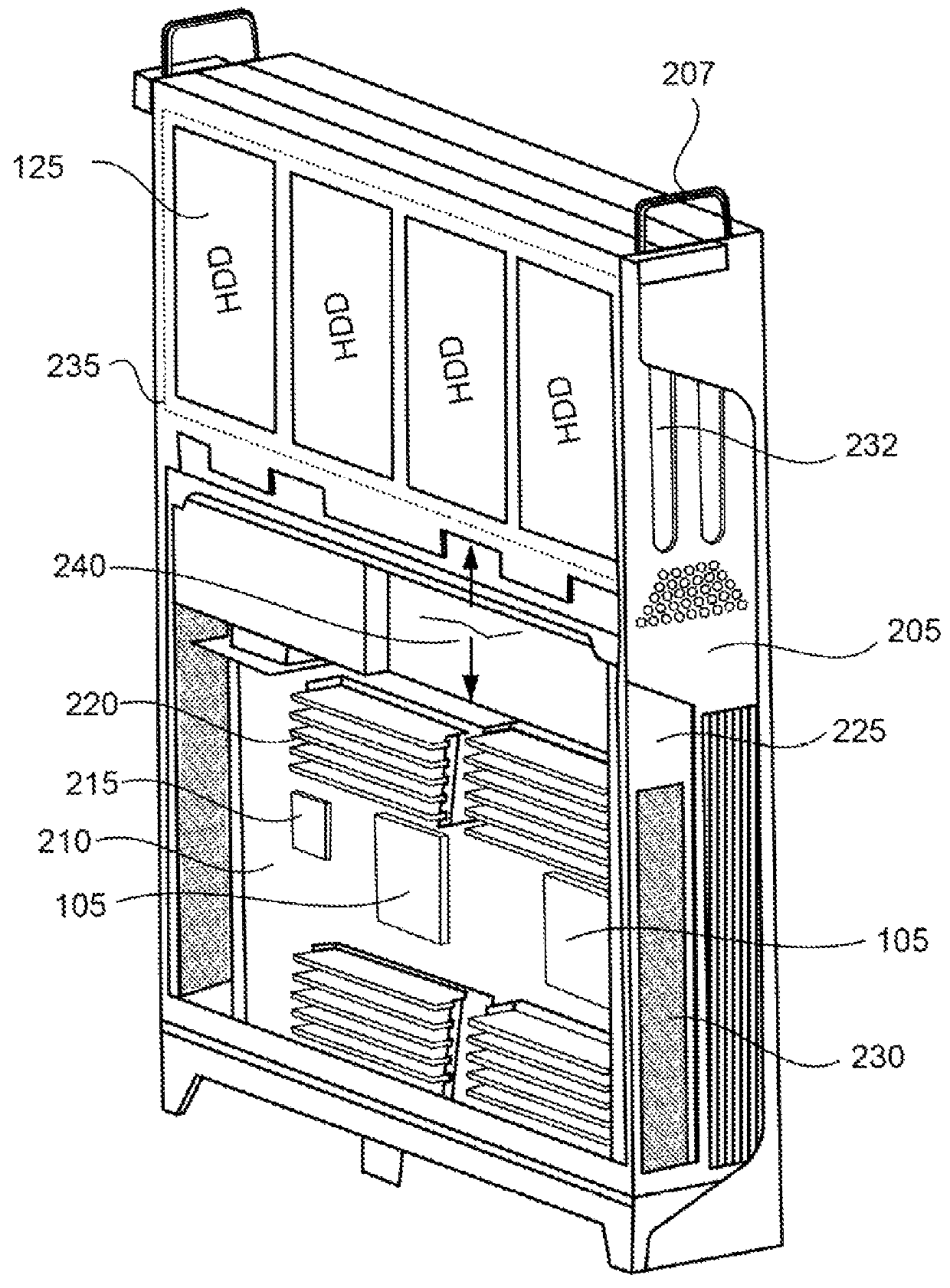

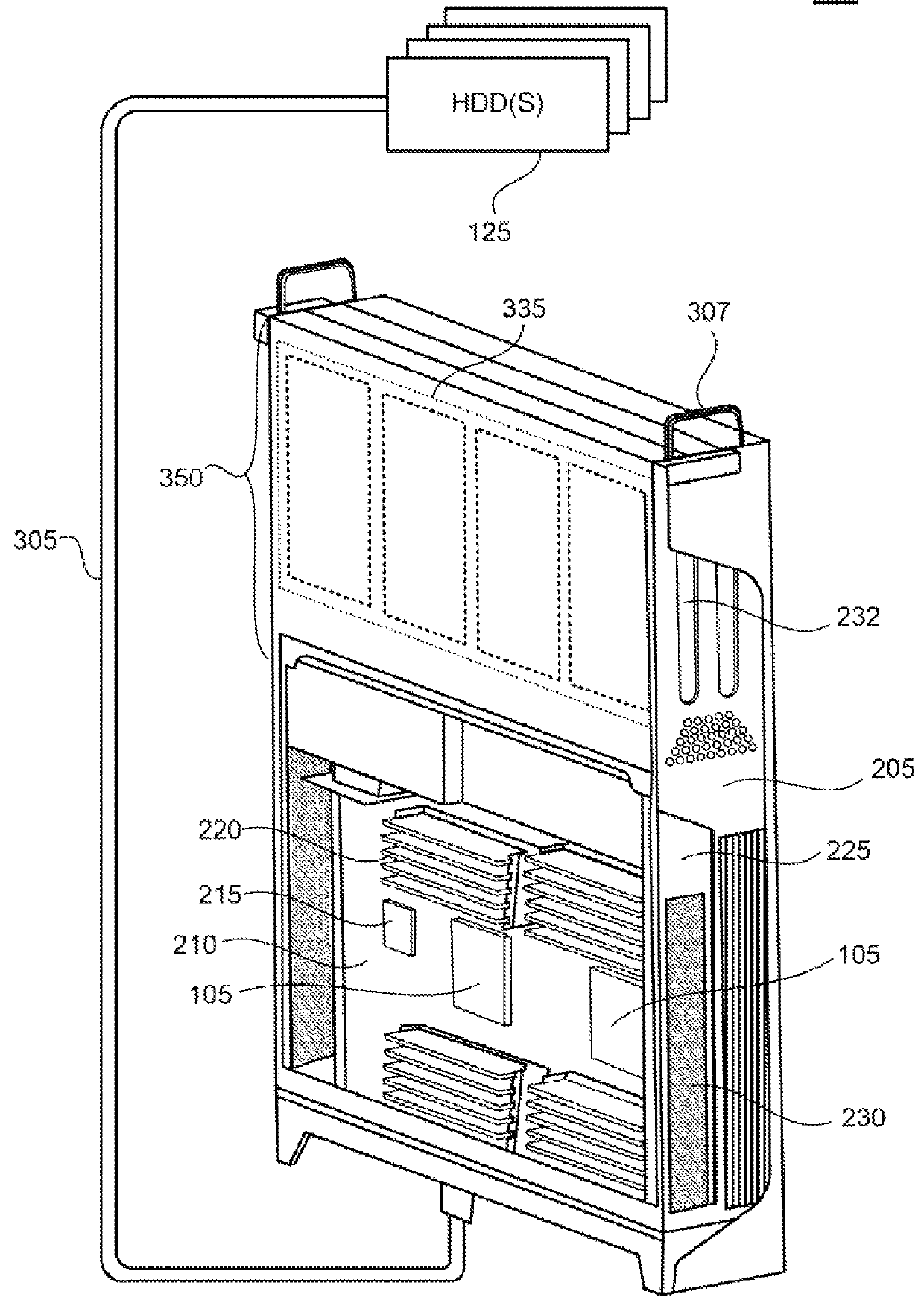

ActiveUS20160240226A1Increase in processing and storage densityHigh densityReducing temperature influence on carrierEnergy efficient ICTElectricityHard disc drive

A system for cooling hard disk drives (HDDs) includes: an enclosure having (i) a lower volume within which a cooling liquid is heated to a boiling point to cause some of the cooling liquid to evaporate, creating a plume of rising vapor and (ii) an upper volume having (a) a HDD cooling area with HDD(s) placed in the direct path of the rising vapor, which cools the HDD(s) during functional operation of the HDD(s) and (b) a condenser located above the HDD cooling area and which cools a substantial portion of the rising vapor that impacts the condenser within the upper volume such that the rising vapor condenses back into liquid phase on contact with the condenser; and a heat source that dissipates heat into the lower volume of the enclosure, sufficient to heat the cooling liquid to the boiling point temperature.

Owner:DELL PROD LP

Vacuum treatment of waste stream with anti-incrustation measures

InactiveUS7140122B1Promote explosionEasy to shredDrying solid materials with heatEvaporation with vapour compressionWaste streamVacuum level

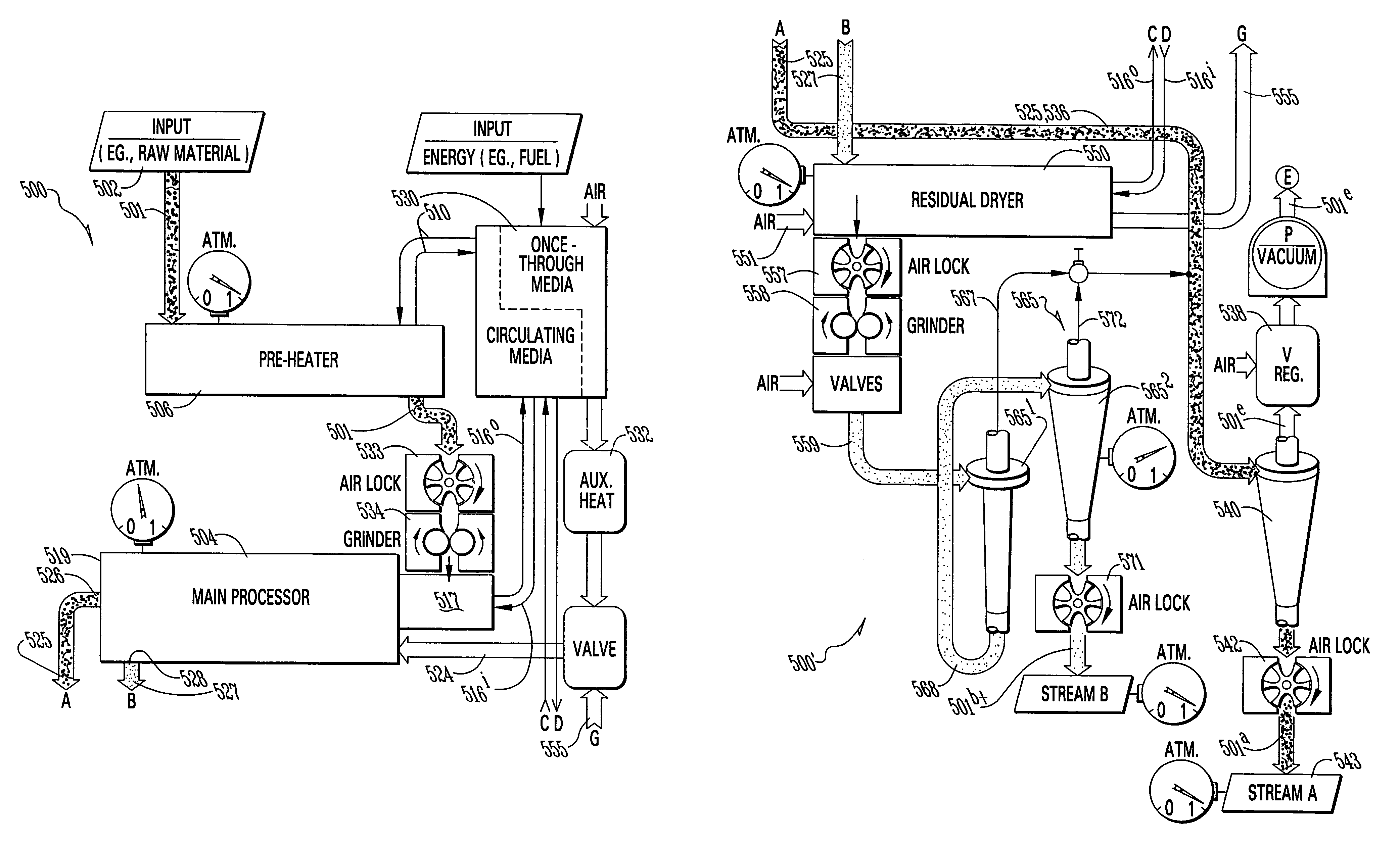

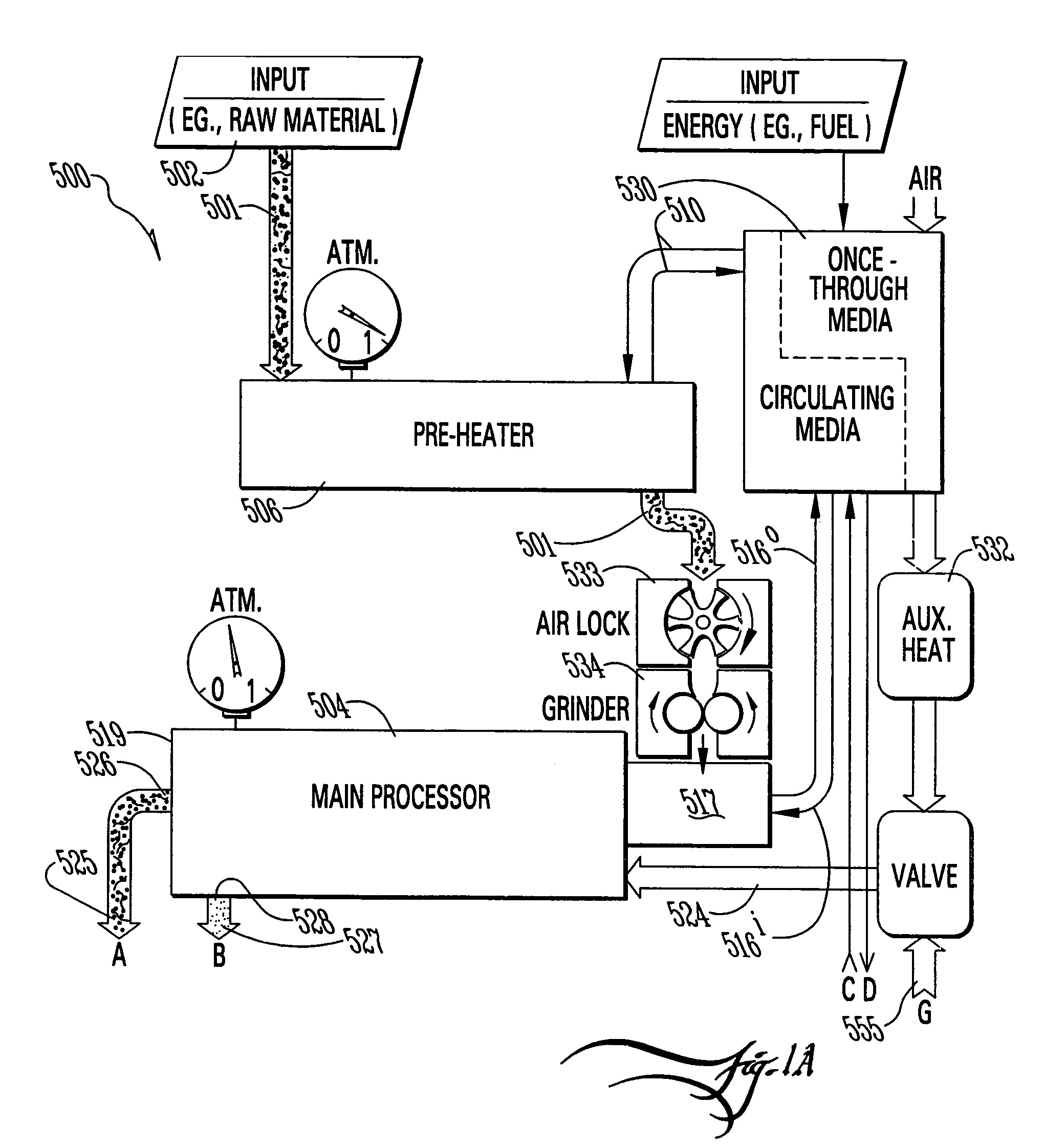

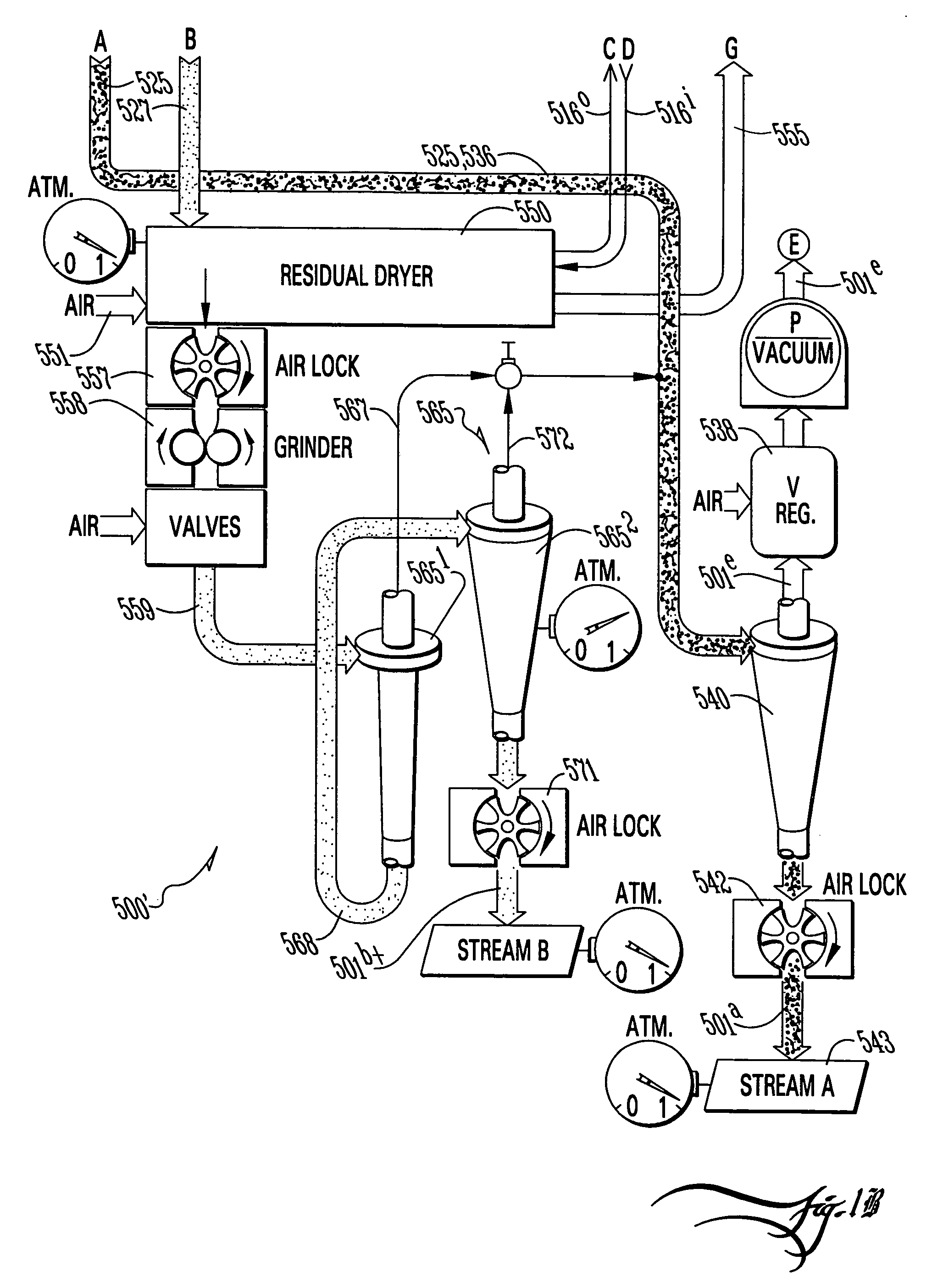

A method of treating a waste stream comprises a vacuum treatment to promote disintegration of the waste material by “flash vapor” production, causing a swiftly vaporizing fraction inside the material to literally explode or shred apart the matrix of the material as a whole. A main processor operates at a level of vacuum that determines a given boiling temperature for a vaporizing fraction, and one which lower than the fraction's boiling temperature for the local vicinity's barometric pressure (eg., atmospheric pressure). The input stream is pre-heated to above the given boiling temperature for that fraction as determined by the main processor's vacuum level without, however, going over the boiling temperature for the local barometric pressure. It is then introduced into the vacuum of the main processor whereby a minor percentage of the vaporizing fraction flashes into vapor, and this presumptively promotes destruction and / or disintegration of the material.

Owner:NEW LIFE RESOURCES

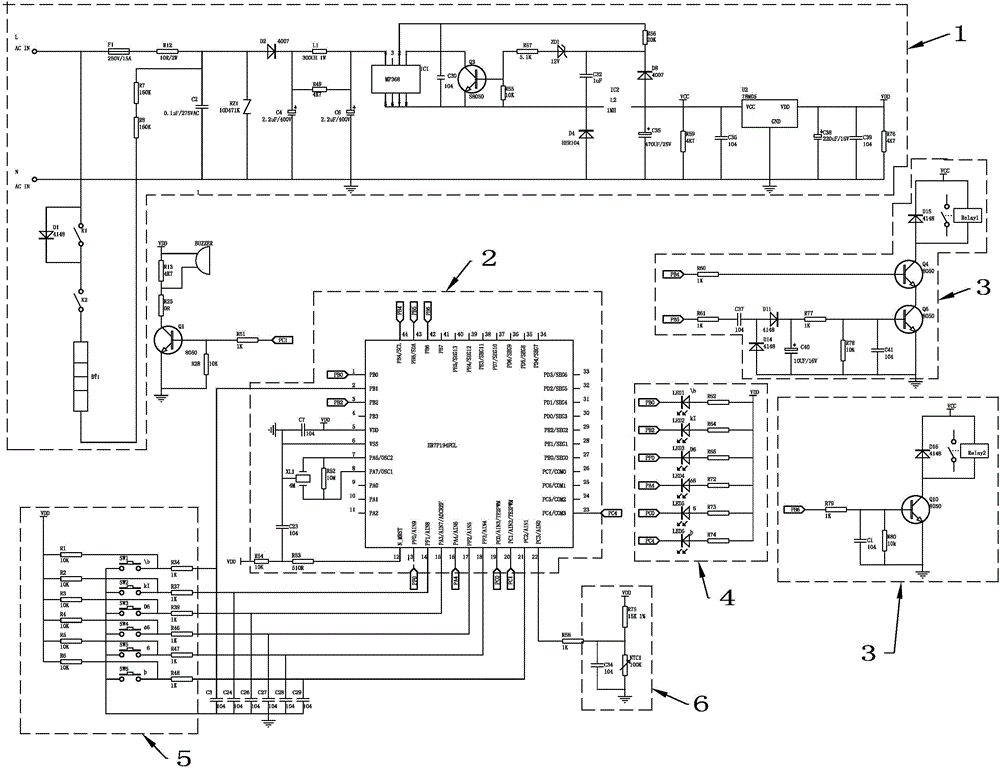

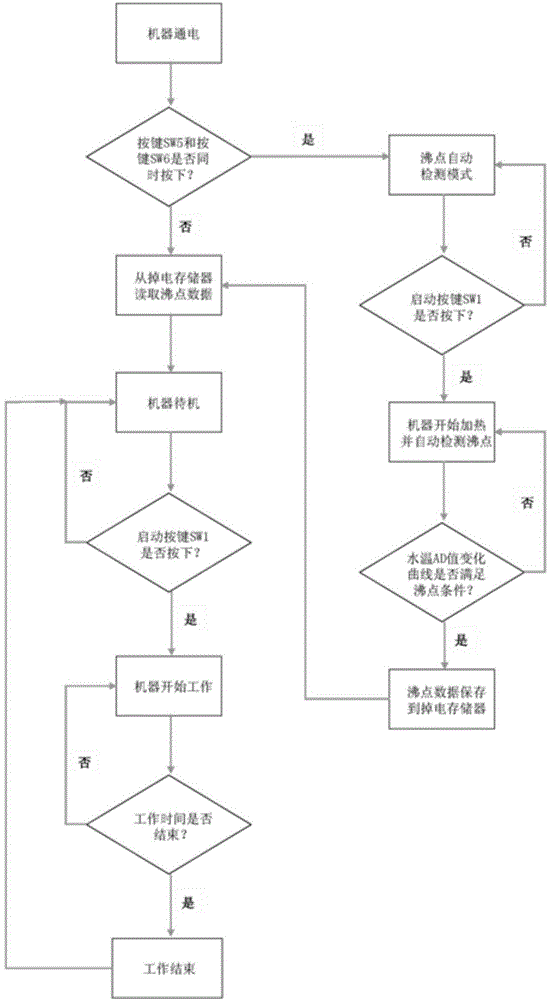

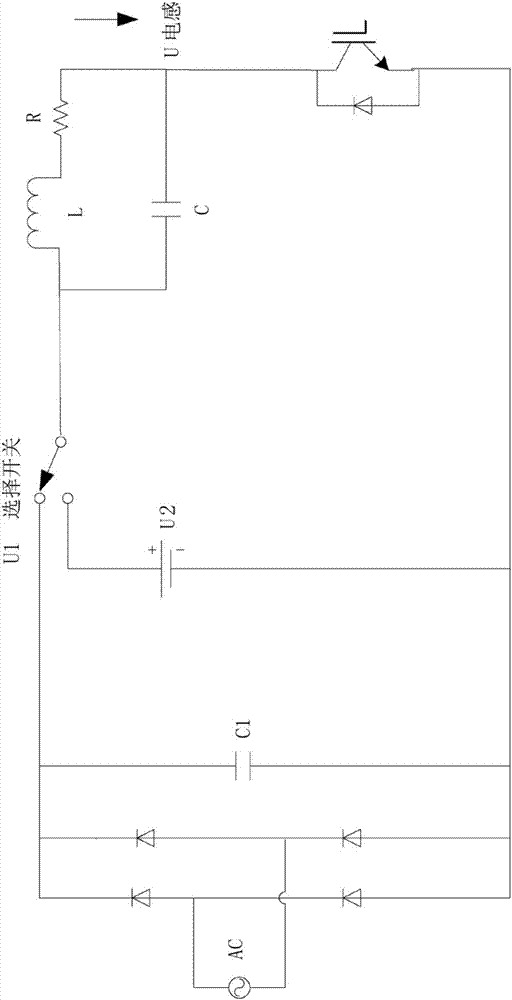

Intelligent circuit of kitchen appliance and method for identifying boiling temperature therefrom

InactiveCN104597944APrevent overflowAvoid placing food cooked in kitchen appliances from spillingTemperatue controlElectricityNegative temperature

The invention discloses an intelligent circuit for automatically identifying the boiling temperature of water at the altitude where a kitchen appliance locates and a method for identifying the boiling temperature. The intelligent circuit includes a power source module, a single chip control module, a heating relay drive module, and an LED (light-emitting diode) lamp drive module, wherein it further includes a key module, a NTC (negative temperature coefficient) temperature detecting module and a power failure memory. The kitchen appliance adopting the intelligent circuit is able to exactly detect the boiling temperature of water at the zone where the kitchen appliance locates and automatically store the boiling temperature in an electrical storage regardless of any altitude; thus when the kitchen appliance with the intelligent circuit is used every time in future, the circuit can immediately close a heating device of the kitchen appliance when the temperature of the food cooked in the kitchen appliance reaches the boiling temperature. Therefore, the intelligent circuit can prevent food cooked in the kitchen appliance from overflowing for excessive heating.

Owner:SHENZHEN BUYDEEM TECH CO

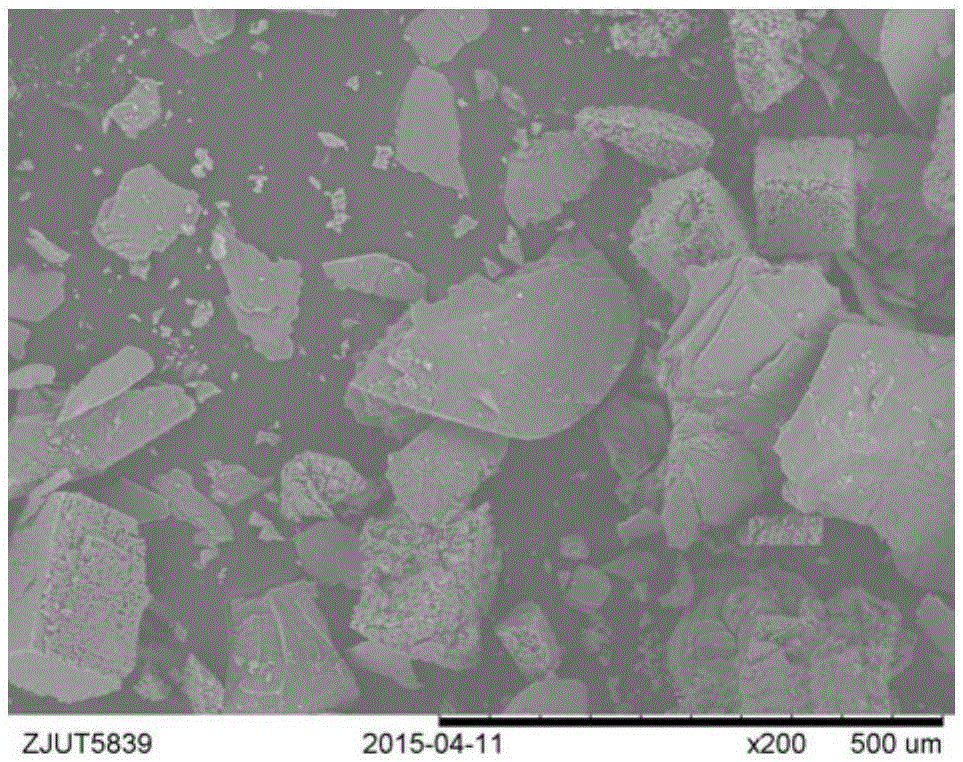

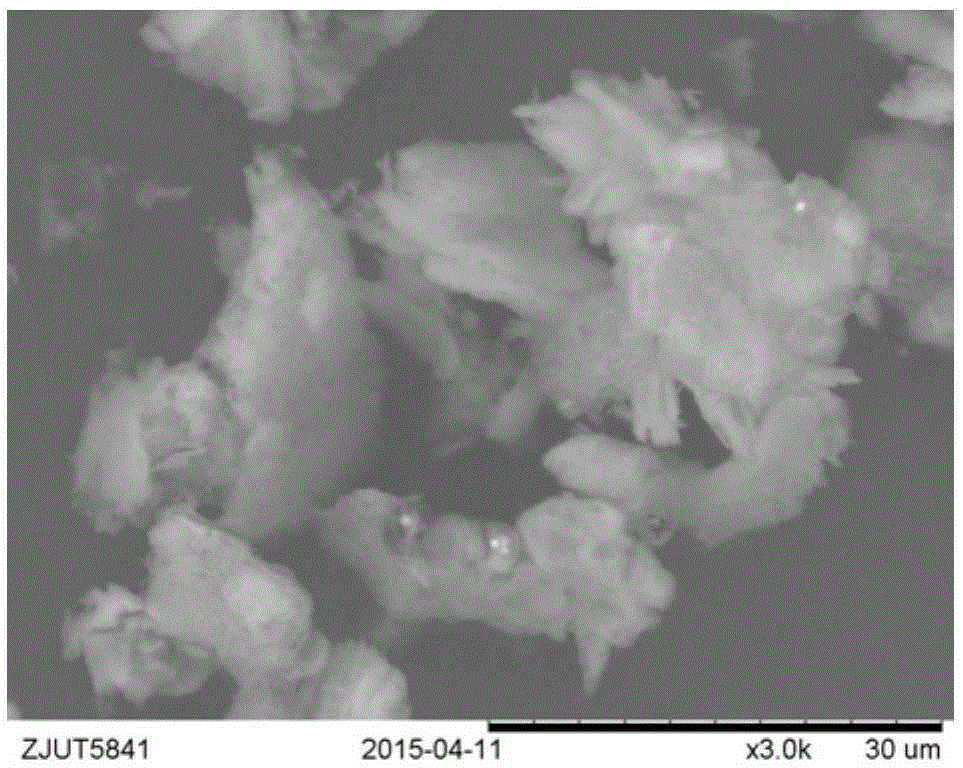

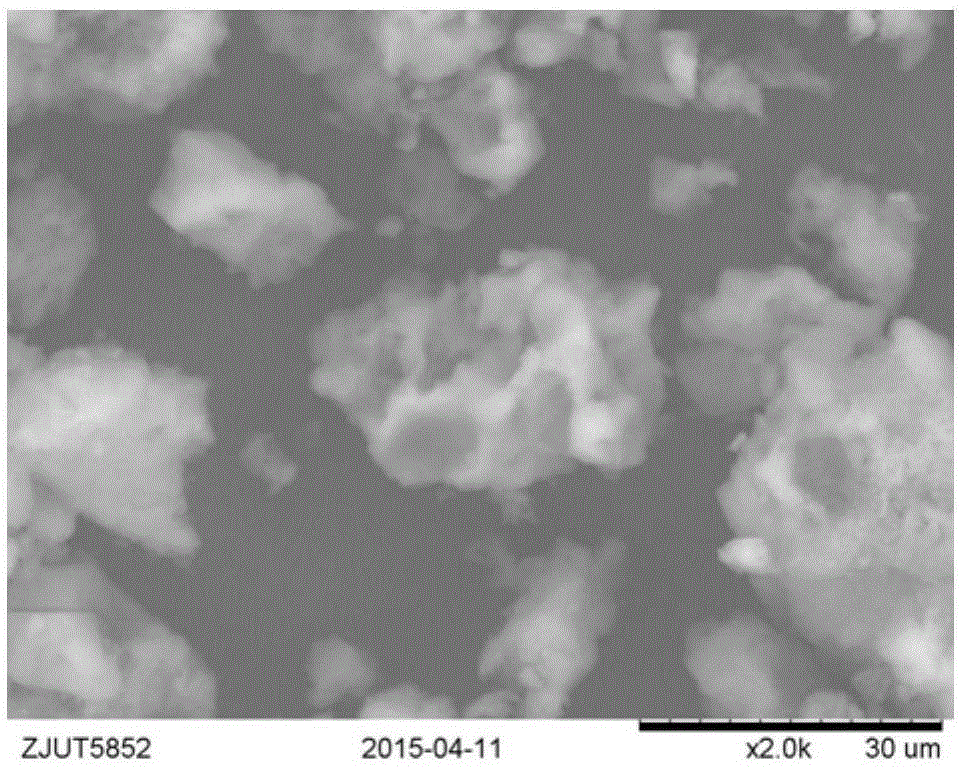

Method of preparing metal organic framework materials through conversion method

ActiveCN105294738AWide range of usesEasy to operateGroup 4/14 element organic compoundsCopper organic compoundsOrganic solventReaction temperature

The invention provides a method of preparing metal organic framework materials through a conversion method. According to the method, firstly, metal salt is dissolved in organic solvent to obtain metal salt solution with the concentration between 0.0025 g / mL and 0.2 g / mL; secondly, the metal organic framework material A is placed in the metal salt solution at the reaction temperature between 20 DEG C and the boiling point temperature of the organic solvent in the metal salt solution for the reaction time of 2-48h, and aftertreatment is conducted after reaction is over to obtain the metal organic framework material B. Mild conditions are adopted for converted synthesis of a metal organic framework which generally requires strict synthesis conditions; traditional high-temperature hydrothermal synthesis conditions are abandoned, operation is simple, and amplification is easy; the synthesized metal organic framework materials are wide in usage, capable of being used for adsorption and catalytic degradation and excellent in performance.

Owner:ZHEJIANG UNIV OF TECH

System for cooling hard disk drives using vapor momentum driven by boiling of dielectric liquid

ActiveUS9335802B2Increase in processing and storage densityHigh densityReducing temperature influence on carrierDigital data processing detailsElectricityHard disc drive

A system for cooling hard disk drives (HDDs) includes: an enclosure having a lower volume within which a cooling liquid is heated to a boiling point temperature to cause some of the cooling liquid to evaporate into a plume of rising vapor; a HDD cooling area with at least one HDD placed in the direct path of the rising vapor, which cools the at least one HDD during functional operation of the at least one HDD; and a heat source that dissipates heat into the lower volume of the enclosure, sufficient to heat the cooling liquid to the boiling point temperature. The system can also include a condenser located above both the HDD cooling area. A substantial portion of the rising vapor that passes through the HDD cooling area and cools the at least one HDD is condensed back into liquid phase on contact with the condenser.

Owner:DELL PROD LP

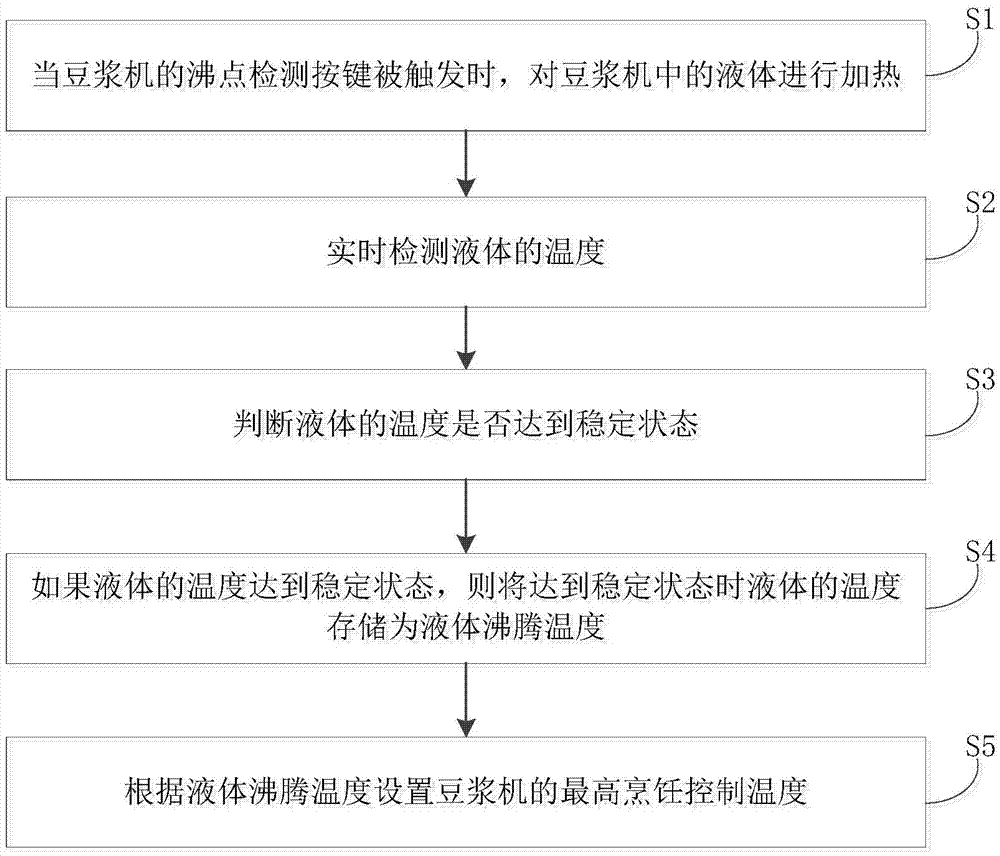

Method and device for heating control of soybean milk machine and soybean milk machine

InactiveCN107019426APrevent overflowImprove experienceBeverage vesselsDough shaping and cutting apparatusStable stateHeat control

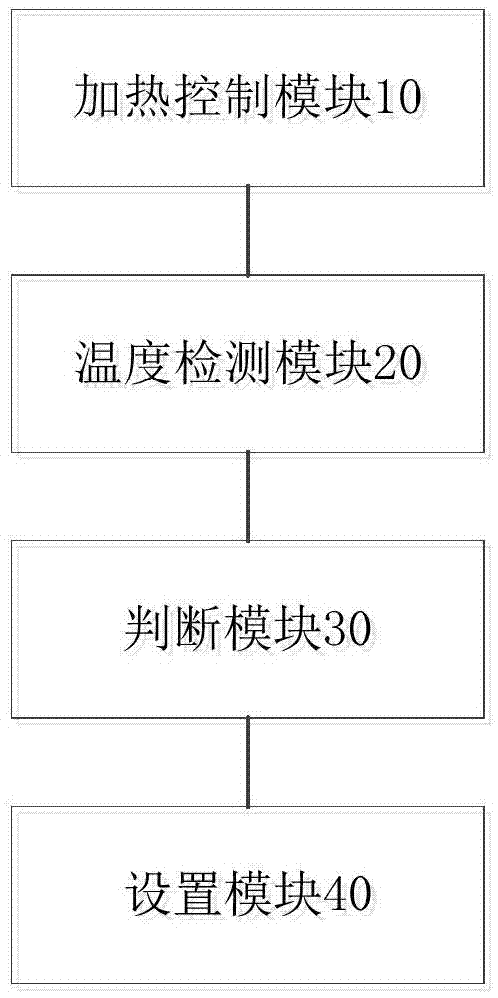

The invention discloses a method and device for heating control of a soybean milk machine and a soybean milk machine. The method comprises the steps of heating liquid in the soybean milk machine when a boiling point detection key of the soybean milk machine is triggered; detecting the temperature of the liquid in real time; judging whether the temperature of the liquid reaches a stable state; storing the temperature, reaching a stable state, of the liquid as a liquid boiling temperature if the temperature of the liquid reaches a stable state; and setting the highest cooking control temperature of the soybean milk machine according to the liquid boiling temperature. By the adoption of the method for heating control, when the soybean milk machine is used in a certain area, the boiling point temperature of the area can be obtained, the highest cooking control temperature of the soybean milk machine can be set according to the obtained boiling point temperature, so that the temperature of soybean milk during pulping can be controlled according to the highest cooking control temperature, in this way, overflow of soybean milk is prevented, and therefore user experience is improved greatly.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Flux suitable for multiple tin-based welding pastes and preparation method thereof

ActiveCN102371443AIncreased range of activityImprove wettabilityWelding/cutting media/materialsSoldering mediaLower limitActive agent

The invention discloses a flux suitable for multiple tin-based welding pastes and a preparation method thereof, relates to a formula of a flux for tin welding pastes and a preparation process, relates to a welding aid material of a surface mount technology (SMT), and belongs to the technical field of welding materials. The flux comprises the following components in percentage by weight: 30.0 to 40.0 percent of solvent, 1.0 to 4.5 percent of active agent, 1.0 to 3.0 percent of wetting agent, 2.0 to 5.0 percent of emulsifying agent, 3.0 to 10.0 percent of thixotropic agent and the balance of film forming agent, wherein the film forming agent is a mixture of two film forming agents, the softening point temperatures of which are respectively in an upper limit range and a lower limit range; and the solvent is a mixture of two solvents, the boiling point temperatures of which are respectively at 150 to 215 DEG C and 220 to 280 DEG C. The prepared flux has strong activity and good welding property and storage stability at different welding temperatures, and can be used for preparing conventional lead-containing or lead-free soldering paste products of Sn63Pb37, SnAg3.0Cu.5, SnAg0.3Cu0.7 and the like.

Owner:云南锡业锡材有限公司

Method and device for rude oil on-line phase-changing water-containing detection

InactiveCN102778410AGuaranteed online detectionNo wasteWeighing by removing componentElectricityHydrogen sulfide poisoning

Provided are a method and a device for crude oil on-line phase-changing water-containing detection. The method is characterized by comprising the following steps: firstly weighing and measuring crude oil detection samples; heating the samples to the boiling temperature of water through an electric heater and obtaining the mass of volatilized gasoline component; heating through the electric heater to keep the boiling temperature of the water constant, wherein the water begins to evaporate at the boiling temperature, the water in the crude oil is totally evaporated when the weighing sensor measures that the mass data are constant, and at this time the mass sum of the mass data measured by the weighing sensor and the mass of the gasoline component violating from the tested samples is the mass of the crude oil; and calculating the moisture content of the crude oil through the total mass of the tested samples and the mass of the crude oil. The method for crude oil on-line phase-changing water-containing detection thoroughly replaces a manual sampling distillation analyzing method, is high in measuring accuracy, saves time and energy, and can achieve real-time detection, the samples for crude oil detection cannot be wasted or discharged outside, the phenomenon of thickened oil hydrogen sulfide poisoning is avoided, and the effect of environment protection is achieved.

Owner:张伟 +2

Method for measuring and evaluating temperature of pot body of induction cooker pot

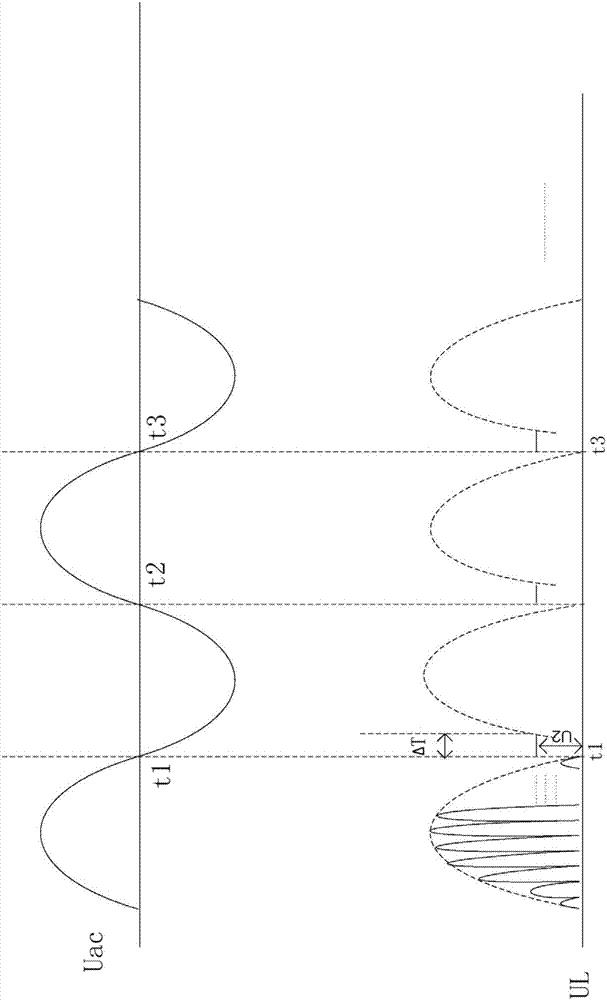

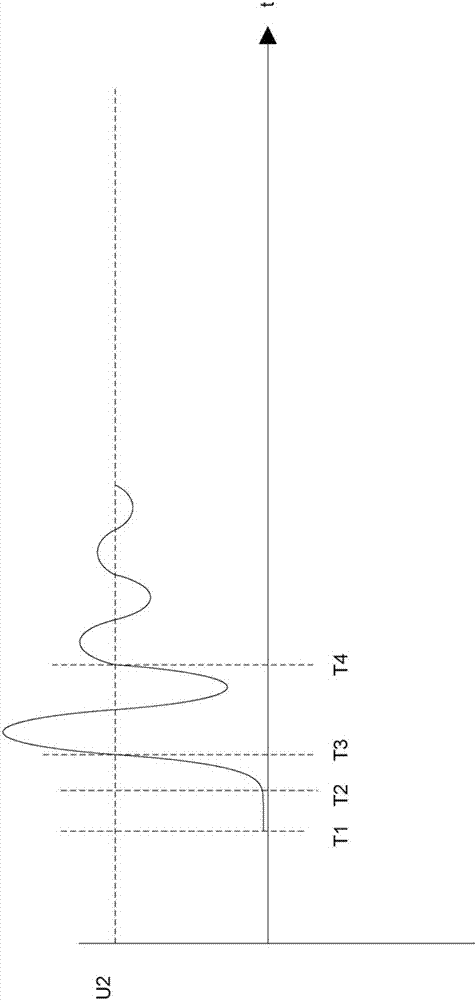

InactiveCN107990995AAddressing measurement gapsJudgment Boiling JudgmentThermometers using electric/magnetic elementsUsing electrical meansBoiling Point TemperaturesMaterials science

The invention relates to a method for measuring and evaluating a temperature of a pot body of an induction cooker pot. The method comprises the following steps: step 1, if a specific stainless steel or stainless steel sandwich induction cooker pot is used on an induction cooker, there is a corresponding relationship between a resonant cycle value in a circuit and the temperature of the pot body; step 2, resonant period T is obtained in normal operation by means of the above method, the temperature t corresponding to the nearest cycle of the T is found in a temperature record table, and the temperature t is defined as the temperature of the pot body; step 3, a cycle curve is used for evaluating the relative temperature, and automatic stopping and heat preservation control after water is boiled are set. The method has the advantages of accurately measuring and evaluating the boiling point temperature of the pot body of the induction cooker pot and performing detection on warm temperature, and deficiencies in the existing measurement are effectively solved.

Owner:王宝彬

Method for heating phase-change material heat storage unit adopting PTC thermistor

InactiveCN101191707AEnsure safetySolve temperature problemsHeat exchange apparatusDisplay deviceThermistor

The present invention develops a method of heating phase-change material heat reservoir by a PTC thermistance and uses PTC thermistance (positive temperature coefficient thermistance) with the property of temperature sensibility; when the PTC thermistance excess a certain temperature, the resistance value of the PTC thermistance increases by step phase to resist current to pass through, thereby achieving the aim of stopping the phase-change material heat reservoir. The phase-change material heat reservoir is positioned on the upper part of the PTC thermistance heater; the power supply of the PTC thermistance is switch on to heat the phase-change material heat reservoir; the power supply of the PTC thermistance is cut off till the external temperature display of the phase-change material heat reservoir reaches the predetermined temperature. The phase-change material heat reservoir is moved to the lower part of the object which need to heat; the phase-change material in a container is changed to a solid state from a liquid state after heat release to achieve the aim of heating objects. The invention solves the problem that the heating temperature of the phase-change material heat reservoir keeps between the melting point temperature and the boiling point temperature of the phase-change material, thereby ensuring the safety of use and enlarging the using range of the phase-change material heat reservoir.

Owner:陈锦标

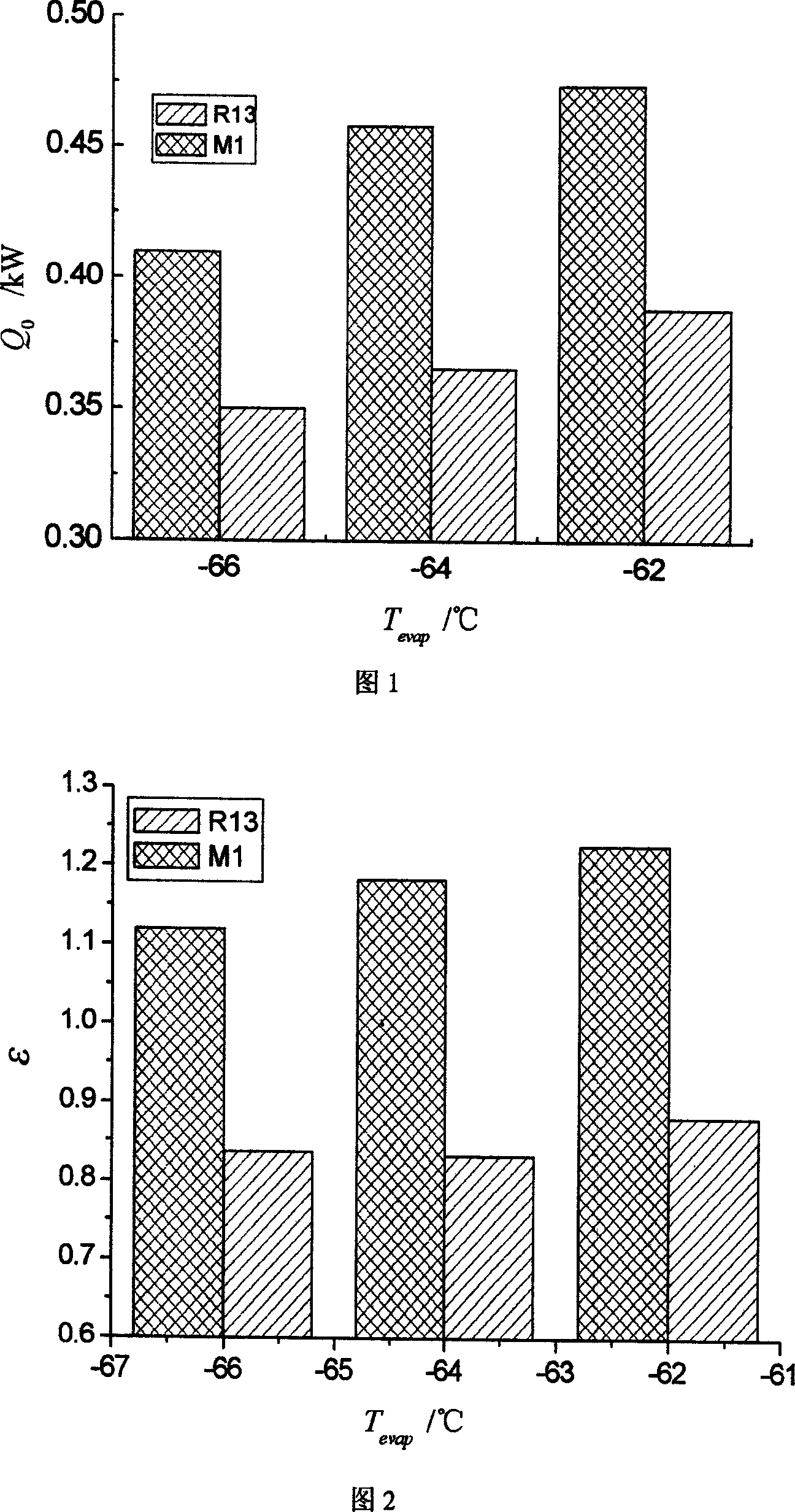

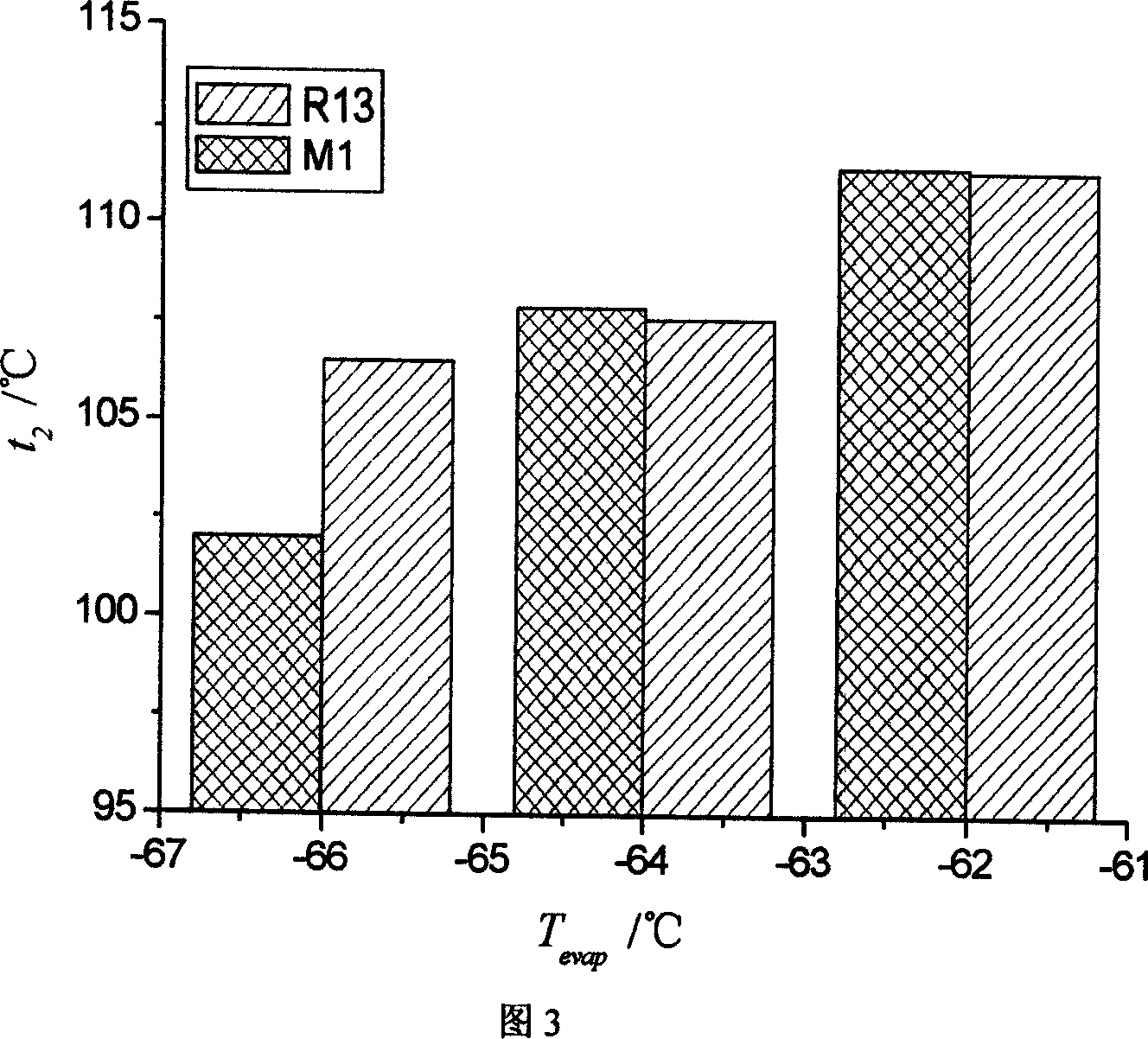

Refrigerant for refrigerating system low-temperature loop

InactiveCN101012367ALower freezing point temperatureLower saturation pressureHeat-exchange elementsFreezing Point TemperatureRefrigerant

The invention discloses a freezing agent of low-temperature circuit, which is characterized by the following: allocating raw material with 60-75% carbon dioxide and 25-40% propane; reducing coagulating point temperature and low-temperature saturated pressure of CO2 as well as combustibility and boiling-point temperature of propane (R290).

Owner:TIANJIN UNIV

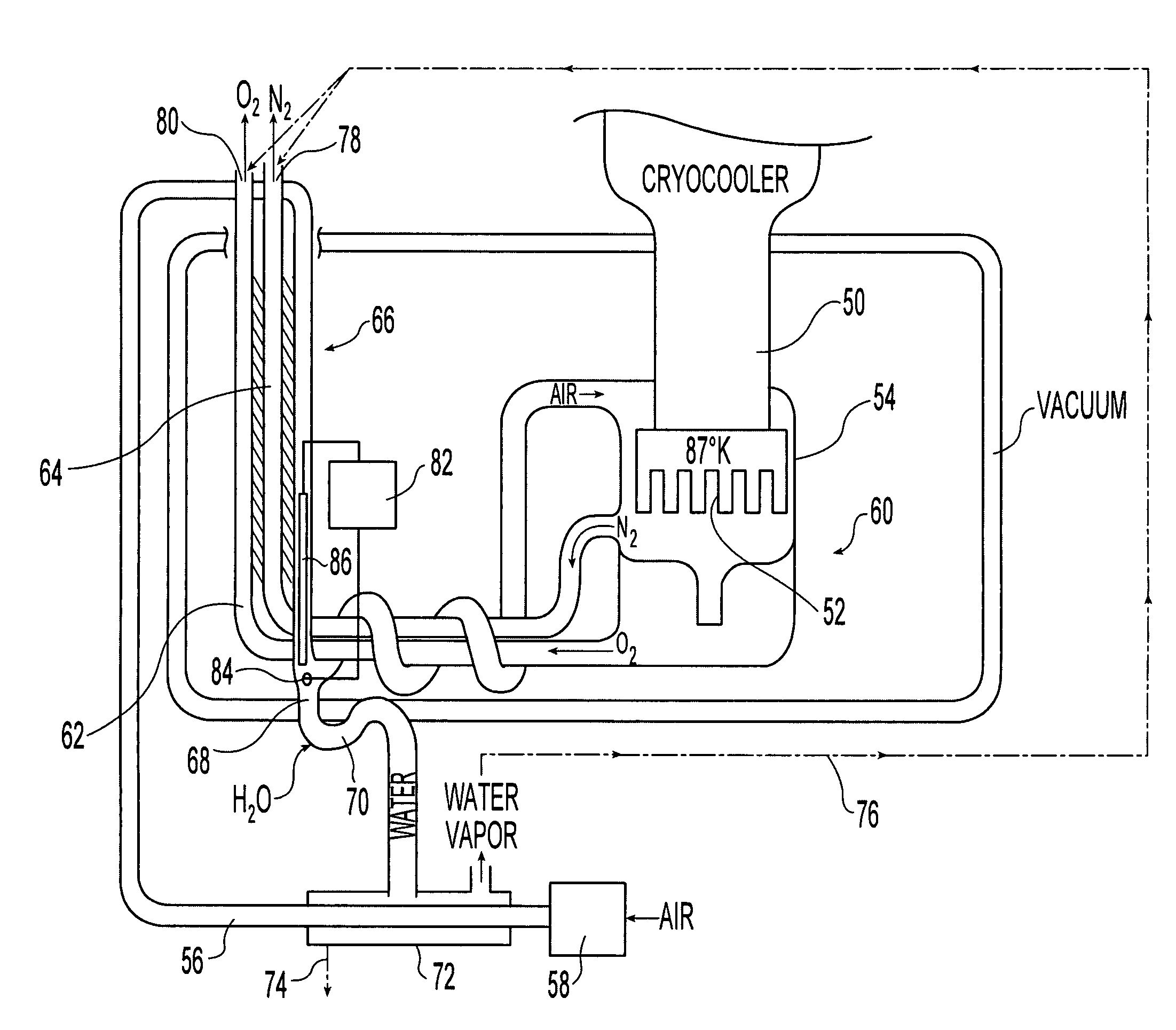

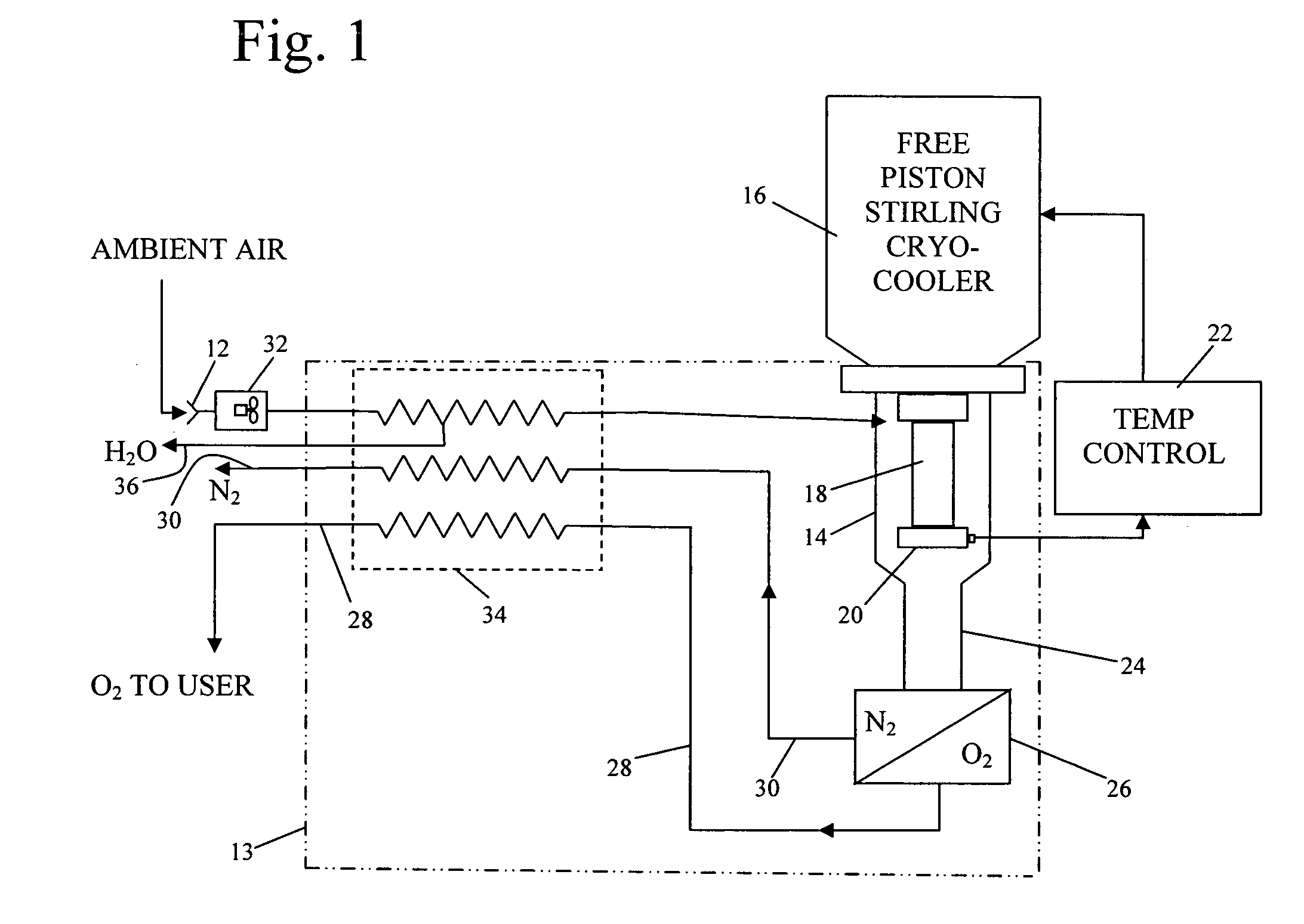

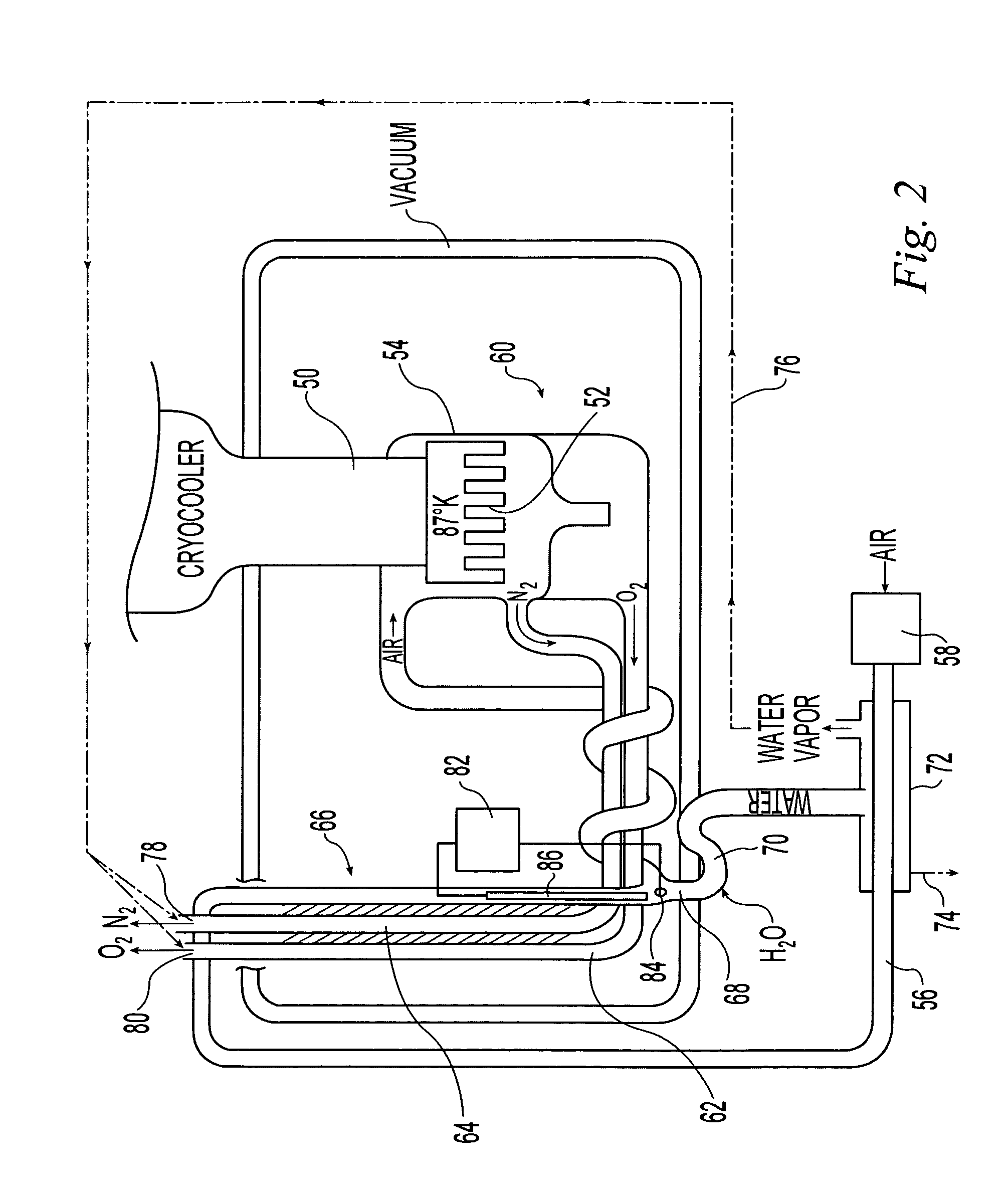

Energy efficient, inexpensive extraction of oxygen from ambient air for portable and home use

Owner:SUNPOWER

Multifuel internal combustion engine

ActiveUS20100083937A1Inhibit deteriorationEasy to driveElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

A multifuel internal combustion engine in which single low boiling point component fuel and at least one kind of fuel having properties different from those of the single low boiling point component fuel are introduced into a combustion chamber CC separately or together thereby operating the multifuel internal combustion engine, includes lubricant-oil temperature detecting unit means (temperature sensor 91) that detects a temperature of lubricant oil, or lubricant-oil temperature estimating unit means that estimates the temperature, and purge control unit means (electronic control unit 1) that prohibits purge control by an evaporation gas purge apparatus (evaporation gas passage 42, check valve 43, canister 44, on-off valve 45) or reduces a purge flow rate of evaporation gas in the purge control, when the detected or estimated temperature of the lubricant oil is near a boiling point temperature of the single low boiling point component fuel at which it is necessary to reduce a fuel injection amount from a fuel injection valve to a predetermined amount or less to adjust an air / fuel ratio of the combustion chamber to a target air / fuel ratio.

Owner:TOYOTA JIDOSHA KK

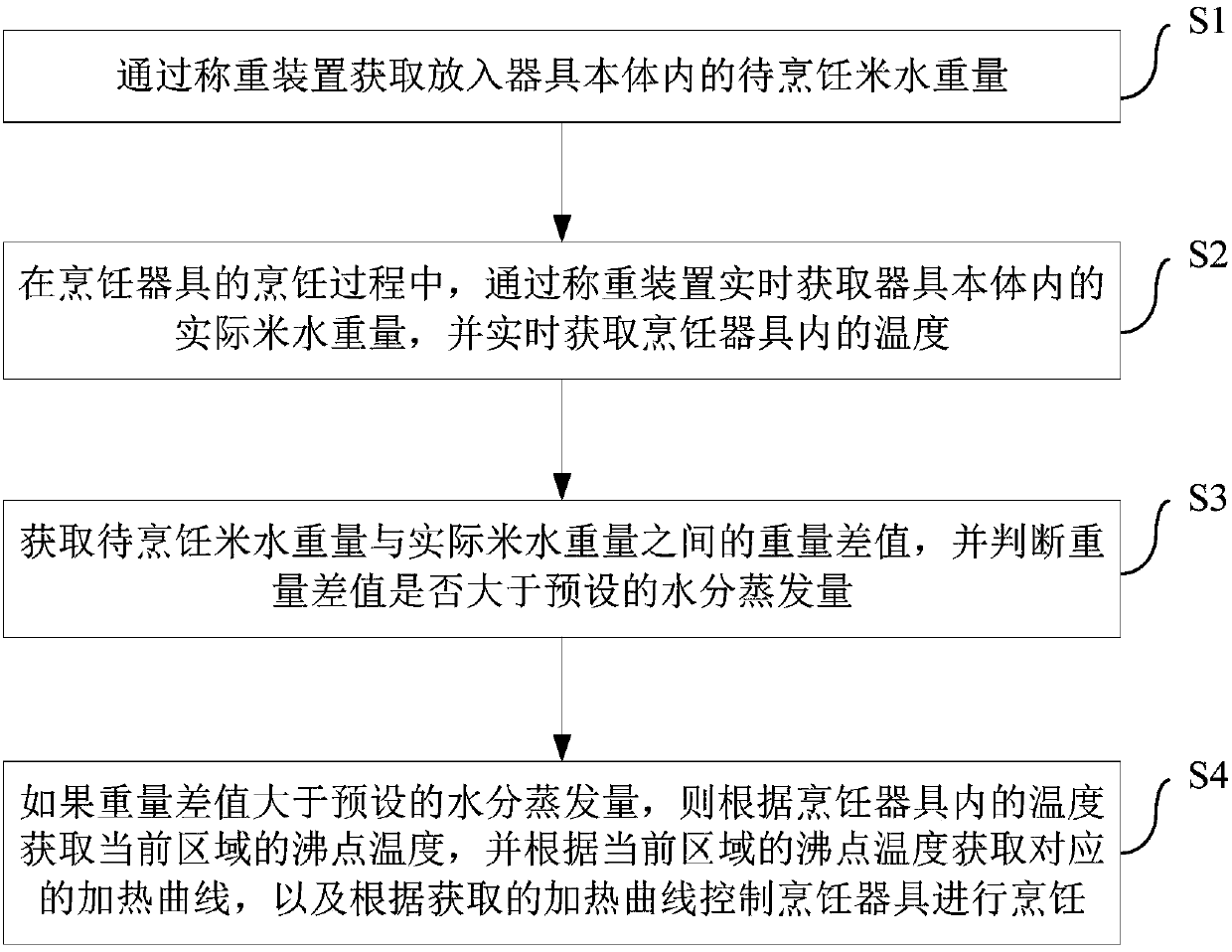

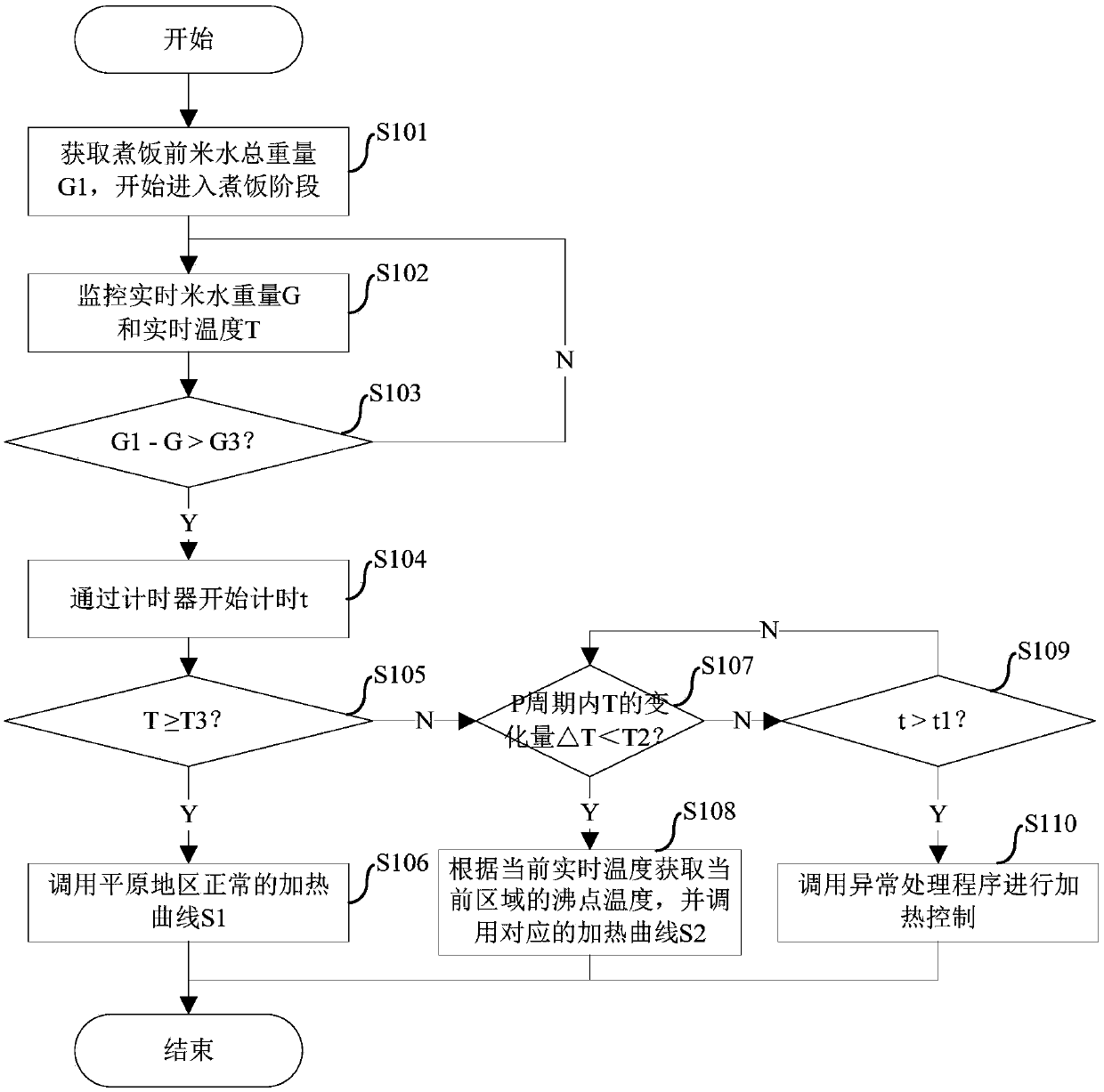

Cooking utensil and cooking control method and device thereof

ActiveCN109691896AGood cooking effectAccurate acquisitionVessels with intergral heatingTime-controlled ignitorsEvaporationProcess engineering

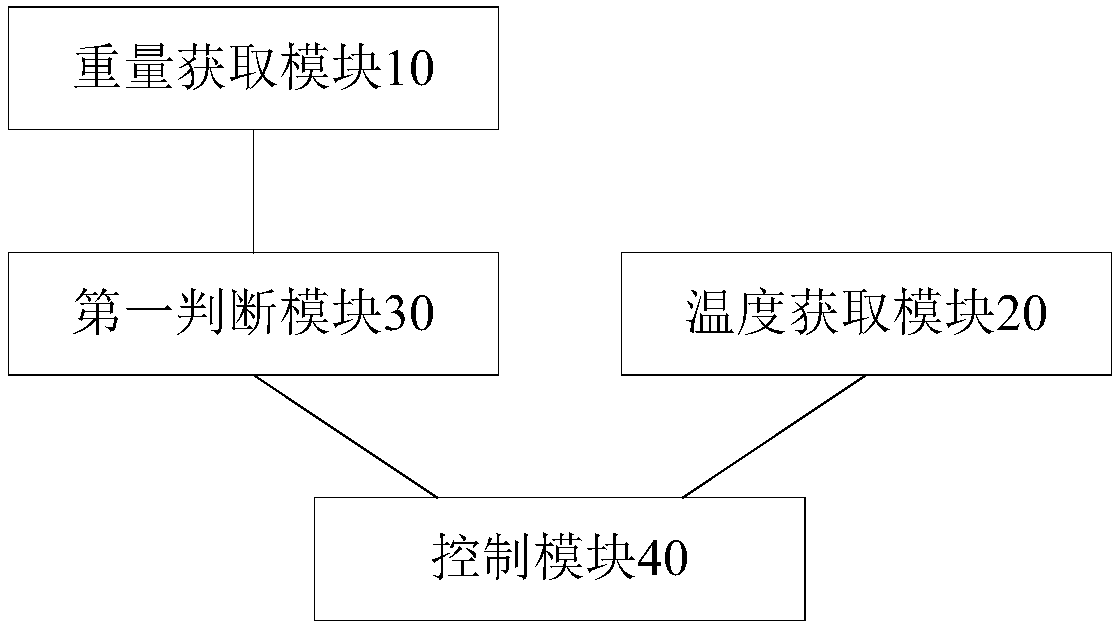

The invention discloses a cooking utensil and a cooking control method and device thereof. The method comprises the following steps: obtaining the weight of rice water to be cooked placed in a utensilbody through a weighing device; in the cooking process of the cooking utensil, obtaining the actual rice water weight in the utensil body in real time through the weighing device, and obtaining the temperature in the cooking utensil in real time; obtaining a weight difference value between the weight of the rice water to be cooked and the actual weight of the rice water, and judging whether the weight difference value is greater than a preset water evaporation amount or not; and if the weight difference value is greater than the preset water evaporation amount, obtaining the boiling point temperature of a current area according to the temperature in the cooking utensil, obtaining a corresponding heating curve according to the boiling point temperature of the current area, and controllingthe cooking utensil to cook according to the obtained heating curve. According to the method, the boiling point of the current area can be rapidly and accurately obtained, so that the cooking utensilis suitable for different altitudes, and the cooking effect is good.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com