Method of preparing metal organic framework materials through conversion method

A technology of metal-organic framework and transformation method, which is applied in the field of preparation of metal-organic framework materials, can solve the problems that hinder the development of high-stability MOF, and achieve the effect of easy amplification, wide application and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

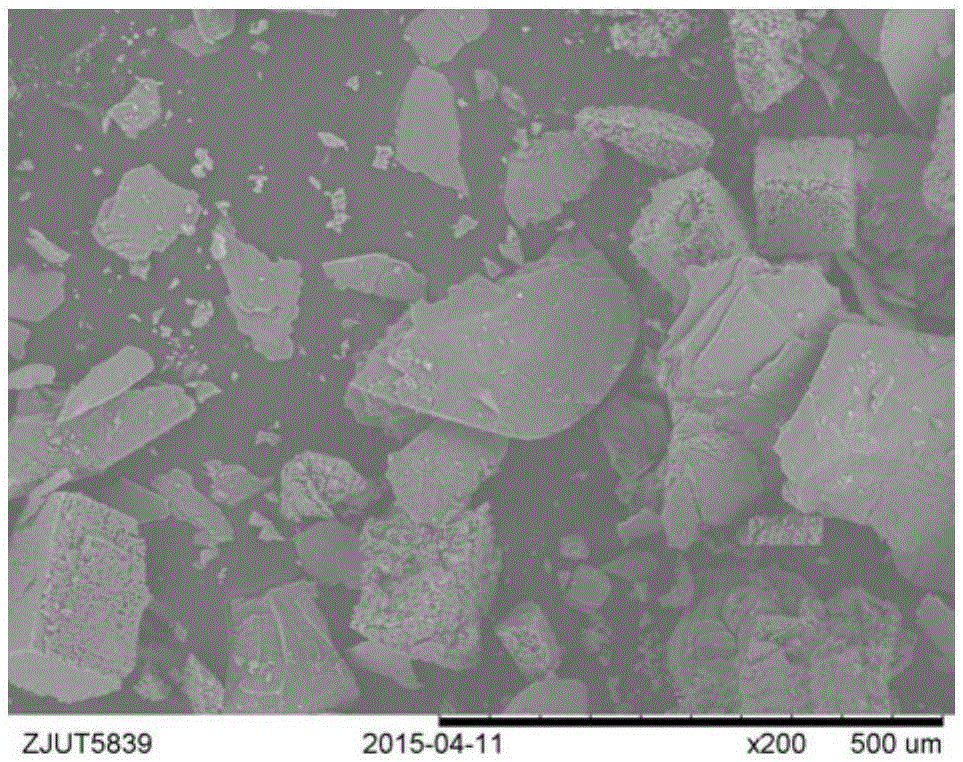

[0029] Example 1 Preparation of CuBDC, MIL-53 and UIO-66 by MOF-5 Conversion of Hydrothermal Synthesis

[0030] (1) Preparation of MOF-5 by hydrothermal method: Weigh 1.73g of zinc nitrate hexahydrate and 0.32g of terephthalic acid and dissolve them in 20mL of NN′-dimethylformamide to obtain two clarified metal-organic framework precursors solution, the two metal-organic framework precursor solutions were mixed and transferred to a hydrothermal kettle, heat-treated at 110°C for 18h, then the hydrothermal kettle was placed at room temperature to cool naturally, and then centrifuged at 5000 rpm, The obtained MOF-5 particles were washed successively with NN′-dimethylformamide (20 mL×2), methanol (20 mL×2), and finally dried at 80° C. to obtain 0.853 g of MOF-5 particles.

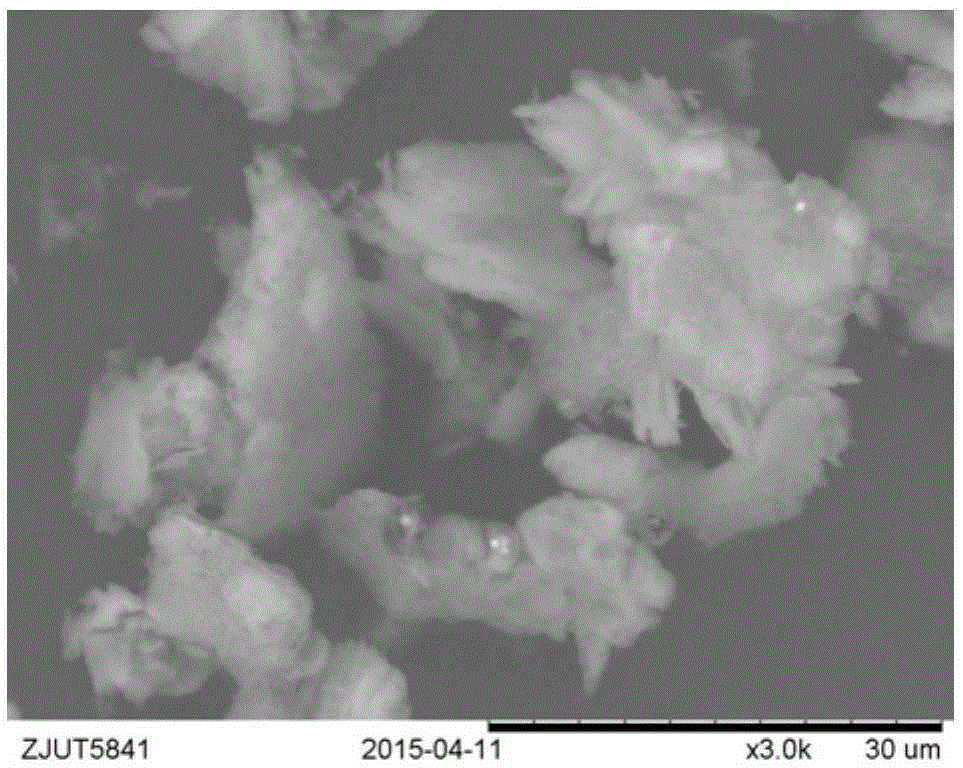

[0031] (2) Conversion and preparation of CuBDC: Weigh 0.5g of copper nitrate trihydrate and dissolve it in 20mL of ethanol to obtain a copper nitrate solution; weigh 0.1g of MOF-5 prepared in step (1), and plac...

Embodiment 2

[0041] Example 2 Preparation of CuBDC, MIL-53 and UIO-66 by conversion of MOF-5 synthesized by stirring

[0042](1) Preparation of MOF-5 by stirring method: Weigh 1.21g of zinc nitrate hexahydrate and dissolve it in 100mLNN'-dimethylformamide, then add 0.34g of terephthalic acid, and then add 1.6g of triethylamine under stirring And reacted for 2 hours, then centrifuged at 5000 rpm to obtain MOF-5 particles, washed with NN'-dimethylformamide (20mL×2) and methanol (20mL×2) in sequence, and finally heated at 80°C Dry to obtain 0.096g of MOF-5 particles.

[0043] The process of converting and preparing CuBDC, MIL-53 and UIO-66 is the same as that of Example 1.

Embodiment 3

[0044] Example 3 Preparation of MIL-53 and UIO-66 by CuBDC Conversion

[0045] (1) Preparation of CuBDC: Weigh 0.93g of copper nitrate trihydrate and 0.66g of terephthalic acid and dissolve them in 50mL of NN'-dimethylformamide respectively to obtain clear solutions of two metal-organic framework precursors. The metal-organic framework precursor solution was mixed and transferred to a hydrothermal kettle, heat-treated at 110 °C for 24 h, then the hydrothermal kettle was placed at room temperature to cool naturally, and then centrifuged at 5000 rpm to obtain CuBDC particles, followed by Wash with NN′-dimethylformamide (40 mL×2) and methanol (40 mL×2), and finally dry at 80° C. to obtain 1.28 g of CuBDC particles.

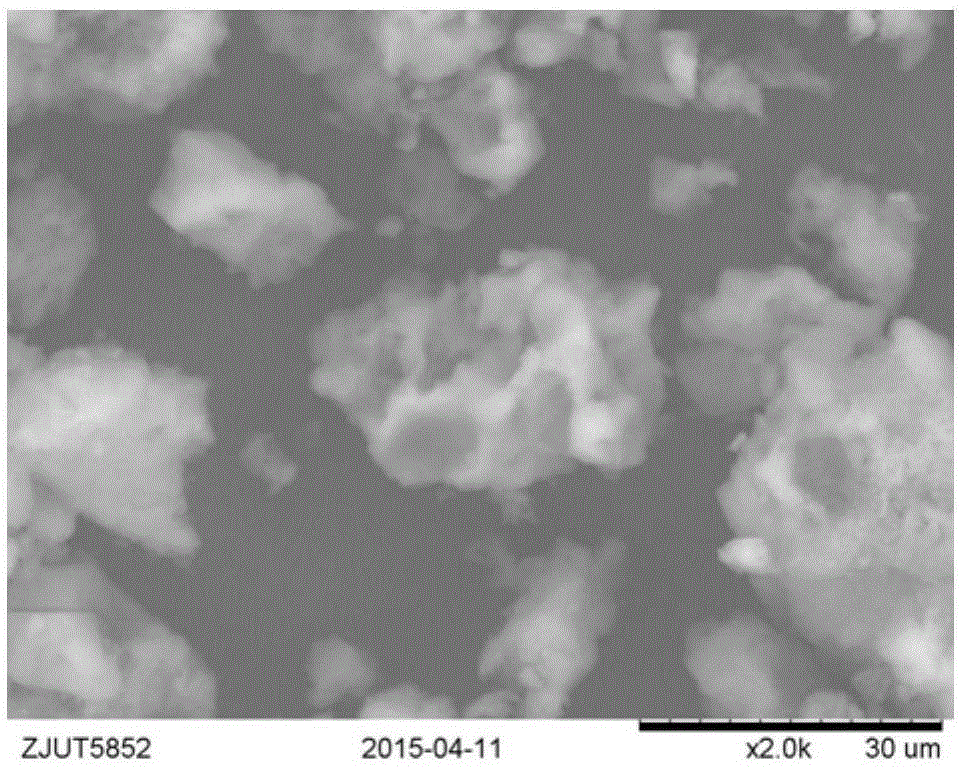

[0046] (2) Conversion and preparation of MIL-53: 4 g of ferric nitrate was weighed and dissolved in 20 mL of ethanol to obtain a ferric nitrate solution. Weigh 0.1 g of CuBDC prepared in step (1), place it in the prepared ferric nitrate solution, react at 20° C. for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com