Coupling heat transfer method of array jet and boiling cooling under high heat flux

A high heat flux density, array jet technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems that cannot meet the heat dissipation requirements of high-power electronic devices, a large amount of coolant flow, large heat transfer, etc., to achieve small temperature rise, Effect of reduced flow rate and high heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

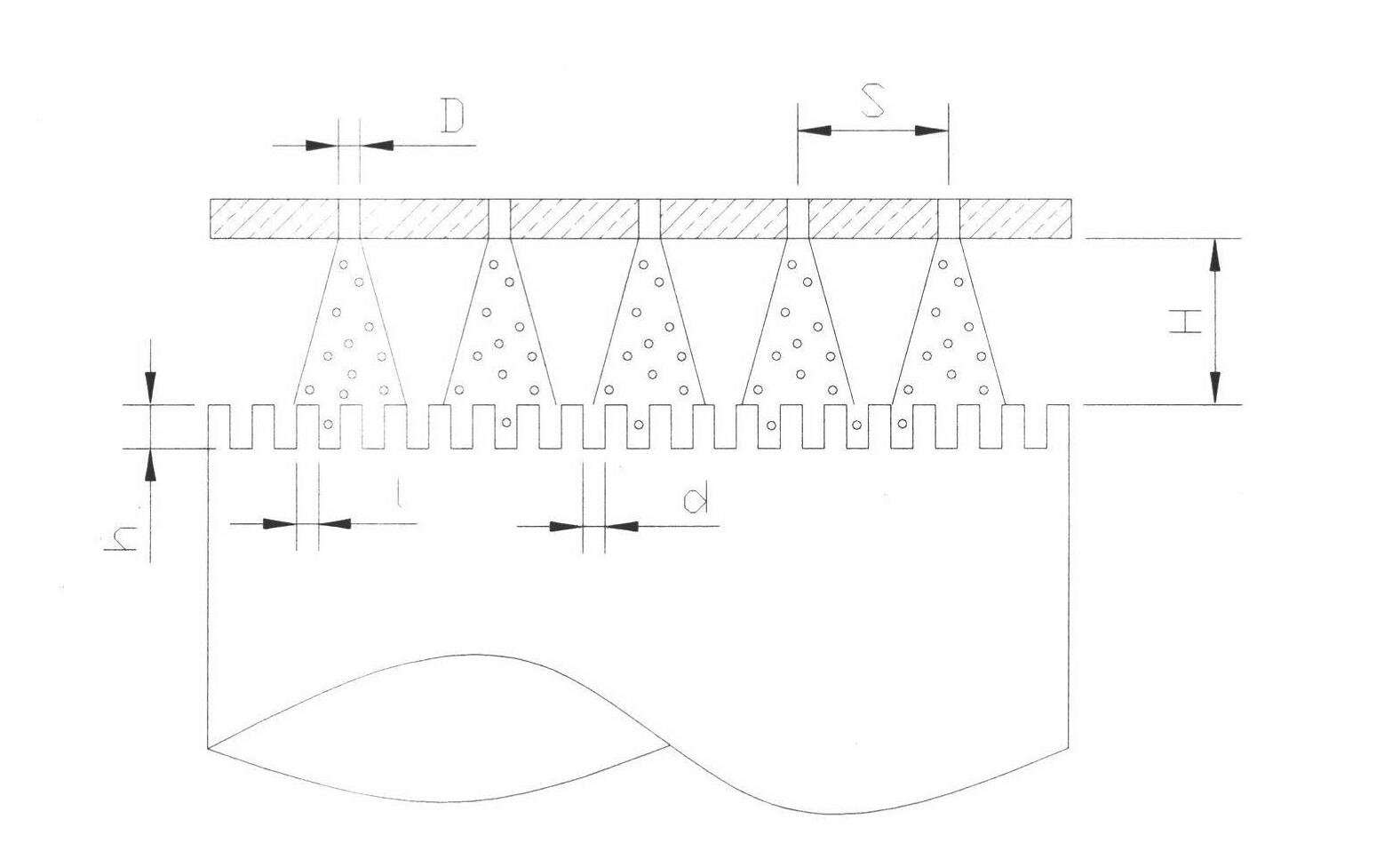

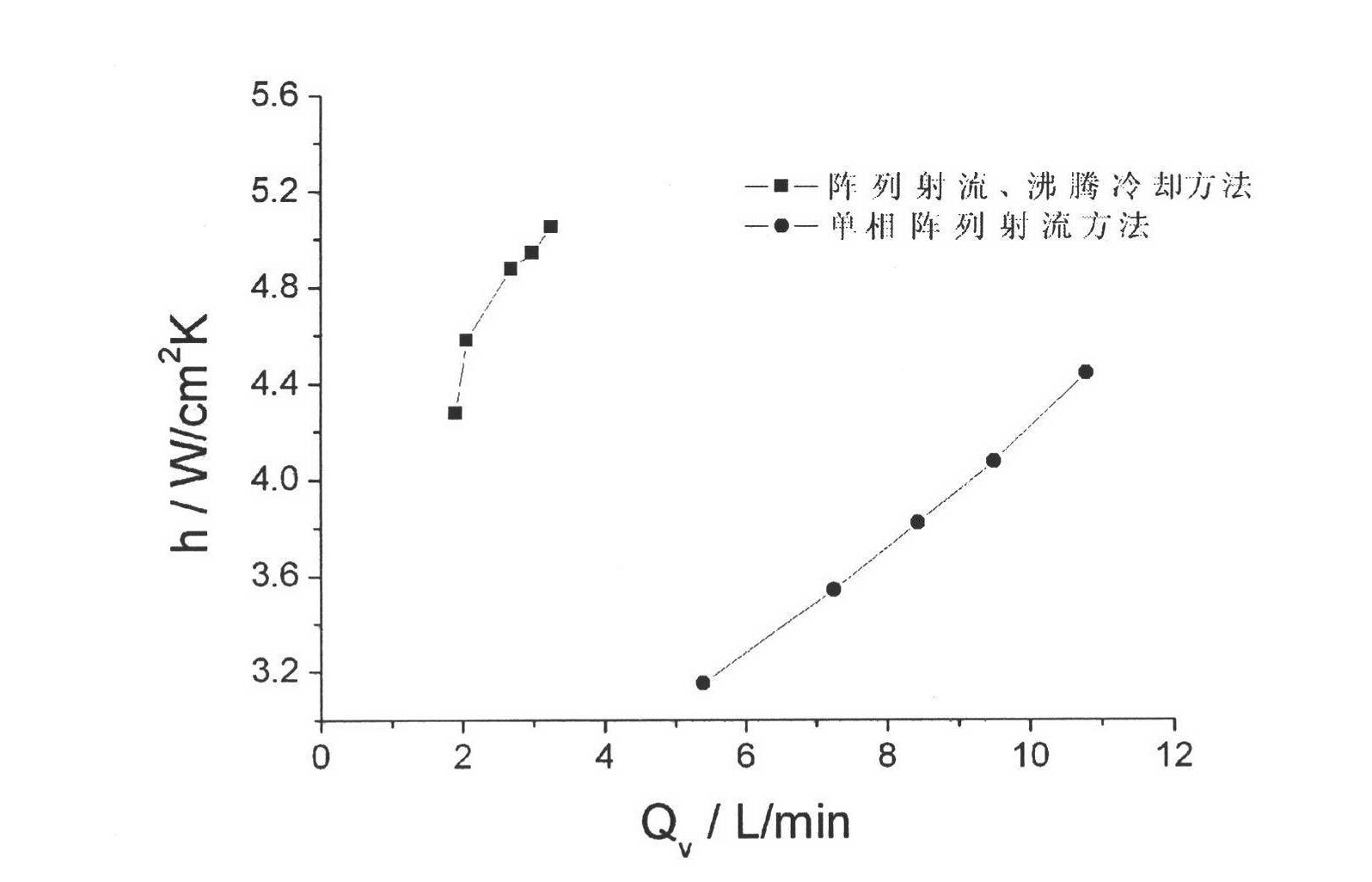

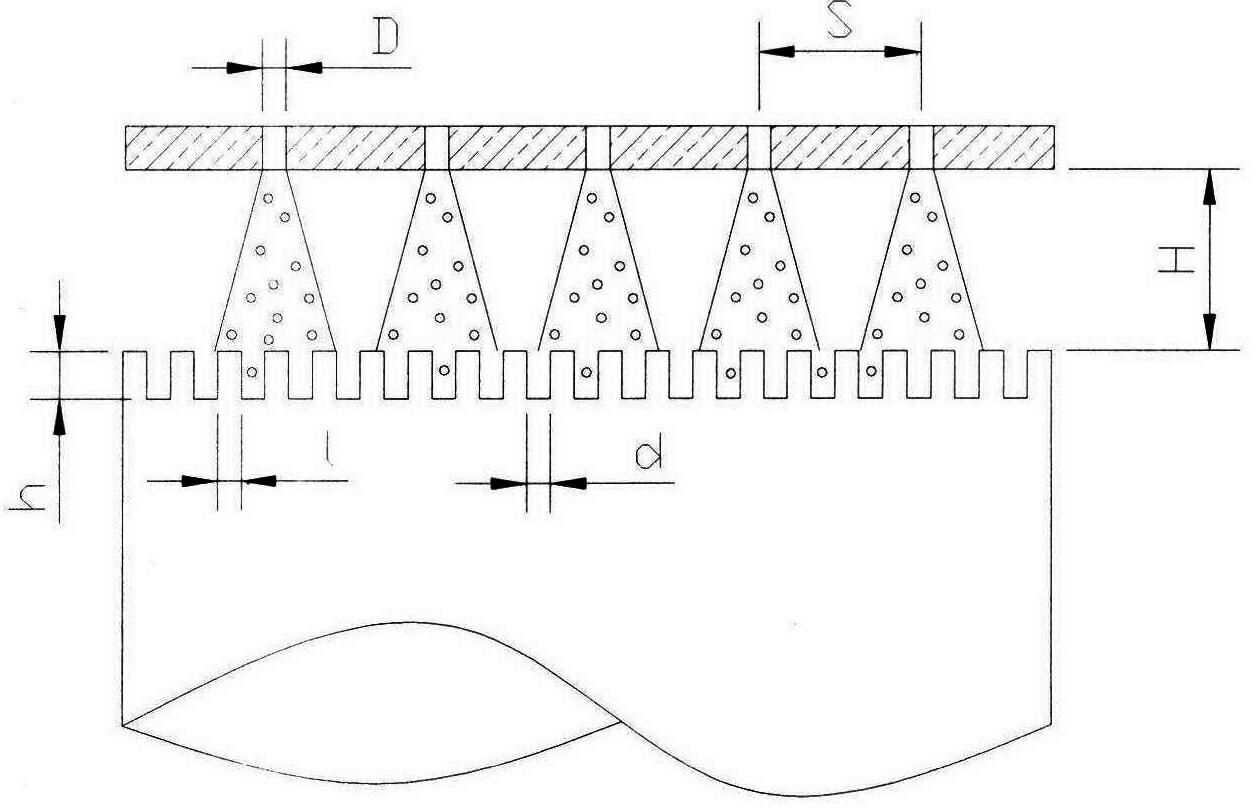

[0011] combine figure 1 , the coupling heat exchange method of array jet and boiling cooling under the condition of high heat flux of the present invention realizes the thermal control ability of array jet cooling and boiling heat exchange, including the selection of cooling liquid, the optimization of single-phase array jet cooling and the control of heat dissipation conditions, Combining single-phase array jet impingement cooling and boiling heat transfer, using the latent heat of evaporation of the cooling liquid to remove the heat of the electronic device, that is, selecting a cooling liquid suitable for the use of the electronic device, and controlling the boiling point of the cooling liquid at -20°C-30°C, such as Freon series and fluorocarbons, etc., can obtain the boiling point temperature within the required range by controlling the temperature and pressure of the cooling liquid, such as by controlling the pressure of the working fluid at -0.5bar-10bar, so that the cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com